Let Sino's Lamination Stacks Empower Your Project!

To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.

To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.

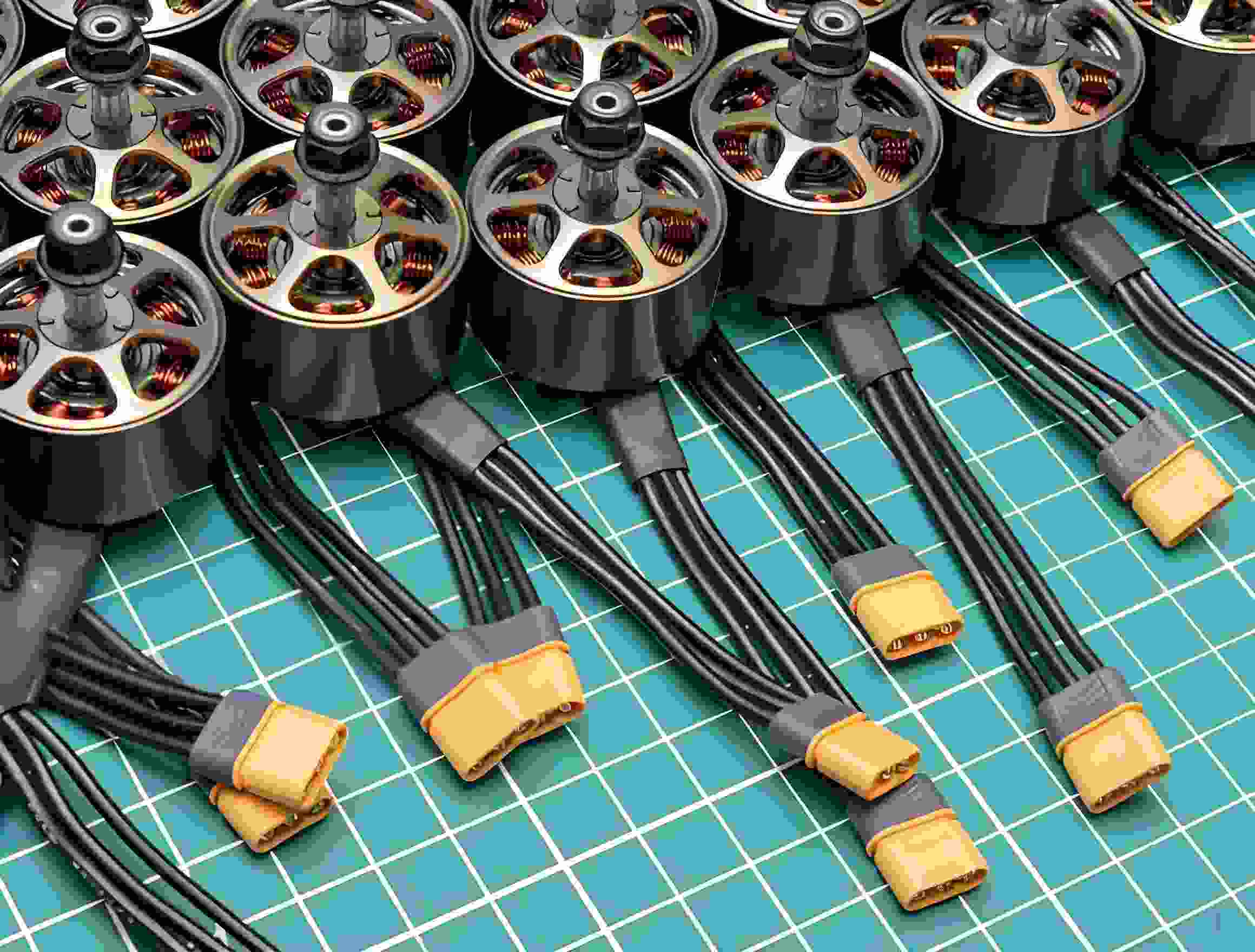

Sino is a leading motor core maker in China. We are committed to supporting the servo motor business around the world. We are experts in designing, developing, and making top-quality rotor cores. We work with various customers, including smart buyers (middlemen), experienced motor makers, and teams developing new technology. We promise to give you not just parts, but key pieces that decide how well new servo systems work, how long they last, and how little power they use.

