Let Sino's Lamination Stacks Empower Your Project!

To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.

To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.

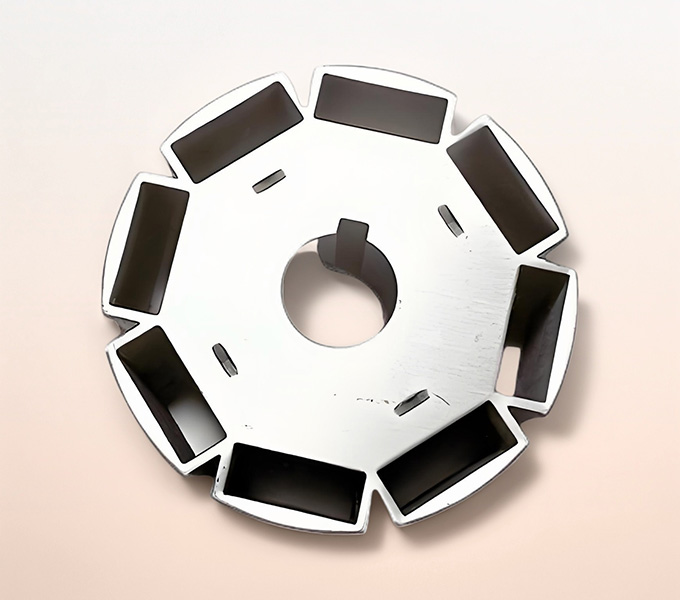

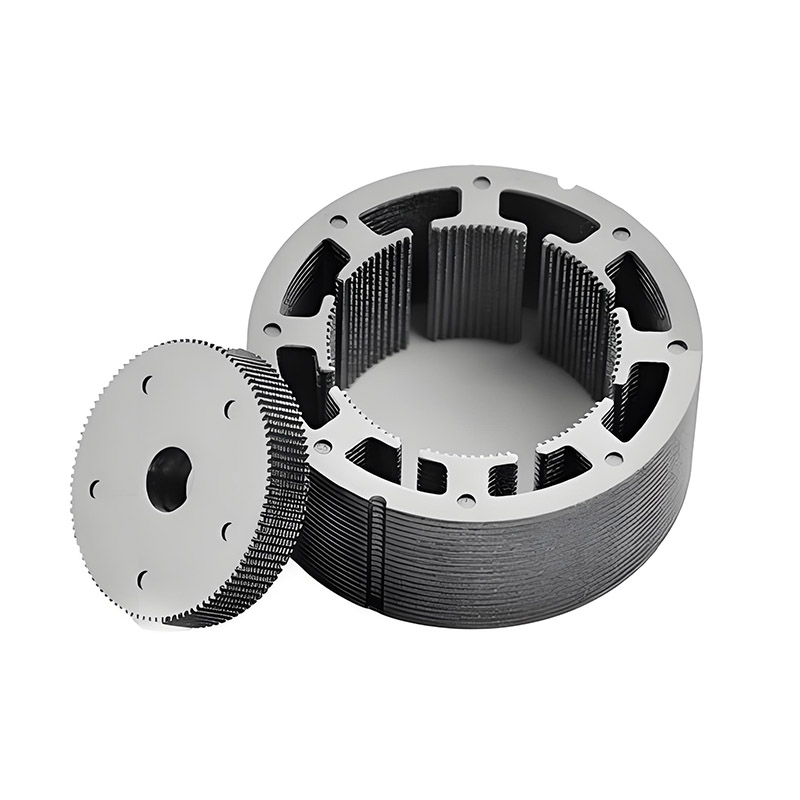

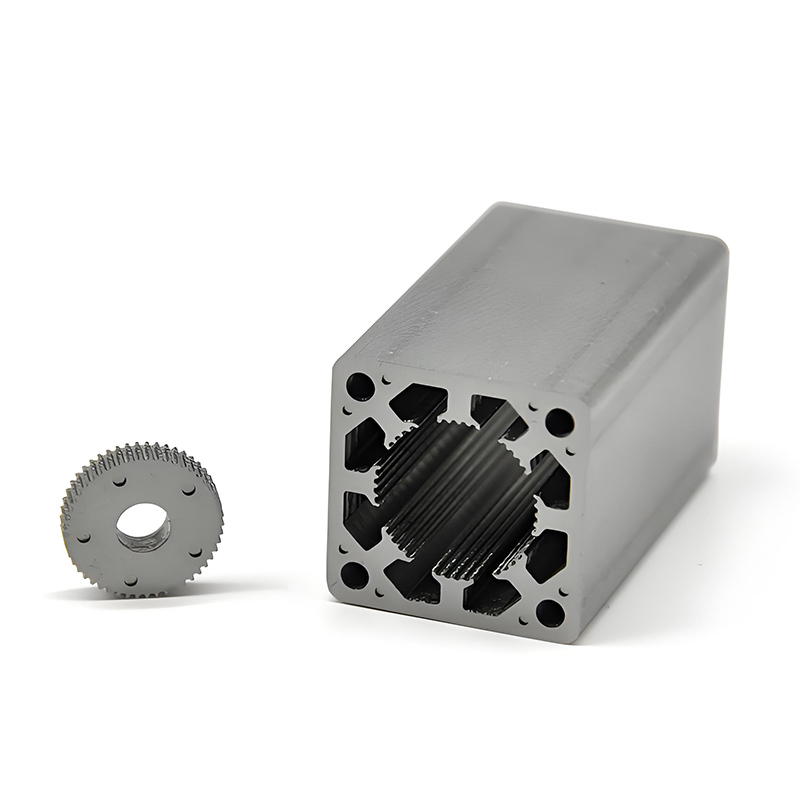

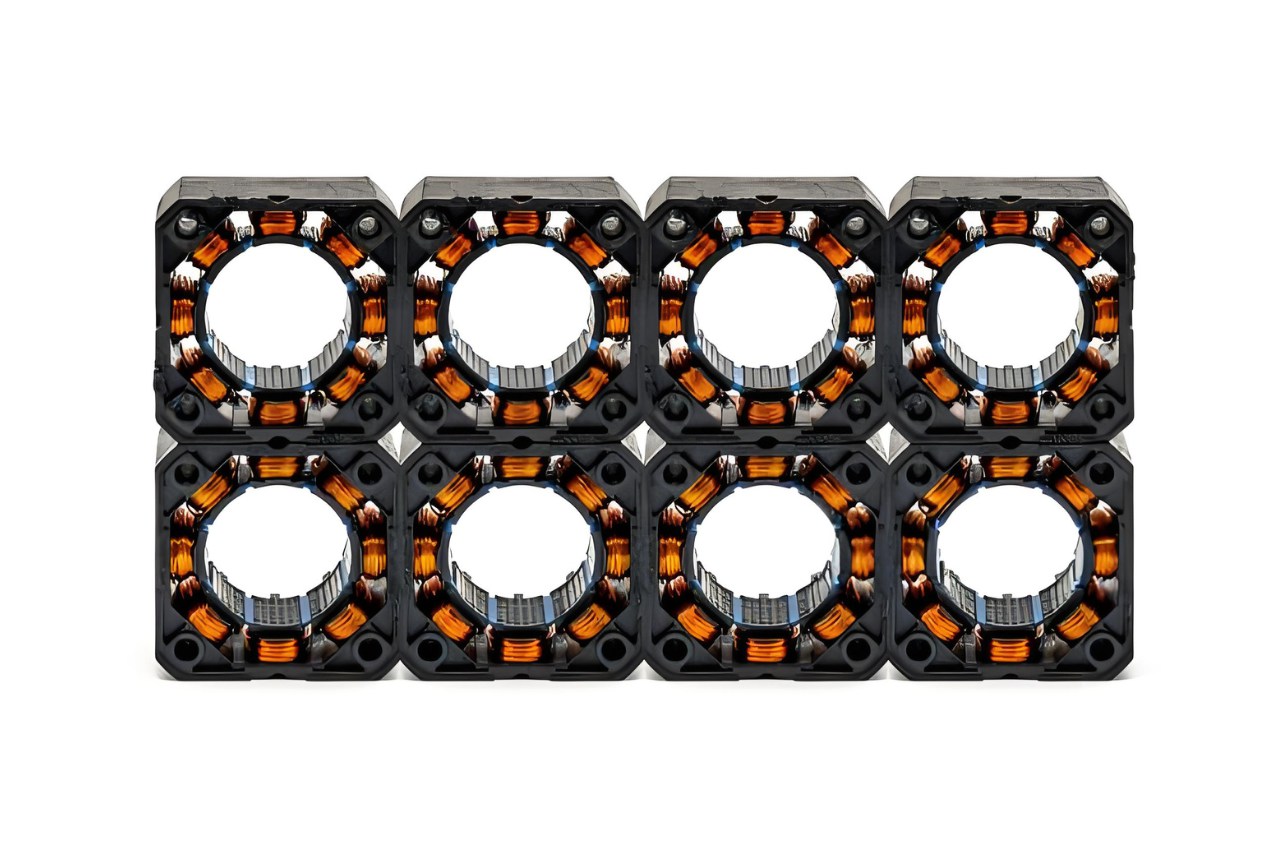

