Let Sino's Lamination Stacks Empower Your Project!

To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.

To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.

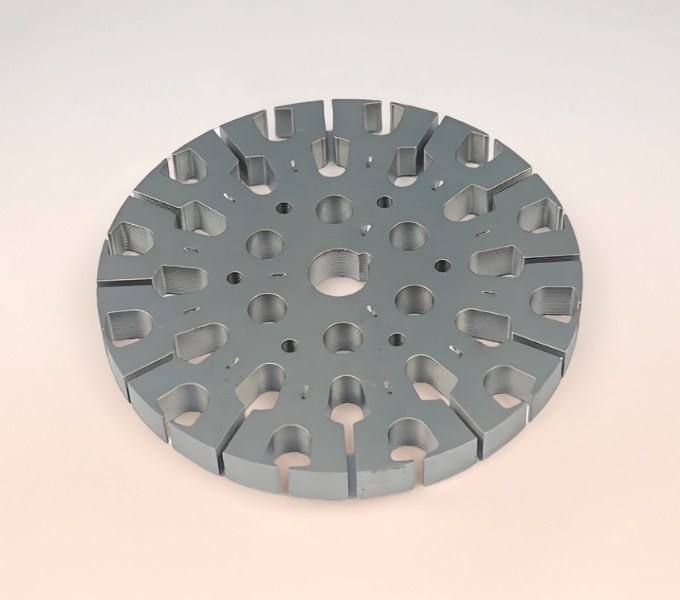

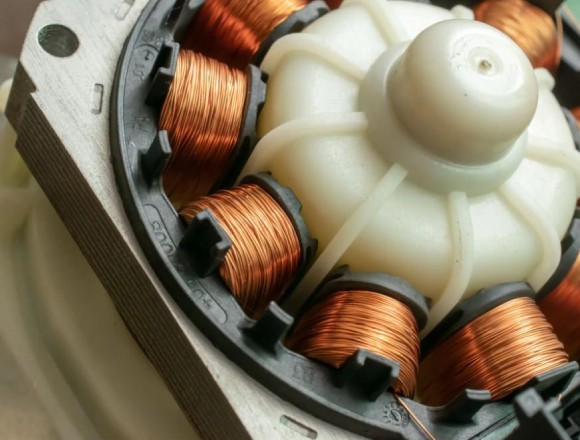

The quiet efficiency and comfortable experience of a ceiling fan are fundamentally determined by its high-quality stator lamination stack. Sino specializes in the precision manufacturing of ceiling fan stator laminations, dedicated to enhancing motor performance and helping you create superior fan products. Choosing Sino means selecting core technology for more energy-efficient, quieter, and reliable ceiling fans.

At Sino, we don’t just stamp out metal; we understand the physics and material science that go into creating truly top-tier laminations. It’s a blend of the right materials, precision manufacturing, and a deep understanding of how these components perform in real-world scenarios.

We meticulously select our raw materials, primarily focusing on electrical steel, often a silicon steel alloy. Adding a small percentage of silicon (typically 1-4%) to iron does a couple of fantastic things:

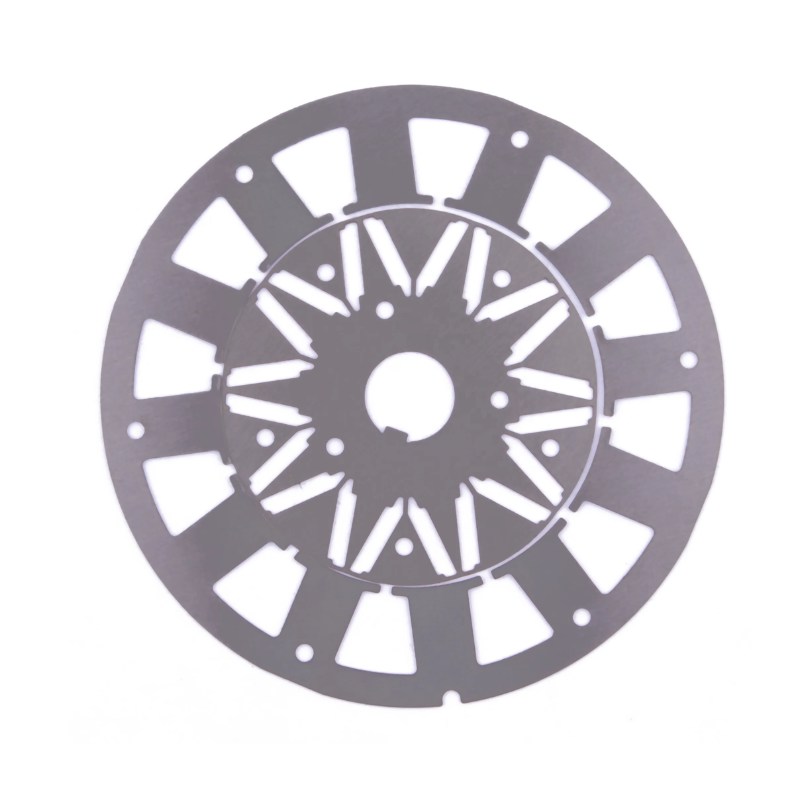

When it comes to laminations, size (or rather, thinness) and isolation matter immensely.

