Building Rock-Solid Cores & Embracing the Sound of Silence

Beyond just electrical benefits, the way a motor feels and sounds is increasingly important, especially in consumer-facing products or precision machinery. Nobody wants a whining EV or a clattering industrial robot. Motor lamination bonding delivers huge advantages here, too.

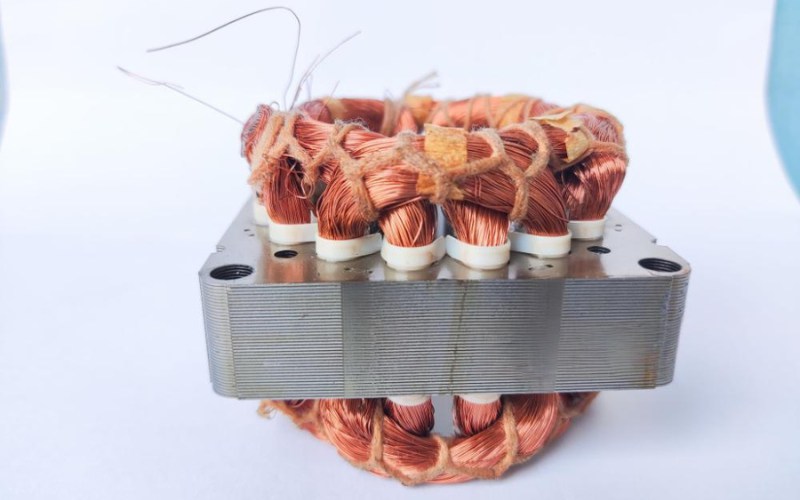

When Sino bonds a lamination stack, we’re essentially creating a single, solid, monolithic unit.

- Superior Stiffness & Stability: Instead of individual plates held at a few points, the entire stack acts as one. This gives it incredible stiffness and dimensional stability. This is critical for high-speed motors where even tiny imbalances or flex can lead to catastrophic failure or, at best, poor performance. A bonded core maintains its precise geometry even under high loads and speeds.

- NVH (Noise, Vibration, Harshness) Reduction: This is where you hear the difference. Loose laminations, or those that can vibrate against each other (a common issue with some mechanical fastening), are a prime source of acoustic noise. It’s like a deck of cards rattling versus a solid block of wood. Bonded cores inherently dampen vibrations. The adhesive layer acts like a tiny shock absorber between each lamination, significantly reducing that annoying hum or whine.

Designing Smarter, Not Just Harder: Unleashing Flexibility & Taming Heat

The advantages don’t stop there. Motor lamination bonding actually empowers engineers to be more creative and efficient with their motor designs.

- More Power, Less Space: Because adhesives create a bond over the entire surface, you don’t need to allocate space for bulky interlocking features or worry about the heat-affected zones of welds that might compromise material properties. This means designers can often pack more active magnetic material (the electrical steel) into a given motor volume. The upshot? You can get more power out of a smaller motor or make existing motor designs more compact without sacrificing performance. This is a massive win for scenarios like electric bikes or portable power tools where every gram and cubic centimeter counts.

- Better Thermal Pathways: “Won’t a layer of adhesive trap heat?” That’s a fair question! But modern engineering adhesives, the kind Sino meticulously selects for motor lamination bonding, can be formulated with thermally conductive fillers. These smart adhesives don’t just bond; they can actually help to conduct heat away from the hottest parts of the core out to the motor housing more effectively than the tiny air gaps that might exist in a mechanically stacked core. Better thermal management means the motor can run harder for longer, or its overall lifespan can be extended because it operates at cooler, less stressful temperatures.

Why Sino’s Motor Lamination Bonding Makes Excellent Financial Sense

Bonding sounds technically superior. But what about the cost? It’s true that the upfront material cost of specialized adhesives and the precision application process might seem higher than, say, just stamping and interlocking. However, when you look at the total cost of ownership and the overall system benefits, motor lamination bonding often comes out way ahead, especially when you partner with an experienced manufacturer like Sino.

- Lifetime Energy Savings: As we discussed, higher efficiency means lower electricity bills. For motors that run continuously or frequently, these savings compound significantly over time.

- Enhanced Reliability & Reduced Warranty Claims: A stiffer, more stable, cooler-running motor is a more reliable motor. Fewer vibrations mean less wear and tear on bearings and other components. This translates to longer operational life and fewer breakdowns, which means happier customers and lower warranty costs for the motor or equipment manufacturer.

- Streamlined Manufacturing Potential: While the bonding process itself requires precision, it’s also highly amenable to automation. At Sino, we’ve invested in state-of-the-art automated dispensing and curing systems. This ensures consistent quality, high throughput, and can ultimately be more cost-effective at scale than some labor-intensive manual or semi-automated traditional methods.

- Enabling Premium Products: Sometimes, the benefit isn’t just about saving money, but about making more money by enabling a premium product. The quietness, the efficiency, the compactness – these are all features that customers are often willing to pay more for.

