Let Sino's Lamination Stacks Empower Your Project!

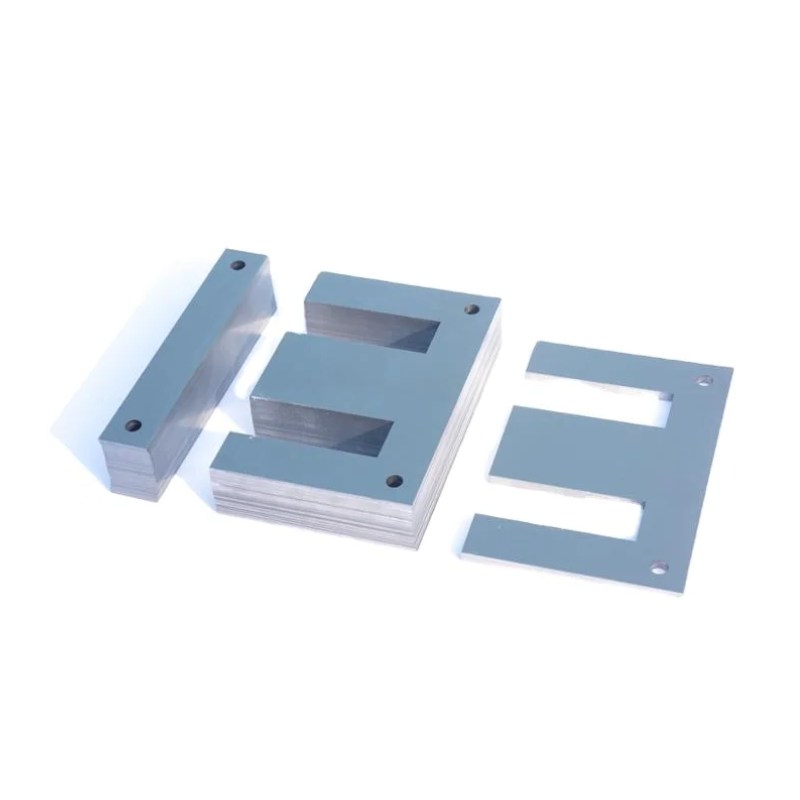

To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.

To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.

Cold Rolled Non-Oriented (CRNGO) electrical steel laminations are crucial for powering countless modern devices, from everyday appliances to sophisticated industrial machinery, with their core advantage lying in efficient and reliable magnetic performance. At Sino, we help motor and transformer makers around the world by providing top-quality magnetic core solutions. Our Cold-Rolled Non-Grain Oriented (CRNGO) laminations are made to give great performance, efficiency, and reliability in many different electrical uses.

CRNGO offers a fantastic balance between solid magnetic performance and affordability. Producing CRNGO steel is a less intricate process compared to its more specialized cousin, CRGO (Cold Rolled Grain Oriented) steel. CRGO is fantastic for things like large power transformers where the magnetic flux follows a very defined path but that specialization comes at a price.

For a huge range of other electrical scenarios, CRNGO hits the sweet spot. Power tools, household appliances, smaller industrial motors, and HVAC systems all need to be efficient and reliable but they also need to be competitively priced. CRNGO makes that possible. At Sino, we work closely with our clients to understand their specific cost-performance targets. Often, after reviewing the requirements, a high-quality CRNGO lamination stack from our facility proves to be the most economically sound solution, delivering the needed magnetic oomph without unnecessary expenditure.

Beyond its magnetic and cost advantages, CRNGO is also a bit of a dream when it comes to manufacturing. These thin steel sheets, which typically include a bit of silicon in their recipe, are wonderfully formable and punchable. This process, known as CRNGO stamping, is one of our core competencies at Sino.

The ease with which CRNGO can be processed translates directly into faster production cycles and lower manufacturing costs for the final lamination stack. The silicon content, usually ranging up to about 3.5%, does more than just help with magnetic properties; it also gives the steel a certain hardness. This hardness is perfectly manageable for our precision stamping dies yet contributes to the overall robustness and longevity of the assembled core. Imagine trying to build a complex jigsaw puzzle. CRNGO’s excellent workability is like having perfectly cut, durable puzzle pieces, allowing us at Sino to create highly precise and complex CRNGO lamination designs efficiently.

Sino offers a variety of surface coatings, each designed to improve certain parts of its performance:

These losses mainly show up as hysteresis loss and eddy current loss which means wasted energy, more heat, and lower efficiency.

