Let Sino's Lamination Stacks Empower Your Project!

To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.

To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.

At Sino, we know the constant need for better efficiency, more power in a smaller size, and easier manufacturing in the electric motor world. As a top Chinese motor lamination maker, we are a leader in providing new solutions that meet the changing needs of motor manufacturers everywhere. Our skill in Segmented Stator Laminations is a key step forward, completely changing how electric motors are designed, made, and how well they work.

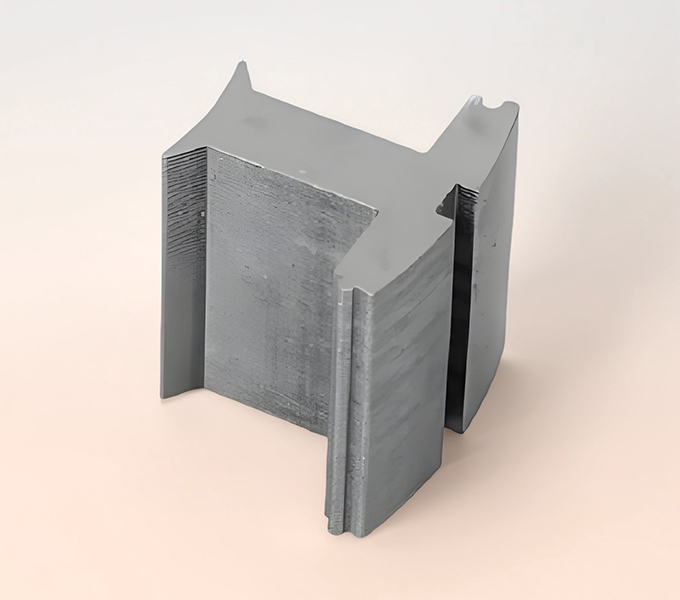

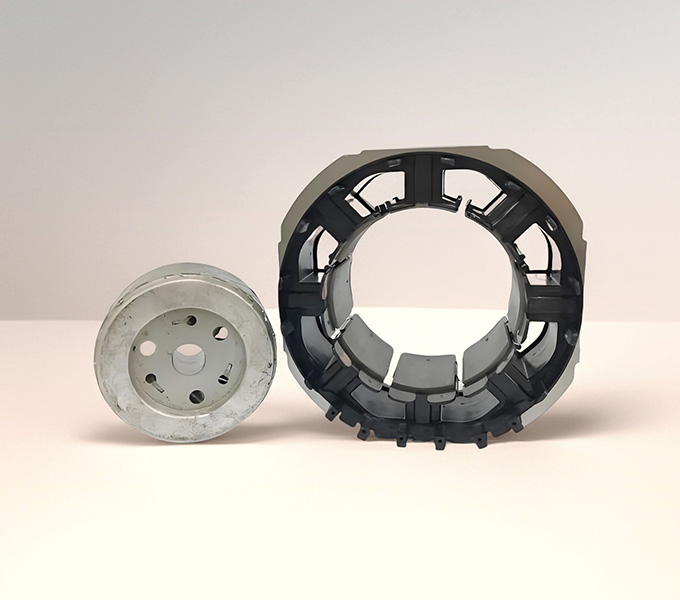

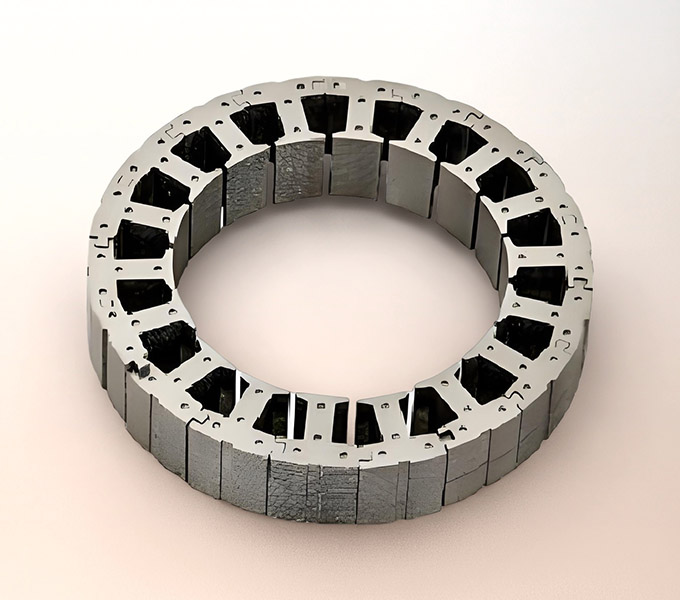

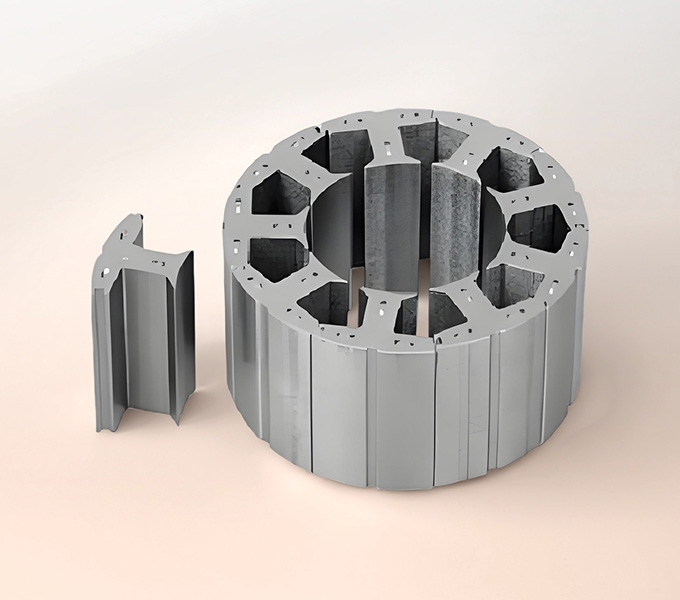

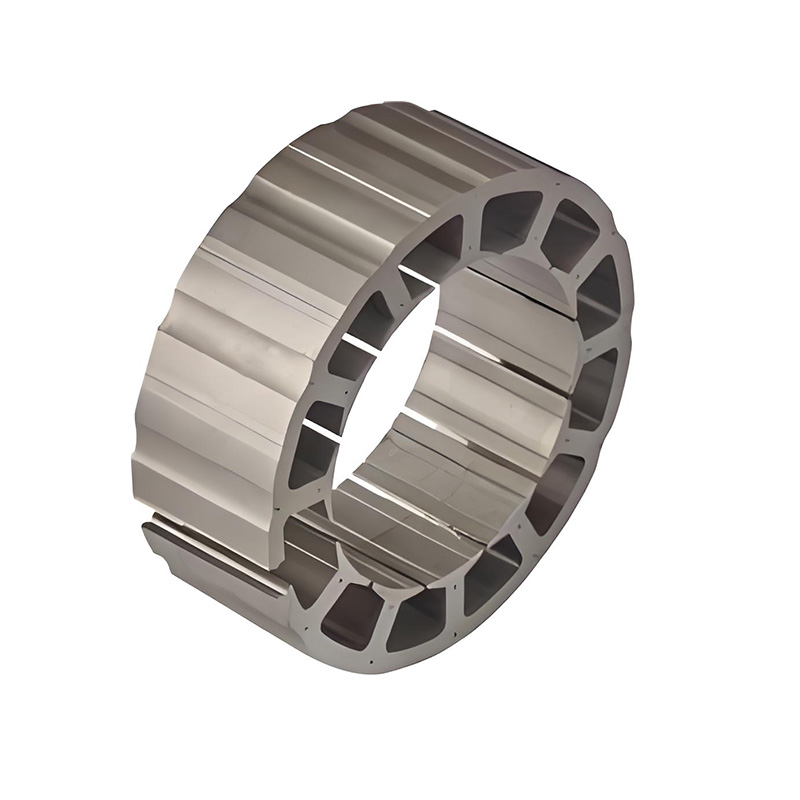

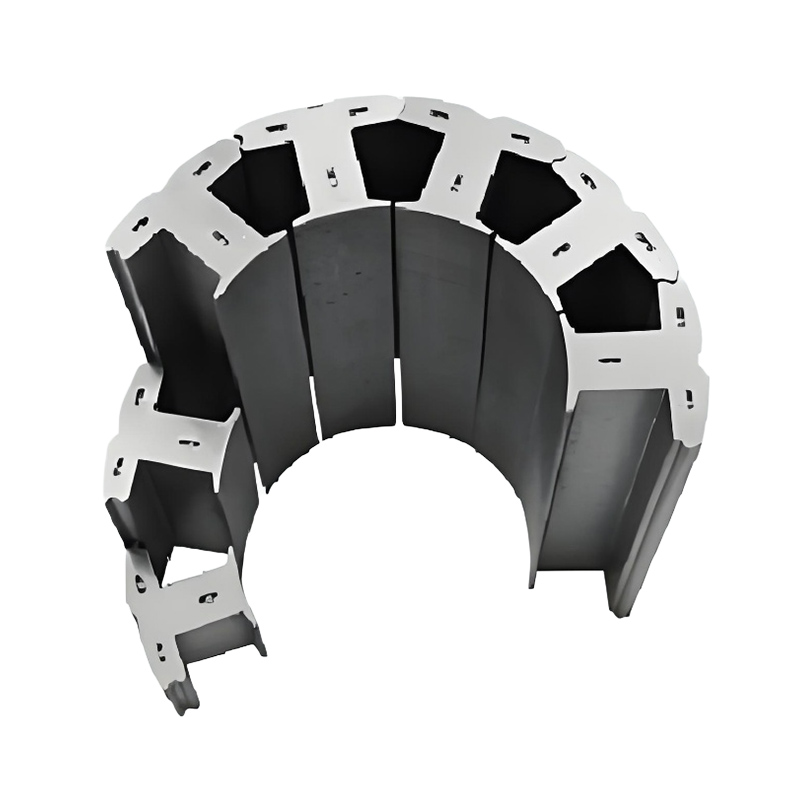

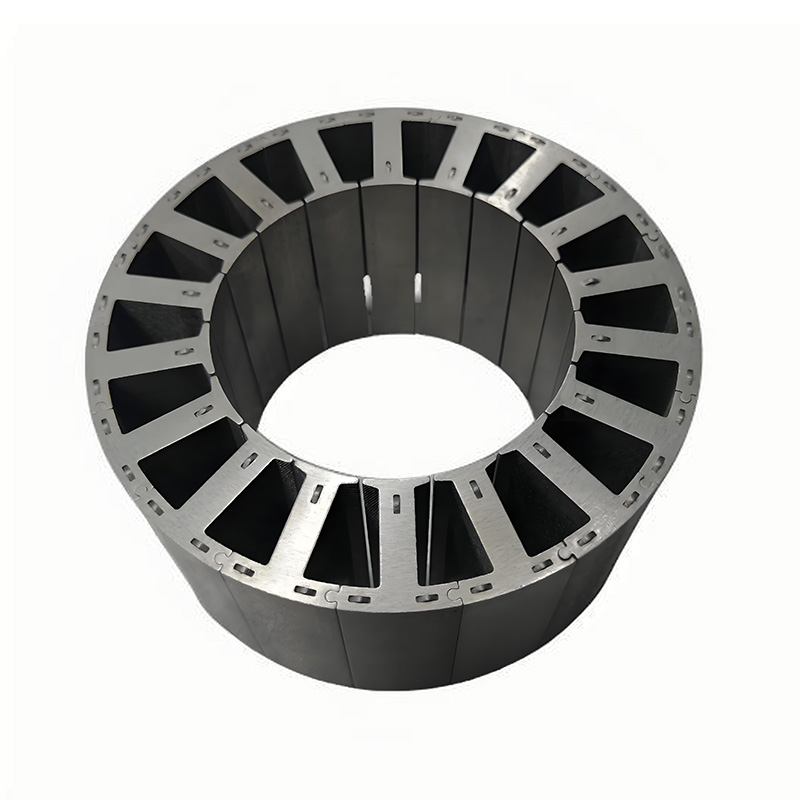

Segmented Stator Laminations are a new way to build the stator core of an electric motor. Unlike the usual full-ring laminations, which are stamped out as one solid ring, segmented stators are built from separate, curved pieces. Each piece, usually made of thin, coated electrical steel sheets stacked together, is carefully designed to get the best magnetic results and reduce wasted energy. These individual pieces are then put together with great accuracy to create the full stator core, often using clever interlocking or dovetail joints for strong mechanical support.

