Let Sino's Lamination Stacks Empower Your Project!

To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.

To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.

At Sino, we work hard to be the top choice for motor and transformer makers. We provide top-quality silicon steel laminations that are the core part of efficient electric machines. With many years of experience based on the long history of improving electrical steel, we know that the performance of your products—from the smallest industrial motor to the biggest power transformer—depends on the magnetic and physical strength of their core materials.

At the core of every efficient transformer, motor, or generator is a simple yet brilliant material: silicon steel. These thin, stacked sheets, known as laminations, are the key to minimizing energy waste and getting the best performance out of almost any AC electrical machine.

The magic really comes from a small but critical addition: silicon. By mixing just 2% to 4.5% silicon into the iron, we fundamentally change how the steel handles electricity and magnetism. Its primary job is to dramatically boost the steel’s electrical resistance, which directly fights against ‘eddy current losses’—a major drain on power. At the same time, this silicon mix also tackles ‘hysteresis losses’ by making it easier for the magnetic field to do its job, improving what’s known as its ‘magnetic permeability’.

At Sino, we don’t just use any silicon steel. We carefully select the grade and type based on your specific scenario:

For applications like large power transformers and distribution transformers where the magnetic flux primarily flows in one predictable direction, GO steel is king. During its manufacture, the crystal grains are aligned in the rolling direction. This “easy” path for magnetization drastically cuts down hysteresis losses. Sino sources premium GO laminated silicon steel and processes it to maintain these delicate grain orientations, ensuring optimal performance in transformer cores.

GOES types often have more silicon (3.0–3.5%) to get the highest electrical resistance and lower eddy current losses even more, which is key for high-efficiency transformers.

GOES shows better magnetic features along its rolled direction: very high magnetic permeability (relative permeability often over 30,000 at 1.5 Tesla), high saturation induction (usually 1.95–2.03 Tesla), and very low core losses (as low as 0.90 W/kg at 1.7 T/50 Hz for the best types).

For electric motors, generators, and smaller transformers where the magnetic flux path is more complex and multi-directional, NO steel is the workhorse. Its grains are randomly oriented, providing good magnetic properties in all directions in the plane of the lamination. Sino offers a wide array of NO silicon steel laminations, perfect for everything from the motor in your washing machine to the alternator in your car.

NGOES types might have a bit less silicon (2.5–3.2%) to keep them easier to shape and bend, which is important for the difficult punching and shaping needed for motor laminations.

NGOES usually has lower permeability (relative permeability around 3,000–8,000), slightly lower saturation induction (1.7–2.0 Tesla), and higher core losses (from 1.5–3.5 W/kg at 1.5 T/50 Hz, depending on the type and thickness).

Impact of Minor Alloying Elements: Besides silicon, other small amounts of elements are carefully controlled to make small adjustments to its features:

It’s one thing to talk about these losses, but let’s look at the tangible benefits. While exact figures depend on the specific grade of steel, frequency, and flux density, the general impact is clear:

Core Material/Structure | Relative Eddy Current Loss | Relative Hysteresis Loss | Typical Scenario | Sino’s Value Proposition |

Solid Iron Core (Hypothetical for AC) | Extremely High | Moderate to High | Unsuitable for most AC devices | Demonstrates the fundamental need for laminations |

Laminated Standard Carbon Steel Core | Moderate | Moderate | Low-cost, low-performance chokes | Sino focuses on superior silicon steel for higher efficiency |

Sino’s Laminated NO Silicon Steel | Low | Low | Motors, generators, small transformers | Optimized material selection, precision stamping for consistent low losses |

Sino’s Laminated GO Silicon Steel | Very Low (if flux aligned) | Very Low | Power & distribution transformers | Expert handling to preserve grain orientation, ensuring maximum efficiency in transformers |

Amorphous Metal Laminations (Reference) | Extremely Low | Very Low | High-frequency, high-efficiency specialty | While excellent, Sino’s silicon steel provides a superior cost/benefit for most needs |

(Source: These are illustrative comparisons based on established principles in electrical engineering texts like “Electric Machines, Drives, and Power Systems” by Theodore Wildi and manufacturer data trends. Specific datasheets from steel producers like ArcelorMittal, Voestalpine, or POSCO provide precise loss curves.)

While reducing wasted energy is a massive benefit, high-quality silicon steel laminations from Sino offer more. They are fundamental to achieving powerful and compact electromagnetic designs.

