Let Sino's Lamination Stacks Empower Your Project!

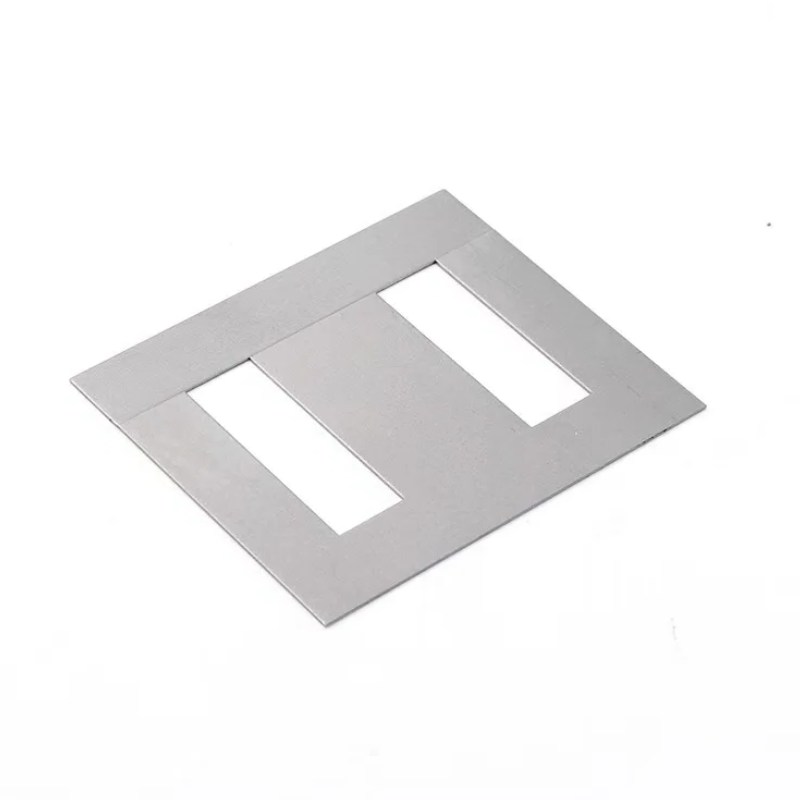

To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.

To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.

As Sino, a top Chinese maker of motor and transformer laminations, we know how important Cold-Rolled Grain-Oriented (CRGO) electrical steel is for how well your products work and how long they last. We want to give you useful information about new technology, the supply chain, costs, and the market competition. This will help you make good choices, lower your material costs, and stay ahead in a changing world market.

At Sino, we don’t just buy CRGO steel and chop it up. We’re craftsmen (and women!) of the magnetic core. We understand that the journey from a roll of premium CRGO steel to a perfectly functioning crgo lamination core is paved with precision.