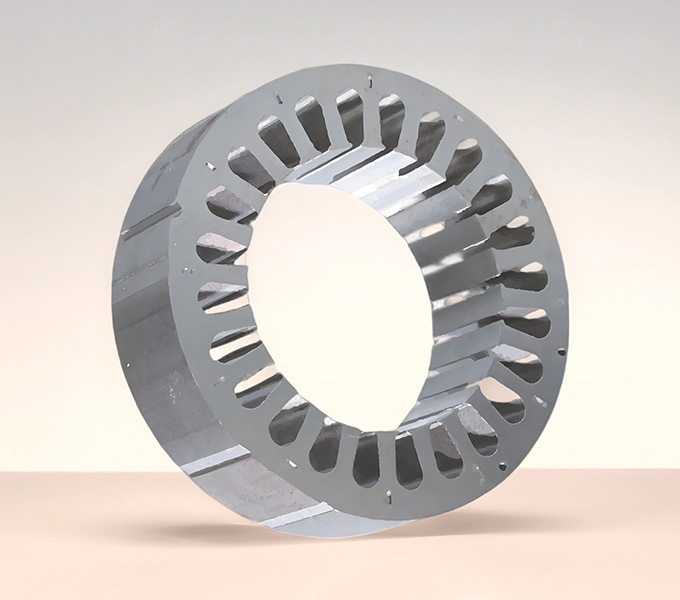

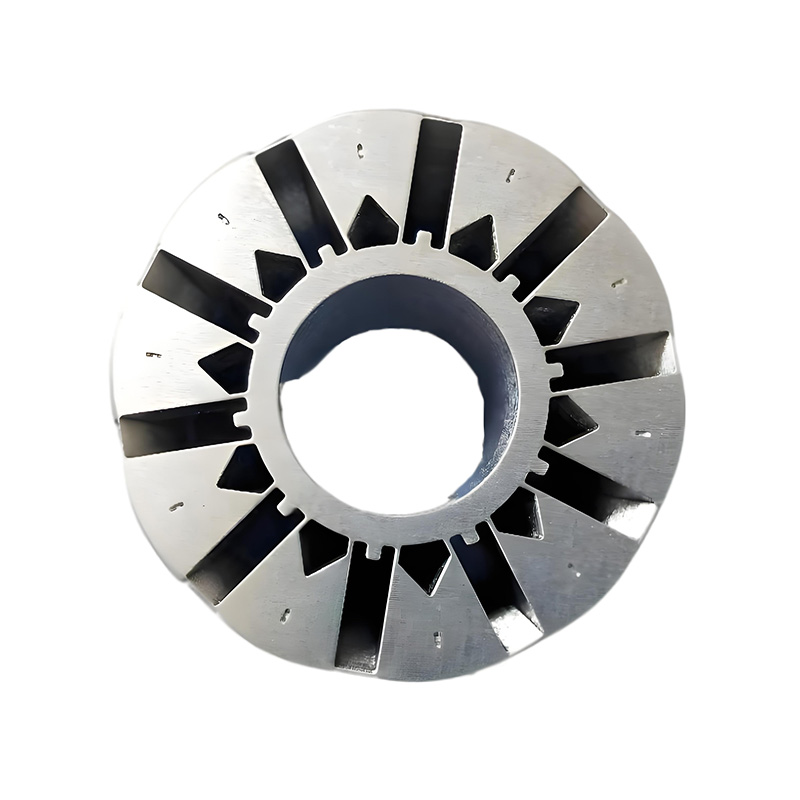

The rotor core is a key part in every top-quality servo motor. It’s a very important piece that decides how quickly it reacts, how well it works, and how good it is overall. The rotor core is more than just a basic part; it’s the piece that exactly changes magnetic forces into spinning movement. This makes possible the very high accuracy and speed control that servo systems are known for.

How the rotor core is designed and what it’s made of are very important for how well the motor can make turning power. It acts like a path for the magnetic flow, working with the stator’s turning magnetic field to create the magnetic forces needed. At Sino, we know how to carefully design the core’s material (how easily magnetism passes through) and its shape to change how strong and smooth the turning power is. For example, we use high-silicon electrical steels. This helps make a lot of turning power in a small size by greatly cutting down wasted energy in the core and making it better at handling strong magnetism.

