Let Sino's Lamination Stacks Empower Your Project!

To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.

To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.

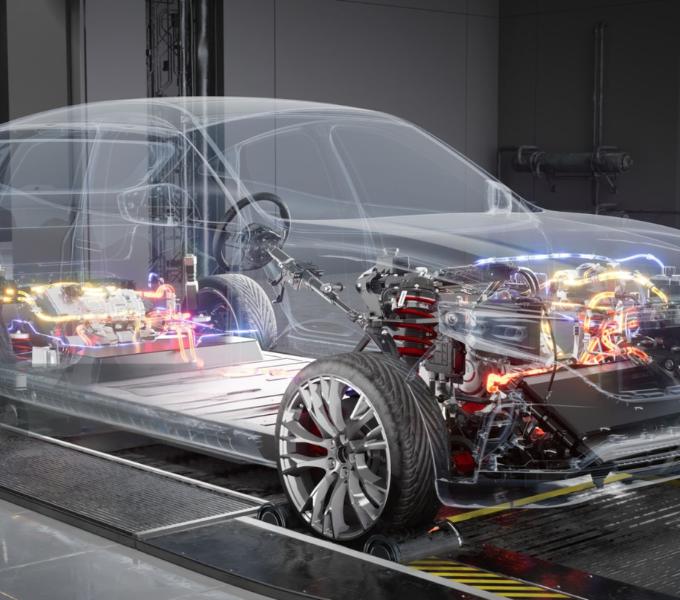

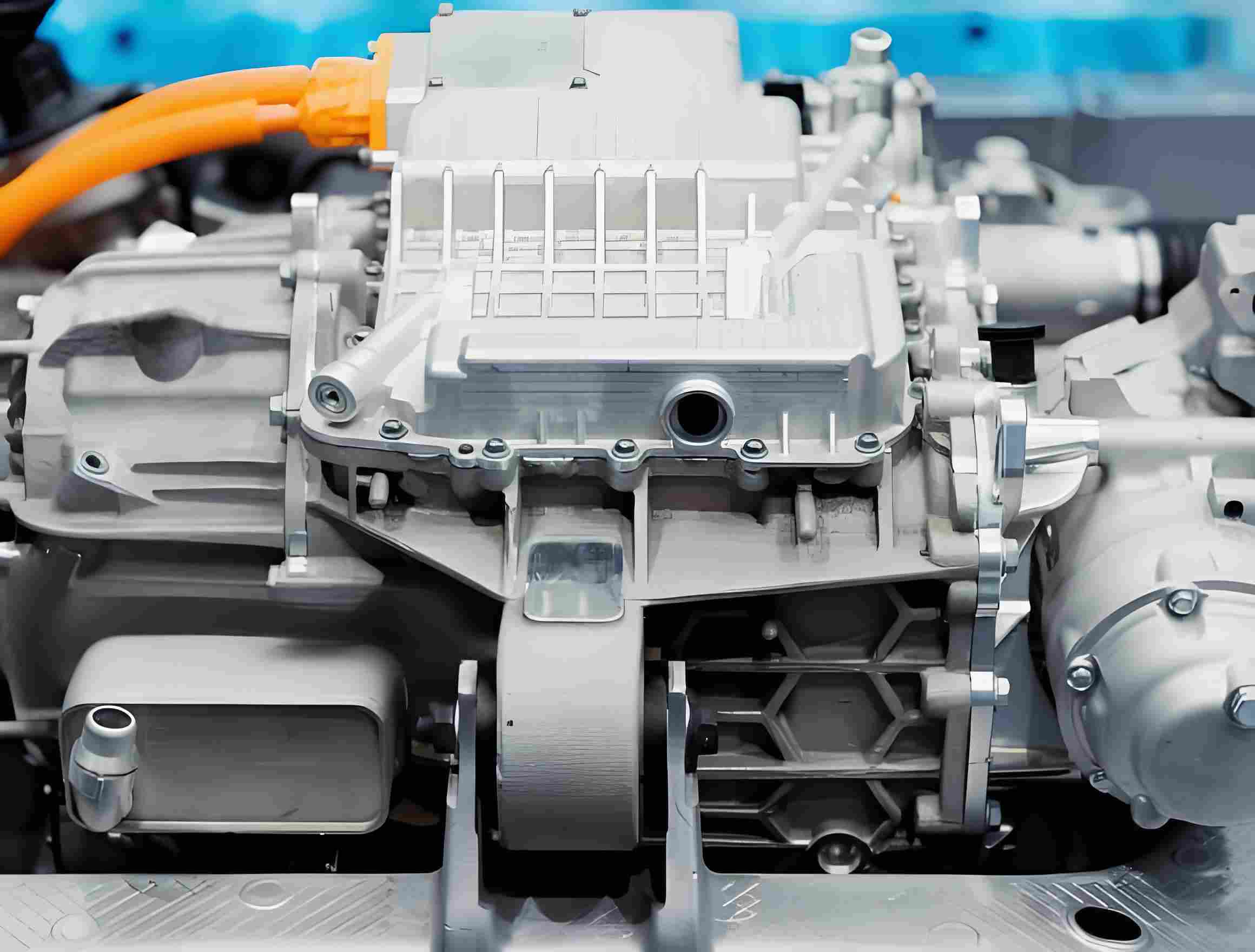

As Sino, a leading motor core manufacturer based in China, we comprehend the unrelenting quest of effectiveness, power density, and dependability in the electrical vehicle (EV) sector. Our goal is to equip EV Electric motor Manufacturers, OEMs, Tier 1 Automotive Suppliers, and R&D groups with innovative lamination options that define the future generation of electrical propulsion.