1

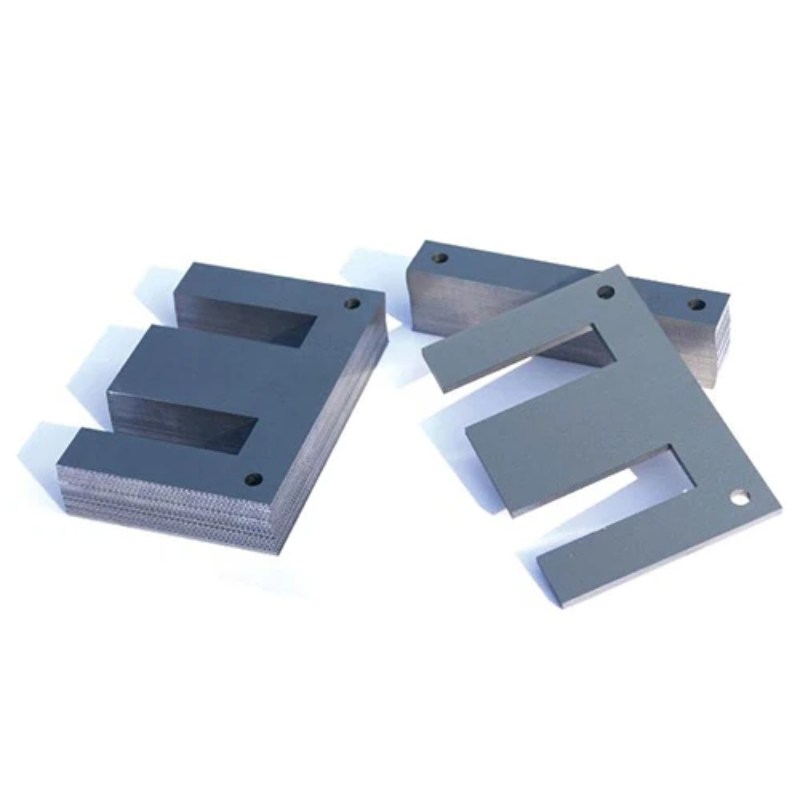

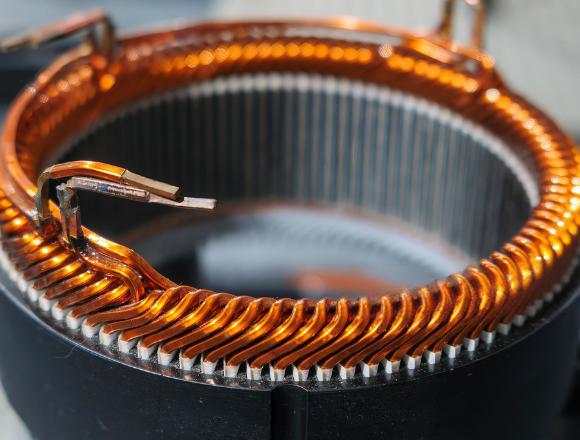

Ensuring every lamination is cut to exact dimensions, with clean edges to minimize burrs which can compromise insulation and increase losses.

2

Preserving the delicate insulation coating on each lamination is paramount. Scratches or damage here can create short circuits between layers, undoing the whole point of laminating!

