Let Sino's Lamination Stacks Empower Your Project!

To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.

To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.

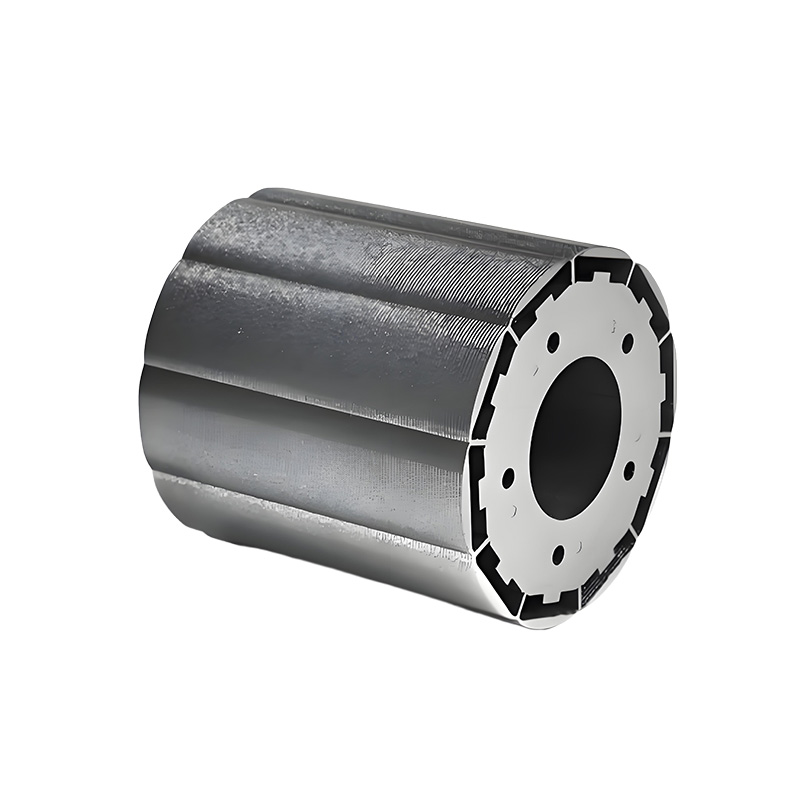

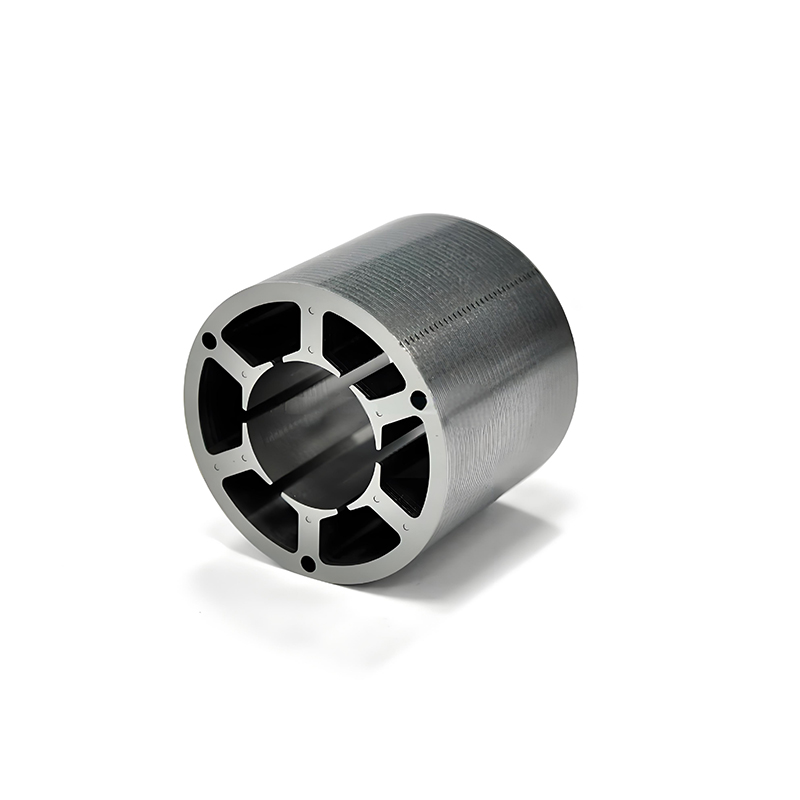

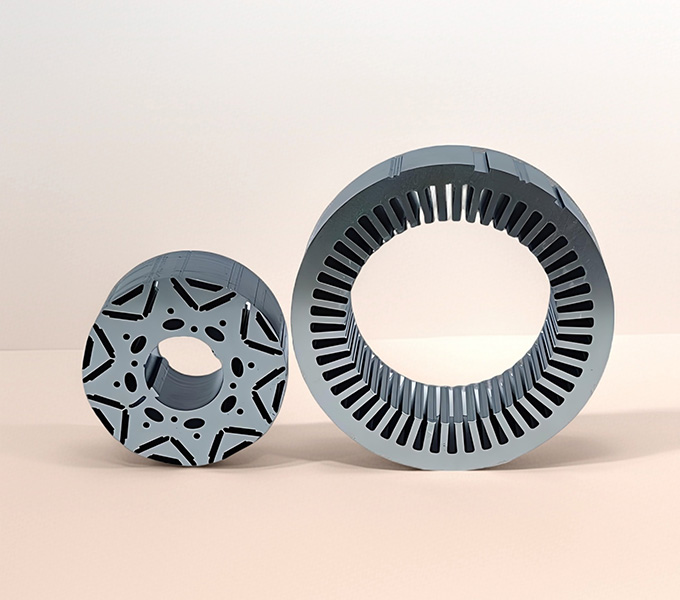

We are Sino, a top global maker of high-quality rotor lamination. We are helping to create the next wave of electric motors. We focus on careful engineering. We find new materials. And we use modern manufacturing. This makes us a partner that motor makers around the world trust. We know what different industries need. This includes the fast-growing electric vehicle (EV) market, heavy-duty industrial machines, and big renewable energy projects. Sino creates custom rotor lamination solutions. These solutions set new standards for how well motors work, how much power they have, and how long they last.

The choice of steel is absolutely fundamental. It directly dictates the magnetic personality of your rotor core (how easily it magnetizes, how much magnetic flux it can carry) and its electrical losses (from both hysteresis and those pesky eddy currents). Get this wrong, and you’re fighting an uphill battle from the start.

1

Adding silicon (Sino often works with grades containing up to 3-4%, sometimes more for specialized needs) to iron dramatically boosts its electrical resistivity. Higher resistivity means less room for eddy currents to flow. Silicon also helps to minimize hysteresis losses. At Sino, we source a range of grades (you might know them by designations like M19, M27, M350-50A, etc., where lower core loss numbers are king) to match diverse performance and budget requirements.