1

Silicon steel, particularly the grades Sino utilizes, boasts high magnetic permeability. This means you can achieve a strong magnetic field (which is essential for the torque in a motor or the voltage transformation in a transformer) with less magnetizing current in your coils. Less current means thinner wires can be used, or I²R losses in the copper windings themselves are reduced. This all translates to better overall device efficiency and potentially lower manufacturing costs for the windings.

2

Every magnetic material has a limit to how much magnetic flux it can carry. Beyond this “saturation point,” trying to push more magnetic field through it yields diminishing returns. The silicon steel core components we produce are made from materials with a high saturation flux density. This allows your devices to operate at higher magnetic field strengths without saturating. So you can design smaller, lighter devices for the same power output. Sino’s silicon steel laminations allow engineers to push the boundaries of design without compromising on magnetic performance.

The applications for high-quality laminated silicon steel are vast and touch nearly every aspect of modern life. At Sino, we're proud to supply laminations that power:

The efficiency of these units is paramount, as even a fraction of a percent loss multiplied across thousands of transformers amounts to enormous wasted energy. Sino's GO silicon steel laminations are vital here, ensuring minimal core losses and maximum grid stability. From your microwave oven to your phone charger, smaller transformers need to be efficient and compact. Sino's NO laminations provide excellent performance for these varied scenarios.

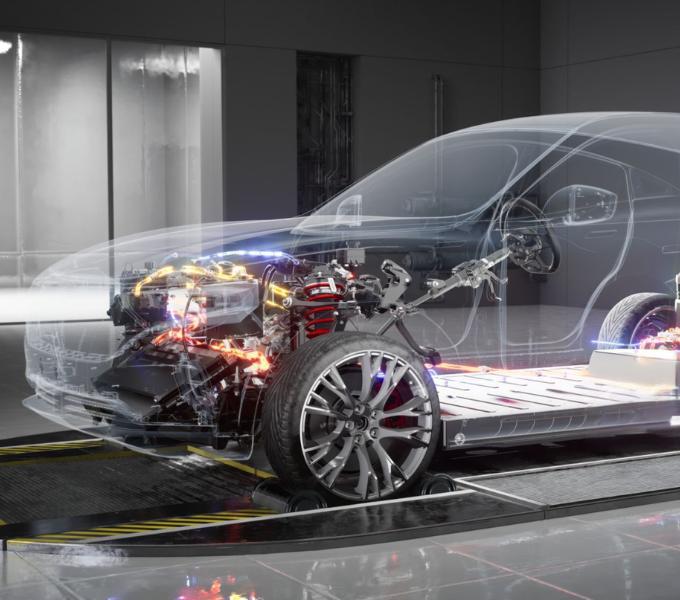

Factories run on electric motors. Efficiency here means lower operating costs and a smaller carbon footprint. Sino's silicon steel laminations for motor stators and rotors ensure that more electrical energy is converted into mechanical work. The heart of an EV's powertrain is its electric motor. High power density (more power in a smaller, lighter package) and high efficiency (longer range) are critical. Automakers rely on precision-engineered silicon steel cores, often made from specialized thin-gauge NO laminated silicon steel, to achieve these demanding performance targets. Sino is equipped to meet these exacting standards.

Whether it's a massive generator in a power plant or the generator in a wind turbine converting wind into electricity, efficient magnetic cores are essential. The durability and consistent magnetic properties of Sino's silicon steel laminations ensure reliable power generation. In renewable energy setups, like wind turbines, maximizing energy conversion is key. The generator's silicon steel core, built with Sino's laminations, plays a big part in harnessing every possible watt from the wind.

Inductors and Chokes: Used for filtering and energy storage in power supplies and electronic circuits.

Solenoids and Relays: For creating motion or switching electrical circuits.

Magnetic Ballasts: For fluorescent lighting (though increasingly replaced by electronic ballasts, which also use magnetic components).

The path from raw iron ore to a high-performance silicon steel lamination is a complex, multi-step process that needs to be exact, use modern technology, and have strict quality checks. At Sino, our factories use the latest methods to make sure every lamination meets the highest world standards for magnetic and physical properties.