3

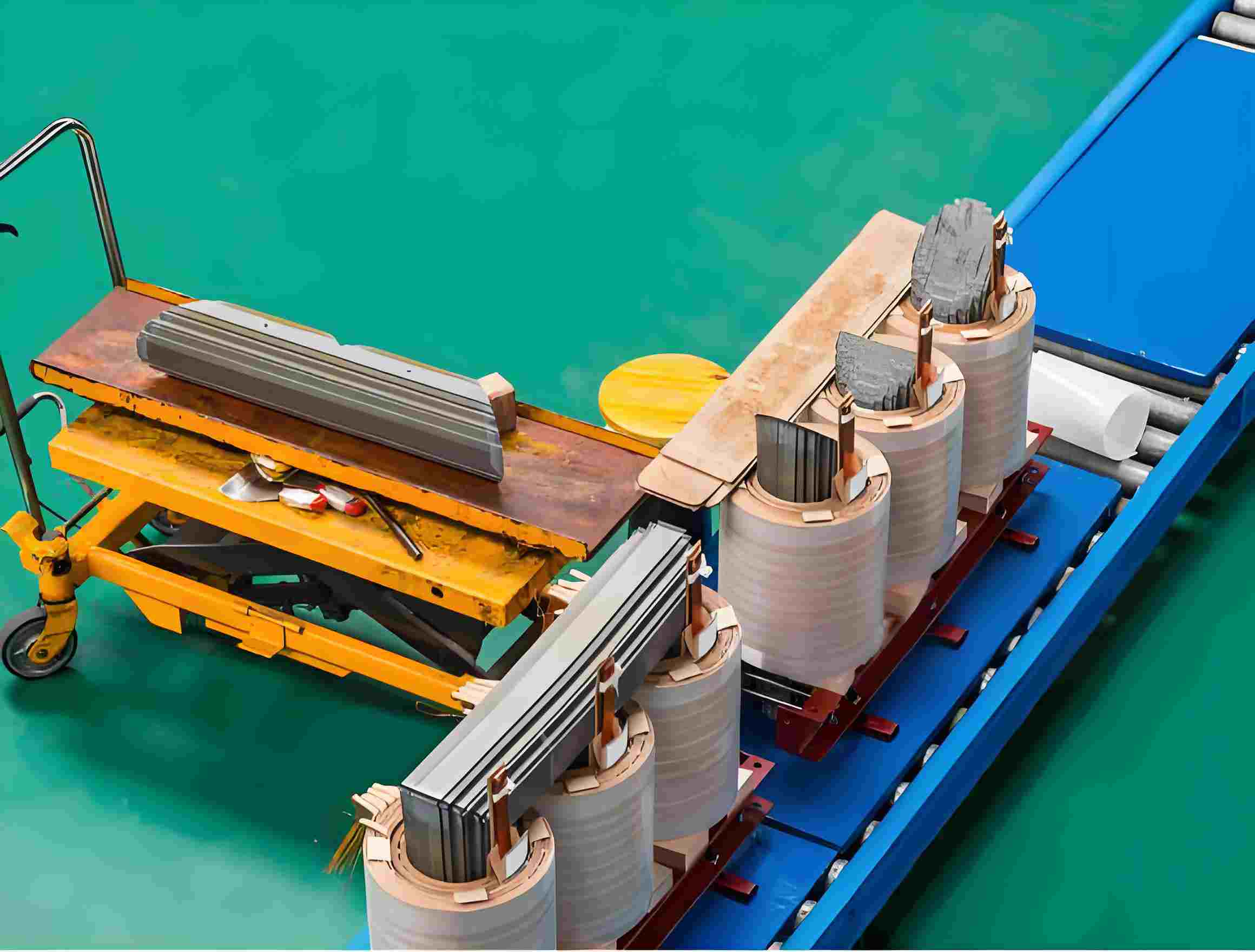

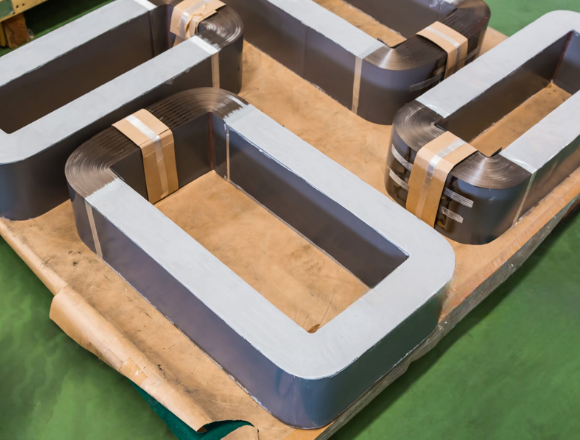

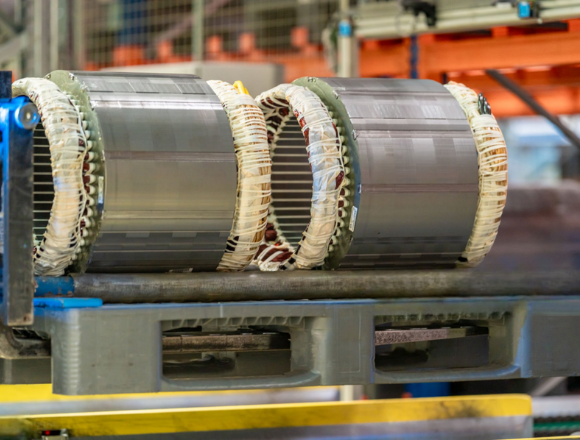

Whether it’s a simple stacked core or a more complex step-lap design for even lower losses and noise, the way the laminations are put together matters. We ensure tight, uniform stacking to maximize the amount of steel in the core (what’s called a high stacking factor) and maintain the integrity of the magnetic circuit.

4

We start with high-grade CRGO steel, because you can’t make a silk purse from a sow’s ear, as the old saying goes.

Making CRGO laminations is a process that requires high precision, and understanding its costs is important for both the makers and their customers. At Sino, we carefully manage every step to improve efficiency and provide good value.

CRGO steel is engineered to have astonishingly low core losses. These losses come in two main flavors: Hysteresis Loss and Eddy Current Loss. While the raw CRGO material provides the foundation for low loss, our manufacturing process is crucial. By ensuring minimal burrs from cutting, preserving the integrity of the insulation coating (often a very thin layer of something like Carlite), and achieving a high stacking factor in the crgo lamination core, we help our customers squeeze every last bit of efficiency out of the material. This means transformers built with Sino laminations waste less energy as heat.

