Let Sino's Lamination Stacks Empower Your Project!

To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.

To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.

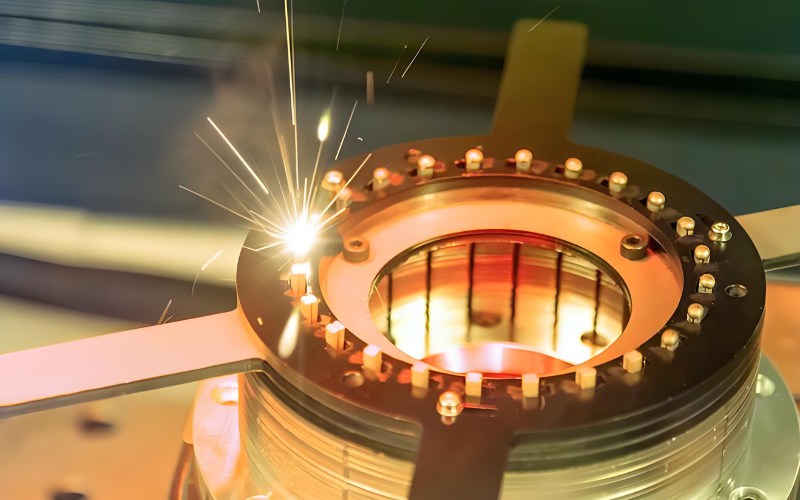

Unlock superior motor performance with Sino’s advanced stator lamination welding. Our precision techniques forge unshakeable cores, delivering exceptional structural integrity and maximizing electrical efficiency by minimizing eddy currents. Benefit from faster, cost-effective manufacturing for robust, high-performance electric motors. Build an unshakeable foundation with Sino.

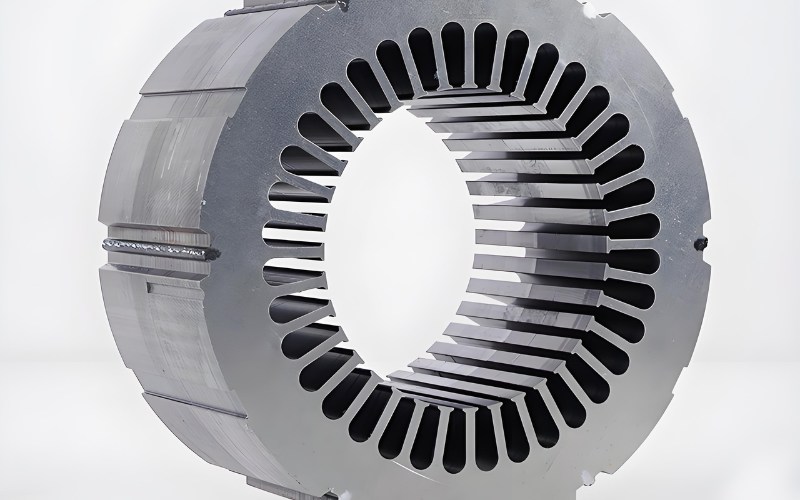

Welding forges a stator core with exceptional structural integrity. Imagine hundreds, even thousands, of paper-thin steel laminations. Now, picture them not just pressed together or held by a few discrete points, but fused along their edges into what is essentially a single, solid piece of engineered metal. That’s the kind of robust unit Sino delivers with our advanced stator lamination welding processes.

Why is this rock-solid build so critical? Well, electric motors aren’t exactly living a life of leisure. During operation, they’re a hotbed of activity:

A poorly assembled core can succumb to these stresses. Laminations might start to separate, leading to annoying buzzing sounds (increased NVH – Noise, Vibration, and Harshness), or worse, a degradation in magnetic performance as air gaps creep in. In extreme scenarios, a loose core can even lead to catastrophic motor failure. Nobody wants that.

At Sino, our stator lamination welding techniques, particularly our precision laser welding, create weld seams that are both incredibly strong and meticulously controlled. Consider, for example, a high-torque industrial motor we produce cores for, destined for a demanding scenario like a mining conveyor belt. These motors face constant heavy loads and vibrations. A riveted core might see loosening over time under such duress. However, our welded cores maintain their tight, unified structure, ensuring the motor keeps running reliably for its entire intended service life. We’ve seen firsthand how this translates to reduced warranty claims and enhanced customer satisfaction for our clients. This resilience is a direct result of transforming a stack of individual plates into a cohesive, unyielding cylinder of power.

We primarily employ state-of-the-art laser beam welding (LBW), and for specific scenarios, highly controlled Tungsten Inert Gas (TIG) welding. The beauty of these technologies, especially laser welding, is the phenomenal precision.

The outcome? Stator cores that maintain excellent magnetic properties. Because the insulation between individual laminations is preserved, the paths for those wasteful eddy currents are effectively blocked. This directly translates to:

We had a client in the HVAC industry who was struggling to meet new energy efficiency standards for their compressor motors. After transitioning to Sino’s laser-welded stator cores, they saw a measurable improvement in motor efficiency – enough to comfortably meet the new regulations and even market their product as “energy-saving.” This wasn’t magic; it was the result of precise stator lamination welding minimizing those pesky eddy current losses. As research from institutes like the Fraunhofer Institute for Laser Technology (ILT) consistently shows, laser welding, when expertly applied, can produce laminated cores with magnetic performance nearly identical to an ideal, unjoined stack.

