Let Sino's Lamination Stacks Empower Your Project!

To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.

To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.

Sino manufactures premium alternator stator core laminations. Our “Right Stuff” philosophy means exclusively using specialized electrical steel. This deliberate choice ensures superior magnetic/electrical properties, minimizing losses for peak alternator efficiency and reliability. Explore why our success is no accident.

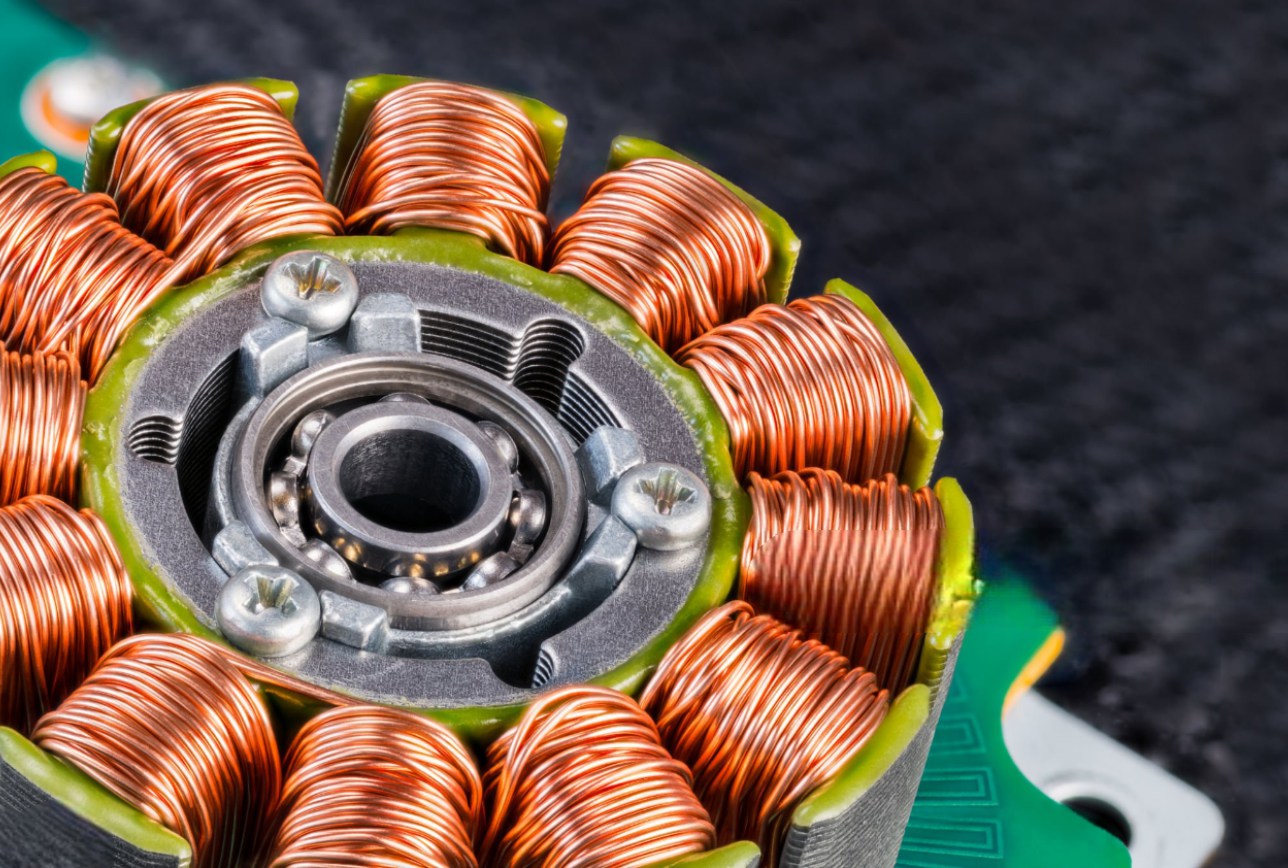

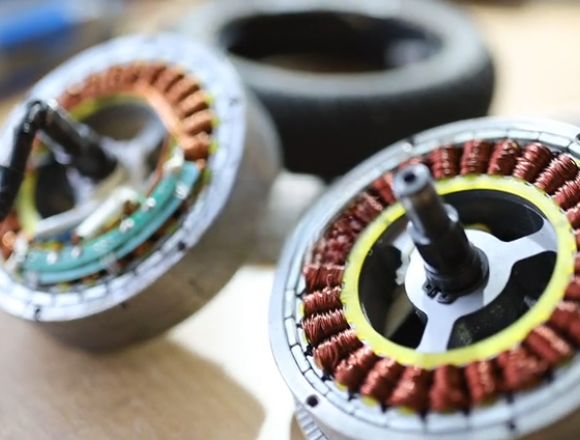

Alternator stator core laminations are the basic parts of any AC generator. They act like a path for magnetism, guiding and focusing the changing magnetic field made by the rotor. Their main job is to help turn motion into electricity really well by losing as little energy as possible inside the core. Cutting down on this lost energy is super important to make the alternator work great and not waste power.