CRNGO has a couple of clever built-in ways to keep these losses in check. Each CRNGO lamination in a stack is electrically insulated from its neighbors (often by a thin oxide layer or a dedicated coating). This insulation breaks up the paths for those eddy currents, dramatically reducing them. Generally, the thinner the lamination, the lower the eddy current losses. Of course, thinner also means more layers for the same stack height, which can add to cost, so it’s a balancing act. Adding silicon to the iron significantly increases the electrical resistivity of the steel. Higher resistivity means less current flow for a given voltage, so eddy currents are further suppressed.

Different applications have different tolerances for these losses. That’s why CRNGO comes in various grades, each offering a specific trade-off between silicon content, permeability (how easily it magnetizes), and core loss.

Here’s a general idea of how some common CRNGO grades stack up. Remember, exact figures can vary a bit between steel mills and specific production batches:

Grade (AISI Designation Example) | Typical Max Core Loss (W/kg at 1.5T, 60Hz) | Nominal Thickness (mm) | Silicon Content (Approx. %) | Common Scenarios & Devices |

M19 | 1.90 – 2.50 | 0.35, 0.47, 0.64 | 2.5 – 3.5 | High-efficiency motors, medium-sized transformers, generators |

M27 | 2.70 – 3.10 | 0.35, 0.47, 0.64 | 2.0 – 3.0 | Good efficiency motors, generators, general transformers |

M36 | 3.60 – 4.00 | 0.47, 0.64 | 1.5 – 2.5 | General purpose motors, appliance motors, lighting ballasts |

M43 | 4.30 – 4.70 | 0.47, 0.64 | 1.0 – 2.0 | Cost-sensitive motors, relays, solenoids, small actuators |

M47 | 4.70 – 5.50 | 0.47, 0.64 | < 1.5 | Low-cost scenarios where losses are less critical, basic solenoids |

So, if a client comes to us at Sino needing a core for a high-performance servo motor, we might recommend a grade like M19 or M27 in a thinner gauge. But for a simple, cost-driven solenoid application, M43 or M47 might be perfectly adequate and more economical. Our manufacturing processes, including careful deburring after CRNGO stamping and ensuring the integrity of the insulation between laminations, also play a vital role in achieving the low core losses promised by the material grade.

Thanks to this winning combination of properties, you’ll find CRNGO lamination stacks from Sino and other quality manufacturers powering an incredible diversity of devices:

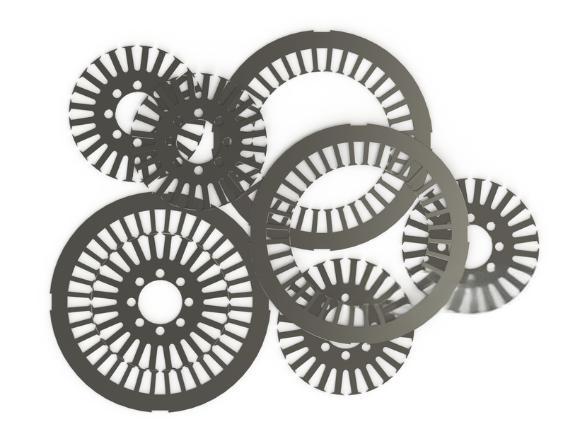

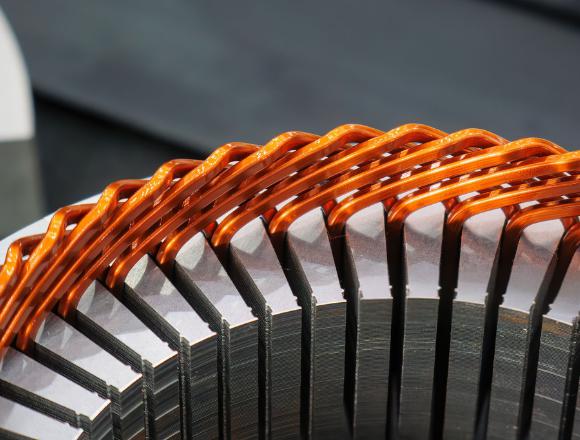

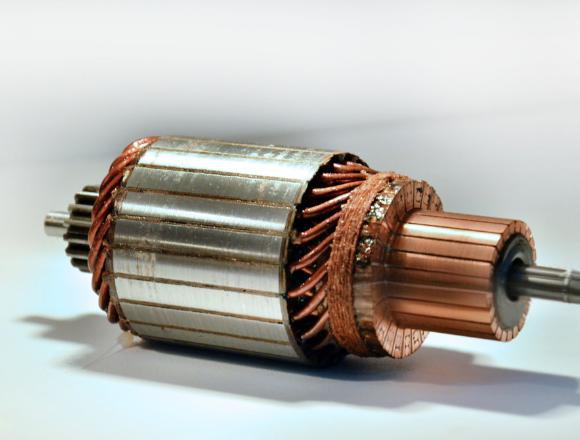

This is CRNGO's bread and butter. From the tiny fractional horsepower motors that make your electric toothbrush vibrate or your coffee grinder whiz, to the hefty industrial AC and DC motors driving conveyors and pumps in factories. The stators (the stationary part) and rotors (the rotating part) in most of these rely heavily on CRNGO. We’ve supplied CRNGO lamination stacks for everything from bespoke robotics motors to mass-produced fan motors.