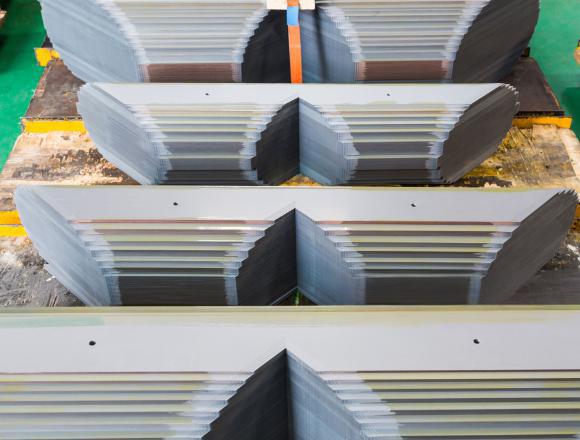

During its manufacture, the steel is cold-rolled and annealed in such a way that the crystal grains within the steel align preferentially in the rolling direction. This property is called high magnetic permeability. That means you need less “push” (magnetizing current) to get the desired amount of magnetic flux flowing through the core.

Sino’s Role: When we cut and assemble a crgo transformer lamination core, we pay meticulous attention to this grain orientation. For designs like mitred cores or step-lap cores, the angles and overlaps are precisely engineered to ensure the magnetic flux predominantly follows this easy path, minimizing “corner losses” where the flux has to turn. This isn’t just about cutting steel; it’s about understanding and respecting the physics of magnetism. Our precision ensures the final core behaves as the designer intended, maximizing that high permeability benefit.

Every magnetic material has a limit to how much magnetic flux it can carry, a point called saturation. CRGO steel boasts a respectably high saturation flux density. That means you can design a core that carries the same amount of magnetic power using less actual steel.

Sino’s Flexibility: We work with various grades of CRGO steel, each with slightly different properties, including saturation flux density. By offering precisely manufactured CRGO laminations from the optimal grade for a specific design, we help engineers create more compact and cost-effective transformers without compromising performance.

Around the globe, the whistle is blowing for greater energy efficiency. Lower-grade, non-oriented steels, or even poorly manufactured CRGO cores, simply can’t deliver the low-loss performance required.

Sino as Your Ally: By consistently delivering top-quality CRGO laminations and assembled crgo lamination cores that perform as expected, we provide a reliable foundation for building transformers that not only meet but often exceed these stringent efficiency benchmarks. When you choose Sino, you’re choosing a supplier committed to helping you build the efficient transformers of today and tomorrow.

At Sino, we pride ourselves on being more than just a factory that cuts and stacks steel. We understand the nuances of CRGO laminations and their critical role in the performance of a crgo transformer lamination core.

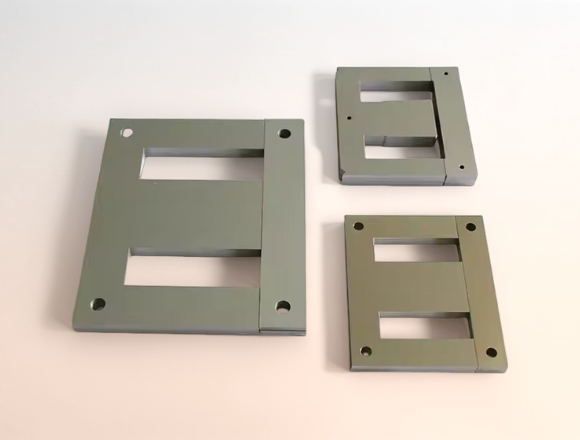

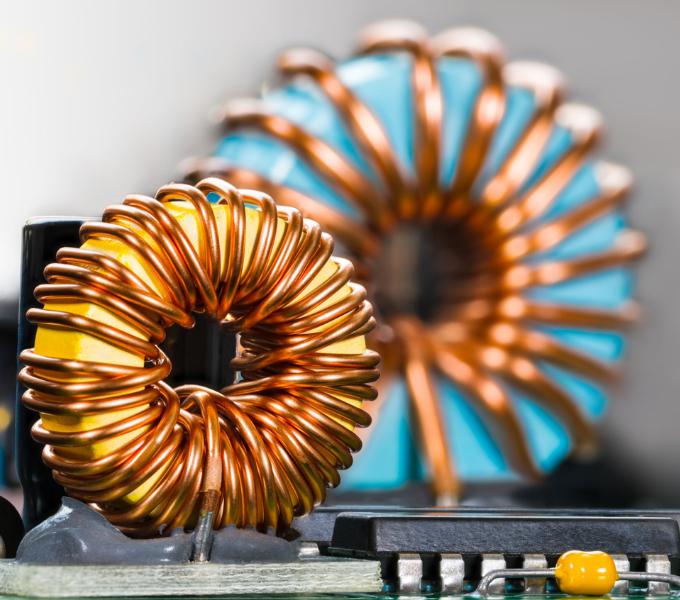

We know that one size rarely fits all. That's why we offer a wide range of customization options. Whether you need laminations for small single-phase transformers or massive three-phase power transformers, specific shapes (E&I, UI, toroidal, custom cut), mitred joints, step-lap configurations, or cores with precise gapping for inductor applications, Sino has the capability and expertise.

