Let Sino's Lamination Stacks Empower Your Project!

To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.

To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.

At Sino, we are a top maker in China that focuses on making high-quality laminated soft iron cores. We sell to many different motor makers all over the world in many industries. Our goal is to give you the basic magnetic parts that help bring your new ideas to life, making sure your products work better, last longer, and perform well in today’s tough market. We know it’s a careful balancing act between choosing the right materials, designing things carefully, and making them very well. This is what’s needed for the new and changing electrical machines of today.

Permeability is a measure of how easily a material can support the formation of a magnetic field within itself. At Sino, the precise composition of our laminated soft iron and our meticulous manufacturing processes are all geared towards maximizing this crucial permeability, giving your designs the magnetic muscle they need.

1

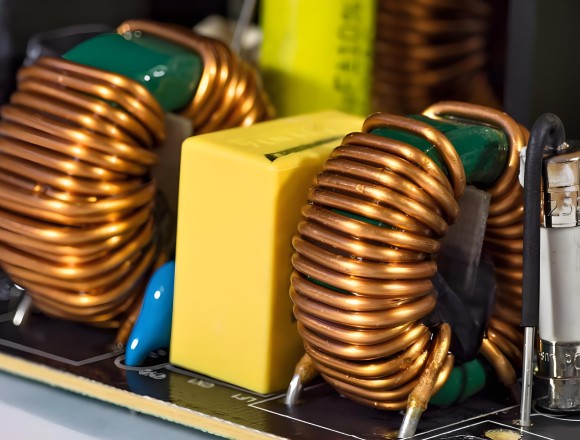

You need to efficiently transfer energy from one coil of wire (the primary) to another (the secondary) using a magnetic field. A high-permeability core means your transformer can be smaller, lighter, and more effective. Sino’s cores ensure that this magnetic handshake between coils is as firm as possible.

2

These components store energy in a magnetic field. A high-permeability core allows you to achieve a desired inductance value with fewer turns of wire. Fewer turns mean less copper, lower resistance, and again, a smaller, more efficient component.

3

These devices rely on strong magnetic fields to either produce motion (motors) or generate electricity (generators). A laminated soft iron core with high permeability amplifies the magnetic field created by the current-carrying coils, leading to more torque in a motor or more voltage from a generator, all for the same amount of input current or mechanical effort.

So, you can see that a laminated soft iron core is more than just a chunk of metal. It’s a carefully engineered solution. And at Sino, we take that engineering to the next level. It’s not just about having the right materials; it’s about what you do with them.

