Let Sino's Lamination Stacks Empower Your Project!

To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.

To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.

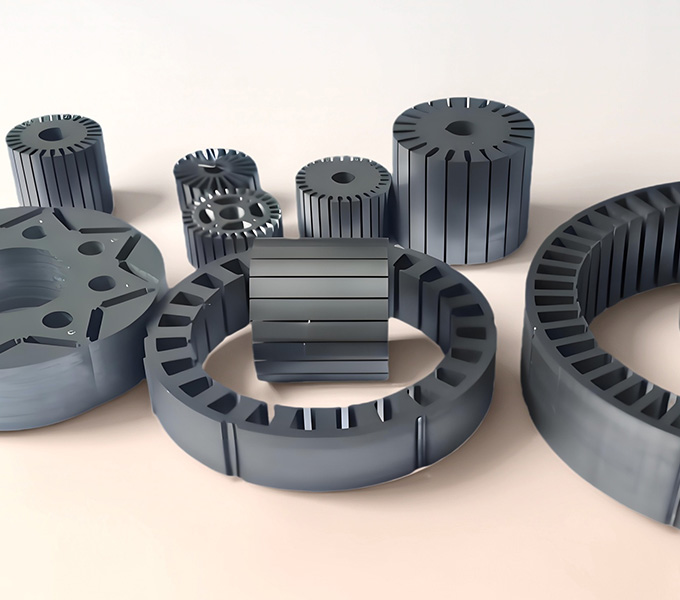

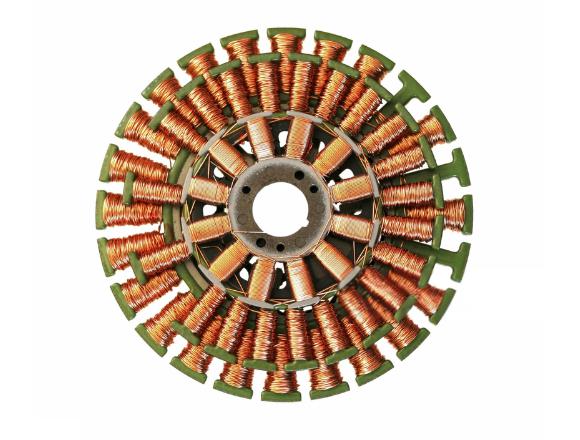

As Sino, a top Chinese maker of armature core laminations, we are focused on giving solutions that work well, are affordable, and are dependable to armature makers in many different industries worldwide. We are skilled in every step of making laminations, from choosing materials and improving complex designs to using modern production methods and strict performance checks.

At Sino, we predominantly utilize high-grade silicon steel (often referred to as electrical steel) which is specifically alloyed and processed for electromagnetic applications, offering a powerful combination of properties:

Sino sources its silicon steel from reputable mills, ensuring consistent quality and magnetic performance, giving your armature core the best possible foundation.

The choice of material for armature core laminations is a basic and important decision that greatly affects the magnetic, electrical, and physical abilities of the final machine. Sino offers a wide variety of materials, each chosen and prepared to meet the needs of a specific use.

We work with many types of electrical steel, each known for its special mix of chemicals, mainly the amount of silicon and control of unwanted elements (C, S, N, Al), which directly affects its magnetic and physical properties:

The final magnetic properties are very affected by how the materials are processed:

