Let Sino's Lamination Stacks Empower Your Project!

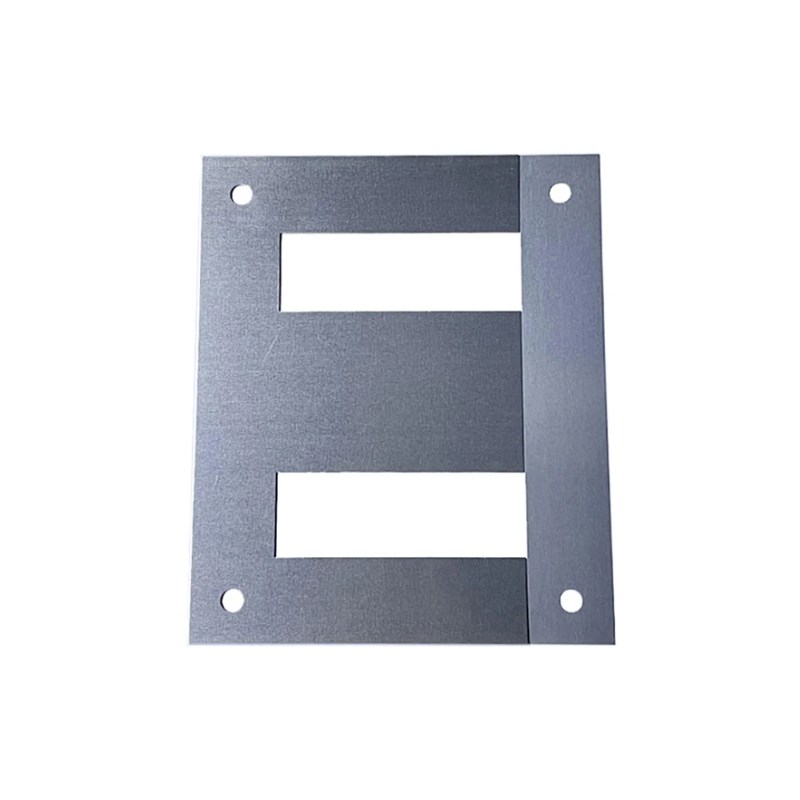

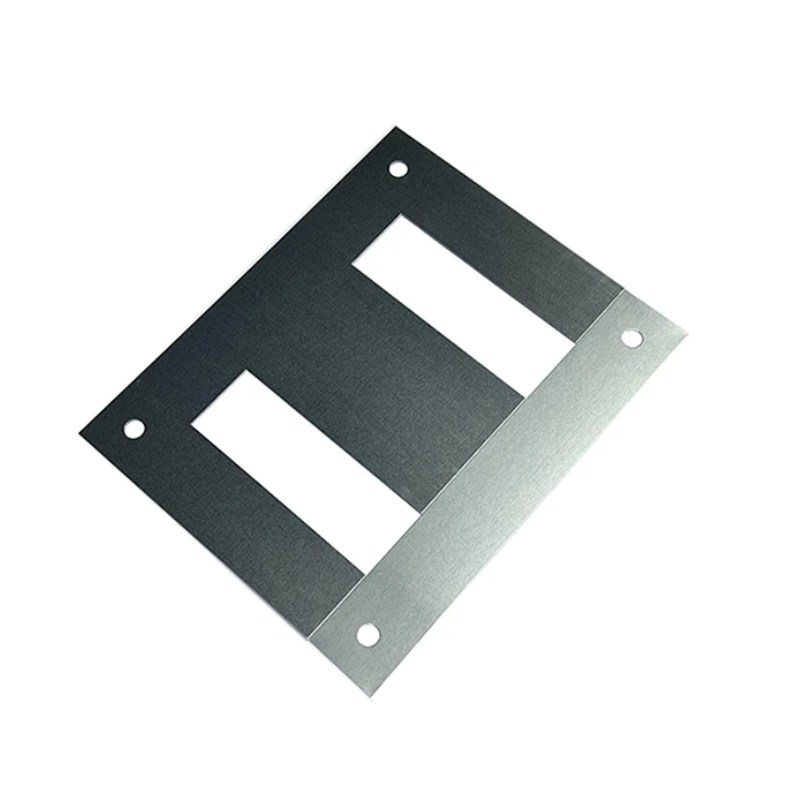

To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.

To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.

As Sino, a world-leading maker of electrical steel laminations, we are committed to making top-quality products that power the world’s motors and transformers. Our focus on new ideas, careful engineering, and deep knowledge of materials ensures our customers, who include everyone from electric vehicle makers to people building power grids, get products that meet the toughest needs for efficiency, reliability, and sustainability.

Electrical steel laminations are the foundational components at the core of countless electromagnetic devices. Their job is to channel and amplify magnetic fields, and it’s their specific magnetic properties that enable the efficient conversion and transmission of electrical energy.

