Let Sino's Lamination Stacks Empower Your Project!

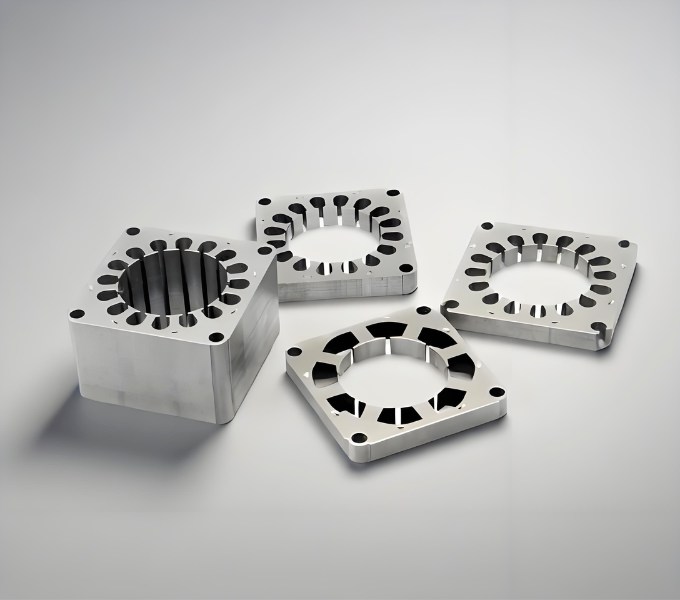

To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.

To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.

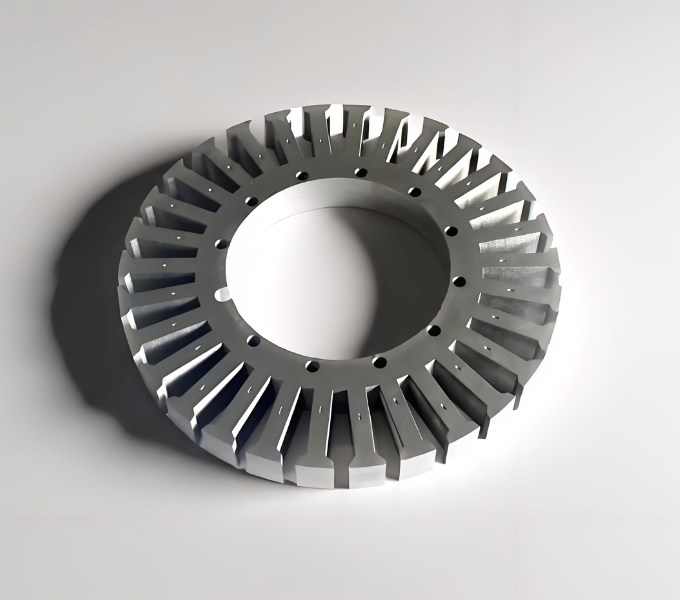

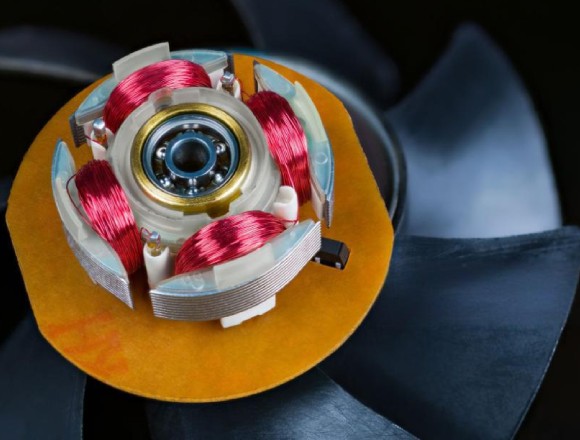

The quiet efficiency and lasting comfort of an electric fan are fundamentally determined by its high-quality stator lamination stack. Sino excels in manufacturing these critical components, dedicated to enhancing motor performance and helping you create superior fan products. Choosing Sino’s electric fan stator laminations means selecting core technology for more energy-efficient, quieter, and reliable fans.