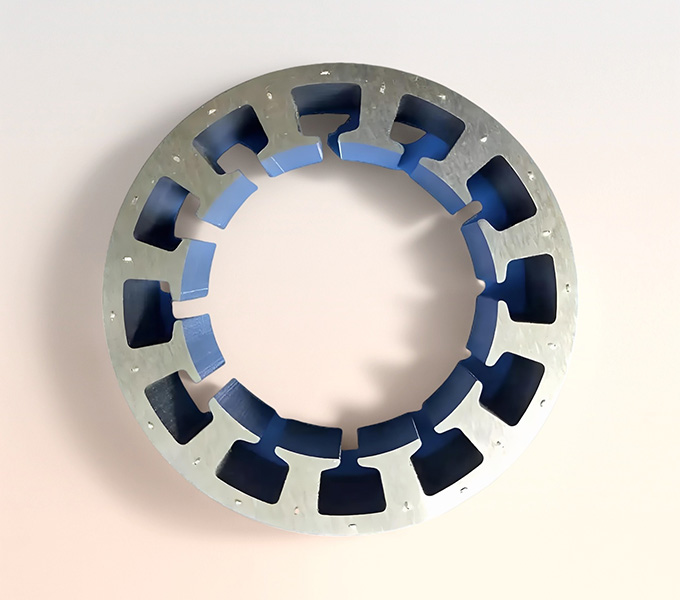

For our Servo Motor Core Laminations, we predominantly employ high-grade silicon steel (often referred to as electrical steel). Adding silicon to iron does a couple of wonderful things: it increases the electrical resistivity (which, as a bonus, further helps reduce eddy currents), and, crucially for hysteresis, it reduces what’s called the material’s coercivity. Lower coercivity means the magnetic domains flip more easily, narrowing that B-H loop and slashing the energy lost as heat during each magnetic cycle. We work with various grades of silicon steel, tailoring the choice to the specific performance demands of the servo motor, whether it’s for a servo motor stator core or a servo motor rotor core on sales.

Sino carefully finds the best thickness for the layers. Recent studies (2023–2024) show that making the layers thinner (e.g., from 0.35 mm to 0.20 mm) in rotor cores, especially when using very good silicon steel (like Nippon Steel’s Super Core), can cut wasted energy from circling currents by up to 30%. This directly means better working performance and better handling of heat. While thinner layers make making them more complicated and expensive, and might cause problems with shaking, Sino’s exact making process reduces these problems. This makes sure it works best without giving up quality.

At Sino, we understand that it’s not just about using laminations – it’s about how those laminations are made and assembled. This is where our decades of specialization in producing lamination stacks, including servo motor stator core and servo motor rotor core on sales, truly sets us apart.

The geometry of each lamination is critical. We employ high-precision stamping presses with meticulously maintained dies, or advanced laser cutting techniques for complex geometries or prototype runs. This ensures minimal burrs (which can compromise insulation and increase inter-laminar losses) and tight dimensional tolerances for perfect stacking.

For making large amounts, Sino uses the newest and fastest stamping machines that work step-by-step. These can do up to 1,200 presses per minute. This makes sure:

That thin insulating layer between laminations is paramount. We ensure our source materials have, or we apply, robust and uniform insulation (like C5 or C6 coatings) that can withstand the stresses of stacking, welding, or interlocking, as well as the operating temperatures of the motor. Any breach here can short-circuit laminations and bring back those dreaded eddy currents.

A well-stacked core is a high-performing core. Whether the design calls for interlocking, cleating, welding, or bonding, our processes ensure tight, uniformly stacked Servo Motor Core Laminations. This minimizes air gaps, which can impede magnetic flux, and maintains the mechanical integrity of the core under operational stresses. Using glue, even though it’s more complicated and costs more, causes the least wasted energy from circling currents between layers. This is a big benefit for jobs where things happen very quickly.

Sino keeps finding new ways in insulation technology. We use newer insulation coatings that aren’t carbon-based, put on using special methods like sol-gel or Chemical Vapor Deposition (CVD). These coatings can cut wasted energy between layers by 10–15% compared to older carbon-based coatings, which is especially good for servo motors that work very quickly.

Our making process includes very important steps done after the main part:

When you integrate Servo Motor Core Laminations crafted by Sino into your designs, what are the concrete benefits you and your customers will see?