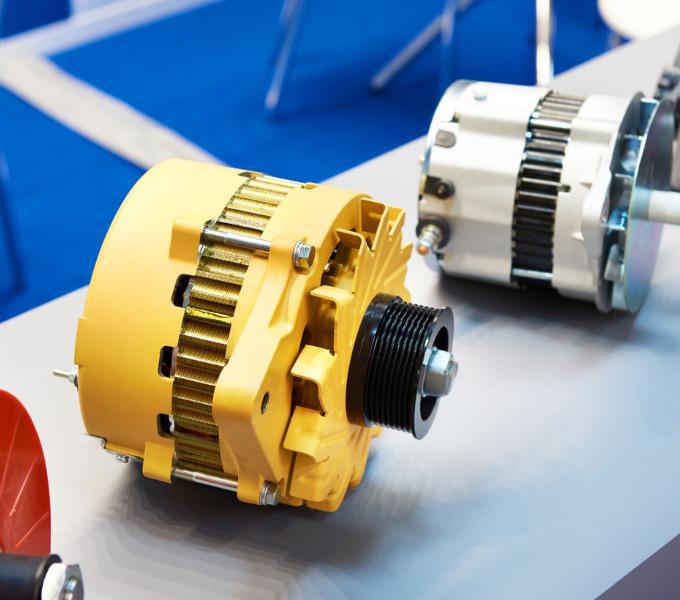

Much like motors but in reverse, many generators, especially smaller alternators or those found in portable power units, utilize CRNGO for their cores due to the complex and rotating magnetic fields involved.