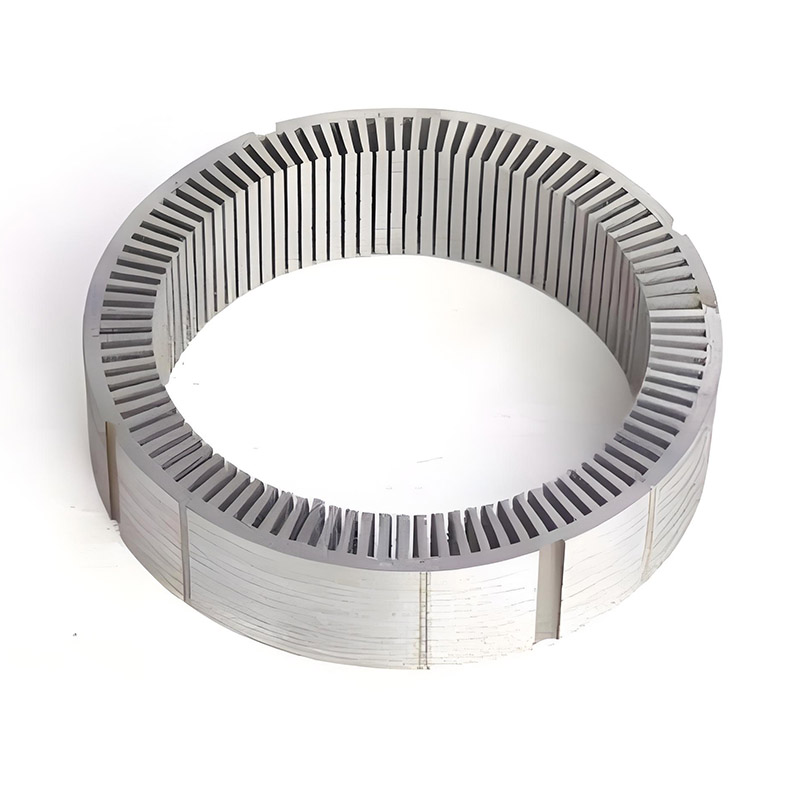

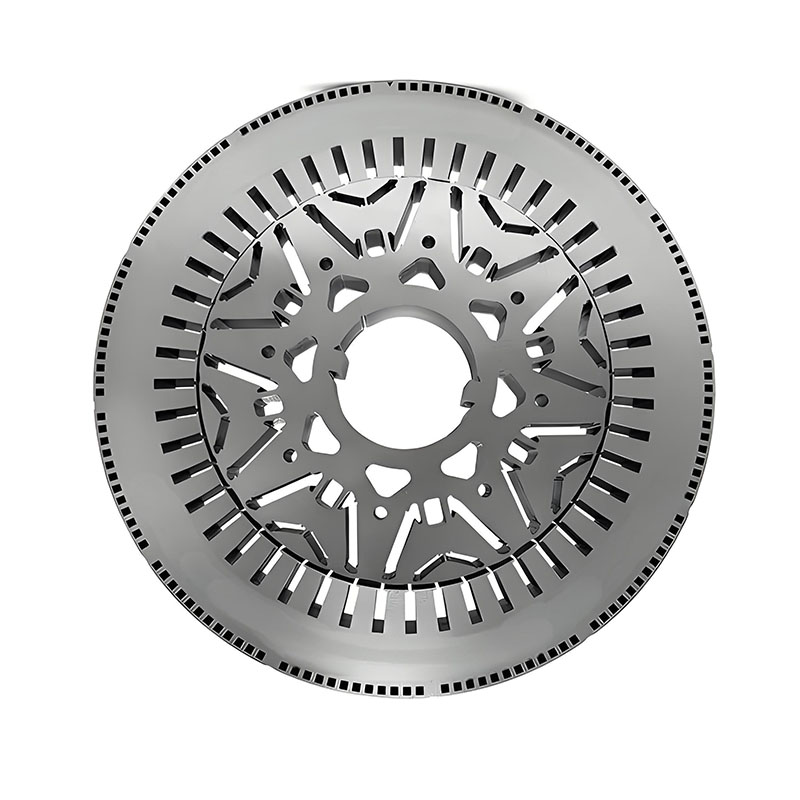

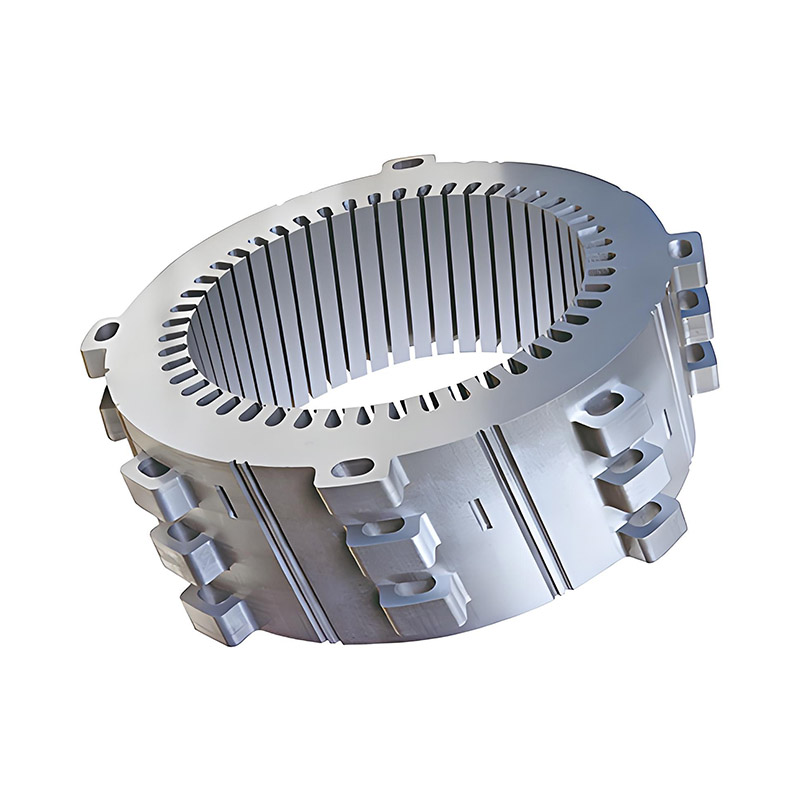

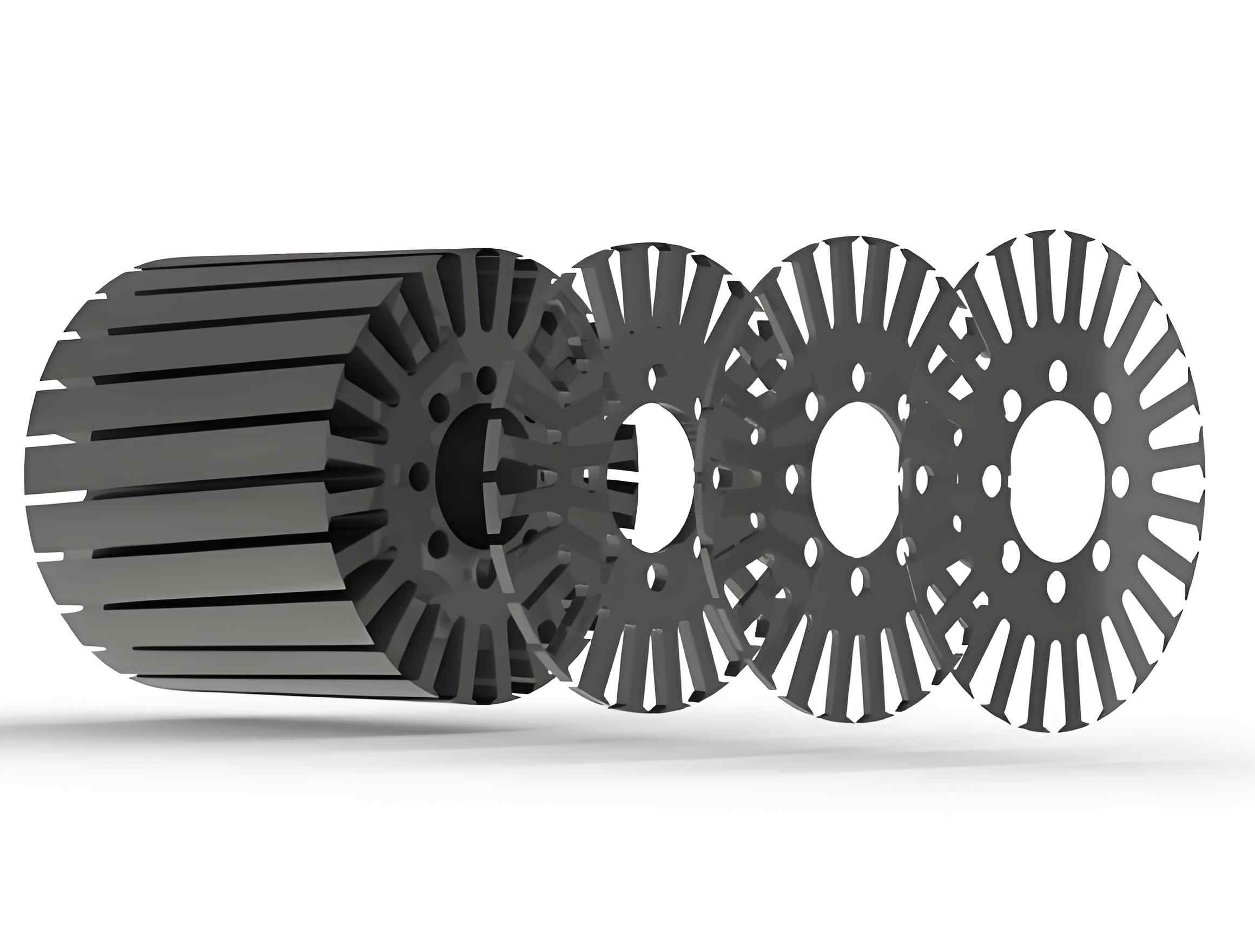

Electric automobile electric motors are the heart of lasting mobility, and at their core lie exactly crafted laminations. These thin sheets of electrical steel, carefully piled to form the stator and rotor cores, are essential to the electric motor’s efficiency. Their main feature is twofold: successfully directing magnetic flux to produce torque and reducing eddy existing losses that develop from rotating magnetic fields. By segmenting the core into protected layers, laminations limit the path of these generated currents, substantially lowering I ² R losses and the associated warm generation.