1

In jobs where quick starting and exact placing are needed, like in robots (e.g., Yaskawa Sigma-7 series) and CNC machines, how much the rotor core resists changing speed (inertia) is very important. Sino focuses on designs that have low inertia, often by smartly using thin layers of electrical steel or newer combined materials. This focus makes quick speed changes and really good quick reaction easier, which is very important for being quick and exact, as needed in top-quality servo jobs.

2

How well a servo motor works and how it handles heat are greatly affected by how its rotor core is designed and what it’s made of. Our making steps at Sino are made as good as possible to reduce wasted energy (like eddy current and hysteresis losses). We do this by using layers cut exactly by laser and aligned well, and using newer materials like amorphous metal alloys (e.g., Hitachi Metals’ Metglas). These have shown they can reduce wasted core energy by up to 30% compared to regular materials, especially when working quickly, which is common in modern servo controls.

3

The complex way the rotor core and the stator work together is key to how well the motor works. Sino carefully designs the rotor core’s slot geometry, skewing, and lamination stacking factor to make the magnetic connection with the stator as good as possible. This exactness reduces uneven turning force (cogging torque) and smooths out shaking (torque ripple), making sure it works smoothly and well. Working together on the design like this is very important, especially in Permanent Magnet Synchronous Motors (PMSMs), where matching up the magnetic centers of the rotor and stator exactly directly affects how well it works and how smoothly it runs.

4

The rotor core is very important for controlling heat. It works like a heat absorber to get rid of wasted energy made inside the core itself and by permanent magnets put inside (in PM servo motors). Sino’s newer rotor core designs include inside cooling paths or use materials that transfer heat very well (e.g., copper infiltration in iron powder cores) to keep the temperature steady. This is very important for making sure it lasts a long time and stopping the magnets from losing their power (demagnetization), which is a common way for motors with permanent magnets to break down.

Let’s revisit that conceptual comparison, keeping Sino’s commitment to excellence in mind:

Feature | “Old School” or Poorly Made Core | Sino’s High-Grade Laminated Core |

Eddy Current Loss | Frustratingly High | Drastically Reduced |

Hysteresis Loss | Noticeable to High | Minimized via Material Selection |

Overall Efficiency | Could Be Better | Excellent |

Operating Temp. | Worryingly Warm | Comfortably Cool |

Dynamic Response | A Bit Laggy | Sharp & Instant |

Power Density | Standard | Optimized for Maximum Output |

Sino’s Focus | (N/A) | Precision, Quality, Performance |

This table illustrates general principles; specific values depend on motor design and operating conditions.

We don’t just grab any silicon steel off the shelf. We meticulously select grades based on permeability, coercivity, thickness, and insulation characteristics to match the intended operational frequency and performance targets of your servo motors. Whether it’s a non-oriented or grain-oriented silicon steel, we know what works best for various servo motor designs.

From incoming material inspection to final stack dimensional checks and electrical testing (like Franklin tests for inter-laminar resistance), quality is woven into every step of our process. We’re not just supplying parts; we’re supplying performance-critical components.

Which rotor core shape is chosen is key to how a servo motor works. It decides how the magnetism flows, how it makes turning power, and if it’s right for certain jobs. At Sino, we know a lot about the main kinds of servo motors: Permanent Magnet Synchronous Motors (PMSM), Synchronous Reluctance Motors (SynRM), and Induction Motors (IM). We understand the small details of their shapes and their big effect on magnetic flow.

Rotor Core Shapes and Magnetic Flow Paths:

Saliency Ratio and Reluctance Torque:

Sino uses the idea of saliency ratio (how the magnetic path is easier in one direction compared to another) to make the motor work best.

Magnet Use and Risk of Losing Power:

Shaking (Torque Ripple) and Unwanted Effects:

Reducing shaking (torque ripple) is very important for working smoothly and being controlled exactly in servo jobs.