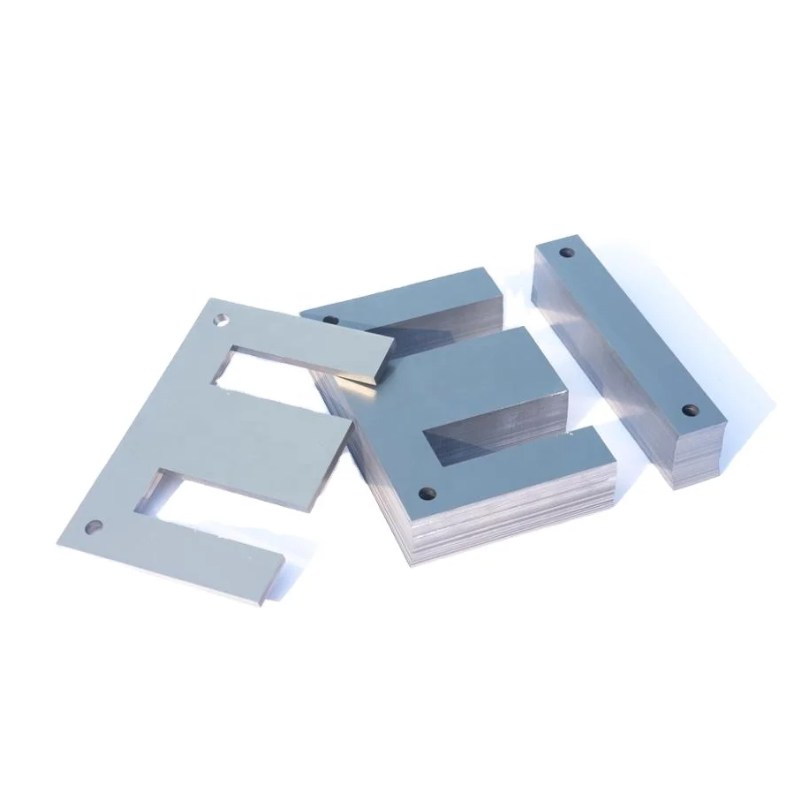

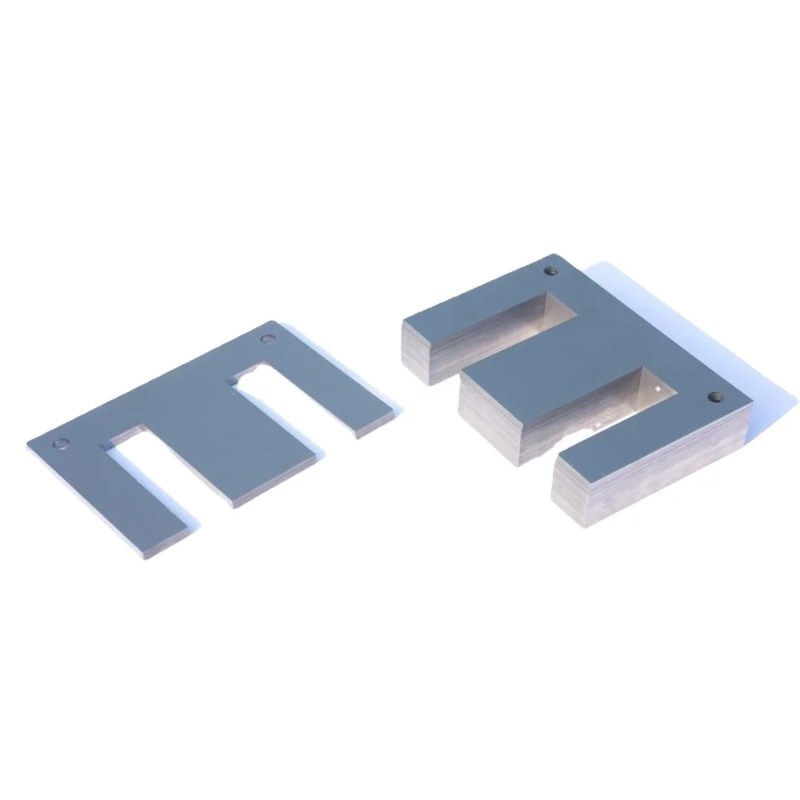

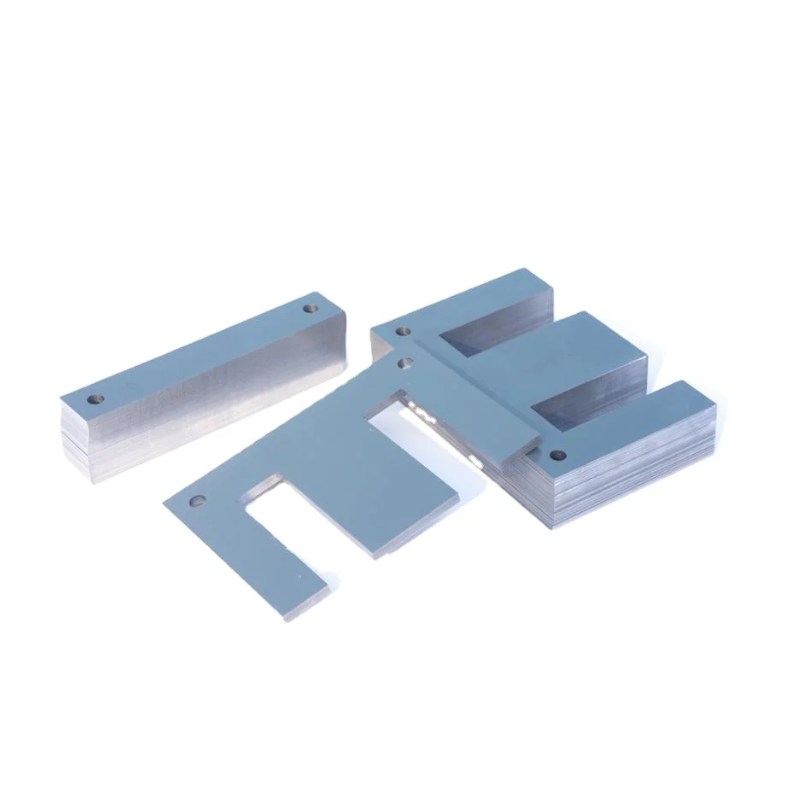

While the colossal transformers you see at substations use CRGO, a vast number of smaller distribution transformers, voltage regulators, instrument transformers (like current transformers or potential transformers), and various types of inductors and chokes find CRNGO to be perfectly suitable. Its cost-effectiveness is a major driver here.

If you’ve ever been near an older fluorescent light fixture, that characteristic hum often came from the magnetic ballast inside, which used a CRNGO lamination core. While LEDs are changing this landscape, countless CRNGO-based ballasts are still in operation.

