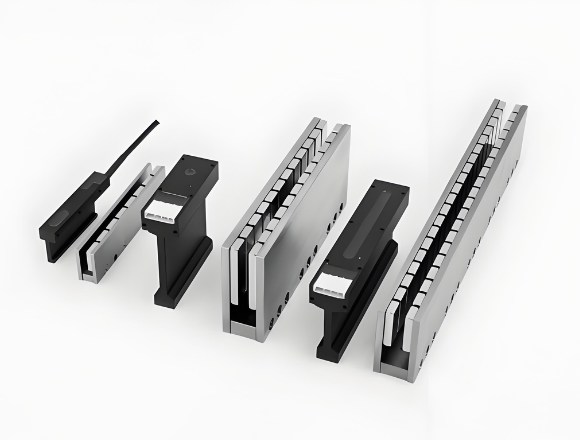

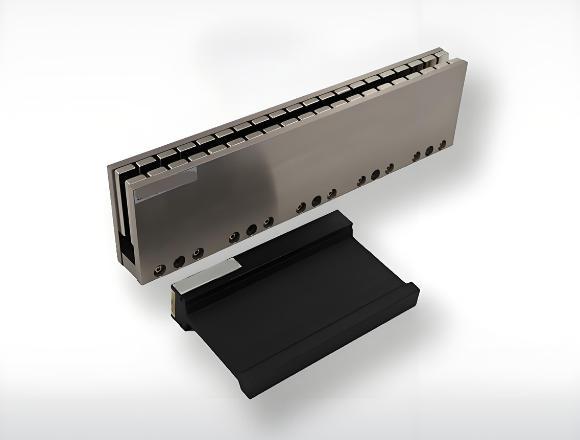

Let Sino's Lamination Stacks Empower Your Project!

To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.

To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.