As Sino, a top manufacturer of very exact motor cores in China, we know that the most important part of a great stepper motor is its core laminations. We use our expert knowledge and are always looking for new ideas, to make sure every stepper motor rotor and stepper motor stator lamination we make has the best quality, accuracy, and works great.

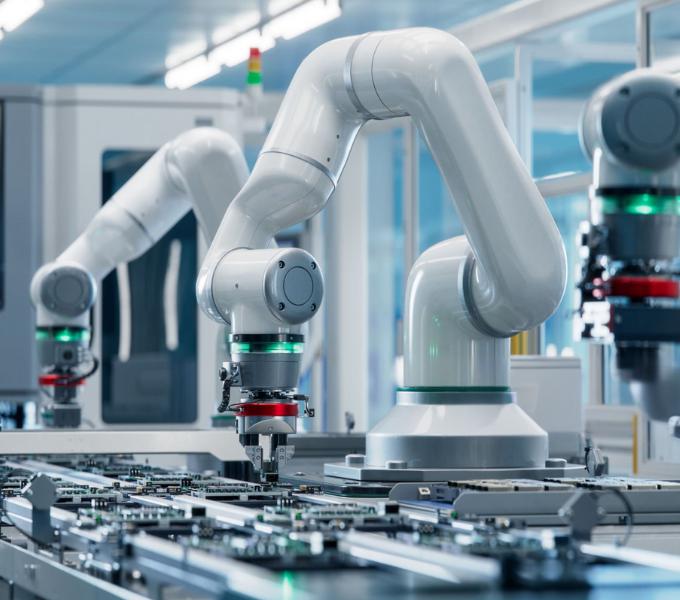

Stepper motors are used everywhere you need exact movement, from factory machines and robots to medical tools and 3D printers. Inside these motors are carefully designed and made laminations that create the stepper motor stator and stepper motor rotor. These thin, coated sheets of special steel are not just for holding the motor together; they guide the magnetic energy that controls the motor’s power, how well it uses electricity, and how it moves.