The choice of electrical steel grade is absolutely critical for squeezing every last bit of performance and range out of an EV. You see, EV motors, especially the high-performance ev traction motor core units, spin incredibly fast, sometimes well over 10,000 or even 20,000 RPM. This means the magnetic fields are flipping back and forth at very high frequencies. Eddy current losses go up with the square of that frequency and the square of the lamination thickness. This is why thinner is often better.

Here’s a simplified look at how different material properties can impact performance, drawing from the kind of data you’d find from leading steel producers like ArcelorMittal (with their iCARe® series for e-mobility) or POSCO (with their Hyper NO grades):

Electrical Steel Grade (Illustrative Sino Guide) | Typical Thickness (mm) | Core Loss (W/kg at 1.5T, 400Hz)* | Silicon Content (Approx. %) | Sino’s Take: Ideal Scenario |

Standard Grade (e.g., M350-50A equivalent) | 0.50 | ~35-45 | ~1.0-2.5 | Cost-sensitive applications, lower speed/frequency motors where ultimate efficiency isn’t the prime driver. |

Mid-Grade NO Steel (e.g., M270-35A equivalent) | 0.35 | ~25-30 | ~2.5-3.5 | A good balance for many mainstream EV motors; decent efficiency without breaking the bank. |

High-Grade NO Steel (e.g., NO20-1200 equivalent) | 0.20 | ~10-15 | ~3.0-3.5 | High-performance ev traction motor core units, high-frequency operation; where efficiency and power density are key. |

Advanced Thin Gauge / High-Si Steel | 0.10 – 0.15 | <10 | ~3.5-6.5 | Ultimate efficiency needs, Formula E, aerospace, or niche EVs where every watt counts. Can be trickier to process. |

Core loss values are highly dependent on specific grade, frequency, and magnetic flux density. This table is for illustrative comparison. Source: Conceptualized from Sino’s internal expertise, industry best practices, and typical data ranges seen in publications from IEEE Transactions on Magnetics and steel manufacturer datasheets.

Table 1: Steel Grade Physical & Loss Characteristics

| Electrical Steel Grade (Illustrative Sino Guide) | Typical Thickness (mm) | Core Loss (W/kg at 1.5T, 400Hz)* |

|---|---|---|

| Standard Grade (e.g., M350-50A equivalent) | 0.50 | ~35-45 |

| Mid-Grade NO Steel (e.g., M270-35A equivalent) | 0.35 | ~25-30 |

| High-Grade NO Steel (e.g., NO20-1200 equivalent) | 0.20 | ~10-15 |

| Advanced Thin Gauge / High-Si Steel | 0.10 – 0.15 | <10 |

Table 2: Steel Grade Composition & Application Scenario

| Electrical Steel Grade (Illustrative Sino Guide) | Silicon Content (Approx. %) | Sino’s Take: Ideal Scenario |

|---|---|---|

| Standard Grade (e.g., M350-50A equivalent) | ~1.0-2.5 | Cost-sensitive applications, lower speed/frequency motors where ultimate efficiency isn’t the prime driver. |

| Mid-Grade NO Steel (e.g., M270-35A equivalent) | ~2.5-3.5 | A good balance for many mainstream EV motors; decent efficiency without breaking the bank. |

| High-Grade NO Steel (e.g., NO20-1200 equivalent) | ~3.0-3.5 | High-performance ev traction motor core units, high-frequency operation; where efficiency and power density are key. |

| Advanced Thin Gauge / High-Si Steel | ~3.5-6.5 | Ultimate efficiency needs, Formula E, aerospace, or niche EVs where every watt counts. Can be trickier to process. |

The choice of electric steel is paramount to the performance of EV electric motor cores. Sino uses a thorough range of products, each with unique magnetic, mechanical, and thermal characteristics tailored for specific EV applications. We primarily concentrate on Non-Grain Oriented (NGO) silicon steels, while actively researching and establishing options utilizing amorphous alloys and nanocrystalline materials for future high-performance demands.