2

For those really demanding scenarios – aerospace actuators or high-performance racing motors where squeezing out every last bit of magnetic saturation is crucial – cobalt-iron alloys. They offer incredible magnetic flux density. While they are pricier and can be trickier to process, Sino has the experience to handle these advanced materials when your design calls for ultimate power density.

3

These are a bit more exotic. They have a non-crystalline, glass-like structure which leads to exceptionally low hysteresis losses, particularly at higher operating frequencies. They can be more brittle and costly, but for certain cutting-edge applications, they’re invaluable. Sino keeps an eye on these emerging material technologies.

These materials can cut energy loss by 70–80% compared to standard steel at high speeds. This makes them perfect for special uses, like in airplanes or advanced robots.

At Sino, we routinely produce laminations with thicknesses ranging from a delicate 0.1mm for ultra-high-frequency scenarios, through common sizes like 0.2mm, 0.35mm, and 0.5mm, up to 0.65mm or even 1mm for certain lower-speed, high-torque applications. For motors buzzing along at hundreds or even thousands of Hertz (think high-speed spindles or traction motors for EVs), we’ll almost certainly be guiding you towards the thinner end of the spectrum (e.g., 0.2mm or 0.35mm). For your standard 50/60 Hz industrial motors, a 0.5mm lamination might offer the best balance of performance and cost-effectiveness. And Sino’s precise coating application and stacking techniques aim to maximize this factor for any given thickness.