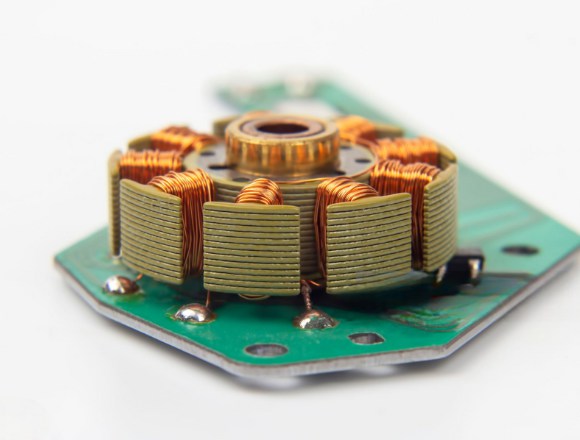

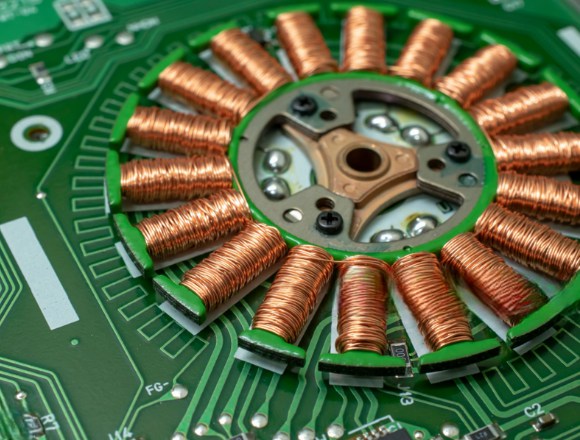

Laminations have two main jobs: first, to make it easy for the magnetic energy from the wire coils to flow, making sure energy is used well; and second, to reduce energy wasted by unwanted electrical currents called eddy currents. Without laminations, the changing magnetic fields in the motor would create big, swirling currents inside a solid metal core. This would create a lot of heat, waste energy, and make the motor work poorly. Cutting the core into thin, coated layers stops these eddy currents from flowing, which greatly cuts down on this waste.

Our laminations are made with the best silicon steel grades. They are very good at:

This helps the motor work with fewer wasted energies.

The edges are smooth and the shapes are very exact.

They come in sizes like NEMA14 and NEMA34.

We meet your needs with many sizes and shapes.

We can make many laminations fast.

At Sino, we follow a very clean process to make sure our parts are the best:

1

2

3

4

5

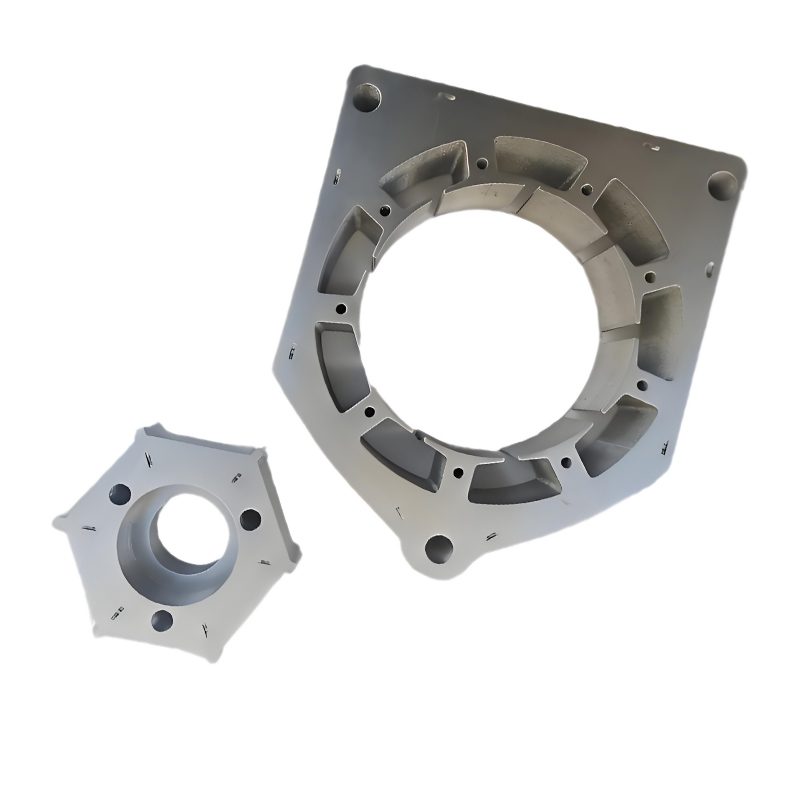

The design of stepper motor core laminations is a smart mix of magnetic science, knowledge of materials, and what’s possible to build. At Sino, we carefully think about everything, from the shapes of the parts to the special qualities of the materials, to make the stepper motor stator and rotor work their best.

