Let Sino's Lamination Stacks Empower Your Project!

To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.

To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.

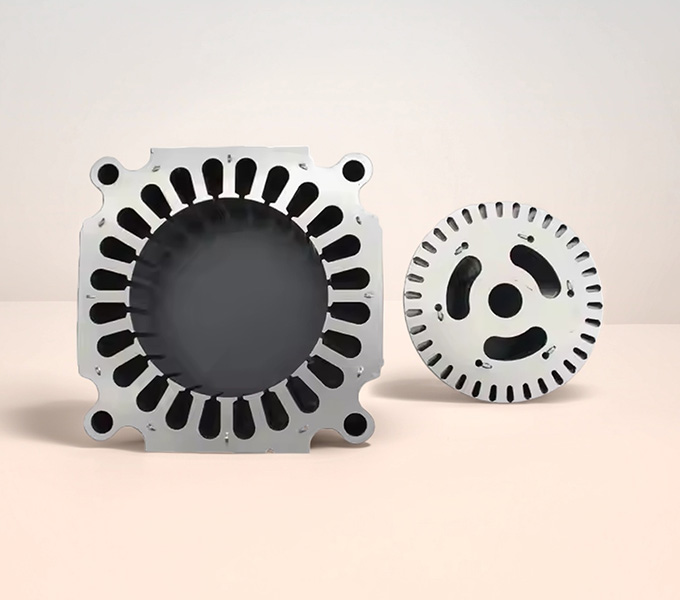

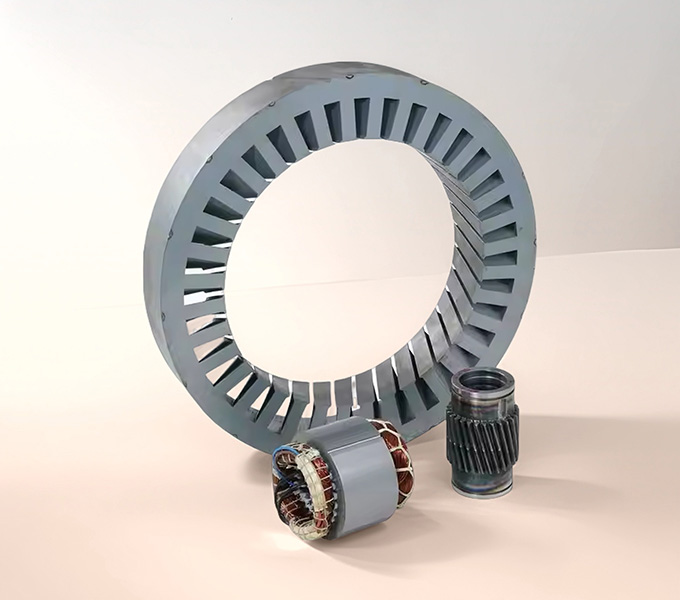

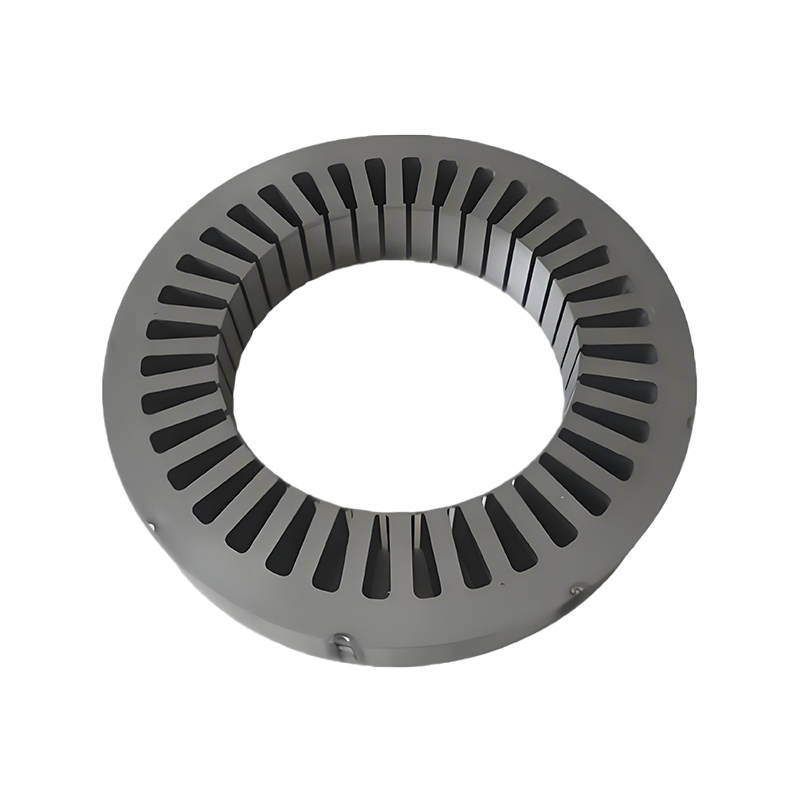

Making generator stator laminations is a very special process that needs to be done with great care and modern tools. At Sino, we use modern methods to produce high-quality laminations and put them together into strong generator stator cores. Sino is your partner you can trust, working hard to give you the modern generator stator core solutions that help you succeed.