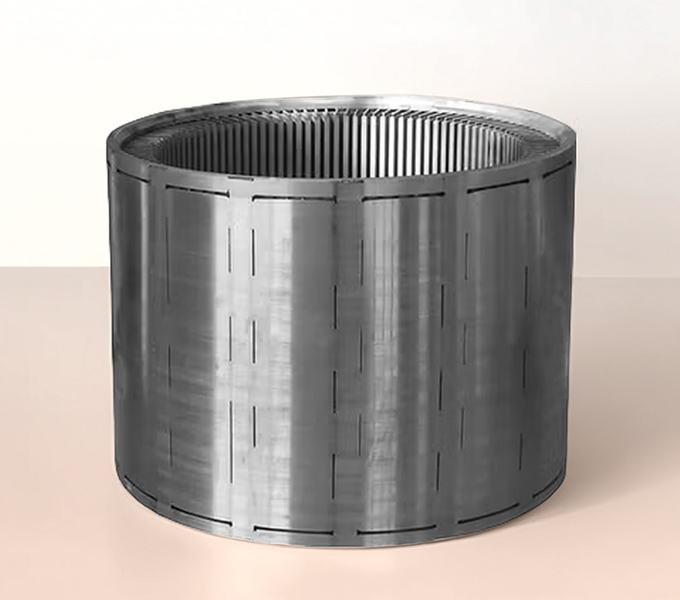

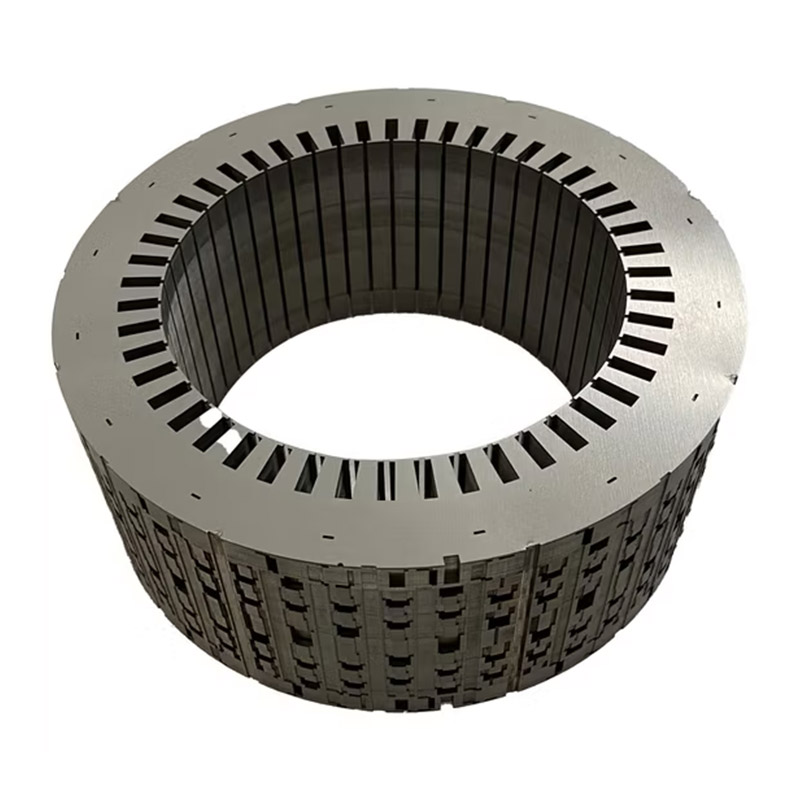

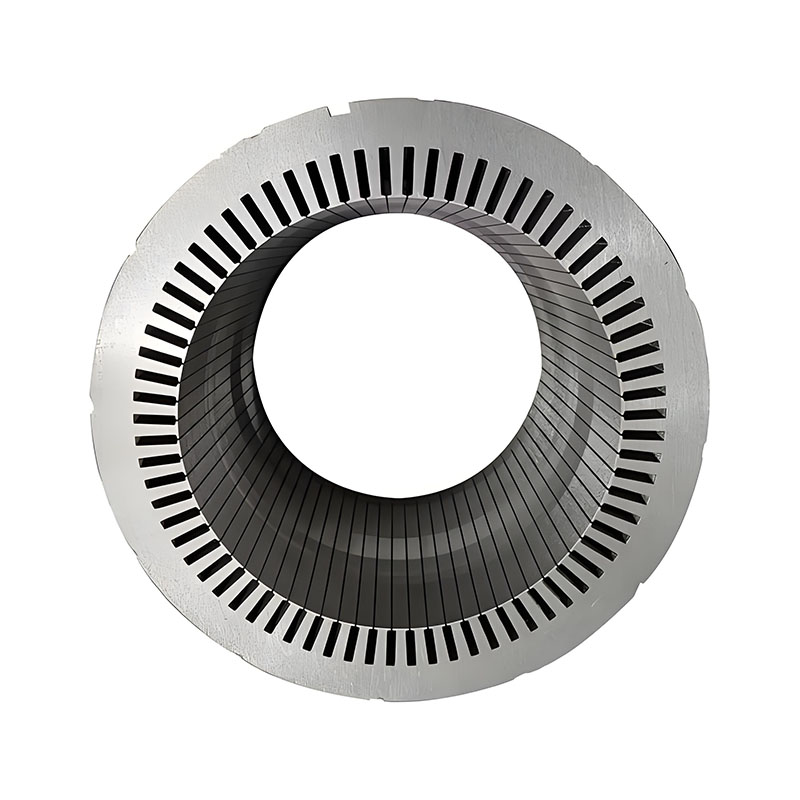

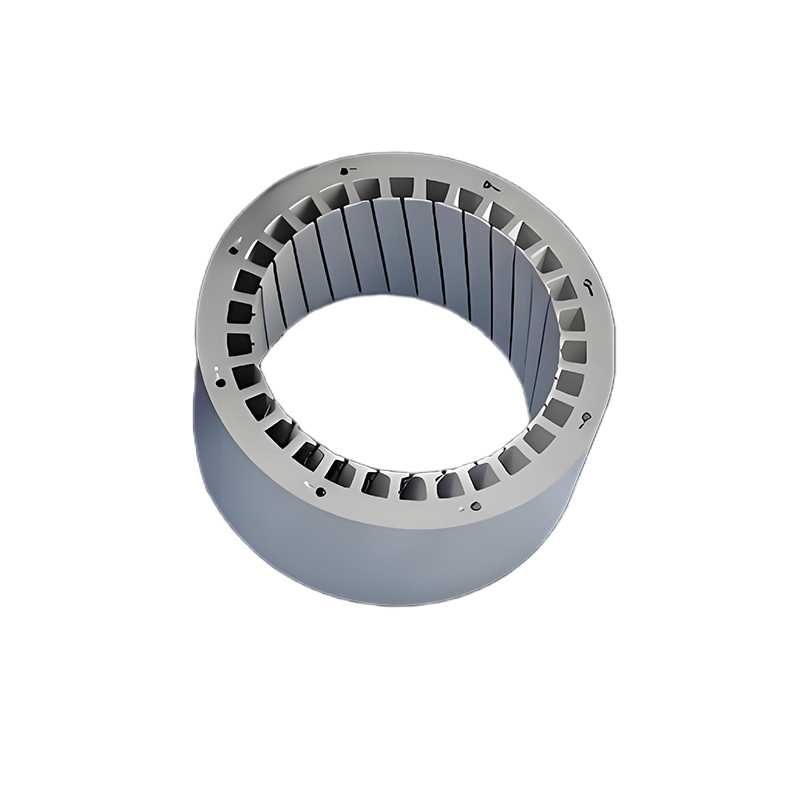

We maintain incredibly tight dimensional tolerances for lamination thickness, flatness, and overall stack dimensions. This precision ensures a high "stacking factor" (more iron, less air gap in the assembled core), which improves magnetic performance. Our standard armature lamination thickness might be 0.35mm or 0.5mm, but we can achieve even finer results for specialized needs.

Our proprietary coating processes ensure a consistent, robust insulating layer on every armature core lamination, crucial for minimizing inter-laminar losses. We test this rigorously.

Whether it's high-speed precision stamping for high-volume production or intricate laser cutting for complex prototypes and smaller batches, Sino employs cutting-edge technology. This results in clean edges, minimal burrs (which can pierce insulation and cause shorts), and accurate slot geometries.

Individual armature laminations must be securely joined to form the final armature core. Sino utilizes various techniques like interlocking (creating small protrusions on one lamination that fit into depressions on the next), precision welding along the outer diameter, or bonding with specialized adhesives, depending on the application's demands for mechanical strength and magnetic performance.

Making sure quality is high is our top priority at Sino:

We think about the effect our processes have on the environment:

From raw material inspection to final stack testing, quality is embedded in every step of Sino’s manufacturing.