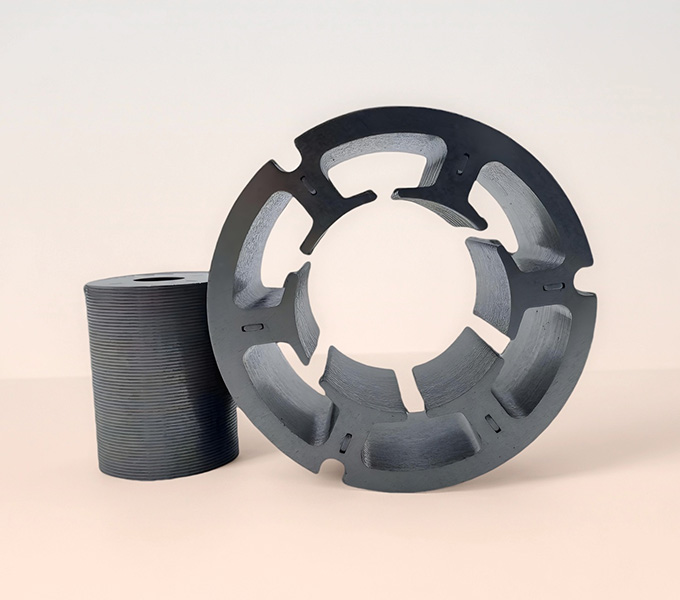

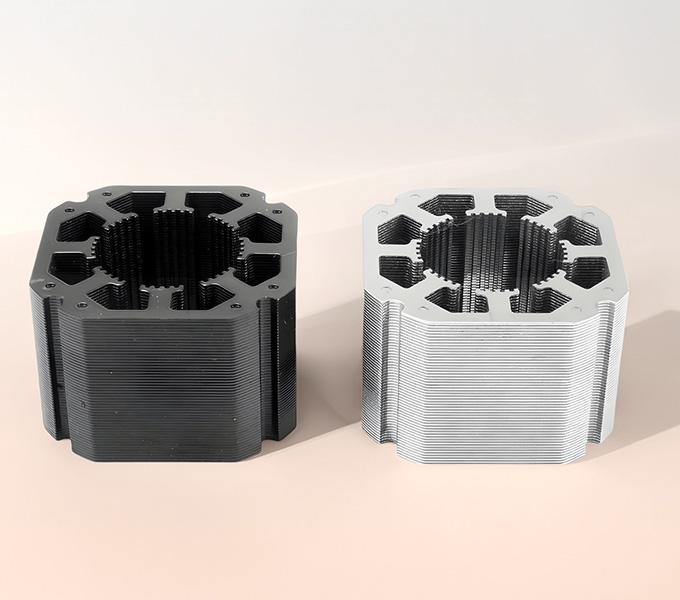

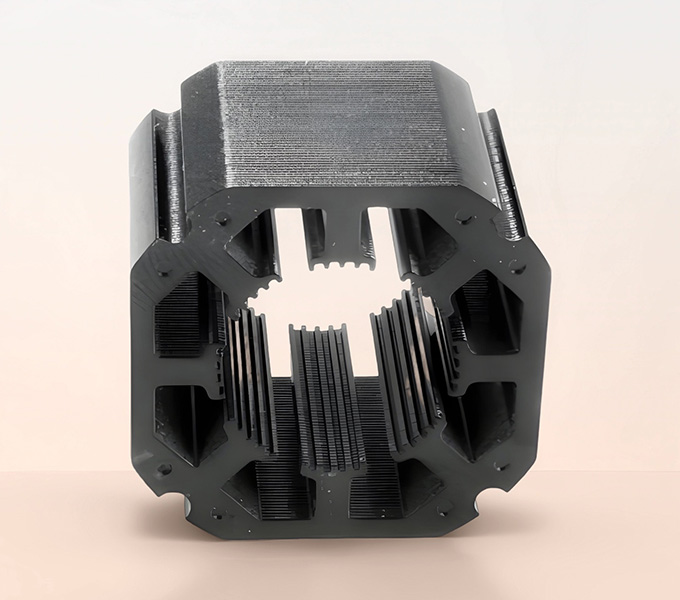

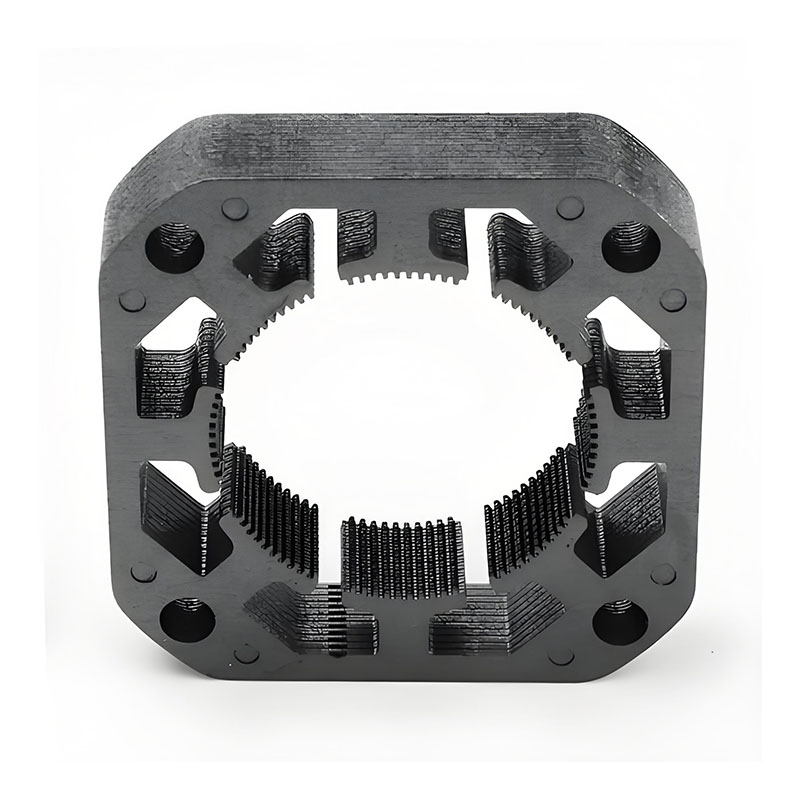

The shape of the laminations, especially the teeth and slots, is very important for guiding the magnetic energy well. Laminations are made to guide magnetic energy well through the stepper motor stator and rotor of stepper motor, which reduces wasted energy and makes the most of its connection with the wire coils. The exact shape and way these silicon steel sheets (usually 0.2–0.5 mm thick) are stacked makes it easy for the changing magnetic fields to flow.

The height of the stack, width of the teeth, size of the slot opening, and thickness of the back part all affect the magnetic path. For example, smaller slot openings with the right bridge thickness (the metal between the slot opening and the air gap) can focus more magnetic energy in the teeth, which gives the motor more power for its size. But making them too small can overload parts of the metal and waste more energy. Our computer tests, based on a lot of research, show that a 0.8 mm slot opening with a 0.5 mm bridge can give the most power while keeping the motor’s unwanted vibration (cogging torque) very low in many designs.

Below is a table that shows the details of our laminations. This table helps you learn more about what we offer.