When we at Sino manufacture segmented stator laminations, we’re stamping out smaller, often geometrically simpler, individual pieces. This allows for much more efficient nesting of these shapes on the steel sheet. This reduction in scrap isn’t trivial; it can be quite significant, directly cutting down your material costs. That’s a direct boost to your bottom line and a nod to more sustainable manufacturing. We’ve seen clients in the appliance sector, constantly battling tight margins, find this benefit particularly compelling.

Sino’s segmented laminations are designed to work with a wide range of motor types and layouts:

Choosing the right way to segment the stator is a very important design choice. It depends on things like the motor’s size, its running speed, how much power it needs to produce, and how many will be made. Sino’s engineering team works closely with our customers to find the best lamination design, making sure the chosen layout gives top performance and is easy to make.

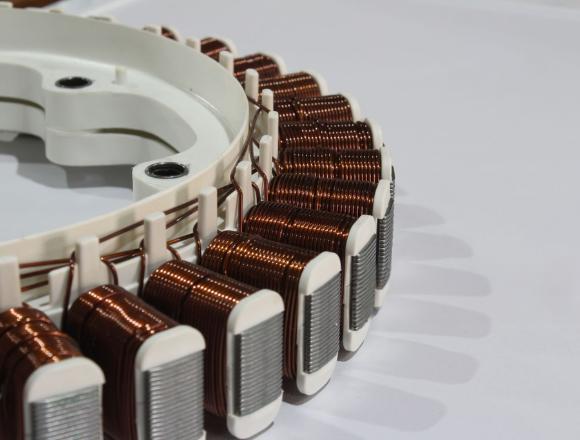

Anyone who’s dealt with motor manufacturing knows that winding copper coils into the narrow slots of a conventional, solid stator core can be a real pain. It’s often a fiddly, labor-intensive task, especially if you’re gunning for a high copper fill factor. A high fill factor means packing as much copper as possible into those slots, which is crucial for reducing electrical resistance and boosting motor efficiency. Trying to achieve this in a closed-slot, one-piece stator is like trying to thread a needle in the dark while wearing mittens.

Enter segmented stator laminations. Because you’re often dealing with individual teeth or segments before they’re assembled into the full stator, the winding process becomes dramatically simpler. Many segmented designs utilize open slots or allow for “tooth-winding” (also known as concentrated winding), where coils are wound directly onto individual stator teeth. This unprecedented access allows for:

1

Sino provides laminations precisely engineered to support these advanced winding methods, ensuring the segments fit together perfectly after your simplified winding process.

2

Winding individual segments is far more amenable to automated processes than trying to automate winding on a complex, bulky single-piece core. This can slash labor costs and improve consistency.

3

The parts of the coil that loop outside the active stator slots (the end-windings) don’t contribute to torque production but do contribute to resistance and copper losses. Concentrated windings on segments naturally lead to shorter end-windings. Less inactive copper means lower I²R losses and, you guessed it, better efficiency.