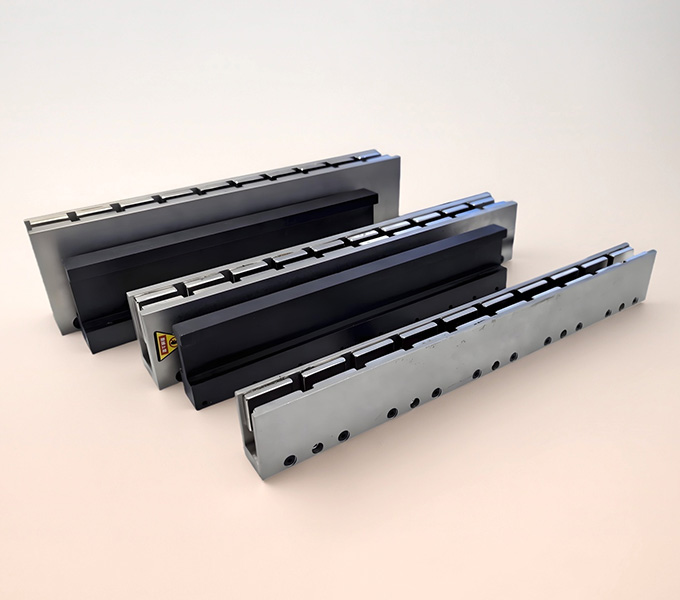

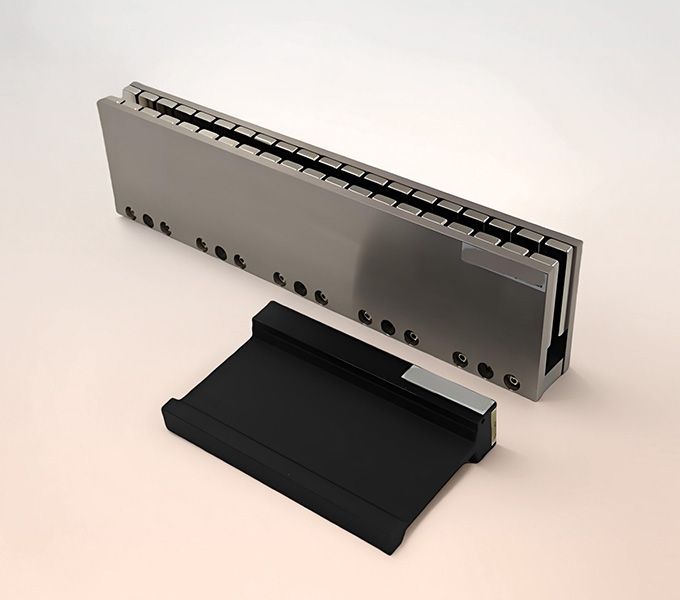

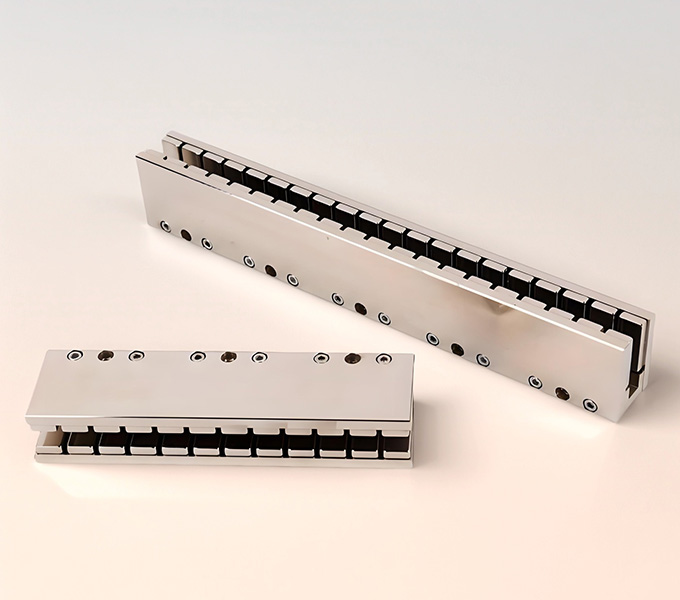

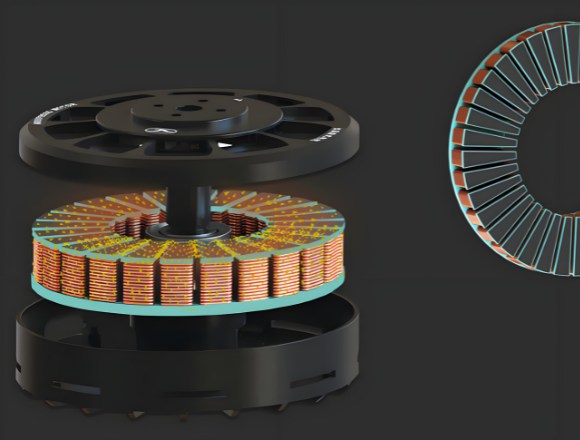

Sino concentrates on the careful production of linear motor stator core laminations. Our commitment is to deliver laminations that not just meet yet surpass the rigorous demands of contemporary linear activity applications, guaranteeing ideal performance, very little pressure surge, and prolonged operational life. Call Sino to experience the benefits our lamination heaps can bring to your Linear Electric motor!

The stator core lamination is the magnetic heart of any type of linear motor, straight affecting its drive generation, performance, and dynamic reaction. Its production accuracy is paramount.

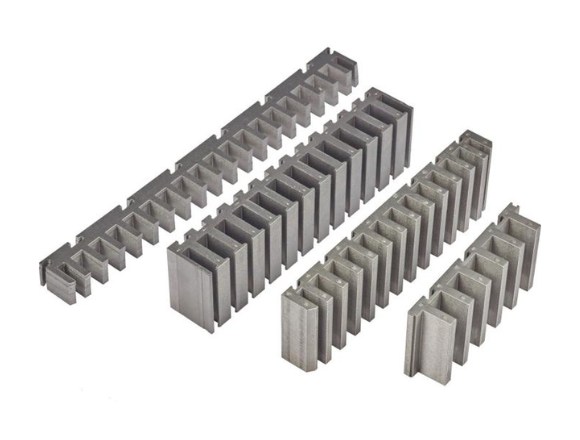

Also minute variances in lamination geometry or product residential properties can cause substantial efficiency degradation, including increased force surge, greater core losses, and raised sound and vibration. For example, research studies have revealed that improving lamination dimensional precision to within ± 10 μm can reduce pressure ripple by as much as 30%, leading to smoother motion and improved accuracy, especially essential in applications like semiconductor wafer phases.