Category | Details |

Material | Silicon steel, Bao Steel, thin-gauge electrical steel (Sura/Arnon), Hiperco alloys. |

Thickness Range | From 0.003 to 0.025 inches (about 0.076–0.635 mm) with a tolerance of ±0.02 mm. |

Bonding Technology | Uses rotary lamination and glue bonding. This helps keep the parts together and reduces vibrations. |

Dimensions | Custom sizes available. We offer parts for NEMA14, NEMA34, and regions like series 35/39/42/57/86/110/130. |

Surface Finish | Precision-stamped or laser-cut edges provide a smooth finish for perfect stacking. |

Production Capacity | Our factory can produce many parts. We can make over 250,000 units per month. |

Our laminated cores are used in many areas. Here are some of the usage scenarios:

Choosing the right material for stepper motor core laminations is very important. We mostly use different types of special electrical steel, chosen for their special magnetic qualities, like letting magnetic energy pass through easily, wasting little energy, and holding a lot of magnetic energy.

Silicon Steel (Fe-Si Alloys): These are the most common materials. Adding silicon makes it harder for electricity to flow, which helps cut down on wasted eddy currents. It also helps magnetic energy flow easily in all directions.

Standard Grades (e.g., 3% Si): Give a good mix of cost and performance for everyday stepper motors.