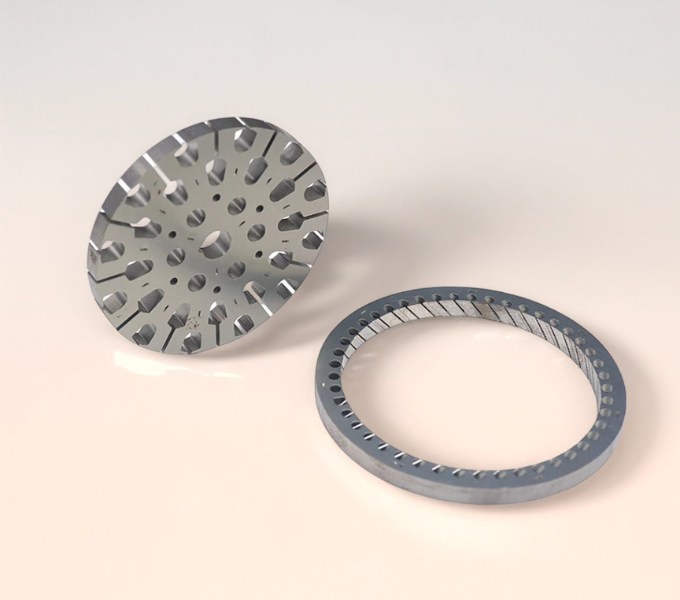

The “stacking factor” is a measure of how much of the core’s volume is actual steel versus insulation and tiny air gaps. Sino’s precision stacking techniques, which can include interlocking, welding, or cleating (depending on the design), aim to maximize this factor while maintaining the integrity of the insulation between layers.

Choosing Sino’s ceiling fan stator laminations isn’t just a component choice; it’s an investment in superior performance, reliability, and customer satisfaction.

This is the big one. Reduced eddy current and hysteresis losses directly translate to higher motor efficiency. For the end-user, this means their ceiling fan consumes less electricity to produce the same (or better) airflow. Over the lifespan of a fan, these savings add up!

Less wasted energy means less heat. A cooler running motor is a happier motor. Excessive heat is a primary enemy of motor longevity, as it can degrade insulation, bearings, and other components over time. Fans built with Sino's laminations tend to run cooler, contributing to a longer operational life and fewer premature failures.

A well-designed and meticulously manufactured laminated core contributes to smoother torque production. This means less vibration and, importantly, less annoying motor hum. In environments where quiet is golden – bedrooms, offices, libraries, even recording studios – a fan that operates almost silently is a massive selling point. The precise magnetic field control afforded by quality laminations minimizes the kind of magnetic noise that can drive you nuts.

Our commitment at Sino goes beyond just meeting specifications. We aim to exceed them. Our manufacturing pathway typically involves:

1

Selecting the right grades of electrical steel.

5

Assembling the laminations into a solid, reliable core using methods like interlocking, welding, or riveting, ensuring alignment and the integrity of the inter-laminar insulation.

6

Multiple checkpoints throughout the process, from raw material inspection to final dimensional and electrical testing (where applicable).

While the nuances of motor design are complex, the benefits of quality laminations are clear and measurable. Industry benchmarks and foundational engineering texts consistently highlight these advantages.

Sino Lamination Focus Area | Typical Material/Specification Example | Impact on Ceiling Fan Performance (with Sino’s Quality) |

Core Material | High-Grade Silicon Steel (e.g., M19-M47 grades) | Superior magnetic properties, leading to significantly reduced hysteresis and eddy current losses compared to standard carbon steel. |

Lamination Thickness | 0.35 mm – 0.50 mm for high efficiency | Optimal for minimizing eddy current losses in typical ceiling fan operating frequencies. Thicker options available for cost-sensitive designs. |

Insulation Type | C5 or C6 Organic Varnish / Oxide | Provides excellent electrical insulation between laminations, crucial for preventing current leakage and maximizing efficiency. |

Stacking Factor | > 0.92 – 0.97 | Maximizes the amount of active magnetic material in the core, leading to a more power-dense and efficient motor. |

Manufacturing Precision | Tight dimensional tolerances, low burr | Ensures proper fit, reduces assembly issues, and minimizes potential shorting paths for eddy currents. |

Resulting Fan Benefits | ||

Energy Efficiency | Up to 15-25% improvement* | Lower electricity bills for consumers, reduced environmental impact. |

Operating Temperature | Reduced by 5-10°C* | Enhanced motor lifespan, improved reliability, greater safety. |

Noise Level | Lowered acoustic noise | Quieter operation, leading to greater user comfort and satisfaction. |

At Sino, our internal testing and client feedback consistently reinforce these figures. When a fan manufacturer partners with us, they’re not just buying steel; they’re buying predictable, enhanced performance for their ceiling fan stator assemblies.

In the competitive world of ceiling fans, differentiation matters. Consumers are increasingly savvy, looking for products that are not only stylish but also energy-efficient, quiet, and built to last. The quality of the ceiling fan stator laminations is a fundamental factor in achieving these goals.

By partnering with Sino, you gain access to:

Don’t let the heart of your ceiling fan be an afterthought. The seemingly simple stack of steel laminations within the ceiling fan stator holds the key to unlocking superior performance.

Ready to elevate your ceiling fan designs and give your customers the quiet, efficient, and long-lasting comfort they deserve? Reach out to the team at Sino today. Let’s discuss how our ceiling fan stator laminations can become the backbone of your next great product. Because at Sino, we believe a better breeze begins with a better core.

Note: To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.

To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.