On the other hand, blemishes such as extreme burr elevation (> 20 μm) can increase complete iron loss by up to 8% as a result of local eddy currents and interlaminar shorting. In a similar way, monotony variances going beyond 15 μm are directly associated with raised sound and resonance levels (up to 4 dB( A) greater), originating from uneven air gaps and fluctuating magnetic pressures.

We at Sino meticulously select our raw materials, often working with grades like M-19, M-27, or even more specialized NGO (Non-Grain Oriented) or GO (Grain Oriented) electrical steels, depending on your specific performance targets and operating frequencies. We don’t believe in a one-size-fits-all approach. We’ll consult with you to understand your operational scenario – be it a high-frequency, high-precision wafer stage or a heavy-duty industrial actuator – to recommend and utilize the optimal material for your linear motor stator core laminations.

To combat hysteresis loss, the electrical steel we select for Sino’s linear motor stator core laminations boasts several key properties:

Think of permeability as how “welcoming” a material is to magnetic fields. High permeability means the iron core can easily channel and concentrate the magnetic flux, leading to a stronger magnetic field for a given amount of electrical current in the windings. This translates to more force, or the ability to achieve the same force with less current (and therefore, less copper loss in the windings!)

Coercivity is a measure of how “stubborn” a material is to being demagnetized. A material with low coercivity snaps back and forth magnetically with minimal fuss and energy loss. This directly reduces hysteresis losses.

Even within a single lamination, higher material resistivity helps to further discourage those mini eddy currents we talked about earlier. Adding silicon to iron (which is why it’s often called silicon steel) is a common way to boost this resistivity without wrecking its magnetic goodness.

What’s the bottom line for you, the designer or user of linear motors? When you choose linear motor stator core laminations from Sino, you’re not just buying stamped steel; you’re investing in performance, reliability, and efficiency.

1

By dramatically slashing eddy current and hysteresis losses, our laminations ensure that more of the electrical power you feed into the motor gets converted into useful mechanical work (force and motion). This means lower energy consumption and operating costs.

2

Lower core losses mean the motor’s magnetic field can build up and change more rapidly. This gives you snappier acceleration, quicker settling times, and overall better responsiveness – crucial for applications like high-speed automation or precision positioning systems.

3

With a highly efficient magnetic circuit, thanks to Sino’s top-tier linear motor stator core laminations, your motor can generate more force for its size, or you can achieve your target force with a more compact design.

To give you a more concrete idea, here’s a peek at what good looks like. The exact specs will vary based on the specific grade of electrical steel and your requirements, but this gives you a general sense:

Property | Sino’s Target Characteristic | Example Material (e.g., SinoGrade M250-35A) | Why This Delivers for You |

Lamination Thickness | Ultra-Thin (e.g., 0.20mm, 0.35mm, 0.50mm) | 0.35 mm | Drastically slashes eddy current paths for lower losses |

Electrical Resistivity | Maximized for the Grade | Approx. 50 µΩ·cm (for silicon steel) | Chokes off internal eddy currents within each lamination |

Max Core Loss (W/kg) | Minimized (e.g., @ 1.5T, 50Hz or 1.0T, 400Hz) | < 2.5 W/kg @ 1.5T, 50Hz | Directly translates to higher motor efficiency & less heat |

Permeability (Relative) | High & Consistent | > 1500 (µr) | Enables stronger magnetic fields, more force, better control |

Insulation Coating Type | Application-Specific (e.g., C5, SINO-Coat+) | C-5 Organic or SINO-Coat+ (High-Temp Inorganic) | Ensures robust inter-laminar resistance, withstands temps |

Stacking Factor | High (typically >95%) | > 96% | More iron, less airgap in the stack for better magnetic performance |

Burr Height | Extremely Low (<0.02mm typical) | < 0.015mm | Prevents insulation damage and inter-laminar shorting |

(Note: Specific values are illustrative and depend on material grade and testing conditions. Sino can provide detailed datasheets for specific materials and lamination stacks.)

