Let Sino's Lamination Stacks Empower Your Project!

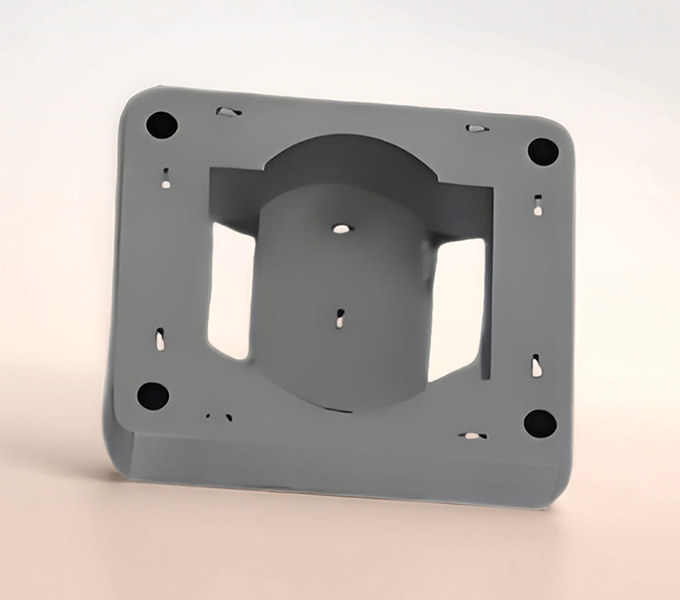

To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.

To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.