At Sino, we have a deep appreciation for the critical role these components play across a wide spectrum of uses:

Introducing a small percentage of silicon (typically between 1% and 4% by weight) into the iron alloy significantly boosts the steel’s electrical resistivity. Not all silicon steel is created equal. There are two main families, and the one you need depends entirely on the specific job it has to do:

Through a highly complex series of rolling and heat-treatment processes, the microscopic crystal grains within the steel are encouraged to line up in a specific, preferred direction – usually the direction in which the steel was originally rolled. In a transformer, the magnetic flux generally follows a well-defined, predictable path, and designers can cleverly align the GOES laminations to take full advantage of this directional superstar.

This type of electrical steel has its crystal grains arranged more randomly. The significant advantage here is that its magnetic properties are pretty much the same in all directions within the plane of the lamination. This isotropy makes NOES the go-to material for the rotating parts of electric motors and generators, or in any scenario where the magnetic flux is swirling around and constantly changing direction.

Knowing what material to use is one critical part of the puzzle; transforming that raw material into high-performance electrical steel laminations is a whole other ball game. It’s where we at Sino truly excel.

Here’s a little peek behind the curtain at how these crucial components come to life:

1

Large coils of specialized electrical steel delivered from top-tier mills are first slit into narrower strips, and then the individual lamination shapes are meticulously cut out. This is usually accomplished through high-speed stamping presses using incredibly precise and durable dies, or sometimes with advanced laser cutting technology for more complex shapes, rapid prototyping, or smaller production batches.

2

Stamping, if not executed perfectly, can create tiny, sharp protrusions called burrs on the cut edges of the laminations. Our stamping processes are specifically designed and continually refined to minimize burr formation. For particularly sensitive applications or highly intricate lamination designs, we also leverage the power of laser cutting, which inherently produces a clean, burr-free edge. We also pay extremely close attention to minimizing mechanical stress. Bending or deforming the steel excessively during the cutting process can actually degrade its carefully engineered magnetic properties. Gentle handling and optimized processes are absolutely key.

3

Annealing relieves any internal stresses that have built up during the stamping or slitting operations. These stresses make the material harder to magnetize and thereby increase energy losses. Annealing also helps the crystal grains in the steel to recrystallize and, particularly for Grain-Oriented Electrical Steel, to grow and align themselves properly. Our annealing cycles are precisely calibrated based on the specific grade of electrical steel being processed, the lamination thickness, and the desired final magnetic properties. Too hot, too cold, held for too long, or not long enough – any significant deviation from the optimal parameters can compromise the final magnetic performance. We monitor and control these critical processes with an unwavering, data-driven focus.

4

Each individual lamination must be electrically insulated from its neighbors. The Specialized Coatings are often designated by industry standards like ASTM C3, C5, or C6 (or their IEC international equivalents). We work with a comprehensive range of coating types to suit different operational scenarios and downstream manufacturing processes. Whether it’s an organic varnish for general applications or an advanced inorganic coating that can handle higher operational temperatures and provide stress relief during annealing, we ensure consistent application for maximum inter-laminar resistance. This consistent, high-integrity insulation is absolutely fundamental to the superior performance of the electrical laminations we deliver.