The meticulous work we put into each armature core lamination translates directly into real-world benefits for you:

Let’s look at how lamination thickness, a key factor Sino controls, impacts performance:

Core Design Aspect | Example Lamination Thickness | Approx. Relative Eddy Current Loss (Illustrative) | Typical Sino Focus for This Scenario |

Traditional/Older Designs | >1.0 mm | High (e.g., 4x or more than 0.5mm) | Upgrading customers to modern standards |

General Purpose Motors | 0.5 mm | Baseline Standard | High-quality, consistent 0.5mm armature laminations |

High-Efficiency Motors | 0.35 mm | ~50% of 0.5mm losses | Precision 0.35mm armature core lamination solutions |

Very High-Speed/Freq. | 0.2 mm or less | Significantly lower | Specialized thin-gauge armature laminations |

Sino's armature core laminations are making a tangible difference across a multitude of demanding scenarios:

In a sprawling manufacturing plant where hundreds of electric motors power everything from conveyor belts to pumps to machine tools, running 24/7, even a few percentage points improvement in efficiency per motor, thanks to superior armature core lamination from Sino, can add up to enormous energy savings annually.

In the world of automation and robotics, speed, accuracy, and responsiveness are paramount. Servo motors need to accelerate and decelerate incredibly quickly and hold positions with pinpoint precision. The low-loss, high-performance armature core lamination stacks from Sino ensure that these motors have minimal magnetic lag and can deliver the dynamic performance required.

From small backup generators to larger units contributing to the grid, the reliability and efficiency of the armature core are non-negotiable. Sino provides robust armature laminations for generator sets that need to perform flawlessly, often under demanding conditions. Our consistent material quality and manufacturing precision help ensure stable voltage output and long operational life, critical for hospitals, data centers, and remote communities relying on consistent power.

The shift to electric vehicles (EVs) is accelerating, and at the heart of every EV is an advanced electric motor. These motors need to be incredibly efficient to maximize range, lightweight to improve vehicle dynamics, and powerful to deliver exhilarating performance. Sino is actively involved in this space, developing and supplying state-of-the-art armature core lamination solutions, including those from novel, high-performance electrical steels, for EV traction motors.

The fans and compressors in heating, ventilation, and air conditioning (HVAC) systems run for countless hours. By incorporating Sino’s efficient armature laminations into the motors that drive these systems, manufacturers can achieve higher SEER (Seasonal Energy Efficiency Ratio) ratings, making appliances more attractive to consumers and better for the environment.

We know that one size rarely fits all, especially in specialized engineering. That’s why Sino offers far more than just off-the-shelf armature laminations.

1

Do you have a unique slot geometry, a specific outer diameter, or a challenging performance target for your armature core? Our engineering team thrives on such challenges. We can work from your drawings or collaborate with you to design and prototype custom armature core lamination stacks perfectly suited to your scenario.

2

While high-grade silicon steel is our mainstay, we keep abreast of the latest advancements in electrical steel technology and can advise on or source specialized materials for unique requirements, such as those demanding exceptionally low losses at very high frequencies or high mechanical strength.

3

Whether you need a handful of prototypes for a new design or full-scale production runs of thousands of armature core units, Sino has the capacity and agility to deliver.

In the intricate dance of magnetic fields and electrical currents that powers our world, the armature core lamination is a critical performer. Its quality dictates efficiency, reliability, and the overall success of your electric machine.

At Sino, we pour our expertise, our commitment to precision, and our passion for innovation into every armature lamination and every armature core stack we produce. We’re not just stamping steel; we’re building the foundations for higher performance, lower energy consumption, and more reliable machinery across countless scenarios.

Don’t let substandard core components compromise your designs. Choose Sino for armature core laminations that deliver on their promise.

Ready to experience the Sino difference in your next project? Contact our engineering team today for a consultation or a quote. Let’s build more efficient, more powerful, and more reliable solutions, together. Your machinery deserves the best, and the best armature core laminations come from Sino.

Note: To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.

To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.