Laat Sino's lamineren Stacks Empower uw project!

Om je project te versnellen kun je lamineerstapels labelen met details zoals tolerantie, materiaal, oppervlakafwerking, of geoxideerde isolatie al dan niet vereist is, hoeveelheiden meer.

Heb je er ooit over nagedacht wat de grote machines in fabrieken en werkplaatsen doet draaien? Veel van deze machines maken gebruik van een speciaal type motor. Deze motor wordt een driefasen inductiemotor genoemd. Het coolste eraan is dat hij uit zichzelf kan starten. Je geeft hem gewoon stroom en hij begint te draaien. Dit is heel belangrijk en de reden waarom deze motoren zo vaak worden gebruikt.

In dit artikel ontdek je de eenvoudige reden achter deze zelfstartende magie. We leggen stap voor stap uit hoe een 3-fasige stroombron een speciale kracht uitoefent. Deze kracht laat de motor draaien zonder hulp van buitenaf. Je hoeft geen ingenieur te zijn om het te begrijpen. We gebruiken eenvoudige woorden en voorbeelden om uit te leggen hoe deze sterke inductiemotor werkt.

Een driefasen inductiemotor is een soort elektromotor. Je kunt hem zien als de belangrijkste motor voor grote klussen in de wereld. Hij is sterk, eenvoudig en je kunt erop rekenen. De naam van de motor zegt veel. "Driefasig" betekent dat hij een speciaal soort elektriciteit gebruikt. Deze stroom heeft drie afzonderlijke stromen. "Inductie" betekent dat hij de kracht van magneten gebruikt om het bewegende deel te laten draaien zonder dat er draden in contact komen met de motor.

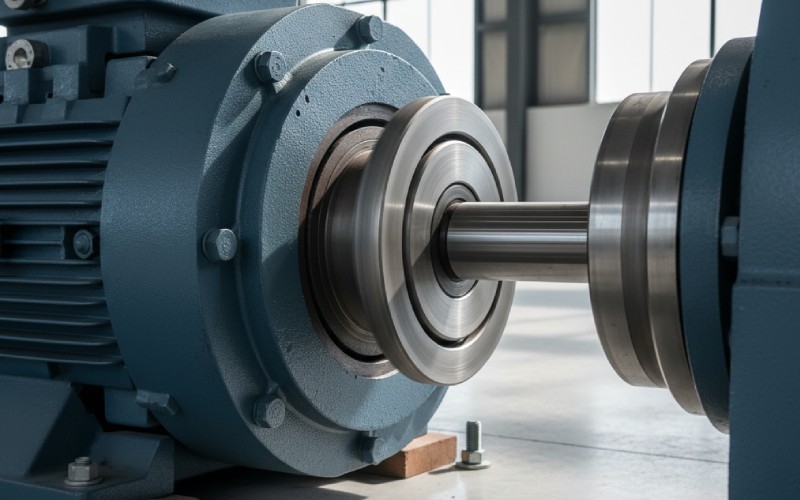

Deze motor heeft twee hoofdonderdelen. Het eerste deel is de stator. De stator is het buitenste deel van de motor dat stilstaat. Het beweegt niet. Het tweede deel is de rotor. De rotor is het deel aan de binnenkant van de motor dat rond kan draaien. De magie van de inductiemotor ontstaat door de manier waarop deze twee onderdelen met elkaar samenwerken. Ze gebruiken elektriciteit en magneten om sterke beweging te creëren en zware dingen te laten draaien.

Het zelfstartende vermogen van een driefasen inductiemotor is zijn bekendste truc. Maar waarom is dat zo belangrijk? Denk eens aan het feit dat je een enorme ventilator moet aanduwen elke keer dat je hem wilt starten. Of stel je voor dat je een zware waterpomp met je handen moet ronddraaien om hem in beweging te krijgen. Dat zou erg lastig zijn en niet erg nuttig. Een zelfstartende motor lost dit probleem op.

Als we zeggen dat een motor zelfstartend is, betekent dit dat je hem alleen maar kracht hoeft te geven. Hij begint dan te draaien en maakt zijn eigen draaikracht. Hij heeft geen duwtje van buitenaf nodig. Er is ook geen speciaal startgereedschap van buitenaf nodig om hem in beweging te krijgen. Deze zelfstartfunctie maakt de inductiemotor heel, heel gemakkelijk te gebruiken. Je zet gewoon een schakelaar om en hij begint te werken. Dit gemak is een belangrijke reden waarom dit type motor in zoveel machines wordt gebruikt.