5

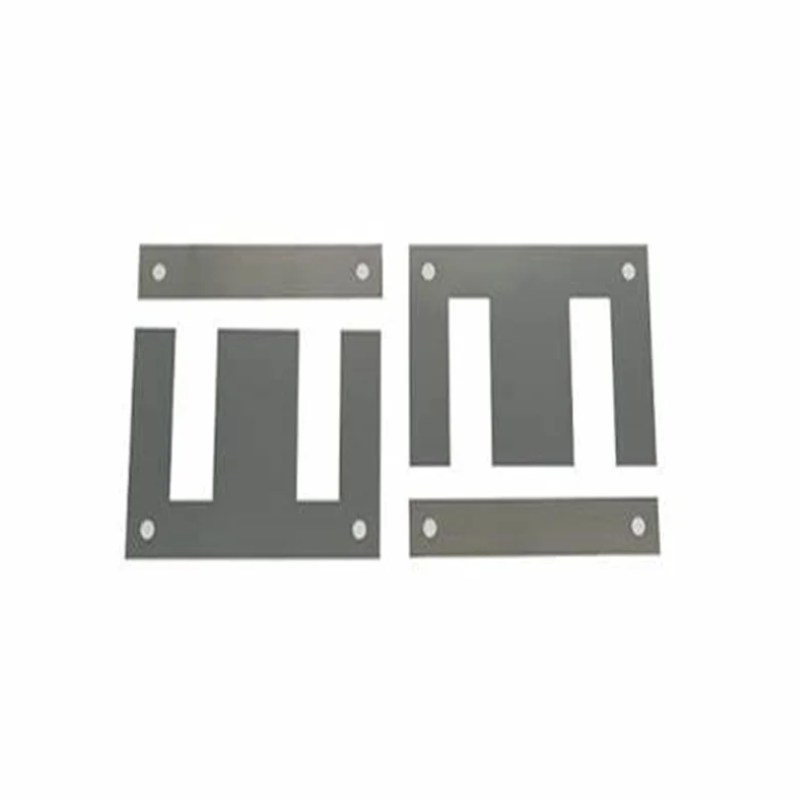

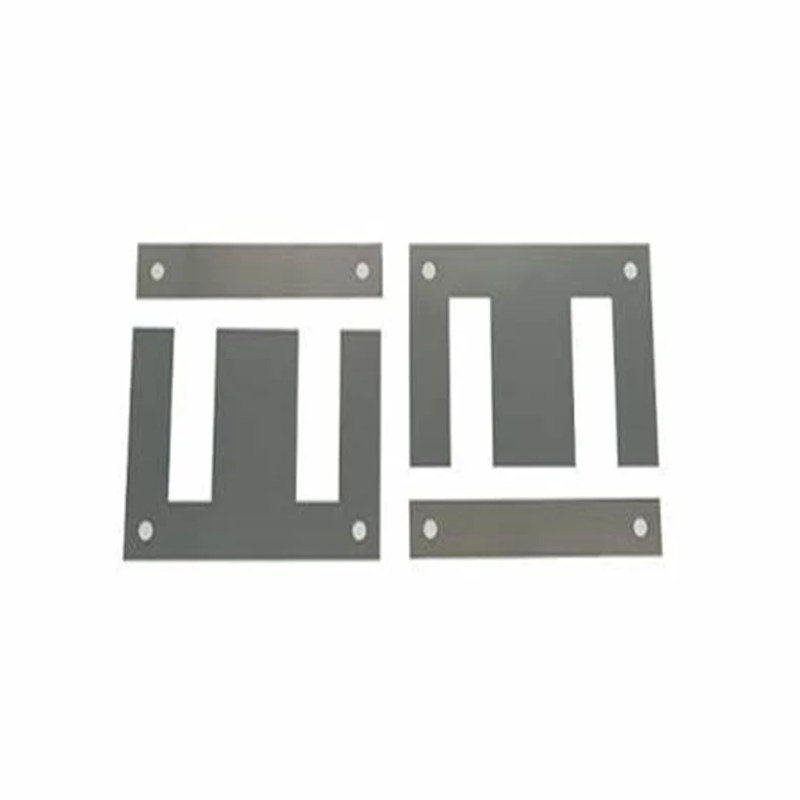

Misaligned laminations can create unintended air gaps within the core. Our assembly processes, whether they involve careful manual assembly for highly custom or intricate jobs or leverage sophisticated automation for high-volume production, are all about ensuring that the final electrical steel lamination stack performs exactly as designed. We can provide fully assembled cores, interlocked stacks ready for winding, or even bonded stacks where the laminations are adhered together using specialized epoxies. Bonded stacks can offer enhanced mechanical rigidity and sometimes even improved acoustic performance.

We firmly believe it’s not just about stamping out pieces of metal; it’s about fostering genuine partnerships, maintaining an unwavering commitment to precision, and harboring a deep-seated passion for enabling superior performance in your products.

Our highly skilled team possesses years of invaluable hands-on experience with the full gamut of electrical steels – from the more standard non-oriented grades suitable for general-purpose motors all the way to the most advanced, high-permeability grain-oriented steels essential for cutting-edge, high-efficiency transformers. This depth of knowledge means we can effectively help you navigate the sometimes-confusing landscape of material specifications and select the absolute best-fit material for your specific performance targets and budgetary considerations. We truly live and breathe this stuff!

At Sino, we thrive on custom projects and unique challenges. Do you need a uniquely shaped lamination for a specialized medical actuator? Perhaps a specific stacking configuration to improve assembly efficiency on your production line? Or maybe an unusual material thickness for a high-frequency power electronics application? Bring it on! We have the operational flexibility and the robust engineering chops to transform your precise requirements into tangible, high-performing reality. We see ourselves as more than just electrical lamination manufacturers; we strive to be genuine solution providers.

Our quality assurance processes are intentionally rigorous, encompassing everything from meticulous incoming material inspection to comprehensive final stack verification using advanced measurement tools. We intimately understand that even a seemingly tiny imperfection in a single lamination can have a significant ripple effect, ultimately impacting the efficiency, reliability, and lifespan of your final product. You can confidently count on Sino to deliver electrical laminations that consistently meet or exceed even the tightest industry tolerances.