Illustrative Table (Sino’s General Observations):

Feature | Thinner Laminations (e.g., 0.20mm by Sino) | Thicker Laminations (e.g., 0.50mm by Sino) |

Eddy Current Loss | Significantly Lower | Higher |

Hysteresis Loss | Can be slightly higher | Generally Lower |

Sino’s Stamping Cost | Marginally Higher | Lower |

Overall Stacking Factor | Slightly Lower | Slightly Higher |

Ideal Frequency Range | High to Very High | Low to Medium |

At Sino, we offer a variety of insulation coatings tailored to different needs, often referred to by industry classifications like C3 (organic varnishes, good all-rounders), C5 (inorganic coatings, excellent for withstanding stress-relief annealing temperatures and providing good insulation), and C6 (often a thicker, more robust inorganic coating for the most demanding insulation requirements).

The chosen coating must be tough enough to withstand the shearing forces of the stamping process, the pressures of stacking, and the motor’s operating temperatures and vibrations without cracking, flaking, or losing its insulating properties. Sino’s quality control includes rigorous checks on coating adhesion and dielectric strength.

This is the workhorse method for high-volume production of rotor laminations, and Sino has invested heavily in state-of-the-art stamping presses and precision carbide tooling. A key challenge here is minimizing burrs. Excessive burrs can compromise the insulation, creating short-circuit paths between laminations and increasing losses. Sino’s meticulous tool design, regular maintenance schedules, and in-process quality checks are all geared towards producing virtually burr-free laminations.

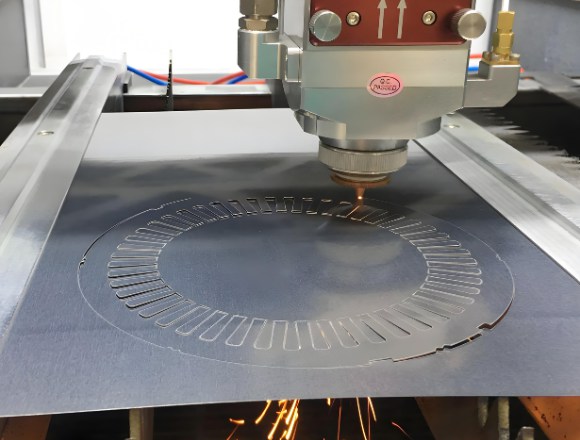

For prototypes, small batches, or incredibly complex lamination geometries, Sino also utilizes advanced laser cutting and Wire EDM (Electrical Discharge Machining). Laser cutting offers fantastic flexibility without the upfront cost of hard tooling and can be very precise. We carefully manage parameters to minimize the heat-affected zone (HAZ) at the cut edge, which can locally alter magnetic properties if not controlled.

Sino offers both stamping and laser cutting. This gives our customers flexibility.

The stamping or cutting process inevitably induces some mechanical stress in the steel. These stresses are bad news for magnetic performance, as they can increase hysteresis losses and reduce permeability. That’s why, for many high-performance rotor laminations, Sino incorporates an annealing step. This carefully controlled heat treatment relaxes the stresses in the material, effectively “healing” the magnetic properties and ensuring the steel performs as intended.

At Sino, we don’t just sell rotor laminations; we provide engineered solutions. We understand that every motor design has unique requirements.

From sourcing certified electrical steel to final inspection of the laminated rotor core, quality control is embedded in every step of our process. We utilize advanced metrology equipment to ensure dimensional accuracy, stack height consistency, and insulation integrity.

Whether you have a fully detailed print for your rotor core or just a concept, our engineering team is ready to collaborate. We can assist with design for manufacturability (DFM), material selection, and optimization to help you achieve your performance and cost targets.