The thin insulation coating on each lamination is its invisible shield. We employ careful handling and processing techniques to maintain the integrity of this coating, ensuring maximum resistance to eddy currents. Common coatings like C5 (Carlite) provide excellent insulation and withstand annealing temperatures.

Our factory is equipped with advanced slitting lines, cutting machines (including CNC cutters for complex shapes), and stacking equipment. This allows for high precision, tight tolerances, and efficient production.

From inspecting incoming raw CRGO coils to final checks on assembled cores, quality control is woven into every step of our process. We aim to ensure that every crgo lamination core leaving our facility meets or exceeds customer specifications and industry standards.

Our engineers and technicians have years of experience working with CRGO steel. They understand its properties and how to get the best out of it. We’re always ready to discuss your specific requirements and offer solutions.

Illustrative Table: Sino’s Role in Maximizing CRGO Benefits

Property of CRGO Steel | Sino’s Manufacturing Focus to Maximize Benefit | Outcome for Your Transformer |

Low Intrinsic Core Loss | Precision cutting (low burr), intact insulation, optimal annealing (if required by customer) | Highest possible efficiency, reduced operating temperature & cost |

High Permeability (Oriented) | Accurate angle cutting (mitres), careful stacking for grain alignment | Lower magnetizing current, optimal magnetic circuit performance |

High Saturation Flux Density | Sourcing appropriate grades, ensuring high stacking factor | Potential for smaller, lighter, more cost-effective core designs |

Material Consistency | Sourcing from reputable mills, stringent incoming material inspection | Predictable, reliable performance from batch to batch |

Note: Specific material grades (e.g., M3, M4, M2H, MOH, HIB grades like 23MOH, 27MOH) will have defined loss and permeability figures from steel mills like Nippon Steel, JFE, POSCO, AK Steel, etc. Sino ensures our processing preserves these inherent qualities.

Our commitment at Sino isn’t just talk. We benchmark our processes against the best in the industry and ensure our products enable our customers to meet:

The applications for our CRGO laminations and assembled cores are as diverse as the electrical world itself:

Those cylindrical or box-shaped transformers on utility poles or ground pads in your neighborhood almost certainly use a crgo transformer lamination core. Sino’s laminations help make these units efficient, reliable, and long-lasting, quietly keeping the lights on and appliances running for millions.

Step-up and step-down transformers in electrical substations handle huge amounts of power. Efficiency here is paramount, as even a small percentage loss translates to significant wasted energy. Our high-quality CRGO laminations are essential for these critical pieces of infrastructure, ensuring stable and efficient power transmission.

Many industrial processes rely on specialized transformers for things like induction furnaces, welding equipment, or variable speed drives. These often have unique design requirements, and Sino's ability to provide custom-cut CRGO laminations and cores is a perfect fit.

As the world turns to renewable energy, efficient transformers are needed to step up the voltage from wind turbines or solar farms for grid connection. Space and weight can be critical, especially in wind turbine nacelles, making the compact design potential offered by high-quality crgo lamination cores from Sino particularly attractive.

Large chokes and inductors, used for filtering and energy storage in power electronics, also benefit from the low losses and high permeability of CRGO laminations, often with specific air gaps incorporated into the core design, which Sino can expertly manufacture.

At Sino, we’re not just cutting steel; we’re helping to power the world more efficiently. We understand the critical role that a well-crafted crgo lamination core plays in the performance of your electrical equipment. Our dedication to precision, quality, and customer satisfaction makes us an ideal partner for manufacturers who refuse to compromise on excellence.

Ready to discuss how Sino’s CRGO laminations can elevate your next project? Get in touch with us today. Let’s build a more efficient future, one perfectly stacked lamination at a time.

Note: To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.

To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.