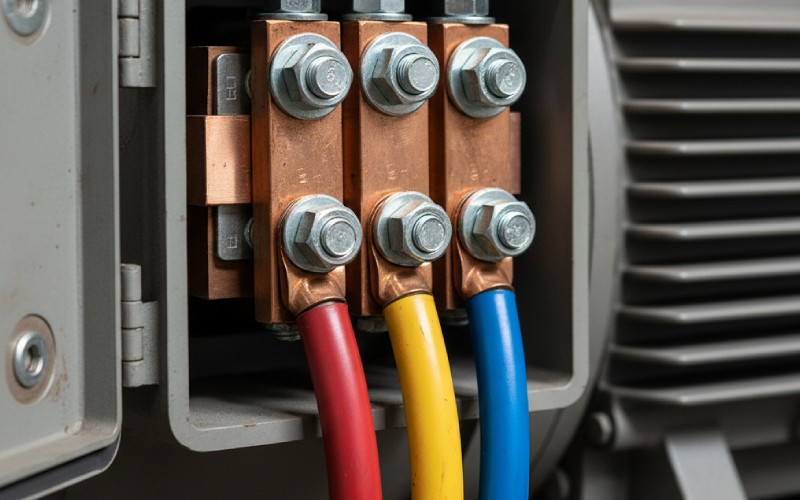

De stator is de basis van de kracht van de inductiemotor. Het is de grote, ronde en zware buitenkant van de motor. Hij blijft perfect stilstaan als de motor aan staat. Binnenin de stator zitten kleine groeven die spoelen van draad vasthouden. We noemen dit de statorwikkelingen. Er zijn drie verschillende sets wikkelingen. Er is één set voor elke fase van de 3-fasige voeding.

Wanneer je de 3-fasige elektrische voeding aansluit op de motor, gaat er stroom door deze statorwikkelingen. Het is de taak van de stator om deze elektriciteit om te zetten in een sterk, magneetachtig veld. Maar het is geen gewoon magnetisch veld. Door de 3-fasige stroom kan de stator een heel speciaal soort veld produceren. Dit veld is een roterend magnetisch veld. Dit veld is het geheim dat de motor de kracht geeft om te starten en te draaien. De stator is het deel dat de "duw" geeft zonder ooit de rotor te raken.

Hier begint het echte plezier. Een 3-fase voeding is niet slechts één stroom. Het zijn drie afzonderlijke stromen, of fasen, van stroom. Deze drie stromen zijn precies goed getimed. Ze worden na elkaar sterker en zwakker. Dit gebeurt in een vloeiend patroon dat zich herhaalt. Het is als drie vrienden die een draaimolen voortduwen. De eerste vriend duwt. Dan duwt de tweede vriend. Dan duwt de derde vriend, en het begint opnieuw. Hun duwbewegingen zijn precies goed verdeeld. Hierdoor draait de draaimolen de hele tijd soepel.

De statorwikkelingen zijn in een cirkel geplaatst. Elke set wikkelingen is verbonden met een van de drie fasen.

Omdat deze vermogenspieken in de juiste volgorde plaatsvinden, verschijnt het totale magnetische veld niet zomaar en gaat het weer weg. In plaats daarvan lijkt het alsof het met een constante snelheid rond de binnenkant van de stator draait. Dit is de roterend magnetisch veld. De stator gebruikt de 3-fasige voeding om dit draaiende krachtveld te produceren, en er hoeven geen onderdelen van de stator te bewegen. De snelheid van dit veld heeft een speciale naam: synchrone snelheid.

| Fase | Machtsniveau | Magnetische veldrichting |

|---|---|---|

| 1 | Hoog | Omhoog |

| 2 | Omhoog | Rechts en omhoog |

| 3 | Laag | Rechts |

(Dit is een eenvoudige grafiek om te laten zien hoe het veld beweegt)

Laten we het nu hebben over het tweede hoofdonderdeel: de rotor. De rotor is het deel van de inductiemotor dat echt draait en de klus klaart. De meest gebruikte rotor wordt een "eekhoornkooirotor" genoemd. Deze lijkt een beetje op een kooi voor een hamster. Hij heeft stevige staven aan de zijkanten die verbonden zijn met ringen aan elk uiteinde. Deze staven zijn vaak gemaakt van aluminium of koper.

Het belangrijkste om te weten over de rotor in een inductiemotor is dat hij niet is aangesloten op externe voeding. Er gaan geen draden naar toe. Hij zit gewoon in de stator en kan vrij ronddraaien. Het is zijn taak om te reageren op het magnetische veld dat de stator maakt. De rotor is het deel dat door het roterende magnetische veld wordt "misleid" om te draaien. Het eenvoudige ontwerp van de rotor, zonder onderdelen die schuren of directe draadverbindingen nodig hebben, maakt de inductiemotor zo sterk en duurzaam.

Hier wordt uitgelegd hoe de stator en de rotor met elkaar samenwerken. De stator produceert een sterk roterend magnetisch veld. Dit veld draait rond in de motor en gaat door de rotor. Als het magnetische veld over de metalen staven van de rotor beweegt, begint een wetenschappelijke regel genaamd "elektromagnetische inductie" te werken. Het bewegende magnetische veld creëert een spanning. Deze spanning zorgt ervoor dat er een sterke elektrische stroom door de staven van de rotor loopt.