Need a few prototypes to validate a new design? Or are you ready to ramp up to tens of thousands of units per month? Sino has the flexibility and capacity to support your project at every stage.

We see ourselves as an extension of your design team. We're here to provide technical support, share our expertise, and work together to overcome challenges.

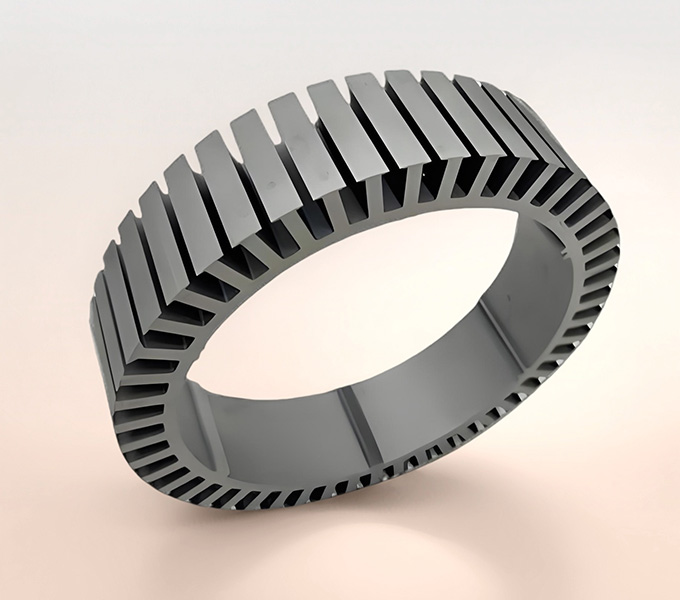

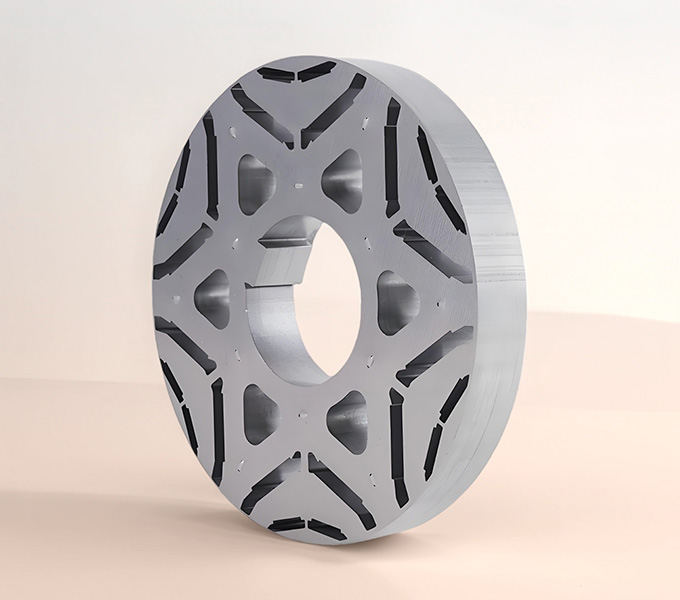

Once the individual laminations are ready, they need to be precisely stacked and securely joined to form the final laminated rotor core. Sino employs several techniques:

Sino is completely focused on quality. We have tough checks at every step of the process.

The journey to a superior electric motor – one that’s more efficient, more powerful, more reliable, and quieter – runs directly through high-quality rotor laminations and a meticulously assembled laminated rotor core. These components might be small, but their impact is enormous.

If you’re tired of compromising on motor performance due to subpar laminations, or if you’re looking for a manufacturing partner who truly understands the nuances of electrical steel and precision stacking, then it’s time to talk to Sino. Let us show you how our dedication to quality, our advanced manufacturing capabilities, and our deep understanding of rotor core technology can make a tangible difference to your products.

Don’t let eddy currents rob your motors of their potential. Contact Sino today for a consultation or a quote on your next rotor lamination project. Let’s build something powerful, together.

Note: To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.

To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.