Let Sino's Lamination Stacks Empower Your Project!

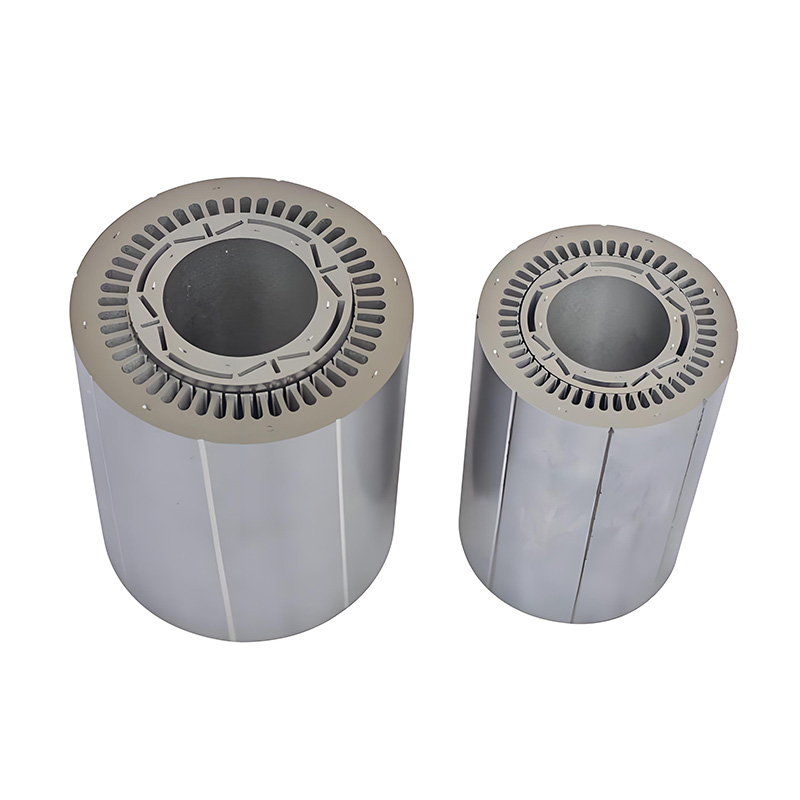

To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.

To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.

As Sino, a top Chinese maker of motor laminations, we know the very important part that core laminations play in how well electric motors work, how much energy they save, and how long they last. Our goal is to help motor makers everywhere, in many different fields, with the newest and best lamination products. We want to show the way to better energy use, more power in a smaller size, and better heat handling, while also looking at the big changes that can come from new materials and ways of making things.

Sino predominantly utilizes high-grade silicon steel, often referred to as electrical steel for adding a small percentage of silicon (typically between 1-4%) to the iron alloy significantly boosts its electrical resistivity. This intrinsic property of the material itself gives eddy currents another hurdle to overcome, further diminishing their impact.

But silicon steel brings more to the table:

By carefully selecting the grade of silicon steel, Sino ensures that your induction motor core – whether it’s for the stator core of an induction motor or the rotor core of an induction motor – possesses the optimal magnetic properties with the lowest possible core losses.

when EV motors run at very high speeds (hundreds of Hz to several kHz) and under strong magnetic fields, regular silicon steels have problems. This is because they lose more energy as heat, especially from eddy current losses and anomalous losses. To get past the problems with regular steels, new and better materials are becoming more popular. They offer better magnetic abilities at high speeds.

Amorphous metals, like those from Metglas and Hitachi Amorphous, are made of atoms arranged randomly, like glass, not in a neat crystal pattern. This special structure gets rid of grain boundaries, which are a big reason for energy loss and the creation of eddy currents.

Nanocrystalline alloys, like Finemet (Fe73.5Si13.5B9Nb3Cu1), Vitroperm, and Nanoperm, are made mostly of iron and have a structure of extremely tiny crystals held within a random, non-crystal structure. This special structure brings together the good points of both amorphous and regular crystal materials.

Lower energy consumption means smaller electricity bills.

Cooler operation leads to longer motor life and less frequent maintenance or replacement.

Motors can deliver their rated power more effectively without being hampered by excessive losses.

For motor designers, low-loss cores can mean the possibility of creating more compact motors for a given power output, or achieving higher power from an existing frame size.