In de rotor loopt nu zijn eigen stroom. Wanneer er stroom door een draad of staaf loopt, maakt deze zijn eigen magnetische veld. Dit betekent dat we nu twee magnetische velden hebben. Het ene is het grote, draaiende veld van de stator. Het andere is een nieuw veld rond de rotor, gemaakt door de nieuwe stroom. Deze twee magnetische velden werken vervolgens op elkaar in. Het veld van de stator duwt en trekt aan het veld van de rotor. Dit duwen en trekken zorgt ervoor dat de rotor begint te draaien.

Koppel is gewoon een draaiende of verdraaiende kracht. Wanneer je een gereedschap gebruikt om een schroef vast te draaien, gebruik je koppel. In een inductiemotor zorgt de manier waarop het veld van de stator en het veld van de rotor samenwerken voor een sterke draaikracht, of koppel, op de rotor. Het roterende magnetische veld van de stator is altijd in beweging. Het trekt de rotor mee. Dit is alsof je een wortel op een stok houdt om een ezel te laten lopen.

Dit koppel geeft de inductiemotor zijn zelfstartende vermogen. Zodra je de 3-fasige stroom inschakelt, verschijnt het roterende magnetische veld. Dit veld creëert meteen een stroom in de rotor. Deze stroom creëert een tweede magnetisch veld en de twee velden produceren samen een koppel. Dit koppel is sterk genoeg om de rotor in beweging te krijgen, ook al wil hij stil blijven staan. Het geproduceerde koppel zorgt ervoor dat de rotor begint te draaien. Hij probeert het draaiende veld van de stator in te halen. Daarom is de motor zelfstartend.

Het is gemakkelijker te begrijpen waarom een driefasen inductiemotor zelfstartend is als je kijkt naar een motor die dat niet is. Dit is de eenfasige inductiemotor. Je vindt deze motoren in dingen in huis, zoals ventilatoren en koelkasten. Een eenfasige stroombron heeft slechts één stroom die heen en weer beweegt.

Wanneer je eenfasestroom aan de stator van een motor geeft, produceert deze geen roterend magnetisch veld. In plaats daarvan ontstaat er een veld dat op één plek sterker en zwakker wordt. Het draait niet. Dit wankele veld kan niet beslissen in welke richting het de rotor duwt. De rotor zit dus stil en maakt een zoemend geluid. Hij heeft geen startkoppel. Om een eenfasige inductiemotor te laten starten, is een extra onderdeel nodig, zoals een condensator. Dit onderdeel helpt om een tweede magnetisch veld te maken dat een beetje van slag is. Dit geeft de rotor het eerste zetje dat hij nodig heeft om in één richting te gaan draaien.

Als we zeggen dat een driefasen inductiemotor zelfstartend is, bedoelen we dat hij geen duw- of trekkracht van buitenaf nodig heeft om te starten. Je hoeft hem niet met je hand rond te draaien. Je hebt ook geen extra elektrische onderdelen nodig om de startbeweging te maken. De motor is zelfstartend omdat zijn eenvoudige ontwerp, bij gebruik met een 3-fasige voeding, zelf zijn eigen startkracht genereert.

Het enige wat de motor nodig heeft, is de juiste soort stroom. De 3-fasige voeding is het geheim. De inductiemotor heeft geen andere hulpmiddelen van buitenaf nodig om in beweging te komen. De manier waarop de drie stroomfasen in de juiste volgorde aankomen, zorgt ervoor dat de stator een roterend magnetisch veld produceert. Dit veld is alle "hulp" die de rotor nodig heeft om te beginnen draaien. Het hele systeem werkt meteen.

De driefasen inductiemotor is een topkeuze voor grote klussen omdat het zelfstartende ontwerp ook heel eenvoudig en sterk is. De rotor heeft geen speciale draden die hun eigen vermogen nodig hebben. Hij heeft ook geen borstels die na verloop van tijd kunnen slijten. De belangrijkste onderdelen zijn de stator, die niet beweegt, en een eenvoudige, stevige rotor. Er zijn maar heel weinig onderdelen die kapot kunnen gaan.

Dit eenvoudige ontwerp, samen met het sterke zelfstartende vermogen, maakt de driefasen inductiemotor een geweldige keuze voor zware klussen. Hij kan zelfs starten als hij zware dingen moet verplaatsen. Hij draait op een snelheid die bijna altijd hetzelfde is. En hij kan vele jaren werken en heeft niet veel onderhoud nodig. Het vermogen om hem gewoon aan te sluiten op elektriciteit en hem elke keer weer te laten starten, heeft van deze prachtige inductiemotor de meest gebruikte motor ter wereld gemaakt.