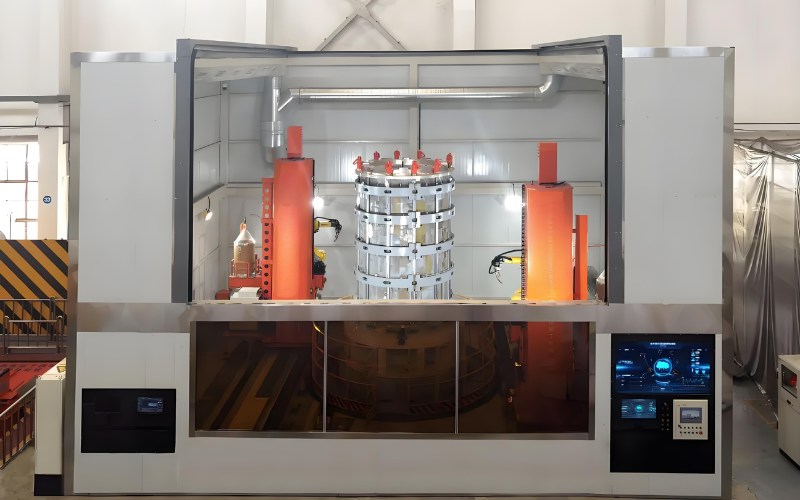

In today’s fast-paced manufacturing world, it’s not just about making a good part; it’s about making it efficiently and cost-effectively, especially when you’re talking high volumes. And this is another area where stator lamination welding, particularly the automated laser welding solutions we’ve implemented at Sino, really pulls ahead of the pack.

Let’s be frank: the initial investment in top-tier laser welding robots and systems like those from industry leaders such as TRUMPF or Coherent is significant. However, when Sino is producing stator cores for, say, a major appliance manufacturer churning out hundreds of thousands of washing machine motors a year, the per-unit cost plummets. The economies of scale make stator lamination welding an incredibly attractive proposition for any high-volume scenario. We’ve even developed proprietary fixtures and handling systems that further streamline the flow of laminations into our welding cells, squeezing out every bit of efficiency.

The precision and minimalist nature of a good weld bead open up new avenues for design. Because welds can be very fine and strategically placed (often just a few thin lines on the outer diameter), engineers aren’t as hemmed in by:

With the freedom afforded by Sino’s stator lamination welding:

We worked with a drone manufacturer who needed an extremely power-dense motor with a very tight diameter constraint. Our ability to provide a solidly welded core without bulky fasteners was a key enabler for their innovative design.

Here’s a quick rundown of how welding stacks up in key areas, reflecting Sino’s capabilities:

Feature | Sino’s Advanced Welding (Laser/Optimized TIG) | Traditional Riveting/Staking | Interlocking Laminations | Adhesive Bonding |

Structural Rigidity & Durability | Excellent (Monolithic structure) | Moderate to Good | Good | Good, but temp sensitive |

Potential for Eddy Current Minimization | Very High (with Sino’s precise control) | Generally Low | Low | Very Low |

Automation Potential | Excellent | Moderate | High | Moderate to High |

Typical Production Speed | Very High | Moderate | High | Moderate |

Tooling Wear & Maintenance | Very Low (non-contact laser) | High (punches/dies) | Moderate (stamping dies) | Low (dispensers) |

Design Compactness/Slot Fill | Excellent | Good | Good | Good to Excellent |

Suitability for High Vibration Scenarios | Superior | Fair to Good | Good | Fair, depends on bond |

Heat Resistance of Joint | Excellent | Excellent | Excellent | Limited by adhesive |

(Source: Internal analysis at Sino, benchmarked against industry best practices and data from equipment partners and publications like “Journal of Materials Processing Technology” and “IEEE Transactions on Industry Applications”.)

At Sino, stator lamination welding isn’t just another process; it’s a core competency we’ve honed through years of experience and continuous investment in technology and expertise. We understand the nuances: the right laser parameters for different steel grades and thicknesses, the optimal weld path design to ensure strength without compromising magnetic flux, and the critical quality control measures to guarantee every weld is perfect.

Our team works closely with your engineers. Perhaps you have a new motor design for a robotics scenario that requires exceptional torsional stiffness. We can prototype different weld patterns and provide data to help you optimize. Or maybe you’re looking to improve the efficiency of an existing industrial fan motor. We can analyze your current core construction and demonstrate the potential benefits of switching to our precision welded stacks.

We also pay meticulous attention to the preparation of the laminations themselves. Clean, precisely stamped laminations with high-quality insulation are paramount for successful welding, and our integrated manufacturing ensures this from the outset.

Sure, advanced stator lamination welding systems require a significant upfront capital outlay. And yes, it demands a high level of process expertise to get it just right. That’s where partnering with a specialist like Sino comes in. You get all the benefits of this cutting-edge technology without the burden of investing in and mastering the equipment yourself. We’ve already climbed that learning curve, so you don’t have to.

When you need stator cores that are tough as nails, electrically efficient, quick to produce in volume, and offer greater design freedom, stator lamination welding is an incredibly compelling technique. At Sino, we’ve taken this process and elevated it, offering our clients stator lamination stacks that form the reliable, high-performance heart of their electric motors.

From initial design consultation to high-volume, automated production, Sino is your trusted partner for stator lamination welding. Let’s talk about how our expertise can help you build better, more efficient, and more reliable motors for whatever scenario you’re tackling next. Give us a call – we’re ready to help you forge the future of your products!

To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.