Sinoのラミネーションスタックにお任せください!

プロジェクトをスピードアップするために、ラミネーションスタックに以下のような詳細なラベルを付けることができます。 寛容, 材料, 表面仕上げ, 酸化絶縁が必要かどうか, 数量などなど。

巨大なジェットエンジンを動かしているのは何なのか、不思議に思ったことはないだろうか。それは単なる1つの部品ではない。すべての部品がチームとなって働いているのだ。その中でも特に重要な部品がステーターとローターです。この記事は、ステーターベーンを理解するための簡単なガイドです。ステーターベーンとは何か?なぜタービンやジェットエンジンにとって重要なのか。また、問題が発生した場合の故障解析がどのようなものかを学びます。世界で最もパワフルなエンジン内部の秘密のヒーローについて学びましょう。

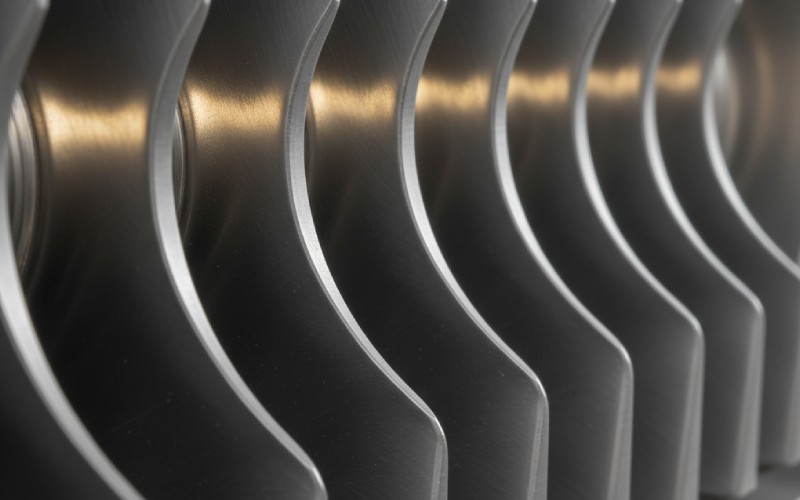

ステーターベーンは一箇所に留まり動かない部品です。タービンやコンプレッサーの内部にあります。非常に正確な場所に設置されるフィンや翼形と考えることができる。回転するローターブレードとは異なります。ステーターはまったく動きません。ステーターの仕事は、空気やガスがエンジン内を移動するのをコントロールすることです。また、その空気やガスの速度も制御します。ステーターは多くの機械に搭載されている。大型のジェットエンジンから小型のターボチャージャー・タービンまで様々です。

各ステーターは、ベーンと呼ばれる多数の小さな翼でできている。これらの羽根はエンジンの外側のケーシングの中に円形に設置されている。ステーターは、空気を圧縮するコンプレッサー部分にあることもある。また、高温のガスから動力を得るタービン部分にもあります。ステーターベーンの最も重要な仕事は、空気やガスの流れを整えることです。次の動翼群に向けます。これらの動翼はローターの一部である。この素晴らしいチームワークがエンジンを強くし、うまく機能させるのである。

ステーターとローターの連携は完璧なダンスのようだ。ローターは非常に高速で回転する。空気やガスの力で押される。そのブレードが空気やガスを押してエンジンを動かす。しかし、空気やガスが間違った方向からローターに当たると、多くのパワーが失われる。そこで役立つのがステーターだ。

ステーターは回転するローターの直前か直後に配置される。回転するローターから空気が出るとき、空気自体も回転している。動かないステーターは、この回転する空気を受け止める。そして、空気の流れを再びまっすぐにする。ガイドベーンのようなものだ。これにより、空気は完璧な角度で次のローター・ブレード群に当たる。この一連のステップ(回転、直線化、回転、直線化)は、エンジン内部で何度も何度も繰り返される。ステーターとローターの間のこのダンスは、エンジンが非常に高い圧力を蓄積するのを助ける。この高い圧力は、より大きなパワーを意味する。ステーターとローターがどのように連動するかは、タービンの性能にとって非常に重要である。

| パート | ムーブメント | 主な仕事 |

|---|---|---|

| ステーター | 一箇所にとどまる(動かない) | 空気またはガスの流れを誘導する |

| ローター | 回転性(非常に速く回転する) | 空気やガスを押し出して仕事をする |

ステーターは、エネルギーを無駄にすることなくエンジンをうまく機能させるために非常に重要である。ステーターがなければ、タービンやコンプレッサーは非常に弱くなってしまう。その最大の理由は圧力だ。コンプレッサーの主な目的は、空気を強く押し付けることです。これは圧力を高めると呼ばれ、各段階で起こります。ステーターはこの圧力を上げる手助けをする。ステーターは、ローターから送られてくる空気を減速させます。この作用により、空気の速度がより大きな圧力に変わるのです。