Here’s a quick look at how Sino’s bonding stacks up:

Feature | Sino’s Motor Lamination Bonding | Traditional (Welding/Riveting/Interlocking) |

Eddy Current Control | Excellent (Uniform, robust insulation) | Fair to Poor (Risk of shorts, coating damage) |

Mechanical Integrity | Superior (Monolithic, high stiffness) | Good (Localized joints, potential for looseness) |

NVH Performance | Top-Tier (Inherent damping, solid structure) | Variable (Can be prone to vibration and noise) |

Design Freedom | High (Optimized material use, miniaturization) | Moderate (Compromises for joining features) |

Thermal Management | Very Good (Can use thermally conductive fillers) | Okay (Air gaps can hinder heat dissipation) |

Overall Motor Efficiency | Maximized | Often Compromised |

Long-Term Reliability | Enhanced | Standard |

Suitability for Automation | Excellent (Consistent, scalable process) | Moderate to Good |

Sino’s Commitment: Precision and Partnership in Motor Lamination Bonding

At Sino, motor lamination bonding isn’t just another service; it’s a specialty we’ve honed through rigorous research, investment in cutting-edge technology, and close collaboration with our clients. We understand that every motor design has unique requirements. That’s why we:

- Meticulously Select Materials: We work with leading adhesive suppliers to choose the optimal bonding agent for your specific scenario – considering operating temperature, chemical exposure, mechanical stresses, and desired thermal conductivity.

- Employ Precision Application: Our automated systems ensure the adhesive is applied with exacting consistency – the right thickness, perfect coverage, no gaps, no excess. This is crucial for both insulation and structural integrity.

- Control Curing Processes: Curing (the process that hardens the adhesive) is done under precisely controlled conditions of temperature and pressure to achieve the maximum bond strength and desired material properties.

- Implement Rigorous Quality Control: Every bonded stack that leaves Sino is subject to stringent quality checks. We verify bond integrity, dimensional accuracy, and electrical insulation to ensure it meets or exceeds your specifications.

- Partner with You: We don’t just take orders. We work with your design engineers to understand your goals. Perhaps you need to hit a specific efficiency target, reduce noise by a certain decibel level, or fit a motor into a tighter space. We can advise on how motor lamination bonding can help you get there.

Real-World Wins: Where Sino’s Bonded Stacks Make the Difference

The impact of high-quality motor lamination bonding is felt across countless industries:

- Electric Mobility (EVs, E-bikes, Scooters): Imagine your next EV gliding almost silently down the road, delivering exhilarating acceleration while maximizing its range. That quiet power and efficiency owe a significant debt to a perfectly bonded motor core, the kind Sino specializes in. Every extra mile squeezed from the battery is a win.

- Aerospace & Drones: Think about a critical surveillance drone that needs to stay airborne for the maximum possible duration, or a delivery drone carrying vital supplies. Lighter, more powerful motors, enabled by the design flexibility of bonded cores from Sino, translate directly to longer flight times or increased payload capacity.

- Industrial Automation & Robotics: In a busy factory, industrial robots and automated systems need to be workhorses – reliable, precise, and increasingly, energy-efficient. A critical pump, a conveyor system, or a robotic arm running cooler, quieter, and longer thanks to the superior thermal and mechanical properties of its Sino bonded motor core means less downtime and higher productivity.

- Renewable Energy: Wind turbines, for example, house massive generators. The efficiency and longevity of these generators are paramount. Bonded lamination stacks can contribute to both, ensuring more green energy is captured and maintenance cycles are extended.

- High-End Appliances: That premium washing machine that cleans your clothes without sounding like a jet engine? Or the high-efficiency air conditioning unit that keeps you cool without racking up a huge energy bill? Chances are, sophisticated motor design, including motor lamination bonding, is playing a key role.

Addressing Any Lingering Questions

Sometimes, engineers new to bonding might ask about the long-term durability of adhesives or repairability. Modern structural adhesives, like those Sino uses, are incredibly robust and designed to withstand harsh operating conditions, often outlasting other motor components. While it’s true that disassembling a fully bonded core is more challenging than a mechanically fastened one, the significant increase in reliability and operational life provided by bonding often makes repair a less frequent concern. The focus shifts from “easy to repair” to “seldom needs repair.”

The Future is Bonded, and Sino is Leading the Way

The evidence is clear: for manufacturers looking to push the boundaries of electric motor performance, motor lamination bonding is no longer a niche option but a mainstream path to excellence. It delivers superior efficiency, reduced noise and vibration, greater design freedom, and enhanced reliability.

At Sino, we’re more than just a supplier of lamination stacks. We are your partners in innovation. We bring the expertise, the technology, and the commitment to quality that turns the potential of motor lamination bonding into tangible results for your products. If you’re ready to build motors that are quieter, more powerful, more efficient, and more reliable, then it’s time to talk to Sino.

Let’s explore how Sino’s advanced motor lamination bonding solutions can elevate your next project. Contact us today!