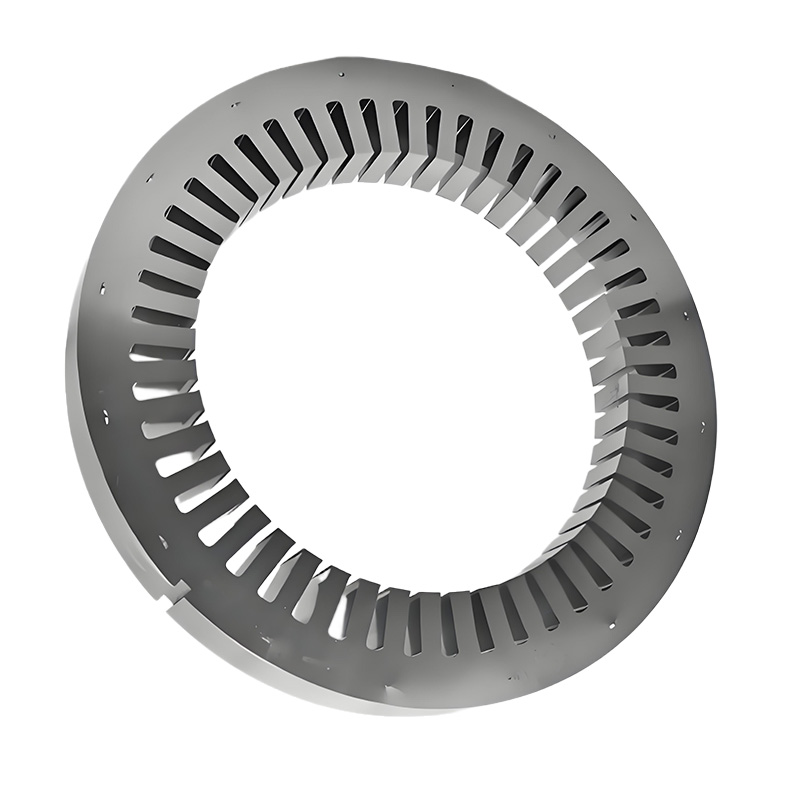

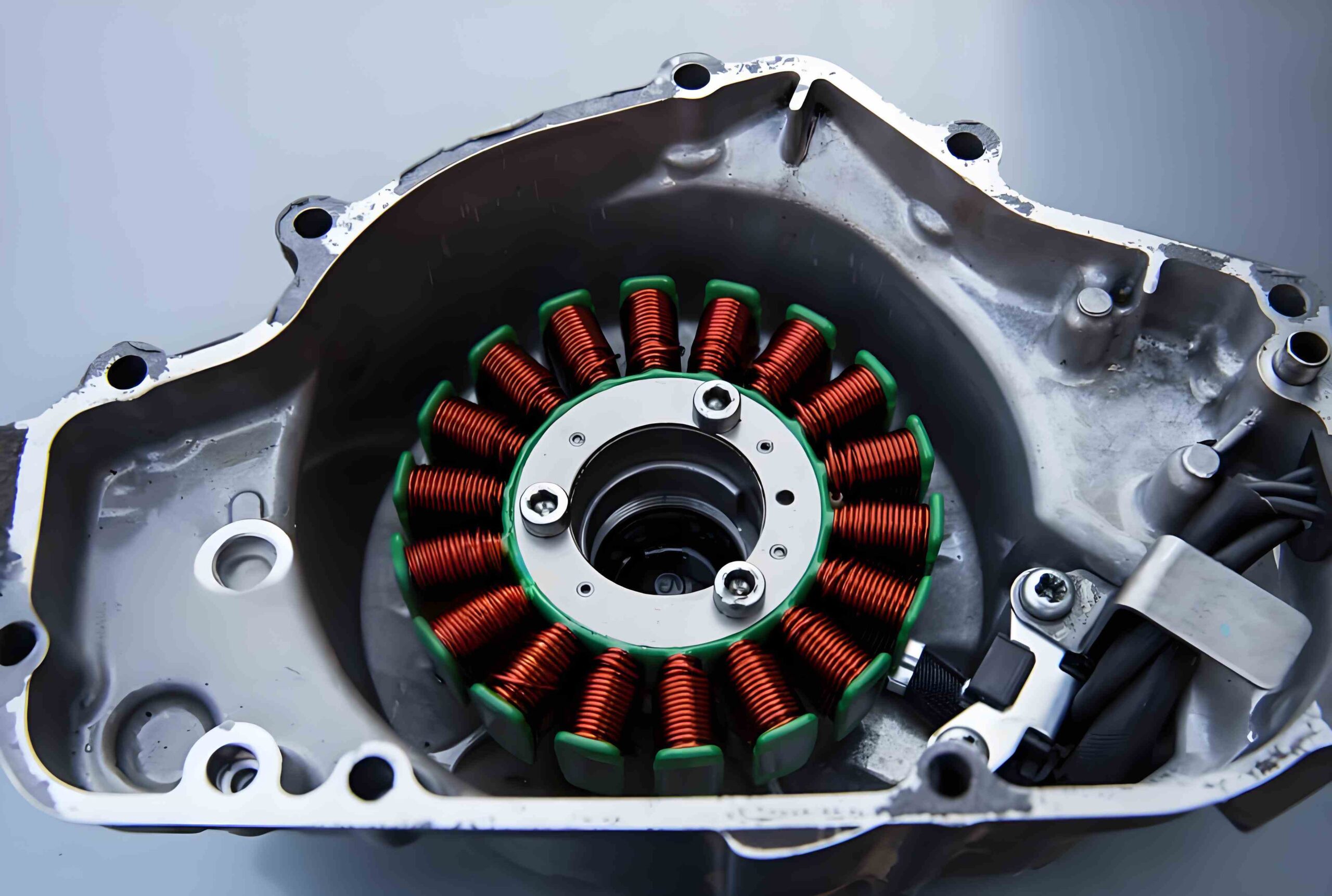

The stator core, often called the heart of an AC generator, guides the magnetic field made by the rotor and creates voltage in the stator windings. How well it works is very important; it directly affects the generator’s total performance, how it handles heat, and how long it lasts. Using layered cores, instead of solid iron, is a basic idea in its design that solves the problems that come with changing magnetic fields.

At Sino, we use thin sheets of electrical steel, usually from 0.1 to 0.5 mm thick, to build our generator stator laminations. These layers work better the smaller the area is for unwanted “eddy currents” to flow. Also, making the core material resist electricity more, for example, by using silicon steel with 3% Si or new amorphous alloys, further stops eddy currents. The insulation between the layers—made with oxide layers, varnishes, or organic coatings—is very important. Even small problems in this insulation can lead to large “hot spots” caused by eddy currents, hurting the quality and performance of the generator stator core.

There is an important choice to make about layer thickness: thinner layers cut down on energy loss from eddy currents, but they are harder and more expensive to make, and they break more easily. For 50/60 Hz power generators, a thickness of 0.23–0.35 mm is common. For uses with high frequency, like those in certain special kinds of generators or power electronics, special amorphous or nanocrystalline ribbons as thin as 0.02 mm are used.

The choice of material for Generator Stator Core Laminations is a science in itself. For decades, the go-to material has been specialized electrical steel, often a silicon steel alloy, and for very good reasons:

Electrical steels are put into two main groups: Grain-Oriented Electrical Steel (GOES) and Non-Oriented Electrical Steel (NOES). While GOES is mostly used in transformers because its properties are different depending on the direction, NOES is the best material for generator stator laminations because its magnetic properties are the same in all directions, which work better for spinning magnetic fields.