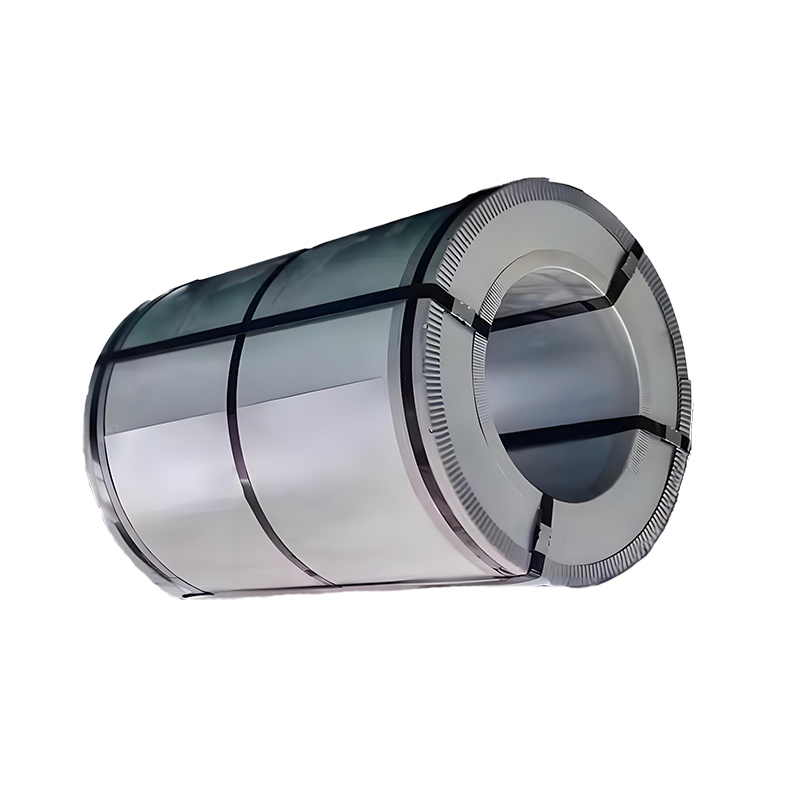

We source high-grade laminated soft iron, typically silicon steel with specific properties tailored for low losses and high permeability. Our incoming material inspection is rigorous – if it doesn't meet our specs, it doesn't make it to the factory floor.

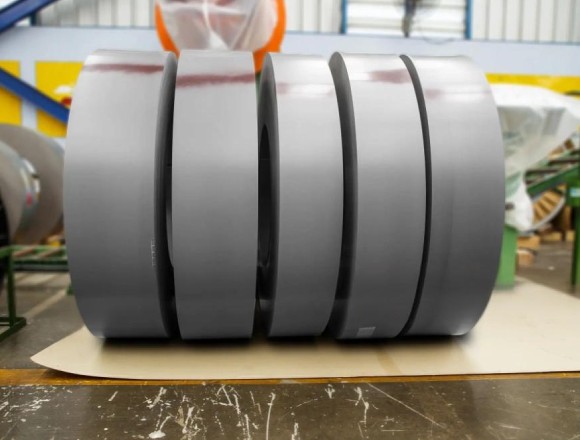

Our advanced stamping and laser cutting technologies ensure dimensional accuracy and clean edges, minimizing burrs that could compromise insulation and increase losses. Whether it’s an E-I lamination, a toroidal shape, or a custom profile, precision is paramount.

We employ sophisticated coating techniques to ensure a consistent, durable barrier that effectively stops eddy currents in their tracks, yet is thin enough not to significantly reduce the "stacking factor" (the amount of iron in the core volume).

After stamping, internal stresses can build up in the iron, which can mess with its magnetic properties. Our carefully controlled annealing processes relieve these stresses, optimizing the material's permeability and reducing hysteresis losses even further.

Whether it's interlocking laminations, riveting, bonding, or welding (for specific scenarios), the way the laminations are stacked and secured is crucial for the core's final performance and mechanical integrity. Our skilled technicians and automated systems ensure tight, uniform stacks that minimize air gaps and maximize magnetic efficiency.

At every step, from raw material to finished core, we implement stringent quality checks. We test for magnetic properties, dimensional accuracy, insulation integrity, and mechanical strength. Our commitment is to deliver a laminated soft iron core that you can trust, every single time.

At Sino, what makes us good isn’t just our materials. It’s also our smart ways of designing and making our products. We are always working to make these better, so our cores perform great, are a good value for the money, and can be trusted to work for a long time for our motor-making customers around the world.

Our studies show that it’s very important to control how thick the layers are to lower the eddy current losses. While making the layers thinner (down to 0.18–0.23 mm for high-frequency jobs) greatly reduces these losses, it also makes them harder to build because it’s tricky to handle and cut very thin materials. We’ve bought special tools and created new methods to handle these problems. This lets us make super-thin layers for tough jobs like EV traction motors and high-frequency transformers.

The stacking factor is a number that tells you how much of the core is actual magnetic material compared to its total size. It’s usually between 0.92 and 0.97. We are always trying to make this number higher by using better coatings. Our inorganic phosphate and organic hybrid coatings are made to make the interlaminar gaps (gaps between layers) as small as possible and the insulation thinner. This gives more room for the magnetic field to work and makes the core perform better.

We make cores in different shapes, and each shape is good for different things:

Our team helps customers pick the best shape for what they need, finding the right balance between performance, price, and how easy it is to make.

Getting the size of the core’s window and legs just right is very important. It helps balance how much copper wire can fit (copper fill factor), how well it cools down, and the strength of the magnetic field (magnetic flux density). We use smart computer programs to look at many different design options and find the best ones. Doing this can make the electrical machines much more efficient by making sure the wires are placed well and heat can escape easily.