Basically, we need laminations because of two main ways the core loses energy. These things happen in iron-like materials when a changing magnetic field passes through them: eddy current losses and hysteresis losses.

When we build the stator core from thin, steel sheets with a coating that stops electricity—that’s what we make at Sino—we block the path for the eddy currents. The coating between each thin sheet, usually a thin layer of oxide or paint, makes it much harder for electricity to pass from one sheet to the next. This makes any eddy currents flow in tiny little circles inside each single sheet, which makes them much smaller and wastes a lot less energy.

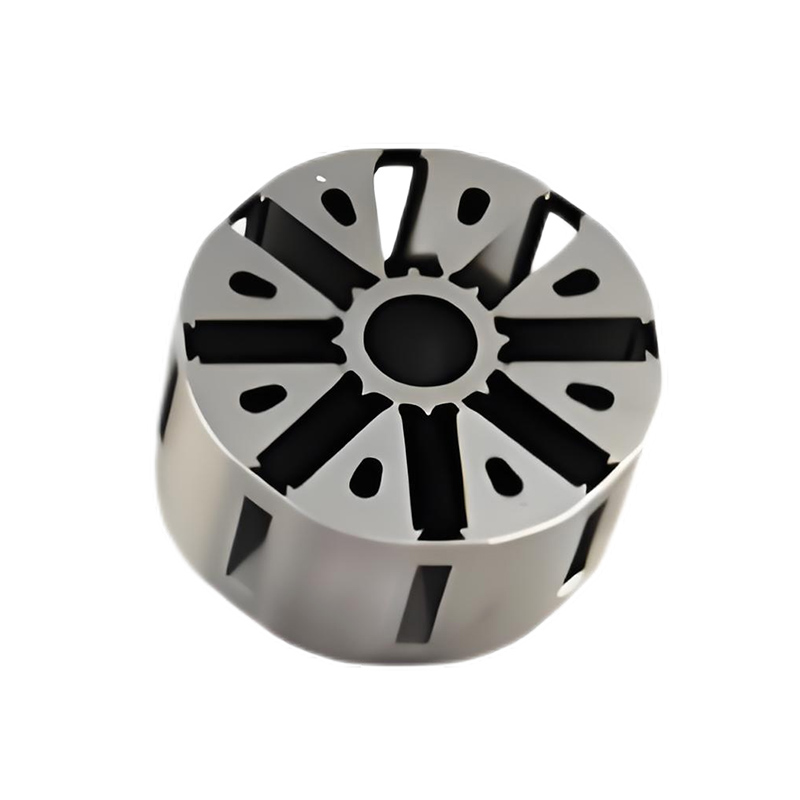

Sino exclusively employs specialized electrical steel, often a type of silicon steel, for our alternator stator core laminations because its magnetic and electrical properties are far superior for this kind of work.

We carefully select grades of steel with an optimized silicon content (typically ranging from 0.5% to 4.5%). Why silicon? Because adding it to iron significantly boosts its electrical resistivity. Think back to Ohm’s Law (Current = Voltage / Resistance). Higher resistance means less current (and thus fewer eddy currents) for any given induced voltage. It’s a fundamental win.

Another energy drain in magnetic cores is hysteresis loss. This happens as the magnetic domains within the steel resist reorienting themselves with each cycle of the alternating magnetic field. It’s like a tiny internal friction. The electrical steels Sino sources are specifically processed to minimize these hysteresis losses, leading to even greater efficiency. We work with mills that can provide materials with guaranteed low core loss figures, often referencing standards like those from ASTM International.

While we want high electrical resistance, we absolutely need high magnetic permeability. This means the material should readily allow magnetic flux to pass through it. It’s like having a wide, clear highway for the magnetic energy to travel, which is essential for the alternator to generate voltage effectively.