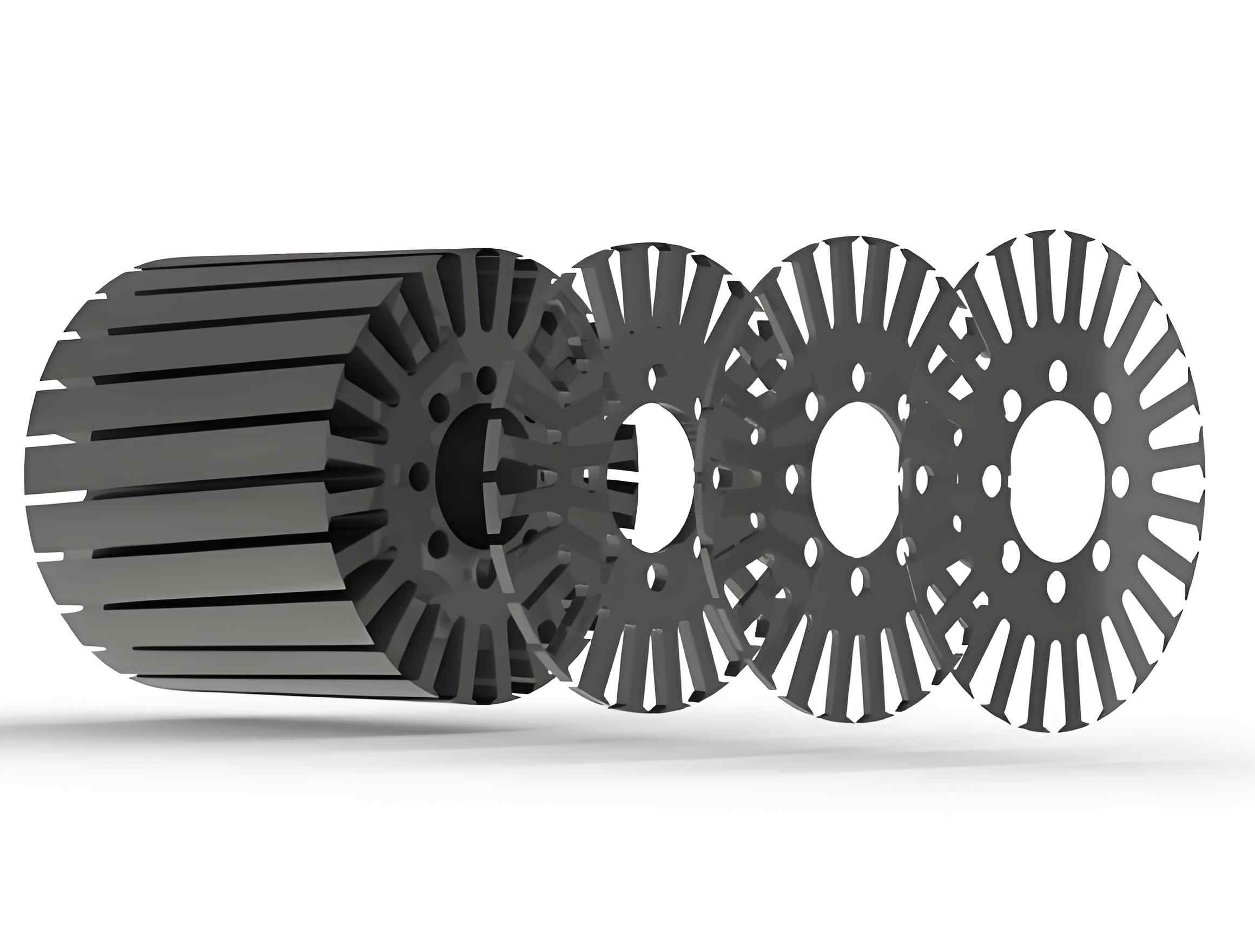

The journey of a Sino lamination involves several exacting steps:

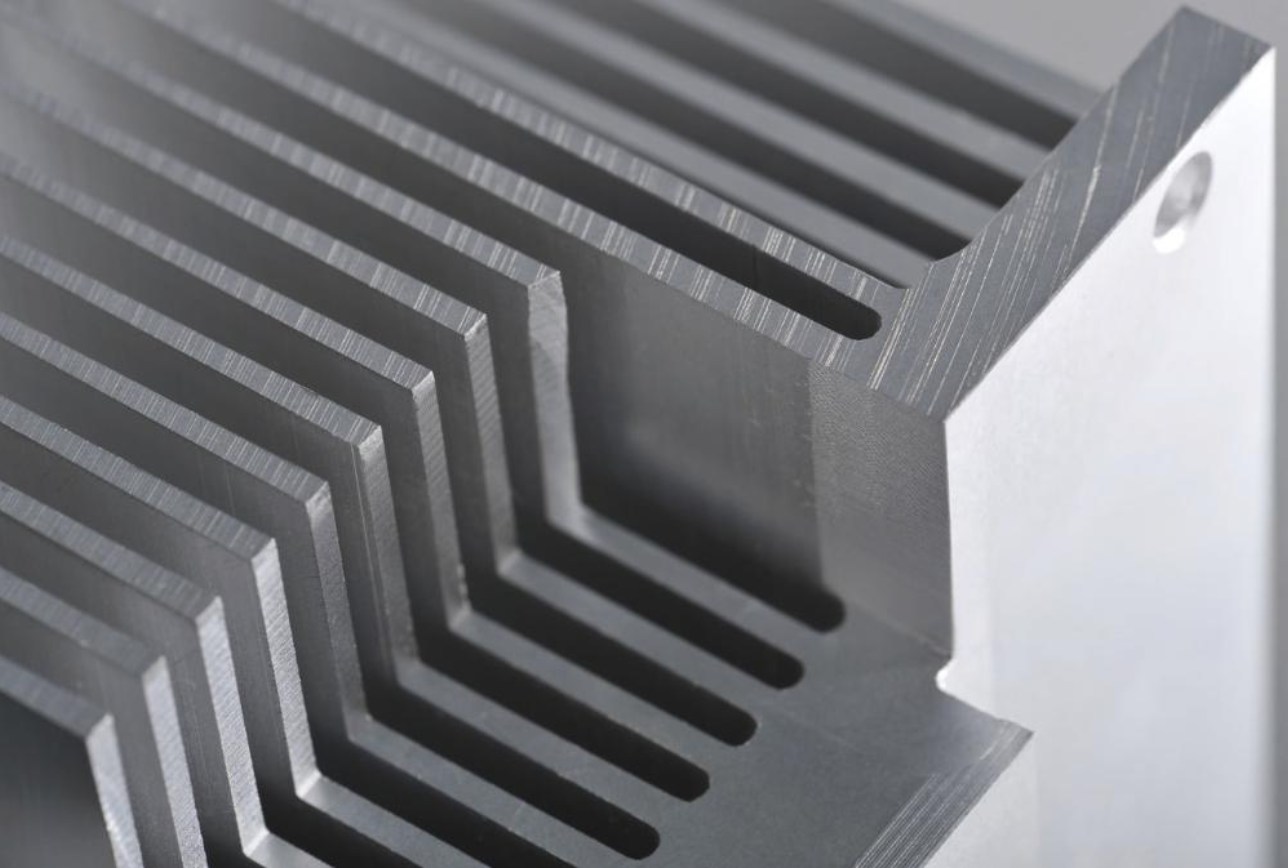

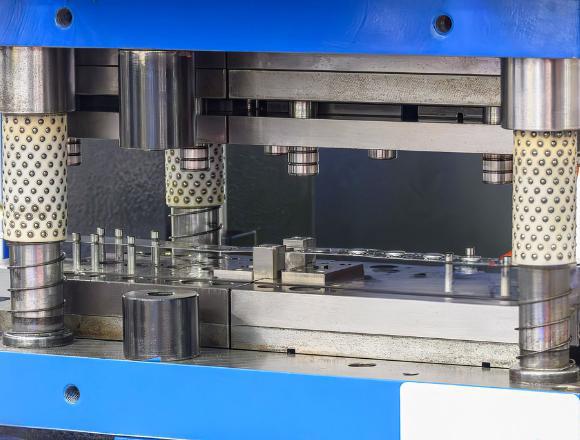

We employ high-speed, high-precision stamping presses with meticulously maintained dies, or advanced laser cutting systems for complex geometries or rapid prototyping. Our goal is to produce laminations with incredibly tight dimensional tolerances and clean edges. Sloppy cutting can lead to burrs.

Burrs are tiny, sharp protrusions of metal left on the cut edge of a lamination. These little villains can be a huge problem. If they’re big enough (>20 μm), they can pierce the delicate insulation layer between laminations when the stack is compressed. This creates an electrical short circuit, effectively undoing all the good work of laminating in that spot! At Sino, our tooling is top-notch, and we often incorporate secondary deburring processes to ensure burr heights are minimal (<10 µm), well within industry standards like those specified by ASTM A976.

The insulation coating (often designated as C-3, C-5, or C-6, each with different properties for adhesion, temperature resistance, and dielectric strength) must be uniformly applied and robust enough to withstand the pressures of stacking and the operating environment of the motor. We ensure our coatings provide excellent inter-laminar resistance.

Healing procedures are exactly managed. C3 layers are generally cured at 180– 220 ° C, while C5 and crossbreed coatings may call for multi-stage curing at greater temperature levels (e.g., 150 ° C pre-bake, 350 ° C last remedy) to attain complete crosslinking and inorganic network development.

The stamping or cutting process, no matter how precise, introduces mechanical stresses into the electrical steel. These stresses can mess with the material’s magnetic properties, increasing coercivity and, consequently, hysteresis losses. For many high-performance linear motor stator core laminations, especially those from cold-rolled electrical steels, we perform a stress-relief annealing cycle. This involves carefully heating the laminations in a controlled atmosphere furnace (750-800°C for 1-2 hours) to relax these stresses and restore the material’s optimal magnetic characteristics.

Once the individual laminations are perfect, they need to be stacked into a core. This isn’t just a random pile! Alignment is critical. We utilize various techniques:

Less energy wasted as heat means your motors run cooler. This can translate to:

A well-built, efficiently operating motor is often a quieter motor. Solid cores or poorly made laminated cores can sometimes contribute to unwanted noise due to magnetostriction effects being exacerbated by losses. Our precision stacks help minimize that.

At Sino, we don’t just manufacture linear motor stator core laminations; we partner with you to optimize your linear motor designs. Whether you’re developing a brand-new, cutting-edge system or looking to enhance the performance of an existing motor, our team is ready to collaborate.

From simple shapes to complex, multi-part stator segments.

Guidance on selecting the ideal electrical steel for your frequency, flux density, and loss targets.

We can support your project from initial concept through to full-scale manufacturing.

Our commitment to precision and quality control is embedded in every lamination stack we produce.

The world of linear motors is dynamic and demanding. Don’t let substandard stator cores hold you back. Elevate your motor performance with linear motor stator core laminations from Sino – where precision engineering meets real-world power.

Ready to discuss how Sino can help you achieve your next performance breakthrough? Get in touch with us. Let’s talk Core Laminations – the kind that power the future.

Note: To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.

To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.