これによってコンプレッサーの働きが格段に良くなる。パワータービンでは、ステーターは逆の働きをする。高温のガスをより速く動かす。そしてそのガスをタービンブレードに向けます。これにより、タービンはより強力に回転する。流れをうまくコントロールできるということは、タービンの効率が良くなるということです。優れたステーター設計は、より優れた空力性能を生み出します。また、無駄なエネルギーが減り、エンジンがよりパワフルになります。ステータは、さまざまなエンジン運転条件下でエンジンが正しく機能するようにします。

ジェットエンジンでは、ステーターとローターの連携が非常に重要だ。ジェットエンジンには、このステーターとローターのチームワークが見られる2つの主要部分がある。手前がコンプレッサー、奥がタービンだ。コンプレッサー部分には多くのステージがある。各段には1組のローター・ブレードと1組のステーター・ベーンがある。ローターは空気にエネルギーと速度を与える。そしてステーターがその速度をより高い圧力に変える。これが何度も繰り返される。燃料が混合される前の空気は非常に濃く、高温になる。

燃料が燃えた後、多くのエネルギーを持った高温のガスは非常に速く後方に移動する。そこでタービン部分に入る。高圧タービンには、ステーターとローターという部品があります。ステーターのノズルからタービンブレードに向けて高温ガスが噴射される。これによりタービンは回転する。この回転作用がエンジン前部のコンプレッサーに動力を与える。ステーターベーンの正確な角度は非常に重要である。わずかなミスでも空気の流れが不安定になり、エンジンにダメージを与える可能性がある。ジェットエンジン内の空気は複雑な流れを経験する。遷音速状態の流れ場で、ほとんど音速のように非常に速く移動する。

これは非常にいい質問だ。ステーターベーンはローターのように動力を発生させるものではありません。ローターは仕事をする部分です。では、ステーターは何をするのでしょうか?ステーターは気流にとって最適な状況を作り出します。これによって、ローターは非常にうまく仕事をすることができる。空気やガスを準備する。

野球のピッチャーのようなものだと考えてほしい。ピッチャー(ステーター)は得点を決めない。しかし、適切なスピードと角度でボールを投げることで、ピッチャーはバッター(ローター)にホームランを打たせるお膳立てをする。ステーターの羽根は、流れに対して主に3つの働きをする:

こうすることで、ステーターはエンジンが無駄なく、より大きなパワーを生み出すのを助ける。ベーンの特殊な空気力学的形状は、この目的のために設計されている。

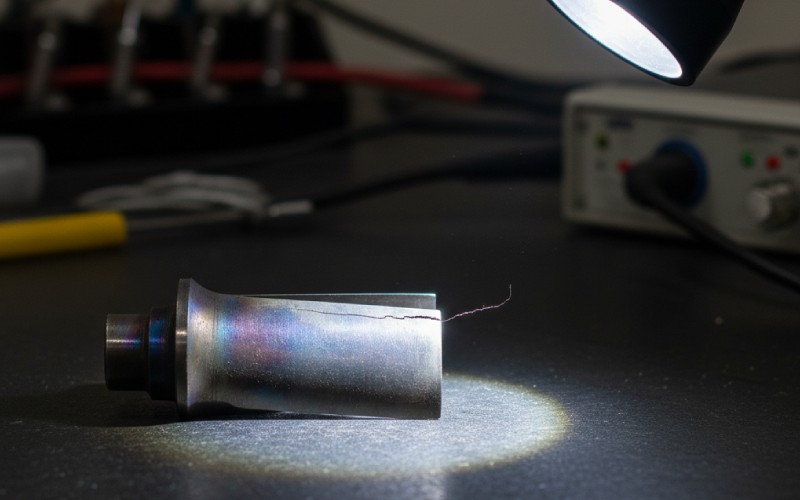

非常に頑丈に作られている部品でさえ壊れることがある。ステーターベーンの故障は、どのタービンにとっても大きな問題だ。部品が破損する主な原因の1つは金属疲労と呼ばれるものです。これは疲労破壊の原因となります。これは、ステーターが常に高速で動く空気にさらされているために起こります。また、温度や圧力の大きな変化にもさらされます。何千時間も使用すると、小さな亀裂が入り、大きくなることがある。これは、後縁と呼ばれるベーンの後縁付近でよく起こります。

