Let Sino's Lamination Stacks Empower Your Project!

To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.

To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.

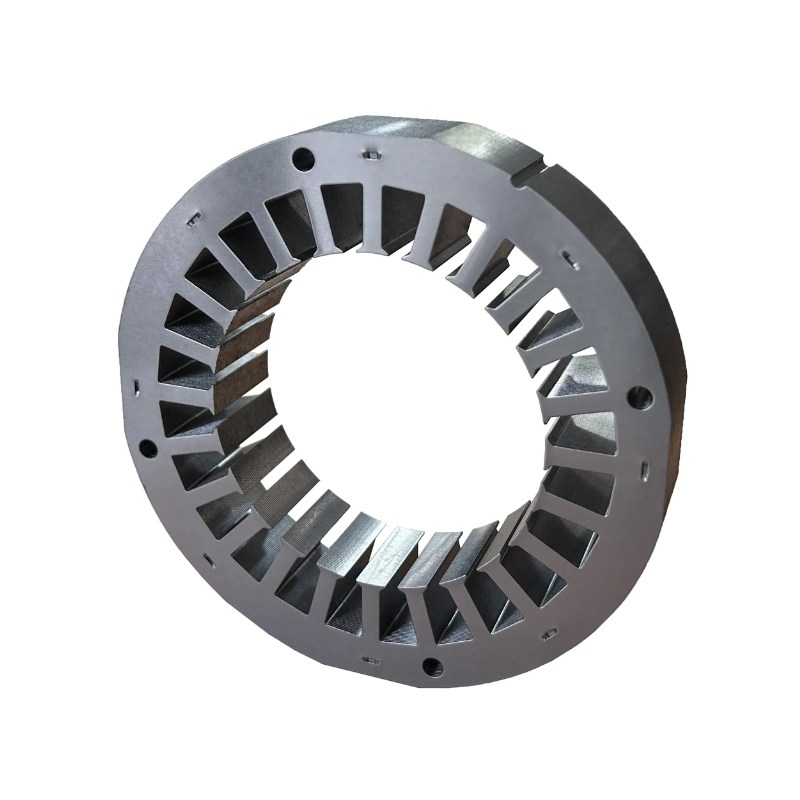

We’re a factory dedicated to manufacturing lamination stacks that form the very heart of high-performing, energy-efficient motors. And here at Sino, crafting these precision components isn’t just what we do; it’s our passion.

The material we choose for Sino’s bldc ceiling fan stator laminations is a highly specialized electrical steel, typically a silicon steel alloy.

Adding a specific percentage of silicon to iron does a couple of brilliant things:

At Sino, our material scientists and engineers work closely with our steel suppliers. We specify particular grades known for their excellent magnetic permeability (how easily they can be magnetized and demagnetized) and low core loss characteristics.

Thinner laminations (often in the range of 0.35mm to 0.5mm for many BLDC ceiling fan stators) provide more layers of insulation in a given stack height, further disrupting those energy-sapping currents. However, going too thin can dramatically increase the number of laminations needed, which can ramp up manufacturing complexity and cost. It can also make the stack less mechanically robust if not handled correctly. At Sino, we work with you to determine the optimal thickness for your specific bldc ceiling fan stator design, considering your performance targets, operational frequency, and cost considerations.

Each lamination needs to be stamped or laser-cut with incredible accuracy. Because:

1

Any tiny burrs or rough edges left from the cutting process can pierce the crucial insulating coating between laminations. If that happens, a short circuit occurs, allowing eddy currents to flow across laminations, negating much of the benefit of having laminations in the first place! Sino employs advanced stamping dies made from high-durability carbide, along with rigorous deburring processes and quality checks, to ensure burr formation is minimized to almost imperceptible levels. For highly complex or prototype designs, we also leverage precision laser cutting.

2

The insulating coating itself (often an organic varnish or an inorganic oxide layer) must be uniform and robust. Sino uses specially formulated coatings designed for excellent dielectric strength and adhesion, applied under controlled conditions.

3

Once the individual laminations are perfect, they need to be stacked together with extreme precision. Misaligned laminations can lead to an uneven magnetic field, increased vibration, and more audible noise – exactly what you don’t want in a premium ceiling fan. Our automated stacking processes, often incorporating interlocking features stamped into the laminations themselves, ensure a tight, perfectly aligned core. This not only guarantees optimal magnetic performance but also contributes to the fan’s overall mechanical stability and quiet operation.

The culmination of all this meticulous material science and precision engineering is a bldc ceiling fan stator lamination stack from Sino that delivers tangible benefits. It’s not just about meeting a specification; it’s about elevating the performance of the final product – your ceiling fan.

Sino Lamination Characteristic | Our Commitment to Excellence | Direct Benefit to Your BLDC Ceiling Fan |

Material Grade & Selection | Premium, low-loss electrical/silicon steel grades | Lower energy consumption, reduced heat generation |

Lamination Thickness Optimization | Tailored from 0.2mm to 0.65mm based on design | Minimized eddy current losses, especially at higher RPMs |

Insulation Coating Integrity | Robust, high-dielectric strength, uniform coating | Maximum eddy current suppression, enhanced reliability |

Precision Stamping/Cutting | Ultra-low burr, tight dimensional tolerances | Reduced core losses, quieter operation, easier assembly |

Proprietary, optimized cycles for magnetic properties | Improved magnetic permeability, lower hysteresis losses | |

Stacking & Assembly | Precise alignment, interlocking options, welding/bonding | Reduced vibration, consistent air gap, mechanical stability |

At Sino, we view ourselves as more than just a component supplier; we aim to be your strategic partner in developing superior BLDC motors. We understand that every fan design has unique requirements, whether it’s for a sleek, minimalist residential fan or a rugged industrial air mover.

Our experienced engineers are ready to work with your team from the initial concept stage. We can help you select the ideal material, lamination thickness, and stack design for your specific performance goals and cost envelope for your bldc ceiling fan stator.

While we offer standard lamination profiles, our real strength lies in our ability to produce custom designs tailored precisely to your motor's magnetic circuit.

Need to test a new design quickly? Sino’s agile manufacturing setup allows for rapid turnaround on prototype lamination stacks, helping you iterate faster and get to market sooner.

Our facilities are ISO 9001 certified, and we implement rigorous quality control at every stage, from raw material inspection to final stack testing. We employ advanced metrology equipment, including CMMs (Coordinate Measuring Machines) and vision systems, to ensure every lamination and every stack meets our exacting standards.hundreds of thousands for mass production, Sino has the capacity and expertise to deliver on time and on budget.

If you’re designing or manufacturing BLDC ceiling fans, and you’re looking for a way to gain a competitive edge, it’s time to look closely at your stator laminations. Don’t let this critical component be an afterthought. By choosing Sino’s precision-engineered bldc ceiling fan stator laminations, you’re investing in:

The quiet revolution in ceiling fan technology is powered by components like ours. We invite you to experience the Sino difference. Let our expertise in lamination manufacturing help you build a better, more efficient, and more desirable BLDC ceiling fan.

Contact us today to discuss your project requirements, request a quote, or learn more about how Sino’s stator laminations can be the core of your success. Let’s work together to make your next fan not just good, but exceptional.

Note: To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.

To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.