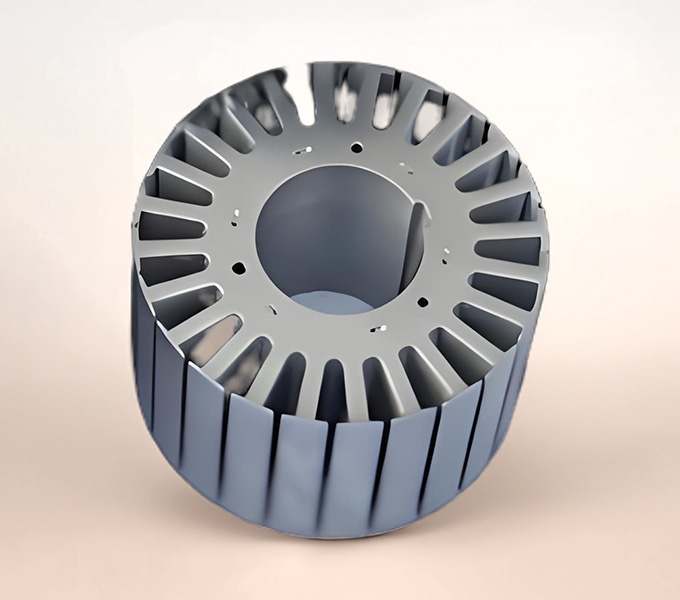

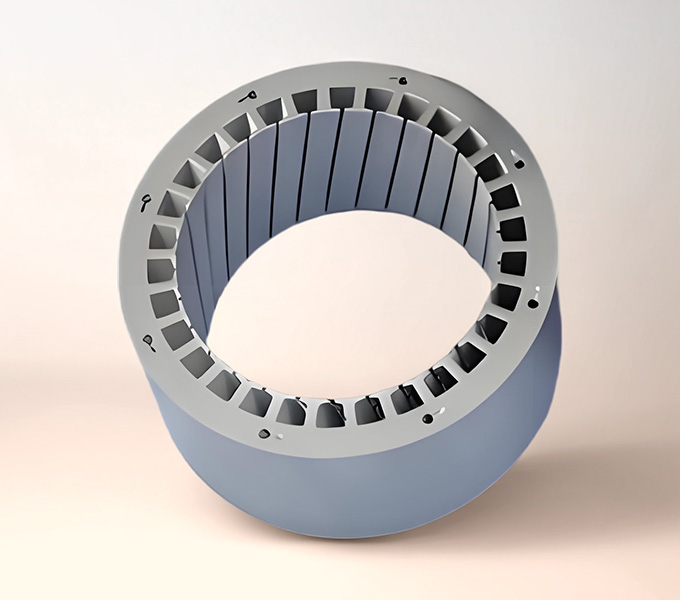

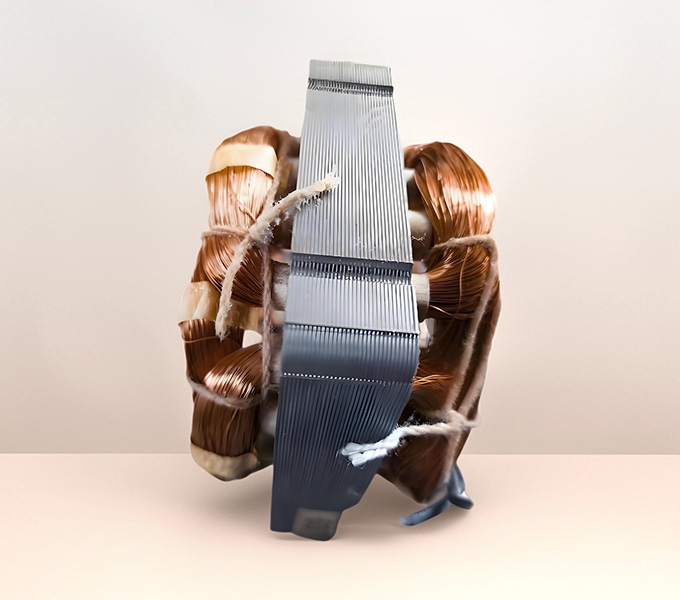

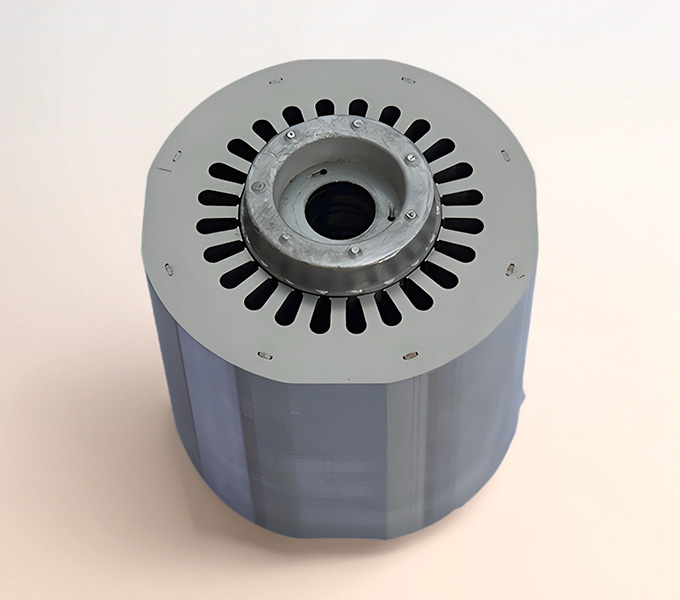