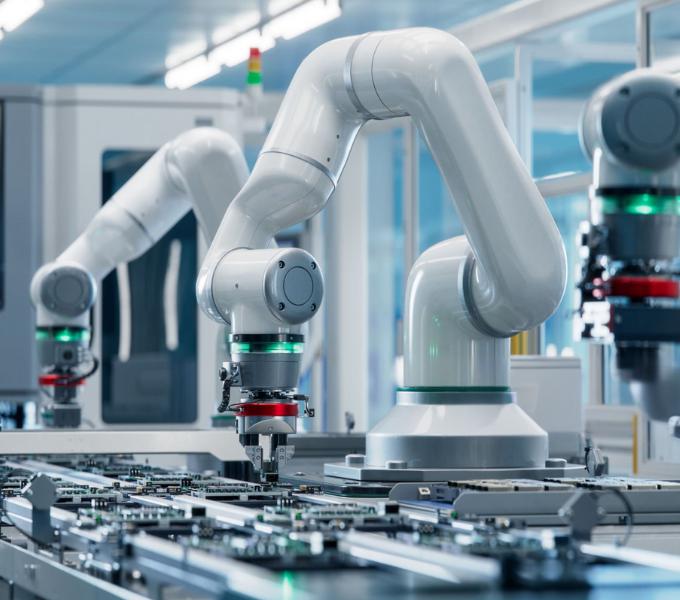

Sino’s factories have the latest technology to make, assemble, and fit segmented stator cores accurately.

Our stamping lines are made for the high accuracy needed for segmented laminations. We also use modern surface treatments, like dry lubricants (e.g., molybdenum disulfide-based coatings) and micro-texturing. These treatments, tested by companies like Bosch and Siemens, reduce friction during assembly, reduce sharp edges, and make the segmented stacks stronger. They also help the insulation stick better and lower the chance of layers separating when heated and cooled.

Putting together segmented stators is a tricky job that needs to be very accurate. Sino uses and keeps investing in advanced automation:

The basic building block of any great stator is the electrical steel. For segmented stator designs, certain types are preferred for their magnetic qualities and because they work well for complex shapes:

Good insulation between the steel sheets is very important to stop eddy currents and make sure the motor lasts a long time.

The benefits of segmented stator laminations directly translate into superior motor performance.

As we’ve touched on, higher copper fill factors and shorter end-windings mean lower resistive losses (I²R losses). Less energy wasted as heat means more energy doing useful work. This isn’t just a marginal gain; it can be the difference that pushes your product into a higher energy efficiency class.

Heat is the enemy of many electrical components, including motors. Segmented designs can inherently offer better thermal pathways. Sometimes, the small gaps between segments (if not detrimental magnetically) can even aid in air or liquid cooling. Moreover, because the windings can be more compact and efficient, they might generate less heat to begin with.

Want more power from a smaller package? Or the same power from a significantly lighter motor? Segmented stators help you get there. The improved copper fill and reduced losses mean you can push more current through for a given size, or achieve the same torque with a physically smaller motor. This is gold dust in scenarios like portable power tools, electric bikes, or any application where space and weight are at a premium.

Besides better efficiency and more power, segmented stators also improve other important motor features:

mechanically strong:

The modular nature of segmented stators opens up a playground for motor designers.

At Sino, we don’t just offer off-the-shelf solutions. We work with you to understand your specific motor design and performance targets. Our expertise in manufacturing segmented stator laminations means we can produce segments with the precise geometry, material properties, and tight tolerances your innovative designs demand.

To make it crystal clear, here’s how segmented stator laminations from Sino stack up against the old guard:

Feature | Conventional Stator (One-Piece) | Sino’s Segmented Stator Laminations | Source/Rationale & Sino’s Value |

Material Utilization | Lower (significant center scrap) | Higher (efficient nesting of segments) | General manufacturing principle; confirmed by industry studies (e.g., E. Bostanci et al. on manufacturing). Sino’s precision stamping maximizes this. |

Winding Process | More complex often manual or semi-auto | Simpler can be fully automated for many designs | Widely acknowledged (Hendershot & Miller, “Design of Brushless Permanent-Magnet Motors”). Sino laminations are designed for ease of winding. |

Copper Fill Factor | Typically 40-60% | Can exceed 70-80% with concentrated windings | Research like F. Parasiliti et al. (2005) on “High Fill Factor concentrated Windings.” Sino segments enable this. |

End-Winding Length | Generally longer | Can be significantly shorter | A direct result of concentrated windings. Less wasted copper. |

Thermal Performance | Can be challenging | Often improved due to winding/design | Better heat dissipation paths, lower intrinsic losses. |