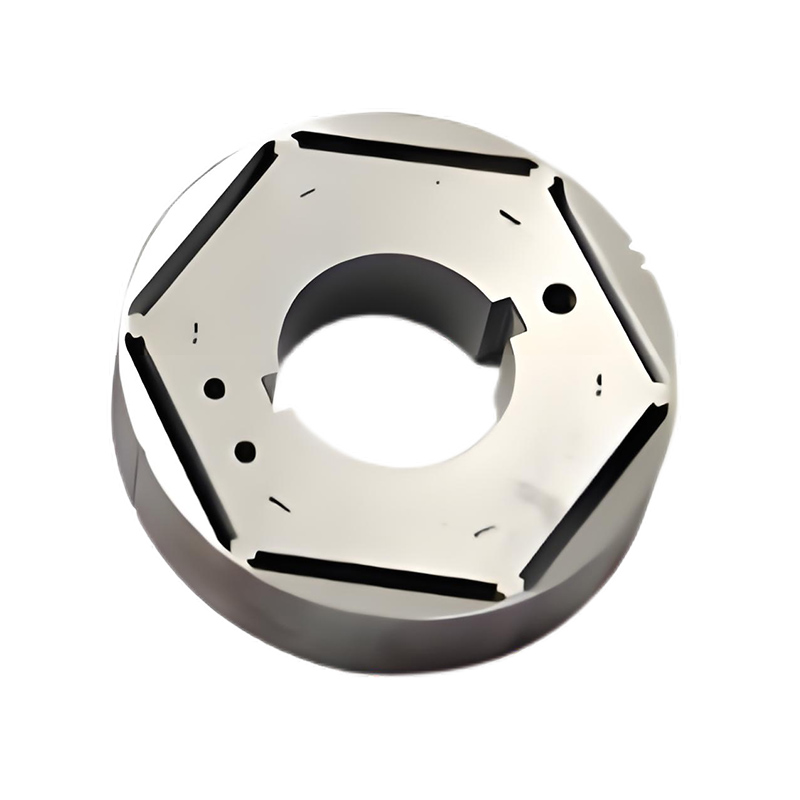

The stamping or laser-cutting process, while precise, can introduce mechanical stresses into the laminations. These stresses can mess with the steel’s magnetic properties. That’s why, at Sino, many of our alternator stator core laminations undergo a carefully controlled annealing process. This heat treatment relieves those stresses, refines the grain structure, and optimizes properties like permeability and coercivity (the magnetic field strength needed to demagnetize the material). It’s an extra step, but one that ensures peak performance.

We employ a range of advanced insulation coatings, tailored to the specific scenario and operating conditions:

1

An organic varnish, good for general-purpose applications, offering a balance of insulation and adhesion.

2

Often based on phosphates or chromates (applied with strict environmental controls, of course!), these coatings can withstand higher temperatures and are often used in more demanding scenarios. Some C-5 coatings also offer self-healing properties to a minor extent.

3

Sometimes a combination of organic and inorganic layers is used to get the best of both worlds – excellent insulation, high-temperature resistance, and good punchability.

4

For some specific steel grades and applications, a controlled surface oxidation process can create a thin, effective insulating layer.

Where do you find these hardworking alternator stator core laminations from Sino making a difference? Pretty much anywhere reliable electrical power generation is needed!

From the compact alternator in your daily driver ensuring your battery stays charged and your tunes keep playing, to the heavy-duty alternators in commercial trucks and buses powering complex electrical systems, Sino’s laminations are there.