The key to great silicon steel is how pure its raw materials are. We start with very carefully chosen iron and control exactly how much silicon is added (usually 2–3.5% for electrical steels). Unwanted materials like carbon, sulfur, and nitrogen are reduced using modern methods like vacuum degassing and secondary refining. Even tiny changes in these elements can seriously weaken magnetic features and increase core losses in both GOES and NGOES, making this first cleaning step very important.

The first big shaping step is hot rolling, done at temperatures between 1100–1250°C. The final temperature and how much it’s squeezed during hot rolling directly affect the steel’s first crystallographic texture. For GOES, the hot-rolled strip’s structure is carefully controlled to get it ready for making the Goss texture later. For NGOES, the goal is to get a consistent grain size and a random direction in the hot-rolled strip. Our special hot rolling plans are fine-tuned to get these specific results, setting the stage for the final product’s performance.

After hot rolling, the material is cold-rolled, usually in one or two steps. Double cold reduction (DCR) is a common method for GOES, which lets us make very thin sheets (down to 0.18 mm for high-frequency uses) and helps to create the needed {110}<001> Goss texture. How much it’s squeezed, which can be as high as 80%, and the inter-annealing steps between cold rolling are tightly controlled to balance work hardening and recrystallization, making sure the material is ready for its final magnetic properties.

Annealing is maybe the most important step in creating the magnetic features of silicon steel.

Laser and Mechanical Scribing: For GOES, advanced domain refinement methods are used after annealing to lower core losses even more. Laser scribing (using very precise lasers) or mechanical scribing creates controlled spots that pin domain walls. This process can lower hysteresis loss by 10–20% at power frequencies. We very carefully adjust the scribing distance, depth, and pattern for specific transformer core uses, making sure it works as well as possible with very little physical damage.

Types and Properties: An important part of lamination performance is the insulating coating put on the surface of each sheet. These coatings stop eddy currents between the layers, which would otherwise greatly increase losses. We use different kinds of coatings:

C6 (organic/inorganic hybrids) are made for high-stress, high-frequency uses, offering better ability to handle heat and stickiness. The coating thickness (usually 1–3 micrometers) and baking temperature (250–350°C) are precisely controlled to ensure the best stickiness, electrical insulation, and ability to handle physical and heat stress during later making steps.

The need for better performance in uses like electric vehicle (EV) motors has created a need for super-thin NGOES (below 0.23 mm, sometimes as low as 0.10 mm). Making these thin sheets needs super-clean steel, exact rolling force control, and advanced oiling systems to avoid surface problems and keep dimensions very precise (e.g., ±0.002 mm). Our special rolling machines are set up to make these advanced materials, meeting the tough needs of the next generation of electric machines.

At Sino, quality control is not just a final check; it’s part of every step of making the product. We use a full range of tests:

We understand that creating a superior silicon steel core is about more than just cutting metal.

We employ state-of-the-art stamping, laser cutting, and notching technologies to produce laminations with exceptionally tight tolerances. This ensures perfect stacking, minimizing air gaps and maximizing magnetic performance. Our automated stacking processes (including interlocking, welding, or bonding) create robust core assemblies ready for winding.

We work closely with leading steel mills and maintain a deep understanding of the properties of various grades of laminated silicon steel. We can advise you on the optimal material selection for your specific frequency, flux density, and loss requirements.

From raw material inspection to final core testing, quality control is embedded in our DNA. We ensure consistent insulation integrity, dimensional accuracy, and magnetic properties, batch after batch. We can provide burr height control, crucial for efficient stacking and minimizing inter-laminar short circuits.

We don't just offer off-the-shelf solutions. Sino thrives on working with you to develop custom lamination designs and silicon steel core assemblies tailored to your unique device parameters. Whether you need a prototype for a new motor design or high-volume production for established transformer lines, we're your dedicated partner.

While we never compromise on quality, our efficient manufacturing processes and global sourcing capabilities allow us to offer competitive pricing, delivering exceptional value.

Your next project, whether it’s a revolutionary electric motor, a next-generation transformer, or a cutting-edge inductor, deserves a core built with the best. By choosing Sino’s silicon steel laminations, you’re not just buying a component; you’re investing in efficiency, reliability, and performance that will set your product apart.

Ready to unlock the full potential of your electromagnetic designs? Let’s talk. Contact Sino today, and let our expertise in silicon steel laminations and silicon steel core assemblies become your competitive advantage. We’re excited to help you power the future!

Note: To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.

To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.