NGO silicon steels, such as high-silicon qualities like NO20 and NO35, are the workhorse of the EV market. They are identified by:.

Leading EV makers, including Tesla, BYD, and Toyota, primarily make use of top-quality NGO steels (e.g., M250-35A, M400-50A) for their blades and stator cores, stabilizing expense, efficiency, and manufacturability. Sino concentrates on giving ultra-thin, high-silicon NGO steels (to 0.15 mm) that offer lower hysteresis and eddy present losses, especially at the high switching regularities normal in contemporary inverter-driven EV electric motors.

Amorphous alloys, such as Metglas 2605SA1, represent a significant leap in core loss reduction, specifically at high frequencies. Their key residential properties include:.

While expense and brittleness stay obstacles for widespread fostering in mainstream EVs, amorphous alloys are being piloted in choose high-speed or high-efficiency applications. Sino is proactively participated in R&D to get rid of these producing challenges and check out hybrid core designs that integrate NGO steel and amorphous layers to stabilize cost and performance.

Nanocrystalline alloys, such as Hitachi’s Finemet and VAC’s Vitroperm, stand for the peak of low-loss magnetic products, especially at very high frequencies.

Currently, nanocrystalline products are limited to premium or niche EV applications, such as high-frequency transformers in SiC/GaN-based inverters (e.g., Tesla Design S Plaid, Lucid Air Fantasize Edition). Sino is very closely keeping track of developments in synthesis and cost decrease approaches, including additive manufacturing and powder metallurgy, which could potentially allow their broader adoption in mainstream EV grip electric motors by 2028– 2030, especially as SiC/GaN inverters push switching frequencies greater.

Expert partner like Sino for your EV motor core laminations isn’t just a procurement decision; it’s a strategic one.

We don’t just stamp metal. We understand the physics, the materials science, and the intricate manufacturing nuances that make or break an ev traction motor core.

We see ourselves as an extension of your R&D and production teams. We’re here to consult, advise, and co-engineer solutions that meet your specific performance, cost, and volume targets.

From advanced electrical steels to precision manufacturing processes and robust quality control, we invest in the tools and techniques that deliver superior EV motor core laminations.

Whether you need a handful of prototypes for a new motor concept or high-volume production for an established EV platform, Sino has the scalability and flexibility to deliver.

Our commitment to quality is unwavering, because we know that the reliability and efficiency of your EV motor depend on the perfection of every single lamination.

1

This is our main technique for automation of laminations. We make use of advanced progressive dies and high-speed presses to accomplish tight tolerances and high throughput. Our concentrate on die design and upkeep minimizes burr formation and ensures optimum material monotony, straight influencing the piling variable.

2

For prototyping, low-volume manufacturing, or complex geometries that are hard to stamp, we utilize innovative laser reducing innovation. This offers high precision and versatility, enabling fast model of designs.