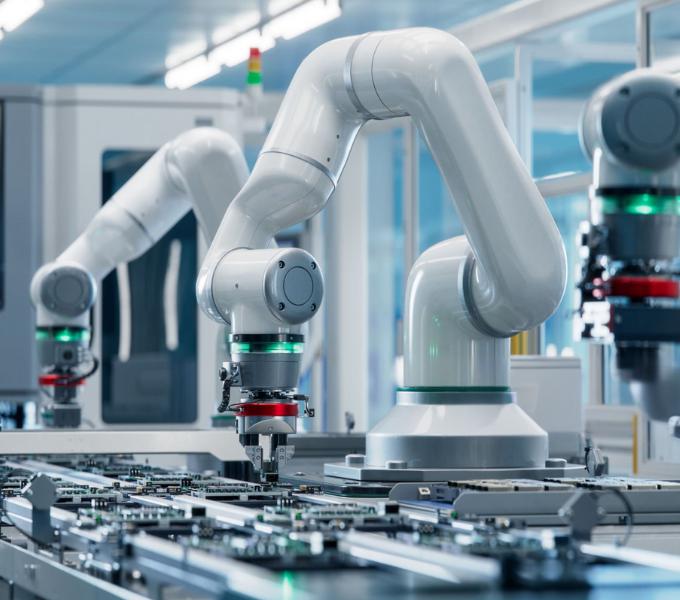

Choosing a supplier for a component as fundamental as Servo Motor Core Laminations is a big decision. At Sino, we’re not just a factory; we’re specialists. We live and breathe lamination technology.

Manufacturing lamination stacks, including servo motor stator core and servo motor rotor core on sales, is our core business. This focus allows us to invest in the best technology, materials, and process controls.

From the raw electrical steel coil to the final stacked core, quality is ingrained in our DNA. We understand that the performance of your multi-thousand-dollar servo motor can hinge on the precision of our few-dollar (or few-cent) laminations.

We're happy to work with your design engineers to optimize lamination geometry, material selection, and stacking methods to achieve your specific performance targets.

We understand the importance of on-time delivery to keep your production lines running smoothly.

Let's look at some scenarios where the quality of Servo Motor Core Laminations from a dedicated supplier like Sino makes a tangible difference:

Sino's laminations contribute to motors that offer high torque density (more power in a smaller package), low cogging torque (for smoother motion at low speeds), and rapid dynamic response.

Poor laminations leading to excessive heat could cause thermal expansion and positioning errors. Our servo motor stator core and servo motor rotor core on sales are engineered to ensure motors run efficiently and maintain their precision even under demanding, continuous operation.

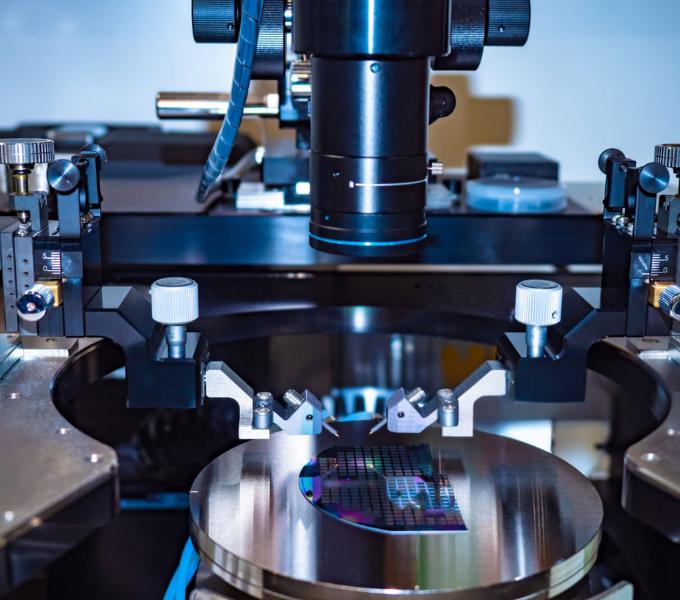

The servo motors used in wafer handling, lithography, and inspection equipment must be exceptionally stable and responsive. The low-loss characteristics and high magnetic performance enabled by our laminations are critical in these ultra-demanding settings.

Any jitter or imprecision can ruin yards of material or create flawed prints. Servo motors built with high-quality laminated cores provide the consistent speed and torque control necessary for flawless output.

If you’re looking to elevate the performance, efficiency, and reliability of your servo motors, it’s time to look at the core. It’s time to talk to Sino. We have a comprehensive range of servo motor stator core and servo motor rotor core on sales, and the expertise to help you select or develop the perfect lamination solution for your needs.

Ready to unlock the full potential of your servo designs? Reach out to us at Sino today, and let’s build something exceptional together.

Note: To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.

To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.