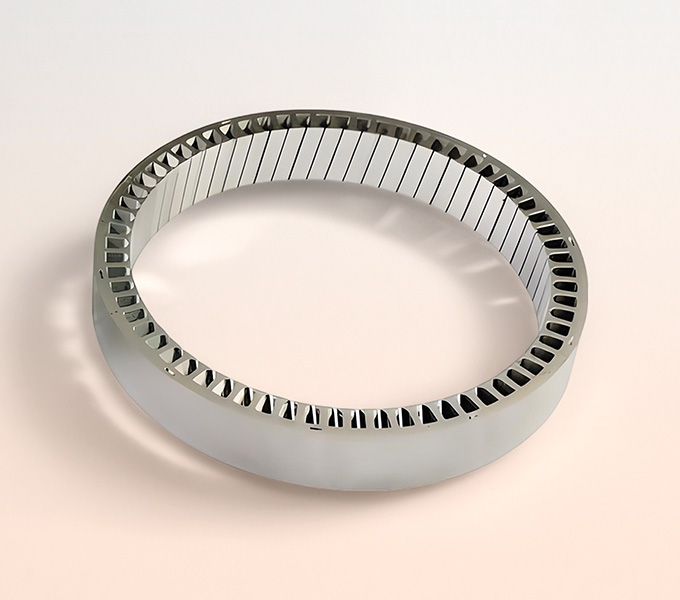

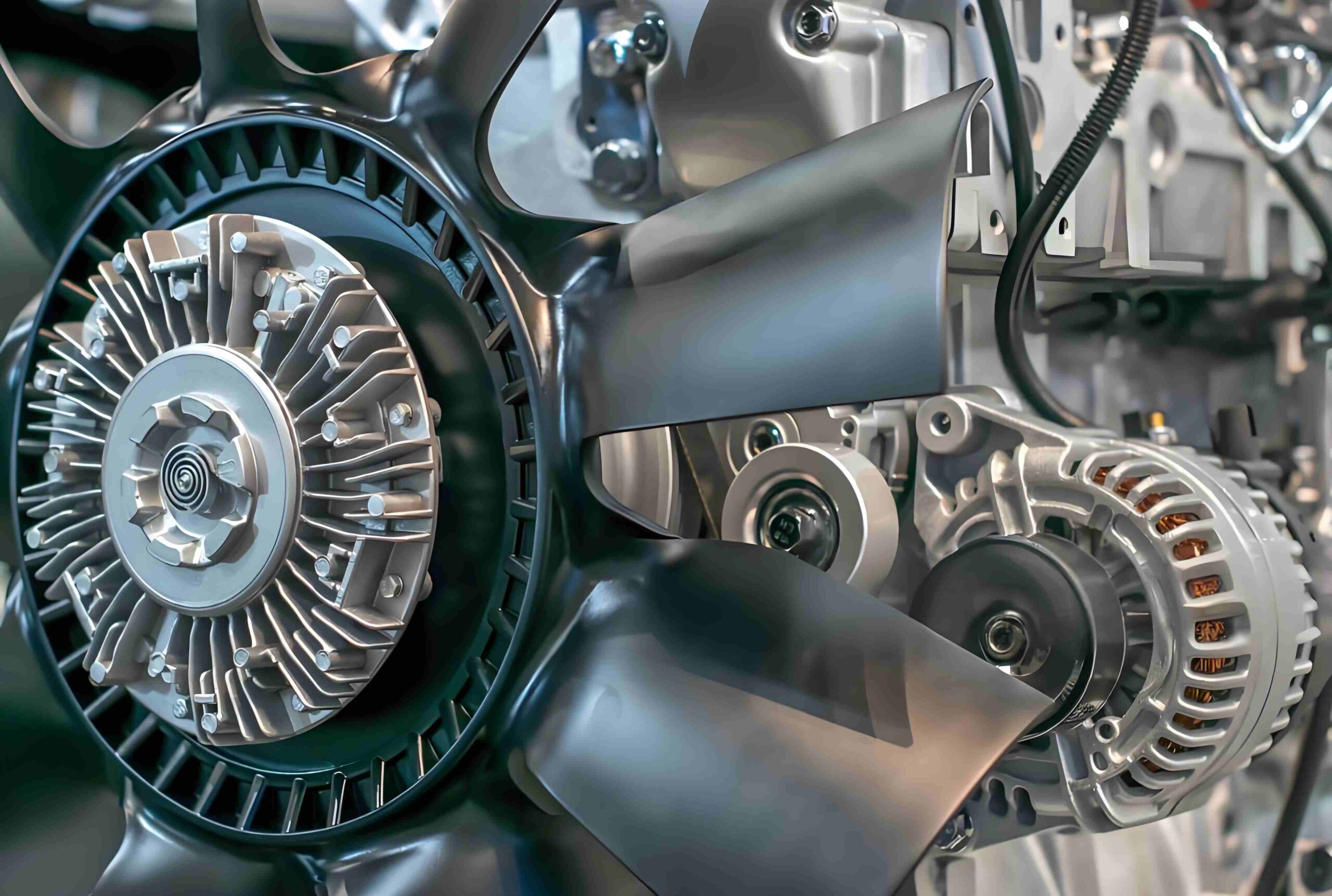

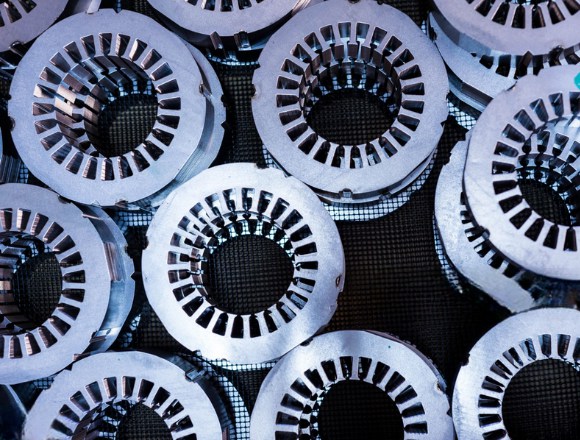

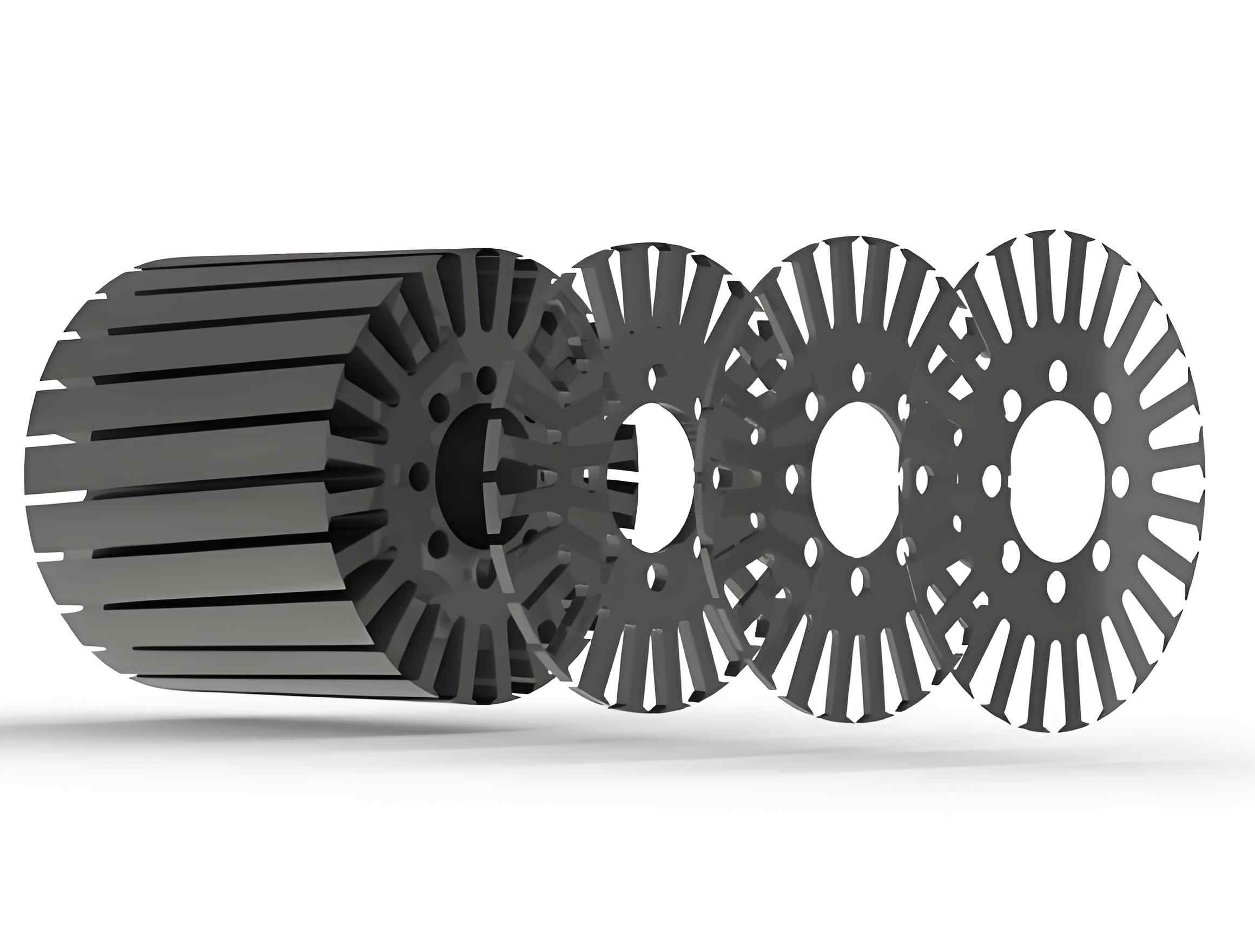

At Sino, we are experts in the careful making of core laminations, the basic parts for high-performance fan motors. We know how to work with many different kinds of fan motors, including Brushless DC (BLDC) motors, which are more and more common because they are efficient, and older induction motors.

The material itself is a massive piece of the puzzle. Sino selects and processes premium-grade silicon steel (often called electrical steel) specifically for its superior magnetic properties and ability to further squash energy losses.

The choice of magnetic material is basic to how well fan motor core laminations work. At Sino, we carefully choose and test materials based on their magnetic and mechanical properties, making sure they work best for specific fan motor uses.

Rules for Choosing Materials: Our selection process looks at:

Key Material Types and Their Properties:

Advanced Testing Methods: Sino uses advanced methods to ensure material quality and performance:

Hybrid Lamination Stack Approaches: Knowing the unique benefits of different materials, Sino is actively looking at and using hybrid stacks. These combine amorphous and nanocrystalline layers to balance cost, loss, and mechanical properties. Recent research shows that such hybrid solutions can lower total core loss by up to 15% and improve mechanical strength, especially for motors running in the 1–10 kHz range. This lets us create solutions that offer the best of both worlds for our partners’ specific needs.