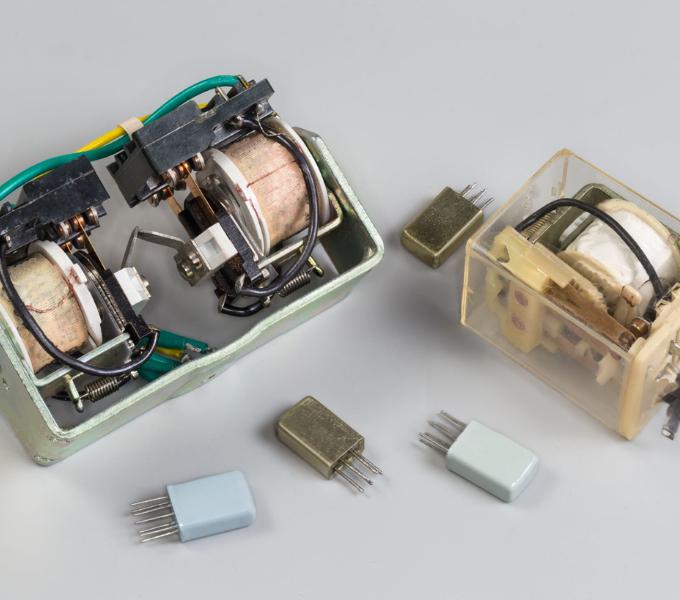

Those clicky little boxes that switch circuits (relays) or the electromagnetic plungers that open and close valves (solenoids and actuators) almost universally use magnetic cores. CRNGO is a very common choice here due to its good magnetic response at a reasonable price point. We produce thousands of CRNGO lamination parts for these types of components weekly.

How does Sino turn this versatile material into the high-performance heart of your product? It comes down to precision, expertise, and a partnership approach.

We don't just buy any CRNGO. We source high-quality electrical steel from reputable mills, ensuring the raw material meets stringent specifications for magnetic properties, thickness consistency, and surface quality. We understand the nuances between grades and can advise you on the best fit for your scenario.

Our factory floor is equipped with advanced, high-speed stamping presses and precision-engineered dies. This allows us to produce CRNGO lamination components with incredibly tight tolerances, minimal burrs, and consistent shapes, even for highly complex geometries. Minimal burr is critical because excessive burrs can pierce the insulation between laminations, leading to increased eddy current losses.

Simply stamping out laminations isn't enough. They need to be assembled into a core or stack. We employ various stacking techniques – including interlocking (where laminations have features that snap them together), welding, riveting, or cleating – depending on the application's mechanical and magnetic requirements. Our automated stacking processes ensure uniform stack height, proper alignment, and optimal compaction, all of which contribute to better magnetic performance.

From incoming material inspection to in-process checks during CRNGO stamping and final stack testing, quality control is woven into our DNA. We measure critical parameters like stack height, lamination thickness, burr height, and sometimes even perform magnetic tests on sample cores.

We see ourselves as your partners. If you have a new design, we can provide design-for-manufacturability (DFM) feedback. If you're looking to optimize an existing product, we can help you explore different CRNGO grades or lamination geometries. We recently collaborated with an automotive supplier to refine their CRNGO lamination design for a new auxiliary motor, resulting in a 5% improvement in efficiency and a slight cost reduction simply by optimizing the slot geometry and material grade.

Our promise of quality is supported by thorough testing procedures:

We use automatic camera systems for very careful visual checks, looking for burrs (with a limit of <20 µm), separation, and other surface problems. Coordinate Measuring Machines (CMMs) and laser scanners are used to check that the measurements are correct, ensuring key features meet the required size within $\pm 0.02 \text{ mm}$. This is needed for the parts to fit and stack together perfectly in customer products.

Sino is dedicated to manufacturing in a way that is good for the environment. We take steps to reduce our impact on the environment:

So, while new magnetic materials are always on the horizon, the humble CRNGO lamination continues to be a powerhouse in the electrical world. Its unique blend of versatile magnetic properties, fantastic manufacturability, solid efficiency, and, crucially, its cost-effectiveness, means it’s not fading into obscurity anytime soon. It’s a practical, proven material that delivers day in and day out.

At Sino, we’re proud to be experts in transforming this remarkable steel into the precision CRNGO lamination stacks that drive your innovations. Whether you’re designing the next generation of electric motors, developing efficient transformers, or creating innovative electromechanical devices, we have the technology, the expertise, and the commitment to quality to be your trusted partner.

Got a project in mind? Wondering if CRNGO is the right fit, or how our CRNGO stamping and stacking capabilities can benefit you? Give us a shout. We’re always ready to talk laminations!

Note: To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.

To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.