Sino의 라미네이션 스택으로 프로젝트에 힘을 실어주세요!

프로젝트 속도를 높이기 위해 라미네이션 스택에 다음과 같은 세부 정보를 레이블로 지정할 수 있습니다. 허용 오차, 재료, 표면 마감, 산화 단열재가 필요한지 여부, 수량등 다양한 기능을 제공합니다.

변압기가 어떻게 작동하는지 생각해 본 적이 있나요? 이 정말 유용한 장치는 우리 집과 마을에 전력을 공급하는 데 도움이 되는 모든 곳에 존재합니다. 하지만 모든 변압기가 똑같이 만들어지는 것은 아닙니다. 변압기는 크게 코어형 변압기와 쉘형 변압기 두 종류가 있습니다. 코어형 변압기와 쉘형 변압기의 가장 큰 차이점은 제작 방식입니다. 이 차이를 아는 것은 모든 작업에 적합한 변압기를 선택하는 데 매우 중요합니다. 이 글에서는 이를 간단하게 설명해 드리겠습니다. 코어 타입과 셸 타입 선택에 대해 알아야 할 모든 것을 보여드리겠습니다. 어떻게 결합되는지, 어떤 용도로 사용되는지, 그리고 필요한 작업에 가장 적합한 것을 선택하는 방법을 배우게 됩니다.

변압기는 전기의 전압 레벨을 변경하는 장비입니다. 전압을 높이거나 낮출 수 있습니다. 이는 전력 시스템에서 매우 중요한 문제입니다. 발전소는 매우 높은 전압에서 전기를 생산합니다. 변압기는 그 전압을 더 높게 만들어 먼 거리를 이동할 수 있도록 합니다. 그 후 다른 배전 변압기가 가정으로 들어오기 전에 전압을 낮춰줍니다. 이렇게 해서 전기를 안전하게 사용할 수 있습니다.

트랜스포머에는 여러 유형이 있지만 가장 잘 알려진 것은 코어 유형과 셸 유형입니다. 왜 크게 두 가지 종류가 있을까요? 그것은 작업마다 다른 종류의 도구가 필요하기 때문입니다. 거대한 발전소에서 사용하는 변압기와 소규모 작업장에서 사용하는 변압기는 요구 사항이 다릅니다. 코어와 권선의 설계 방식에 따라 각 변압기 유형은 특정 작업에 유용합니다. 코어 유형과 쉘 유형 중 어떤 것을 선택할지는 정격 전력(kva), 전압 레벨, 가격, 물리적 크기 등을 기준으로 결정됩니다.

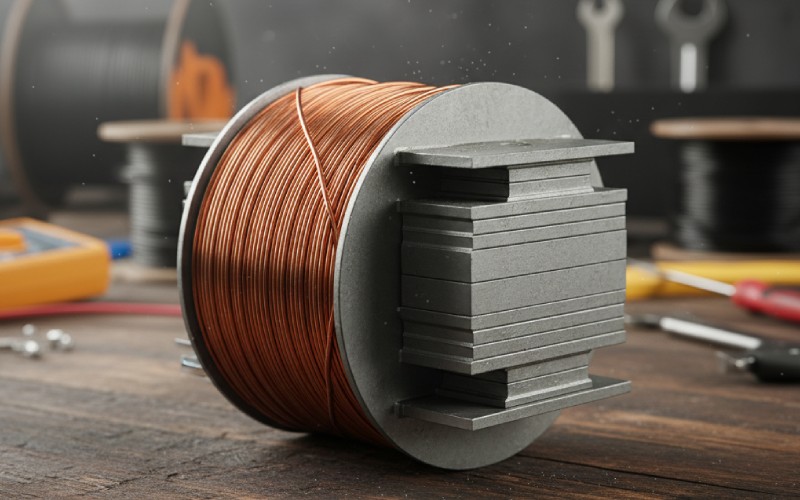

코어형 변압기는 구조가 매우 간단합니다. 직사각형을 머릿속에 그려보세요. 코어는 특수 강판으로 만들어집니다. 다리라고 불리는 두 개의 직립 부품이 있습니다. 또한 위쪽과 아래쪽에는 요크라고 하는 두 개의 평평한 부분이 있습니다. 이 코어는 자기 회로를 위한 하나의 단일 경로를 만듭니다. 코어형 변압기에 대해 기억해야 할 주요 아이디어는 권선이 코어를 둘러싸고 있다는 것입니다. 이것은 이 유형의 변압기의 특별한 부분입니다.

코어형 변압기에서는 권선이 두 개의 팔다리를 감싸고 있습니다. 대부분의 경우 저전압 권선이 코어 바로 옆에 먼저 감겨 있습니다. 그 후 고전압 권선이 저전압 권선을 감싸고 있습니다. 이는 전기를 안전하게 분리하기 위한 것입니다. 고전압 권선을 저전압 권선에서 분리하는 것이 더 쉽습니다. 철심에서 분리하는 것보다 더 쉽습니다. 이러한 종류의 변압기 설계는 많은 전력 변압기에서 많이 볼 수 있습니다. 코어형 변압기는 자속을 제어하는 간단하고 좋은 방법을 제공합니다.