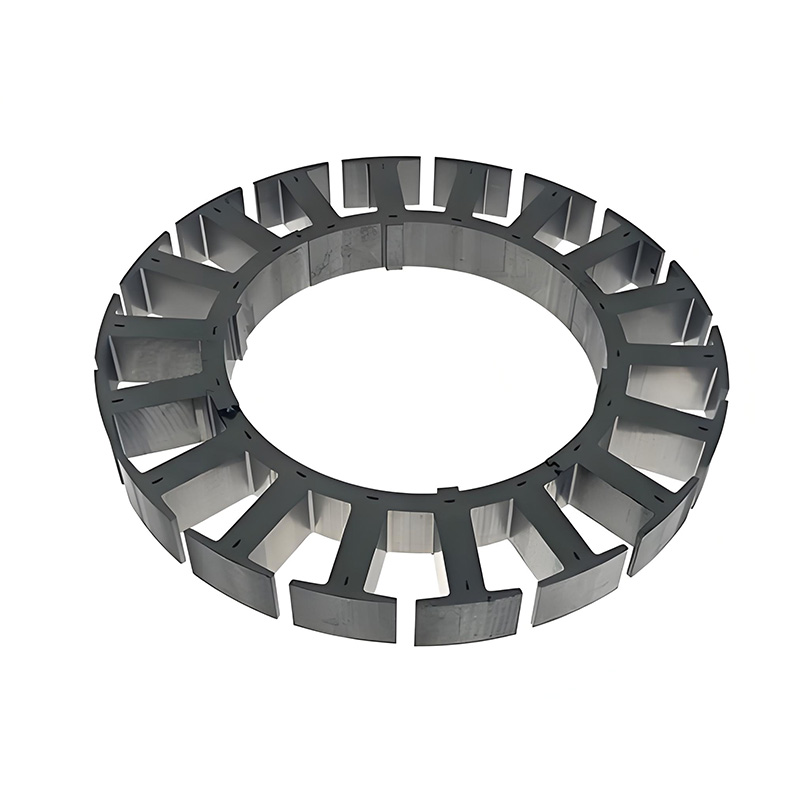

For cars, stator laminations are usually made to be produced quickly and to be small. Normal designs, like ones with 36 or 48 slots, are made to work with automatic machines that stack and build them. This makes a good balance between working well and being easy to make a lot of.

Wind turbines rely on massive generators, and the stator cores in these giants utilize specialized laminations to efficiently convert wind energy into electricity. Similarly, some larger solar inverter systems and power conditioning units incorporate inductive components that benefit from high-quality laminated cores.

Portable generators for campsites or emergency home backup, as well as larger industrial standby generators, all depend on alternators built with efficient stator cores.

Sino’s alternator stator core laminations ensure these units deliver power reliably when it’s needed most, minimizing fuel consumption thanks to reduced electrical losses.

Many large industrial motors can also operate as generators in certain regenerative braking scenarios. The principles of efficient core design apply here too. Furthermore, specialized industrial machinery often has unique power requirements met by custom-designed alternators or generators.

Alternators on boats and ships face harsh, corrosive environments and demand high reliability. Sino can provide alternator stator core laminations with enhanced protective coatings and robust assembly techniques to withstand the rigors of marine life, ensuring consistent power for navigation, communication, and onboard systems.

At Sino, being really good at making things is a key part of what we offer. We use a bunch of advanced, modern methods to make the single laminations and put them together into finished stator cores. All of this is supported by very strict quality checks to make sure the size is perfect and the coating works right. Our ways of making things are designed to be fast for big orders and very exact for special jobs.

For making a lot of parts, progressive die stamping is still the top method in the industry:

For jobs that need to be flexible and exact, laser cutting is a must-have:

Once stacked, the alternator stator core laminations need to be securely held together. Sino offers various methods:

We often use precision welding along the outer periphery of the stack. The key here is to control the weld penetration to avoid short-circuiting the laminations near the weld zone. Our automated welding processes are fine-tuned for this.

For some designs, we can stamp interlocking features directly into the laminations themselves. When stacked, these features lock together, providing mechanical strength without the need for welding. This method is excellent for minimizing any potential magnetic shorting.

In certain scenarios, especially for larger cores, cleating or riveting might be employed, again with careful consideration to avoid compromising the insulation.

When you choose Sino, you’re not just buying a component; you’re investing in a partnership built on expertise and a relentless pursuit of quality.

We source only high-grade electrical steels from reputable mills, ensuring the foundational magnetic and electrical properties are top-tier.

Our state-of-the-art manufacturing facility, equipped with advanced stamping presses, laser cutters, automated stacking lines, and precision welding stations, means every lamination and every core stack meets exacting specifications.

Got a unique design or a challenging operational environment? Sino’s engineering team thrives on collaboration. We can work with you to develop custom alternator stator core laminations tailored to your exact needs, optimizing for size, weight, efficiency, or specific performance characteristics.

From initial design consultation through to prototyping and mass production, our team is here to provide technical support and ensure a smooth supply chain. We understand that our components are critical to your success.

At Sino, we’re passionate about pushing the boundaries of what’s possible with these components. We believe that by focusing on the details – the right steel, the perfect insulation, the most precise cut, the most secure stack – we help our customers build better, more efficient, and more reliable alternators.

If you’re looking for a partner to supply alternator stator core laminations that truly deliver on their promise, look no further than Sino. Let’s power the future, together.

Note: To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.

To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.