We genuinely see ourselves as an extension of your design and engineering team. We’re always happy to engage with you early in your design process, offering valuable insights and suggestions that could potentially save you significant time, reduce overall costs, or even unlock previously unattainable levels of performance. Have you encountered a particularly tricky magnetic design challenge? Let's brainstorm potential solutions together. Are you unsure about the complex trade-offs between different electrical steel grades or various insulating coating types? We can patiently walk you through the pros and cons of each option in the context of your specific needs. Our ultimate goal is your unequivocal success.

We don’t just make vague claims about quality; we believe in backing them up with tangible data. While we don’t conduct fundamental steel property testing (that’s the primary domain of the specialized steel mills), we meticulously ensure that our advanced manufacturing processes not only preserve but also optimize the inherent beneficial qualities of the high-grade materials we use. We can provide you with comprehensive data related to achieved stacking factors, precise dimensional accuracy reports, and thorough insulation integrity test results for the electrical steel lamination stacks we produce. You’ll often see crucial industry performance data presented in a format similar to this, and it’s precisely this kind of detailed information that guides our daily operations and quality control:

Feature | Example Grain-Oriented (e.g., M3 Grade eq.) | Example Non-Oriented (e.g., M19 Grade eq.) | Sino’s Focus for Your Specific Needs |

Best Suited For | High-Efficiency Power Transformers | Motors, Generators, Various Actuators | Precisely matching material to your scenario |

Typical Thickness (mm) | 0.23, 0.27, 0.30 | 0.35, 0.47, 0.50 | Optimized for operational frequency & loss targets |

Target Core Loss (W/kg) | Very Low (e.g., <1.0 @ 1.7T, 50Hz) | Low (e.g., <3.0 @ 1.5T, 50Hz) | Directly maximizing your device’s energy efficiency |

Sino’s Manufacturing Aim | Preserve delicate grain structure, minimize stress | Ensure uniform properties, maintain tight tolerances | Unlocking the steel’s full inherent potential |

(Important Note: The core loss values indicated are generally the targets for the raw electrical steel material itself; Sino’s crucial role is to ensure that our sophisticated manufacturing processes do not degrade that potential but instead allow it to be fully realized in the final assembled stack!)

Choosing Sino as your partner means choosing a company deeply committed to delivering not just physical parts, but tangible performance, enhanced reliability, and genuine peace of mind. We’re incredibly proud to be among the leading electrical lamination manufacturers who are passionately dedicated to helping you power the future, more efficiently and more sustainably.

Electrical steel laminations crafted by specialist manufacturers like Sino are humming away, often completely unseen, in an absolutely astonishing array of devices that shape our daily lives, drive our industries, and enable technological progress.

Every single percentage point of efficiency gained in transformers saves enormous amounts of energy and precious natural resources. Sino provides top-grade laminations for transformers of all conceivable sizes, from small electronic transformers found in consumer devices to large, multi-MVA power transformers, ensuring the grid operates as smoothly and efficiently as possible.

In an electric motor, the stator (the stationary part) and often the rotor (the rotating part) are constructed from these precision lamination stacks. They create and shape the magnetic fields that interact to produce the torque and motion that we rely on in countless ways. Sino is increasingly involved in supplying high-grade, thin-gauge electrical laminations specifically for demanding EV motors and various other e-mobility applications.

Whether it’s a colossal generator in a major power plant (be it hydro, thermal, nuclear, or wind-powered) or a smaller, more portable backup generator for a hospital or business, they all rely on magnetic cores made from high-quality electrical laminations to efficiently channel magnetic flux and induce electrical current. The primary demands in this arena are for exceptional reliability over long operational lifetimes and maximum power conversion efficiency with the absolute minimum of energy loss.

Advanced MRI (Magnetic Resonance Imaging) machines utilize powerful electromagnets, and numerous other diagnostic and therapeutic devices incorporate precision motors, actuators, and sensors that all require high-performance lamination stacks for their accurate operation.

Your trusty washing machine, your indispensable refrigerator, your climate-controlling air conditioner, your powerful vacuum cleaner – a great many of these everyday conveniences contain electric motors built with these vital lamination components.

Welding equipment, uninterruptible power supplies (UPS), variable frequency drives (VFDs), and switched-mode power supplies (SMPS) all make use of transformers or inductors with laminated cores.

Are you currently designing a new motor, transformer, generator, inductor, or any other device that critically relies on an efficient and reliable magnetic core? Are you perhaps looking to improve the performance and efficiency of an existing product, or are you simply seeking a dependable, knowledgeable, and quality-focused partner for your high-quality electrical steel lamination requirements?

Get in touch with the experienced and friendly Sino team today. Let’s schedule a conversation to discuss your project in detail, explore your specific technical requirements and commercial objectives, and allow us to demonstrate how our extensive expertise in electrical laminations can help bring your innovative designs to life – more efficiently, more reliably, and more effectively than ever before.

Note: To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.

To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.