3

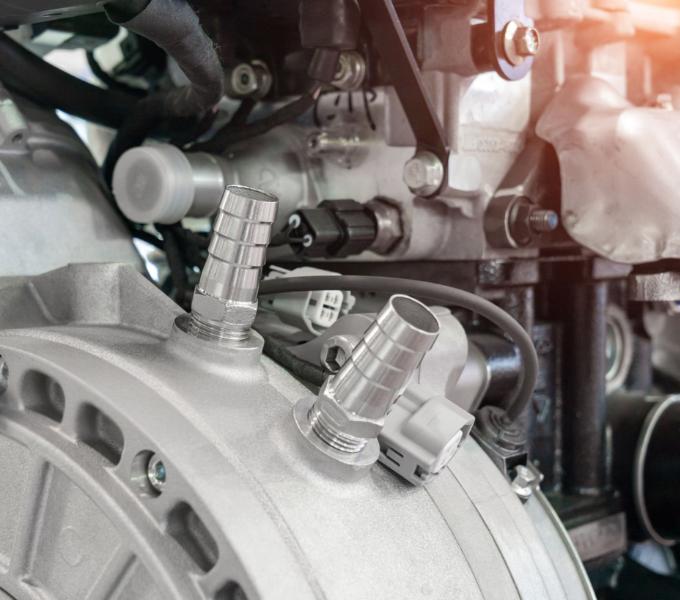

The inter-laminar insulation is crucial. We handle various coating types, from organic to inorganic, ensuring their application and curing (if needed) are flawless. Our handling protocols are designed to prevent any scratches or damage that could compromise this vital barrier.

4

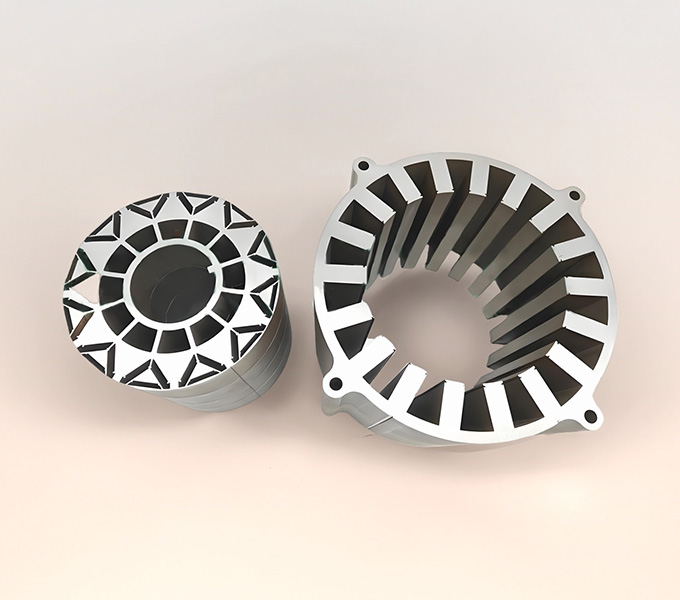

How the laminations are stacked and joined to form the final EV motor core laminations (stator or rotor core) is also key.

Enhancing lamination geometry, slotting, and stacking factors is crucial for achieving target efficiency metrics such as efficiency, power thickness, and thermal monitoring throughout various motor geographies (e.g., radial flux, axial change, irreversible magnet synchronous electric motors, hesitation motors). At Sino, we utilize progressed style concepts and sophisticated simulation devices to deliver remarkable lamination services.

The stacking aspect, specified as the proportion of the web iron material density to the complete stacked core density, is an essential parameter for exact calculation of magnetic change thickness and core losses. Typical worths for electric steel laminations in EV motor cores range from 0.92 to 0.97.

The approach of setting up lamination heaps dramatically influences the final motor core’s efficiency, dependability, and NVH (Noise, Resonance, Violence) features. Sino offers and advises on different advanced setting up strategies:

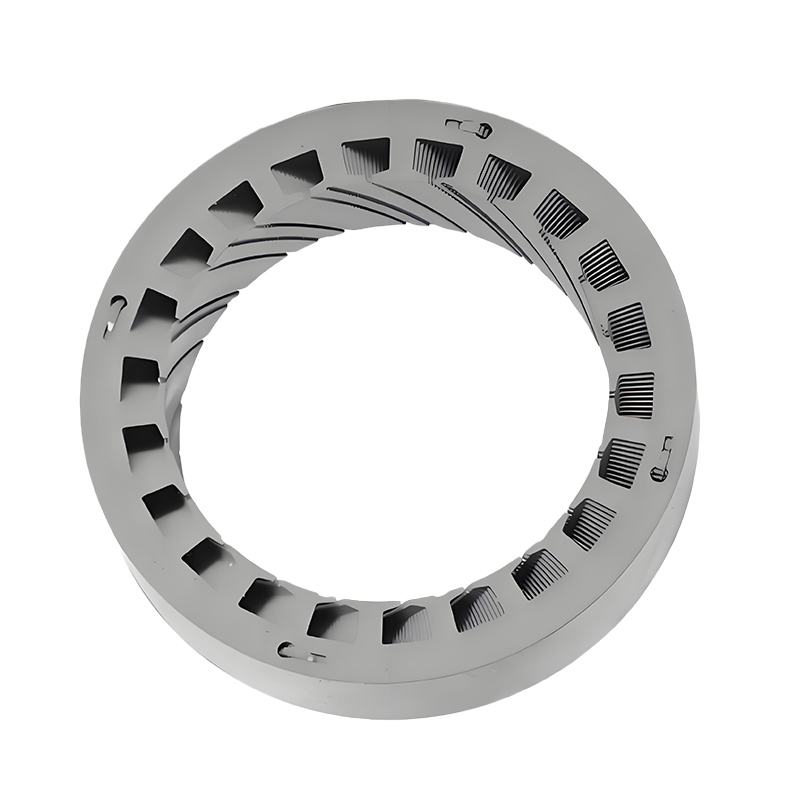

Interlacing entails precision marking of laminations with attributes like tabs, ports, or dovetail shapes that mechanically engage throughout stacking. Laminations are stamped with particular attributes (e.g., sync joints, snap-fit tabs, tongue-and-groove systems) and then mechanically involved using automated presses.

Can provide a very robust stack, but the heat can damage insulation near the weld and potentially create localized short circuits if not controlled meticulously. At Sino, our automated welding processes are finely tuned to minimize the heat-affected zone.

Glue bonding includes applying a thin layer of specialized glue in between laminations, complied with by stacking and curing. A thin layer of epoxy or acrylic-based adhesive (generally 10– 30 μm thick) is used, laminations are stacked, and afterwards cured (thermal, UV, or dual-cure).

Our laminations help make electric vehicle traction systems work great. They lead to:

Less wasted energy means the car uses less battery power. This gives the EV a longer range. Our laminations help achieve core loss optimization and iron loss minimization.

This is called torque density improvement. Our laminations help the motor create a strong magnetic field (magnetic flux density) before hitting limits where the magnetism can't get stronger (saturation flux limits). We can check this using lamination BH curve analysis.

Good thermal conductivity and lamination heat dissipation help keep the motor cool. This is important because motors can get hot, and staying cool helps them last longer and work better. We design for good lamination cooling channels.

Special designs and materials can help with lamination noise reduction and lamination vibration damping, reducing magnetostriction effects (a kind of noise steel makes when it gets magnetized). This makes the car ride smoother and quieter.

Our laminations help reduce torque ripple (power bumps) and harmonic distortion (wasted power shapes).

Our EV motor core laminations are used in many places in electric transport:

The main motor that drives the wheels in Battery Electric Vehicles (BEVs) and Hybrid Electric Vehicles (HEVs).

Where the motor is part of the axle.

Motors that act like generators when slowing down to put energy back into the battery.

In electric motorcycles, buses, trucks, and even things like drone propulsion motors or motors for industrial robotics.

The EV market is evolving at lightning speed. The demand is for motors that are even more efficient, more power-dense, lighter, and quieter. This translates directly into challenges and opportunities for EV motor core laminations. We’re seeing trends towards even thinner laminations (sub-0.1mm in some research!), novel amorphous or nanocrystalline materials for ultra-low core losses, and more integrated motor designs.

At Sino, we’re not just watching these trends; we’re actively preparing for them, investing in research and development to ensure we can offer the next generation of EV motor core laminations that will power the vehicles of tomorrow. Your journey towards a more efficient, high-performing ev traction motor core starts with the right laminations, and that journey can start with Sino.

If you’re looking to push the boundaries of EV motor performance, let’s talk. We’re confident that our expertise in EV motor core laminations can help you achieve your goals and drive the future of electric mobility. Let’s build something exceptional together.

Note: To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.

To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.