For many electric fan scenarios, non-oriented electrical steels offer a fantastic balance. They provide good magnetic properties in all directions and are more forgiving in the stamping process.

Sino works closely with our clients to select the optimal grade of electrical steel based on their specific fan design, target efficiency, and cost parameters. We understand that a high-end, whisper-quiet ceiling fan might warrant a different grade of steel than a budget-friendly desk fan. Our expertise ensures you’re not over-engineering (and overpaying) or, conversely, cutting corners that could lead to problems down the line.

Another crucial knob we tune at Sino is the thickness of each individual lamination. Thinner is generally better for slaying eddy currents. But, as with most things in engineering, there’s a trade-off. At Sino, we don’t just pick a thickness out of a hat. We leverage our deep understanding of electromagnetic principles and manufacturing realities. We might recommend 0.50mm laminations for a standard fan but explore 0.35mm options for a premium, ultra-high-efficiency design where every fraction of a watt counts. It’s about finding that sweet spot where performance gains justify any incremental cost, ensuring the stator of electric fan is perfectly tuned.

Consider this simplified comparison:

Feature | The Upside | The Flip Side | Sino’s Approach for Electric Fans |

Thinner Laminations | Dramatically lower eddy current losses, leading to higher motor efficiency. | Higher manufacturing cost per stack, more parts to assemble. | Typically 0.35mm – 0.50mm for good balance. |

Thicker Laminations | Lower manufacturing cost, simpler to produce. | Higher eddy current losses, potentially lower efficiency, more heat. | Usually 0.65mm, reserved for very low-cost. |

Optimal Insulation | Essential for separating laminations and minimizing eddy currents. | If too thick on thin laminations, can reduce active magnetic material. | We use advanced C-4/C-5 coatings, optimized for thickness. |

Material Grade | Higher silicon content = lower core losses. | Can be more brittle and expensive. | Tailored selection based on fan requirements. |

All the fancy materials and optimal thicknesses in the world won’t mean much if the laminations aren’t made and put together with absolute precision.

1

We use state-of-the-art presses and meticulously maintained dies to punch out the laminations into their complex shapes – complete with the teeth and slots that will house the copper windings. Any burrs, rough edges, or deformities from the stamping process can be disastrous. They can slice through the vital inter-laminating insulation, creating short circuits between adjacent sheets. Our quality control at this stage is rigorous, ensuring clean cuts and perfect profiles every time.

2

As mentioned, that thin layer of varnish or oxide coating between laminations is your champion against eddy currents. We ensure this coating is applied evenly and cured properly to provide robust electrical insulation without being excessively thick, which could reduce the amount of active magnetic material in the stator.

3

Once stamped and coated, the laminations need to be stacked and securely fastened together to form the stator core. Common methods include riveting, welding specific points on the outer diameter, or using interlocking features stamped into the laminations themselves (“interlocking”). Sino employs techniques that ensure a tight, dimensionally stable stack while minimizing any short-circuiting paths that could compromise the insulation. A poorly assembled stack can lead to annoying vibrations, audible hum, and increased losses.

When you partner with Sino for your electric fan stator laminations, you’re not just buying a part; you’re investing in:

Our precision-engineered laminations minimize energy losses, meaning your fans do their job using less electricity. This is a win for the end-user’s utility bill and for the environment.

Cooler running motors last longer. By effectively managing eddy currents and associated heat, our laminations contribute to a longer operational life for your fans, reducing warranty claims and enhancing brand reputation.

A well-built stator core, made from high-quality, precisely stacked laminations, contributes to smoother, quieter motor operation. No one likes a fan that rumbles or whines.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

We see ourselves as more than just suppliers; we’re partners. Our team is ready to work with you to understand your specific needs for the stator of electric fan in your unique designs, offering tailored solutions.

Interested in learning how Sino’s electric fan stator laminations can elevate your products? Get in touch with our engineering team today, and let’s build cooler, better fans together!

Note: To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.

To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.