High-Silicon Electrical Steels (3.0–6.5% Si): New work by top steelmakers like Nippon Steel, JFE Steel, and POSCO have made special steels (non-oriented electrical steels or NOES) that waste much less energy (up to 30% less than standard 3% Si types) and are better at resisting electricity. These types, like JFE Super Core and POSCO Hyper NO, allow for thinner layers (as thin as 0.15 mm) and are used more and more in fast-moving stepper and servo motors, especially for robots and very exact machines.

Cobalt-Iron (Co-Fe) Alloys (e.g., Hiperco 50A, Hiperco 27): From makers like Carpenter Technology and VACUUMSCHMELZE, these metal mixes can hold much more magnetic energy (up to 2.4 T, compared to 2.0 T for normal Fe-Si) and let it flow 20–30% more easily. Even though they cost 10–20 times more than regular steel, they are necessary for space, medical, and top-level factory stepper motors where getting the most power from the smallest size is key.

Amorphous and Nanocrystalline Alloys: Materials like Metglas 2605SA1 and FINEMET FT-3M waste 70–80% less energy than Fe-Si when the motor is running fast (above 400 Hz). But they are brittle and hard to work with (for example, cutting with lasers and stacking), which stops them from being used in many small, fast stepper motors, though people are still studying how to use lasers to build them for tiny stepper motors.

High-Entropy Alloys (HEAs): New research is looking at special metal mixes (FeCoNi-based HEAs) that have good magnetic qualities and can be adjusted to be stronger or more flexible, but they are still hard and expensive to make.

By incorporating Sino’s Stepper Motor Core Laminations, which minimize heat generation from eddy currents, you’re effectively giving your motor a longer, healthier life. Cooler operation allows motors to be deployed in more demanding environments, perhaps with higher ambient temperatures or in tightly enclosed spaces where heat dissipation is a challenge.

By severely restricting eddy currents even at high frequencies, Sino’s laminations allow the stepper motor to maintain its torque and responsiveness at much higher RPMs. This means faster cycle times in automated machinery, quicker movements in robotics, and generally a more dynamic performance envelope.

At Sino, we understand that you’re not just buying stacks of metal; you’re investing in the performance and reliability of your end product.

Our manufacturing processes are fine-tuned for ultimate precision, ensuring uniform lamination thickness, clean edges from our stamping dies, and consistent insulation quality. This translates directly to predictable and superior motor performance.

We work with a range of high-grade silicon steels and can advise on the best material for your specific scenario, balancing performance needs with cost considerations.

We can customize stepper motor core laminations to your specific specifications, including particular stack heights, special interlock designs, and unique coatings. Our capabilities also extend to producing laminations for virtually any stepper motor rotor design.

From raw material inspection to final product testing, quality is embedded in every step of our process. We know that even a tiny flaw in a lamination can impact motor performance.

We've supplied laminations for a vast array of scenarios, from miniature motors in medical devices to robust units in industrial automation. We bring this experience to the table to help you succeed.

The accuracy and performance of laminations are tied directly to how they are made. At Sino, we use a mix of proven methods for making large amounts and new, advanced technologies to make the best quality stepper motor stator and rotor parts.

High-speed stamping is the main way to make stepper motor laminations when you need a lot of them, because it is very fast and cheap for large numbers.

Precision laser cutting is very flexible, which makes it perfect for making test versions (prototypes), small batches, and complex shapes.

Sino chose the right manufacturing process for the job. We use high-speed stamping when our partners need large numbers of parts, which keeps costs down and delivery fast. For special, small-batch, or very custom stepper motor stator and rotor of stepper motor designs, our precision laser cutters give us the flexibility and accuracy we need.

When you choose Sino for your Stepper Motor Core Laminations, you’re choosing a partner dedicated to enhancing the heart of your motor. You’re opting for reduced energy waste, cooler operation, higher speeds, and ultimately, a more competitive and reliable product.

Let’s discuss your specific needs for Stepper Motor Core Laminations, whether for the stepper motor stator, the rotor of stepper motor, or the complete assembly. We’re here to provide the precision-engineered solutions that will make your motors, and your products, truly shine.

Note: To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.

To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.