故障のもう一つの大きな原因は、揺れ、つまり振動だ。エンジンの高速回転によって部品が揺れることがある。ステーターベーンにとってちょうど良い回転数で揺れが起こると、バラバラになるほど激しく揺れることがある。氷のかけらや壊れたコンプレッサーのブレードなど、エンジン内の小さな破片がステーターに当たって故障することもあります。一つのステーターベーンが故障すると、一連の悪い現象が始まります。ローターやエンジンの他の部品にダメージを与えることもある。たった一つの小さなステーター部品の破損から始まる故障の報告は多い。

ステーターが故障すると、工学的な故障解析が始まる。これはエンジニアにとっての探偵小説のようなものだ。彼らの目標は、部品が壊れた理由を正確に突き止めることです。そうすることで、二度と同じことが起こらないようにするのだ。まず最初にすることは、壊れた部品を注意深く集めることである。調査員は部品の表面を顕微鏡で観察する。どこで亀裂が入ったのかを見つけるためだ。

エンジニアは特別なツールを使う。数値解析は、ステーターが対処していた力と熱のコンピューターモデルを作成することができる。このコンピューターモデルは、応力が一カ所で高すぎるかどうかを示すことができる。また、数値的および実験的研究も行われる。この研究では、壊れた部品と同じような部品を壊れるまでテストする。同じように壊れるかどうかを調べるためです。XCTが使われることもある。これは強力な3Dレントゲンで、部品を切断することなく、目に見えない問題を金属の内部から調べることができる。座標測定システムは、ベーンが正しい形状とサイズで作られたかどうかをチェックすることができる。問題の主な原因を見つけることで、それを解決するための良い方法を提案することができる。

走行中のタービン内部を見ることはできない。では、ステーターに問題があるかどうかを知るにはどうすればいいのでしょうか?パイロットやエンジニアはある兆候を探します。故障しているステーターは、スムーズな空気の流れを台無しにします。これはいくつかの異なる問題を引き起こす可能性がある。

以下は、よく見られる兆候である:

エンジニアは常にステーターをより良いものにしようとしている。目標は、より強く、より軽く、無駄を省いてより良く機能させることだ。重要な分野のひとつが空力形状の最適化だ。つまり、最適な形状を見つけるということだ。強力なコンピューターモデルを使うことで、設計者はエネルギーをあまり失うことなく空気を誘導する羽根の形状を作ることができる。これは、パーツをよりうまく機能させるための数値研究の一部である。これは、低レイノルズ数条件と呼ばれる高高度のような条件では特に重要である。

ステーターに使用される素材も良くなっている。新しいタイプの金属は、より高い熱と応力に対応できる。これは、ガスが最も高温になるエンジンのタービン入口部分で非常に重要だ。より優れた製造方法も役立っている。例えば、TA19チタン合金部品の表面の完全性を高めるために、キャビテーション研磨統合ウォータージェットピーニングと呼ばれるプロセスを使用することができます。この工程により、金属の表面はより強くなり、亀裂が入りにくくなります。これにより、最新のエンジンに使用されているTA19チタン合金の完全性が向上します。

そう、3Dプリンターとも呼ばれるアディティブ・マニュファクチャリングが、ステーターベーンの製造を変えつつあるのだ。以前は、複雑な形状のステーターを作るのは難しく、多額のコストがかかっていた。アディティブ・マニュファクチャリングでは、金属粉末から1層ずつステーターを作ることができる。そのため、これまで作るのが難しく、不可能だった新しい形状を作ることができる。例えば、ステーターの内側に冷却チャンネルを印刷することができる。このチャンネルは、非常に高い熱を処理するのに役立つ。

この新技術は、より優れた最適化を実現する方法だ。また、航空機にとって非常に重要な重量の軽い部品を作ることもできる。しかし、まだ課題もある。3Dプリントされた部品の幾何学的強度と品質を良好なものにすることは非常に重要です。多くの人が、LPBFで作られたステーター部品の幾何学的精度を研究しています。この作業は、LPBFで作られたステーターの羽根の精度が、古い方法で作られたオリジナルの部品と同等か、それ以上であることを確認するためのものです。この技術が向上すれば、次に製造されるエンジンには、3Dプリントされたステーター部品が多く見られるようになるだろう。