New Processing Methods: We are always investing in advanced post-processing methods, like pulsed laser annealing and additive manufacturing of soft magnetic composites, to further lower core loss and improve ductility, pushing what materials can do.

By offering a wide range of materials and using careful testing, Sino makes sure our partners get the best lamination solution for their fan motor applications, balancing how well it works, how much it costs, and how easy it is to make.

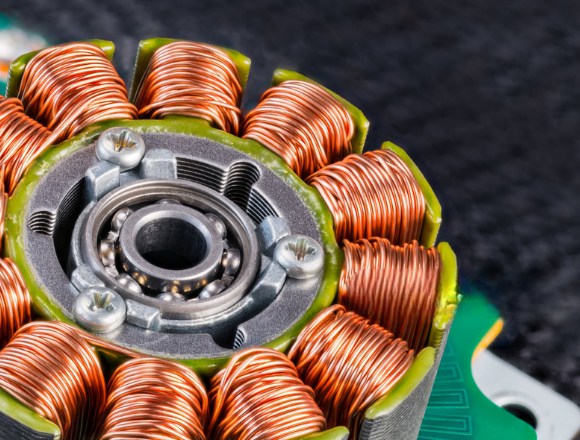

We have thin slices of special steel. But if you just stack them metal-on-metal, you’re almost back to square one. The eddy currents would just find sneaky paths across the lamination edges. That’s why the insulating layer between each lamination is absolutely critical, and at Sino, we ensure this insulation is robust and consistent.

To maximize the amount of active steel in the core (the “stacking factor”).

To withstand the pressures of stamping, stacking, and motor assembly.

To effectively block current flow between laminations.

To maintain its integrity throughout the motor’s operating life.

Sino employs various advanced coating technologies, including:

1

(often organic varnishes or epoxies): These provide excellent insulation, good adhesion, and can withstand significant temperatures. They are a popular choice for many Fan motor core laminations.

2

(enamels or inorganic coatings): Often selected for even higher temperature resilience or specific chemical resistance.

3

(like C-0 or “steam blueing”): A simpler, cost-effective option formed by controlled oxidation of the lamination surface, suitable for certain scenarios.

What does all this meticulous engineering mean for you and your products? It means tangible, bottom-line benefits:

This is the big kahuna. By slashing eddy current and hysteresis losses (collectively known as “core losses” or “iron losses”), Sino’s laminations ensure that more of the electrical energy you feed into the motor gets converted into useful spinning power. For the end-user, this means lower electricity bills. For the fan manufacturer, it means a product that can boast superior energy ratings.

Less wasted energy directly translates to less heat. A motor that runs cooler is a happier motor. It experiences less thermal stress on its windings and bearings, leading to a significantly longer operational lifespan and greater reliability. This is crucial for fans that run continuously or are embedded in critical systems.

Minimizing these unpredictable losses means the motor performs more closely to its design specifications across a wider range of loads and temperatures. No more surprise dips in airflow when things get a bit warm.

When a motor is more efficient, it might not need to be as bulky to produce the same power. Sino’s high-performance Fan motor core laminations can enable designers to create smaller, lighter fans without sacrificing oomph, opening doors for innovative product designs.

Excessive electrical noise and vibration can often be traced back to poorly managed magnetic fields and core losses. Well-designed and precisely manufactured laminations contribute to smoother, quieter motor operation – a key selling point for many fan applications, from bedroom ceiling fans to sensitive laboratory equipment.

Core Feature & Sino’s Approach | Effect on Eddy Currents | Effect on Hysteresis | Overall Efficiency & Performance with Sino |

Solid Iron Core (Hypothetical Baseline) | Very High | Moderate | Very Low, Hot, Inefficient |

Generic, Thicker Laminations | Moderate | Moderate | Mediocre at best |

Sino Thin Laminations (Precision Gauges) | Dramatically Low | Moderate | Significantly Improved Efficiency |

Sino High-Grade Silicon Steel | Lowered Further | Optimized Low | Peak Magnetic Performance |

Sino Robust Inter-laminar Insulation | Maintains Low Eddy Currents | No Direct Effect | Ensures Long-Term Lamination Integrity |

(This table illustrates general engineering principles. Sino provides specific performance data based on customized lamination designs and material grades for your fan motor stator requirements.)