We are looking into using Additive Manufacturing (AM), also known as 3D printing, to make early test versions of our cores. Studies show that methods like binder jetting and laser powder bed fusion can be used to print complex laminated soft iron cores right on the spot, with magnetic properties made just for a specific job. Making lots of them this way is still hard and expensive. But AM gives us amazing freedom to create special, high-performance core designs when we are making early test versions (prototypes).

We know our customers have different budgets to work with. We use a method called life-cycle cost analysis (LCCA) to show why spending more money at the start on better materials and building methods is a good idea. The money saved over time from using less energy and needing fewer repairs often makes up for the higher price at the beginning. This makes it a great deal in the long run.

We care about the environment and try to use sustainable methods. More and more, people are using recycled electrical steel and creating manufacturing systems where waste is reused. We make sure our work has as little impact on the environment as possible, and our products are designed to be recycled, following international environmental rules. With the right heat treatment (re-annealing), recycled materials can work just as well as new ones.

The versatility of the laminated soft iron core means you'll find them, or the lamination stacks we produce for them, in an astonishing array of scenarios. At Sino, we cater to them all:

From the behemoths in electrical substations stepping down high-voltage power for your neighborhood, to the tiny transformers in your phone charger or audio equipment, our laminated soft iron cores are essential for efficient voltage conversion.

Whether it's the motor powering your washing machine, the industrial motor driving a factory conveyor belt, the traction motor in an electric train, or the delicate servo motors in robotic arms, Sino's lamination stacks form the heart of these machines, ensuring high torque and efficiency.

From massive generators in power plants (hydro, thermal, nuclear) to smaller backup generators and those in wind turbines converting kinetic energy into electricity, our laminated soft iron cores are crucial for maximizing energy conversion.

Used in power supplies to smooth out current, in filters to block unwanted frequencies, and in resonant circuits, these components rely on the predictable and high-performance characteristics of Sino's laminated soft iron materials.

For devices that create linear motion or switch electrical circuits using magnetism, our cores provide the focused magnetic force needed for reliable operation.

We believe in backing up our claims. While specific performance data will vary based on the exact grade of laminated soft iron and core design, the principles are well-established.

Conceptual Comparison: Why Laminated Soft Iron Wins

Feature | Solid (Non-Laminated) Common Iron Core (AC) | Sino’s Laminated Soft Iron Core (AC) | The Sino Advantage |

Eddy Current Losses | Extremely High | Very Low | Precision, ultra-thin laminations with superior insulation dramatically cut current paths. |

Hysteresis Losses | Moderate to High | Low | Premium “soft” magnetic material (e.g., silicon steel) with optimized annealing. |

Magnetic Permeability | Good | Excellent | High-purity materials and stress-relief annealing ensure maximum flux concentration. |

Overall Efficiency | Poor | Excellent | Synergistic reduction in all major loss types, boosting device performance. |

Operating Temp. | Can be Dangerously High | Significantly Lower | Less energy wasted as heat means cooler operation and longer device lifespan. |

Material Grade | Often Basic Iron | Specialized Silicon Steel Grades | Sino selects materials specifically for magnetic applications. |

Manufacturing | Simple Casting/Machining | Complex Stamping, Coating, Annealing, Stacking | Sino’s advanced processes unlock the material’s full potential. |

When you choose Sino, you’re not just buying a component; you’re investing in decades of specialized experience, cutting-edge manufacturing capabilities, and an unyielding commitment to quality. We understand that the performance of your final product often hinges on the quality of its core components, and we take that responsibility seriously.

Whether you need standard E-I laminations by the ton, intricately shaped custom laminated soft iron cores for a groundbreaking new motor design, or expert advice on selecting the optimal laminated soft iron material for your specific scenario, our team is ready to collaborate. We thrive on challenges and are dedicated to helping you achieve superior efficiency, reliability, and performance in your electrical and electronic devices.

Don’t let energy losses sap your product’s potential. Let Sino provide the high-performance laminated soft iron core that will power your innovations. Reach out to us today, and let’s discuss how we can help you build a more efficient and powerful future, one precisely engineered lamination stack at a time. We’re not just making parts; we’re energizing progress.

Note: To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.

To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.