Here’s a quick rundown of what makes a great lamination material:

Property | Sino’s Target Characteristic | Why It’s a Big Plus for Your Generator |

Electrical Resistivity | Maximized for Grade | Puts the brakes on eddy current formation |

Magnetic Permeability | Optimized for Flux Density | Ensures the magnetic field works smarter, not harder |

Hysteresis Loss | Minimized through Material Science | Reduces energy wasted as heat during magnetic field changes |

Mechanical Strength | Robust and Stable | Withstands the rigors of assembly and long-term operation |

Insulation Integrity | Superior & Long-Lasting | The critical shield against inter-laminar shorts |

Dimensional Accuracy | Precision Engineered | Guarantees perfect stacking and consistent performance |

Surface Finish | Smooth & Clean | Optimizes stacking factor and insulation effectiveness |

Cost-Effectiveness | Value-Driven | High performance without breaking the bank |

(Source: Sino Internal Engineering Standards, aligned with best practices from IEEE Std 432™ and IEC 60404 series)

We’ve established that Generator Stator Core Laminations are pretty sophisticated. But what happens when things start to go sideways? The arguments for investing in top-quality laminations, like those from Sino, become crystal clear when you consider the potential headaches:

This is a major concern for generator operators. Over many years of service, the constant thermal cycling (heating up during operation, cooling down when offline), relentless vibrations, potential contamination from oil mist or moisture, or even tiny imperfections from the original manufacturing process can cause the inter-laminar insulation to degrade. It might start small, a tiny breach, but it can spread.

When that insulation fails and laminations short together, you’ve created a new, unintended pathway for those pesky eddy currents. These currents concentrate in the shorted area, leading to localized overheating – what engineers call “hot spots.” These aren’t just warm patches; they can get seriously hot. That’s a repair bill you really don’t want to see, often involving extensive downtime and significant cost. In extreme cases, runaway hot spots can even lead to melting of the core steel itself – a catastrophic failure.

Generators vibrate. It’s a fact of life. Over tens of thousands of operating hours, combined with thermal expansion and contraction, the clamping pressure holding the lamination stack together can gradually reduce. If the core becomes loose, individual generator stator laminations can start to vibrate independently and fret against each other. This fretting action can wear away the insulation, creating more short circuits and hot spots!

The industry has developed some pretty clever diagnostic techniques to sniff out trouble before it escalates into a full-blown crisis. The argument for proactive testing is simple: it’s far cheaper to find and fix a small problem than to deal with a massive failure.

1

(Electromagnetic Core Imperfection Detection): This is a widely respected test. Technicians pass a relatively low excitation current through the core and use a special sensor, like a Chattock potentiometer, to detect any fault currents that are flowing between laminations due to insulation breakdown.

2

(or Loop Test): Temporary windings are wrapped around the stator core, and it’s energized to near its normal operating magnetic flux density. Then, engineers use high-resolution thermal imaging cameras to meticulously scan the entire inner surface of the core. Any significant hot spots, indicative of shorted generator stator laminations, show up clear as day.

3

Never underestimate the power of a trained eye! During planned major outages, a thorough visual check of the core can reveal tell-tale signs like discoloration from overheating, evidence of fretting (a rusty-looking dust), or any physical damage to the laminations.

We don’t just manufacture Generator Stator Core Laminations; we engineer solutions designed for maximum efficiency, unparalleled reliability, and extended operational life. Our commitment to quality permeates every step of our process:

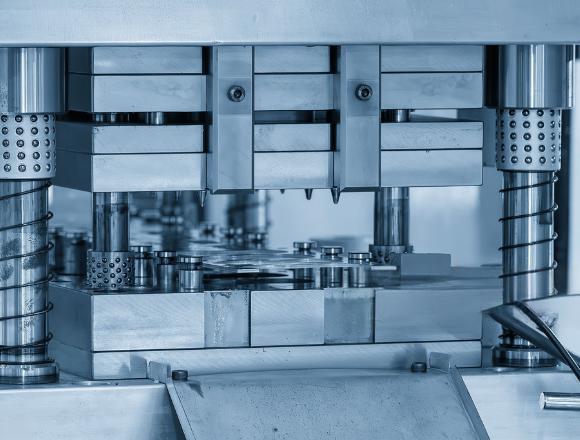

We employ state-of-the-art stamping presses and, for more complex geometries or specialized orders, advanced laser cutting technology. This ensures exceptional dimensional accuracy and repeatability, meaning every lamination fits perfectly, minimizing air gaps and maximizing the effective magnetic area.

After cutting, even the tiniest burr on the edge of a lamination can pierce the insulation of its neighbor, creating a potential short circuit. Sino utilizes sophisticated deburring processes, both mechanical and chemical, to ensure exceptionally smooth, burr-free edges. This attention to detail is critical for long-term insulation integrity.