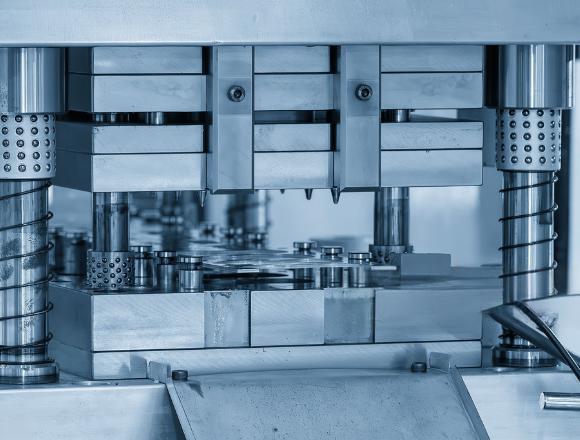

It often starts with your vision. Our engineers can work from your existing fan motor stator designs or collaborate to develop optimized lamination profiles that maximize flux paths, minimize leakage, and fit your specific mechanical constraints. We utilize advanced magnetic modeling software to predict performance before a single piece of metal is cut.

Precision High-Speed Stamping:

Laser Cutting:

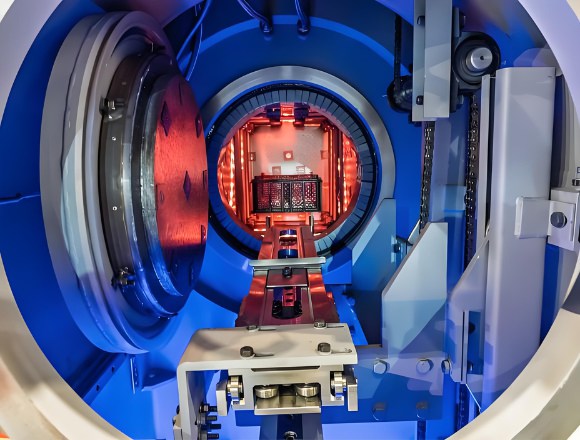

This controlled heat treatment process is vital for developing the ideal magnetic properties in silicon steel. Sino’s annealing furnaces feature precise temperature and atmospheric controls to ensure uniform grain growth and stress relief, unlocking the material’s full potential.

Our standard stress-relief annealing (750–850°C, 1–2 hours, H2/N2 atmosphere) can bring back up to 90% of the original magnetic properties.

How the laminations are stacked is just as important as the laminations themselves. We utilize various techniques – including interlocking (for inherent rigidity), precision welding, or cleating – to create solid, dimensionally accurate stator and rotor cores. Our automated stacking lines ensure consistency and high throughput.

Choosing Sino for your Fan motor core laminations isn’t just a transaction; it’s a partnership aimed at elevating your product’s performance, reliability, and market competitiveness. Here’s what sets us apart:

We live and breathe motor core technology. Our team brings decades of collective experience to your projects.

From premium raw materials to state-of-the-art manufacturing and stringent QC, quality is non-negotiable.

We understand that one size rarely fits all. We excel at creating bespoke lamination solutions tailored to your unique fan motor designs and performance targets.

We see ourselves as an extension of your engineering team, working with you to solve challenges and achieve optimal outcomes.

While we focus on premium quality, we also understand the market. We strive to offer a competitive fan stator price point for the superior value and long-term reliability our laminations deliver. Your total cost of ownership will be lower thanks to fewer failures and better efficiency.

Whether you need prototypes or high-volume production runs, Sino has the capacity and process controls to deliver consistently and on time.

From incoming raw material inspection to dimensional checks, magnetic property testing of sample cores, and final inspection, quality is woven into every step of Sino’s manufacturing process. We understand that the performance of your final fan motor hinges on the quality of our laminations.

If you are looking for reliable, high-quality fan motor core laminations, talk to Sino. We are ready to help you make your fans better.

Contact Sino today. Let’s discuss your specific scenario and explore how our expertly crafted lamination stacks can provide the efficient, reliable heart your fan motor.

Note: To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.

To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.