Power Density | Standard | Potentially Higher | Achievable through better fill factors and thermal performance. |

Design Flexibility | More constrained | Greater modularity and design options | Allows for novel configurations and potentially easier scaling of motor families. Sino supports custom segment designs. |

Assembly | Simpler single piece core handling | More complex assembly of multiple parts | This is a trade-off, but the winding benefits often outweigh this. Sino’s high-tolerance parts ensure smooth assembly. |

Inter-segment Magnetic Gaps | None (solid core) | Small gaps require careful design & manufacturing | A key consideration. Sino’s precision minimizes these gaps and their impact. Research by N. Bianchi & S. Bolognani often delves into segmentation design criteria. |

Table information synthesized from common findings in electric motor design literature and Sino’s manufacturing expertise.

The performance of a segmented stator hinges on the precision of its components. Those inter-segment gaps, if not meticulously controlled, can indeed introduce unwanted magnetic reluctance (resistance to magnetic flux) or even localized eddy currents, potentially nibbling away at the performance gains. This is why at Sino, we’re obsessed with:

Our advanced stamping and manufacturing processes ensure that each segment is produced with exceptional dimensional accuracy. This means when you assemble them, they fit together snugly, minimizing air gaps.

We utilize high-quality electrical steels chosen specifically for their magnetic properties and suitability for your motor's operational demands. Our material knowledge helps in mitigating any potential negative effects from segmentation.

For many designs, we can incorporate interlocking features (like dovetails or other keyed shapes) into the laminations themselves. These not only aid in precise alignment during assembly but also enhance the mechanical robustness of the final stator core.

Cleanly cut laminations with minimal burrs are crucial for good stacking, reduced eddy current losses, and electrical insulation integrity. Sino's processes are geared towards delivering just that.

The beauty of segmented stator laminations is their versatility. If you need a motor that pushes the boundaries of performance, efficiency, or compactness, there’s a very good chance that a segmented design, built with top-quality laminations from Sino, is your answer.

EV motors need to be incredibly power-dense, highly efficient to maximize range, and offer excellent thermal performance. Segmented stators tick all these boxes. Many advanced EV traction motors now leverage segmented designs for these very reasons. Sino can supply the high-performance laminations that these demanding automotive scenarios require.

For modern factories with their armies of robots, or sophisticated logistics systems, the motors in these machines need to be compact, precise, and reliable. The ease of achieving high fill factors and tailored performance with segmented stator laminations makes them ideal for robotic joints, servo motors, and other actuators.

Large direct-drive wind turbine generators can be enormous. Manufacturing and transporting massive, single-piece stator cores is a logistical nightmare. Segmented approaches allow for the stator to be built in manageable sections, simplifying manufacturing, transport, and even on-site assembly. Sino has the capacity to produce large, precise segments for such green energy scenarios.

Consumers want quieter, more energy-efficient washing machines, dishwashers, dryers, and HVAC systems. Segmented stators can contribute to motors that run smoother, quieter (due to optimized magnetic design and winding patterns), and hit high energy ratings.

In scenarios where every gram counts and reliability is non-negotiable, the high power density and potential for enhanced fault tolerance offered by some segmented stator designs are invaluable. From unmanned aerial vehicles (UAVs) to specialized actuators, Sino can provide laminations meeting stringent quality and performance criteria.

Precision pumps, centrifuges, and scanning equipment often require motors with smooth operation and compact footprints. The design flexibility of segmented stators allows for optimization specific to these sensitive applications.

The primary consideration often cited is the increased complexity of the final stator assembly compared to simply handling a single-piece core. By providing segmented stator laminations manufactured to exceptionally high precision, with features that aid alignment, we significantly de-risk your assembly process. The upfront benefits in winding automation, material savings, and performance gains often far outweigh the slightly more involved assembly, which itself can be highly automated with modern robotics and fixturing.

Are you looking to:

If any of these ring true, it’s time to talk to Sino. Let our expertise in segmented stator laminations help you build better, smarter, and more competitive electric motors. Don’t let old manufacturing methods hold you back. Embrace the segments, embrace the future.

Note: To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.

To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.