The insulation between the layers is as important as the steel itself. Sino uses modern coating systems to make sure our generator stator laminations have good insulation and can handle heat well:

These coatings are designed to keep insulating well even after being heated and cooled many times (up to 800°C), which is very important for high-performance generators that are heated many times when being made or run at high temperatures.

Quality isn’t just a buzzword for us; it’s embedded in our DNA. From incoming raw material inspection (verifying the grade and properties of the electrical steel) through every manufacturing stage to final pre-shipment checks, our quality assurance teams are relentless. We operate under stringent quality management systems (e.g., ISO 9001 certified) to guarantee that every batch of generator stator laminations leaving our facility meets or exceeds the most demanding specifications.

We understand that not all generators are created equal. Sino has the capability and expertise to produce Generator Stator Core Laminations for a vast array of generator designs, from smaller industrial units to massive utility-scale turbines. We can work from your precise drawings or collaborate with your engineering team to develop optimal lamination designs for new applications or refurbishment projects.

For clients who require fully assembled stator core stacks, Sino offers precision stacking services. We ensure correct alignment, uniform clamping pressure, and verification of the assembled core’s integrity, delivering a component ready for winding and installation.

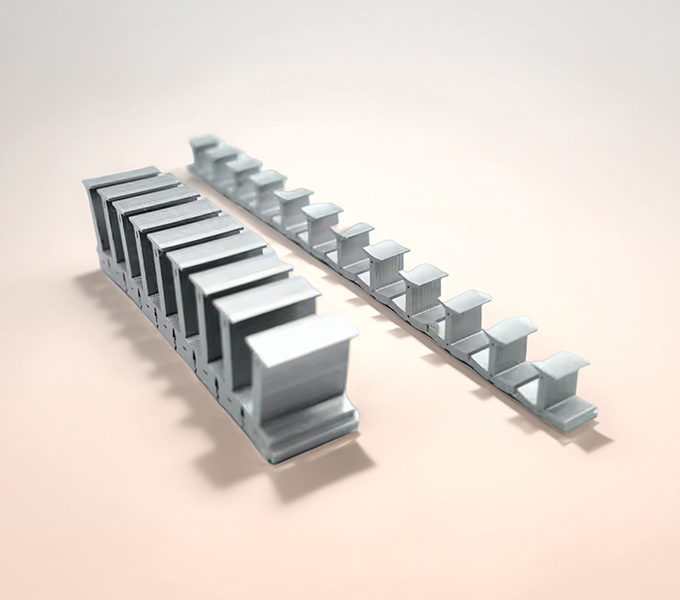

Precision Stamping: For making large numbers of generator stator laminations, progressive die stamping is still the main method. Sino uses modern stamping machines that can make over 1,000 parts per minute, being accurate down to ±5 μm. For difficult shapes and when very clean edges are needed, especially in special generator uses, fine blanking is used. While slower (usually <200 parts/minute), fine blanking makes rough edges very small (<10 μm) and keeps the parts very flat, which is important for the best stacking in the generator stator core.

Laser Cutting: Fiber laser cutting is used more and more for making early models and for smaller production amounts, allowing for fast design changes and making cuts as thin as 20–30 μm. However, laser cutting can create a heat-damaged area (HAZ) of 10–50 μm, which hurts the magnetic quality unless it is heated after cutting. Sino invests in modern, very fast lasers (picosecond/femtosecond) to make the heat-damaged area smaller, making sure the magnetic quality of our generator stator laminations is good.

Heating the parts after stamping or laser cutting is a very important step to get back their magnetic quality and reduce energy loss in the core of generator stator laminations. Our usual heating process involves raising the heat to 750–850°C in a special atmosphere of hydrogen or nitrogen for 2–4 hours, then cooling them down slowly (<10°C/min) to prevent problems with the material’s structure. Sino also uses quick heating cycles (under 1 hour) for high-silicon electrical steels, to find a balance between making things fast and getting the best quality, making sure that every generator stator core gets its planned magnetic performance.

The way generator stator laminations are bonded into a solid core has a big effect on its strength, how it handles heat, and its magnetic and electrical features. Sino offers different bonding methods made to fit the needs of each use:

Bolt-through Assembly: While not as common in modern, small designs, it is still used in big industrial machines where being easy to fix and having changeable parts is most important.

The shape of each generator stator lamination—including the width of the teeth, height of the yoke, and slot opening—directly affects how the magnetic field is spread out, how much energy the core loses, and saturation. For instance, making the teeth wider can lower the magnetic field strength in the teeth, which reduces strong magnetic spots but can possibly increase energy loss in the core because the magnetic field has to travel farther. The yoke needs to be tall enough to stop the magnetic field from getting too strong there, especially in high-power uses. The width of the slot opening affects how easy it is to put in the wire coils and how much magnetic field leaks out; smaller openings reduce leakage but make it harder to make the part and put in the wires.

Sino offers different slot shapes for our generator stator laminations, each with its own pros and cons:

The stacking factor, which is the amount of iron compared to the total height of the lamination stack, is a very important number for the performance of a generator stator core. For high-quality laminations, it is usually from 0.94–0.97. However, the making processes like stamping, laser cutting, and interlocking can create rough edges and bending, which makes the stack less dense. Studies show that rough edges over 20–30 μm can make the stack 1–2% less dense and increase energy loss from eddy currents in small spots. Sino uses modern ways to remove rough edges and stack carefully, including glue bonding and laser welding, to lessen these problems and ensure the best stacking factor for our generator stator laminations.

How stable the generator stator core is is greatly affected by the pressure used to clamp it together during assembly. Not enough pressure can lead to the layers shaking and making more noise, while too much pressure can bend the layers, making the stack less dense and increasing energy loss. Sino uses the best amount of clamping pressure, usually between 1–3 MPa, checked with computer models, to make sure the structure of our generator stator cores is strong and works well.

To reduce the bumpy feeling and the noise and shaking that comes with it, especially in high-performance generators, Sino uses methods like angling the stator slots or teeth (by 1–2 slot widths). While this works, angling too much can lead to more energy loss in the copper wires and less power. We use special methods, often combined with computer analysis (FEA), to find the best balance between these different needs, making sure our generator stator laminations help make the generator quiet and work well.

Our team is here to listen, understand your specific requirements, and provide timely support.

Got a challenging design or a unique operational scenario? Our engineers are ready to share their deep knowledge of materials science and lamination technology.

We understand the importance of on-time delivery to keep your projects and maintenance schedules on track. Sino has built a robust and resilient supply chain.

The world of power generation is constantly evolving, and so are we. Sino continually invests in research and development to explore new materials, enhance manufacturing techniques, and push the boundaries of lamination performance.

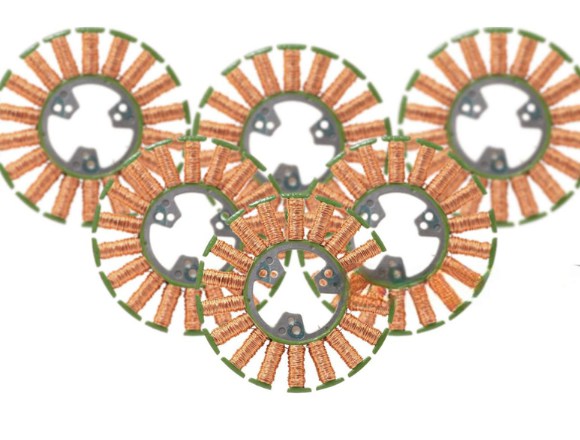

Our generator stator core laminations are used in many different types of machines that make power:

In large power plants that use water to make electricity, the stator core is a giant ring made from our laminations . These cores are huge and require precise stacking and strong bonding. They need very efficient core loss minimization.

The motors that power electric cars and trucks use special stator and rotor cores made from laminations . These require very high precision and efficiency. We work with electric vehicle traction motor companies.

The generators in wind turbines rely on high-quality laminations to capture as much energy as possible from the wind . These applications often benefit from grain-oriented steel for maximum efficiency.

Laminations are also used in smaller generators, starter motors, and other electrical machines.

Large power plants using gas or steam also use cores made from these laminations.

While mainly for generators, the same lamination technology is used for the stator cores of powerful industrial motor manufacturers' products . These motors drive pumps, compressors, and HVAC systems.

At Sino, we pour our expertise, precision, and passion into every lamination we produce. We believe that by delivering the highest quality generator stator laminations, we’re not just supplying a part; we’re contributing to a more efficient, more reliable, and ultimately more sustainable energy future.

If you are building or servicing generators or high-performance motors, the quality of your generator stator core laminations is fundamental to success. At Sino, we provide the high-quality, precision laminations you need to build efficient, reliable, and powerful machines.

Let us help you optimize your design and manufacturing process with our expert knowledge, advanced technology, and commitment to quality.

We are ready to provide the right silicon steel lamination solutions for your project, from electric motor stator parts to large generator cores.

Note: To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.

To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.