이제 쉘 타입 변압기를 살펴볼 수 있습니다. 코어형 변압기가 권선이 바깥쪽에 있다면 쉘형 변압기는 정반대입니다. 이러한 설계에서는 코어가 권선을 감싸고 있습니다. 쉘형 코어에는 세 개의 팔다리가 있습니다. 중앙에 하나의 팔다리가 있고 바깥쪽에 두 개의 팔다리가 있습니다. 마치 코어가 내부의 중요한 부분을 보호하는 단단한 껍질과 같습니다. 이것이 코어형과 쉘형 트랜스포머의 가장 큰 차이점입니다.

쉘 타입 변압기에서는 주 권선과 두 번째 권선이 모두 중앙 사지에 배치됩니다. 권선은 이 중간 사지 위에 하나씩 배치됩니다. 자기 코어는 자속이 이동할 수 있는 두 개의 경로를 제공합니다. 중간 코일에서 나오는 자속은 두 개로 나뉩니다. 그런 다음 바깥쪽의 두 팔다리를 통해 흐릅니다. 이 설계는 권선을 훌륭하게 지지하고 안전하게 유지하는 데 도움이 됩니다. 쉘형 변압기는 이러한 매우 강력한 설계로 인해 많은 저전압 작업에 선호됩니다.

코어형과 쉘형 변압기의 가장 큰 차이점은 권선의 위치입니다. 내부에 무엇이 있고 외부에 무엇이 있는지가 관건입니다.

이러한 기본적인 제작 방식의 차이로 인해 변압기의 크기부터 작동 방식까지 변압기의 모든 것이 달라집니다. 1 차 및 2 차 권선은 각 변압기 유형마다 다른 방식으로 설정됩니다. 따라서 성능도 달라집니다. 변압기 제조업체는 사용자의 필요에 따라 디자인을 선택합니다.

자기 회로는 자속이 변압기 내부로 이동할 때 자속이 지나가는 길입니다. 이 도로의 설계는 변압기를 잘 작동시키는 데 매우 중요합니다. 코어형 변압기에서는 자속이 이동할 수 있는 도로가 하나뿐입니다. 자속은 하나의 큰 고리에서 팔다리와 요크를 통해 이동합니다. 이 설계는 때때로 소량의 누설 자속을 생성할 수 있습니다. 이는 낭비되는 에너지와 같습니다.

쉘형 변압기는 자기 회로가 더 효과적입니다. 권선이 중앙 사지에 배치되어 있기 때문에 자속이 바깥쪽으로 흐르고 바깥쪽 사지를 통해 다시 들어오는 두 개의 길이 있습니다. 이렇게 하면 자속의 자기 경로가 더 짧아집니다. 경로가 짧다는 것은 자기장을 만드는 데 더 적은 에너지가 필요하다는 것을 의미합니다. 즉, 쉘형 변압기는 종종 자화 전류가 덜 필요하고 효율이 더 높을 수 있습니다. 자속이 두 개의 경로를 갖는 변압기의 설계는 쉘형 변압기의 큰 장점입니다.

고전압으로 작업할 때는 일반적으로 한 가지 유형의 변압기가 가장 적합합니다. 코어형 변압기는 일반적으로 고전압을 사용하는 작업에 더 적합합니다. 권선에 절연체를 넣기가 더 쉽기 때문입니다. 저전압 권선이 코어 옆에 배치되고 고전압 권선이 그 주위를 감싸기 때문에 안전을 위해 재료를 추가할 수 있는 공간이 많습니다. 따라서 대형 전력 변압기 및 배전 변압기와 같은 고전압 작업에 안전하고 신뢰할 수 있는 선택이 될 수 있습니다.

반면에 쉘형 변압기는 저전압 애플리케이션에 자주 사용됩니다. 권선은 중앙 사지에 서로 가깝게 밀집되어 있습니다. 따라서 매우 높은 전압 레벨에 필요한 특수 절연을 추가하기가 더 어렵습니다. 그러나 이 촘촘한 권선 설계는 전압이 낮고 전류가 높은 요구 사항에 적합합니다. 따라서 대규모 전력 시스템과 고전압으로 작업하는 경우 코어형 변압기가 더 나은 옵션일 수 있습니다. 전압이 낮은 경우에는 쉘 타입 변압기를 선택하는 것이 좋습니다.

변압기의 제작 방식에 따라 냉각 및 수리가 얼마나 쉬운지도 달라집니다. 변압기는 작동 중일 때 뜨거워집니다. 변압기가 손상되지 않도록 식혀야 합니다. 코어형 변압기에서는 권선이 외부에 있습니다. 즉, 권선이 공기나 특수 냉각 오일에 닿아 있습니다. 따라서 열이 쉽게 빠져나갈 수 있습니다. 열이 권선을 떠나 공기 중으로 곧장 빠져나갈 수 있습니다. 또한 문제가 발생할 경우 권선을 점검하고 수리하기가 더 간단합니다.