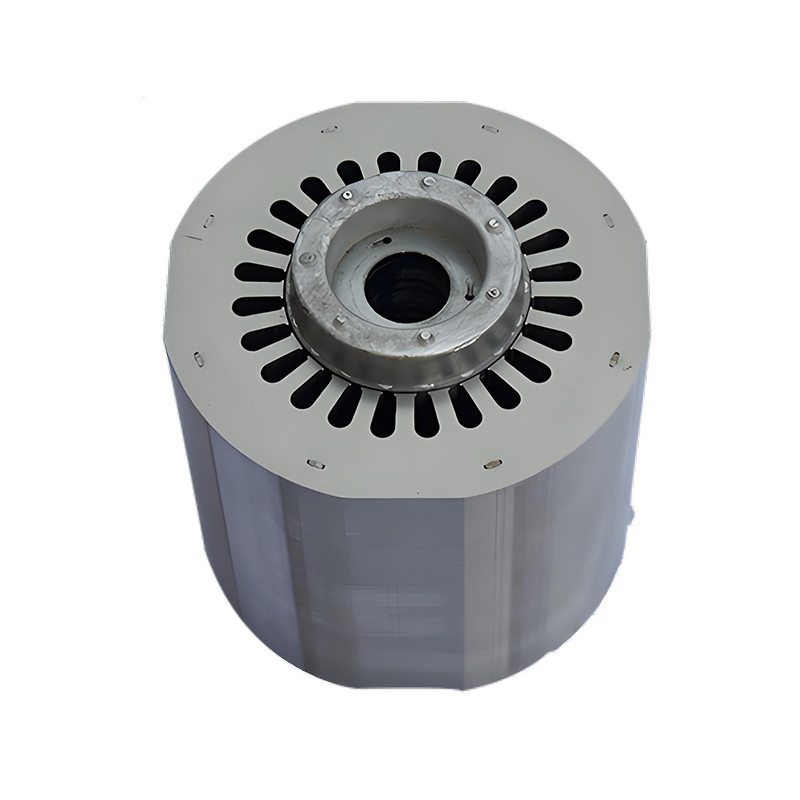

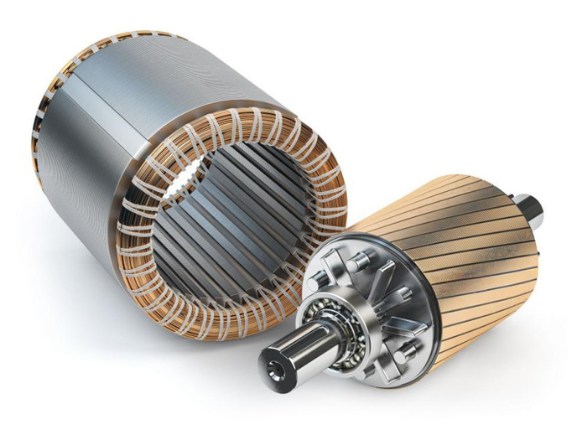

An induction motor has two main core components that benefit immensely from Sino’s precision laminations:

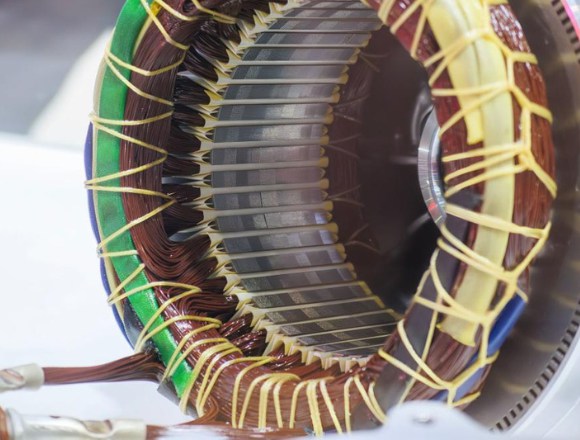

This is the stationary part that holds the stator windings. When energized, these windings create the rotating magnetic field. The stator core of an induction motor, built from Sino’s laminations, serves several vital functions:

This is the rotating part of the motor. In squirrel-cage induction motors (the most common type), the rotor core of an induction motor houses conductive bars (usually aluminum or copper) that are short-circuited by end rings.

The way laminations are made has a big effect on their final magnetic and physical qualities. Sino uses the most modern methods and keeps putting money into new ways of making things to deliver better products.

Stamping is the most common way to make laminations because it’s fast and doesn’t cost too much for making a lot of them. However, the cutting process bends the metal and leaves stress in it at the cut edge. This makes the magnetic abilities a bit worse, usually increasing energy loss by 5–15% compared to the original material. Afterwards, a step like a special heat treatment (stress relief annealing) is often needed to fix these problems.

Laser cutting is very exact and can be used for many different shapes, especially for making samples and complex parts. However, it heats up a small area, creating a Heat-Affected Zone (HAZ) that is usually 10–100 μm wide. This HAZ has changes in its tiny internal structure and leftover stress, all of which together make the magnetic abilities worse. Studies show this can increase energy loss by 10–30%. How much worse it gets depends on the laser settings (power, speed, gas used, etc.).

At Sino, manufacturing induction motor core laminations is more than just stamping steel. It’s a science and an art we’ve honed through years of dedication.

1

We employ advanced, high-speed stamping presses and precision carbide dies to ensure every lamination meets exacting dimensional tolerances. This precision is vital for uniform stacking, minimizing air gaps within the core, and ensuring consistent magnetic properties.

2

We source only high-quality electrical steel from reputable mills, with traceable certifications. We understand the nuances of different steel grades and their suitability for various motor designs and operational demands.

3

The interlaminar insulation is paramount. We utilize various coating types (like C5 or C6) applied and cured under controlled conditions to guarantee high electrical resistance between laminations, preventing short circuits that would negate their benefits. Rigorous testing, including inter-laminar resistance checks (Franklin tests), is part of our standard quality control.

4

For certain grades of electrical steel, a carefully controlled annealing process after stamping is crucial to relieve mechanical stresses induced during punching and to restore optimal magnetic properties. Sino has the in-house capability to perform this critical step.

5

From raw material inspection to final stack dimensional checks, quality control is embedded in our process. We adhere to international standards (e.g., ISO 9001) to give you complete confidence in our products.

When you choose Sino for your induction motor core laminations, you’re not just buying a component; you’re investing in the heart of your motor’s performance and reliability. Whether you’re designing the next generation of energy-efficient industrial motors, specialized servo motors, or robust traction motors, our laminations for the stator core of an induction motor and the rotor core of an induction motor provide the foundation for excellence.

We understand that one size rarely fits all. That’s why we work closely with our clients, offering:

Don’t let outdated core technology hold your motors back. Embrace the efficiency, durability, and performance that Sino’s precision-engineered induction motor core laminations deliver. Let’s work together to build motors that are not just powerful, but also smart and sustainable.

Ready to give your motors the core they deserve? Contact Sino today, and let’s discuss how we can energize your next project!

Note: To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.

To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.