쉘형 변압기에서는 권선이 코어 내부에 위치합니다. 코어가 담요처럼 작동하기 때문에 권선을 식히기가 조금 더 어려울 수 있습니다. 자연 냉각도 잘 되지 않습니다. 하지만 코어 자체는 문제없이 냉각할 수 있습니다. 수리할 때가 되면 쉘형 변압기는 작업하기가 더 어려울 수 있습니다. 권선에 접근하려면 먼저 코어를 분해해야 합니다. 이 때문에 수리가 더 복잡하고 비용이 많이 듭니다. 이는 올바른 변압기를 선택할 때 고려해야 할 중요한 사항입니다.

특히 대형 변압기의 경우 우수한 기계적 강도를 갖는 것이 매우 중요합니다. 변압기가 작동할 때 권선은 강한 전자기력을 느낍니다. 이러한 힘으로 인해 권선이 움직이거나 손상될 수 있습니다. 쉘 타입 변압기는 이 부분에서 큰 장점이 있습니다. 코어가 권선을 감싸고 있어 권선을 매우 잘 지지합니다. 코어의 두 반쪽 사이에 배치된 권선은 제자리에 단단히 고정됩니다. 따라서 쉘형 설계는 기계적 강도가 뛰어나 고강도 작업 및 고전력 애플리케이션에 적합합니다.

코어형 트랜스포머는 권선을 자연스럽게 지지하지 못합니다. 코일이 외부에 있기 때문에 코일을 안정적으로 고정하고 압력을 받을 때 움직이지 않도록 하기 위해 추가 부품이 필요합니다. 하지만 쉘형 디자인이 자연적으로 더 튼튼합니다. 쉘 코어의 요크와 팔다리는 코일을 위한 강력하고 안전한 상자를 만듭니다. 이러한 추가적인 기계적 지지력은 쉘형 변압기가 열악한 작업 환경에서 사용되는 큰 이유입니다.

때로는 차트가 많은 말보다 더 잘 설명할 수 있습니다. 다음은 코어형과 셸형 트랜스포머의 주요 차이점을 보여주는 간단한 차트입니다.

| 기능 | 코어 유형 변압기 | 쉘형 변압기 |

|---|---|---|

| 코어 및 권선 | 권선이 코어를 둘러싸고 있습니다. | 코어가 와인딩을 둘러싸고 있습니다. |

| 코어의 모양 | 두 개의 팔다리가 있는 직사각형 모양입니다. | 팔다리가 3개(중앙 팔다리 1개, 바깥쪽 팔다리 2개)입니다. |

| 자기 회로 | 자기 회로가 하나 있습니다. | 두 개의 자기 회로가 있습니다. |

| 와인딩 | 둥근 원통형 권선을 사용합니다. 저전압 및 고전압 권선이 양쪽 팔다리에 있습니다. | 샌드위치 스타일의 레이어드 와인딩을 사용합니다. 보조 와인딩은 중앙 사지에 배치됩니다. |

| 기계적 강도 | 자연적인 기계적 강도가 낮습니다. | 더 높은 자연 기계적 강도. |

| 냉각 | 와인딩을 식히는 것이 더 쉽습니다. | 와인딩을 냉각하는 것은 더 어렵지만 코어는 잘 냉각됩니다. |

| 수리 | 와인딩을 수정하는 것이 더 쉽습니다. | 와인딩을 고치는 것이 더 어렵습니다. |

| 최상의 대상 | 고전압 애플리케이션(고전압, 낮은 kva)에 사용됩니다. | 저전압 애플리케이션(저전압, 높은 kva)에 가장 적합합니다. |

| 누출 플럭스 | 누출 플럭스가 더 많습니다. | 누출 플럭스가 적습니다. |

| 임피던스 | 임피던스가 더 높습니다. | 임피던스가 낮습니다. |

이 차트는 코어 유형과 셸 유형의 차이점을 빠르게 확인할 수 있는 방법입니다. 각 트랜스포머에 대한 중요한 세부 사항을 기억하는 데 도움이 될 수 있습니다.

그렇다면 최종 결정은 어떻게 내릴까요? 올바른 변압기를 선택하는 것은 필요한 사항에 따라 달라집니다. 모든 상황에 '최선'인 변압기는 하나도 없습니다. 코어형과 쉘형 변압기 모두 훌륭한 디자인입니다. 전 세계의 배전 및 전력 변압기에 사용되고 있습니다. 변압기가 필요한 작업에 따라 올바른 변압기를 선택하면 됩니다.

다음 질문에 대해 생각해 보세요:

이러한 질문에 대한 답을 찾으면 변압기 전문가와 협력하여 배전 요구 사항에 맞는 완벽한 변압기를 찾을 수 있습니다. 두 가지 유형의 변압기는 오늘날 우리 세계에서 매우 중요한 역할을 담당하고 있습니다.

다음은 코어 타입과 셸 타입 트랜스포머에 대한 가장 중요한 아이디어를 간략하게 정리한 것입니다: