Let Sino's Lamination Stacks Empower Your Project!

To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.

To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.

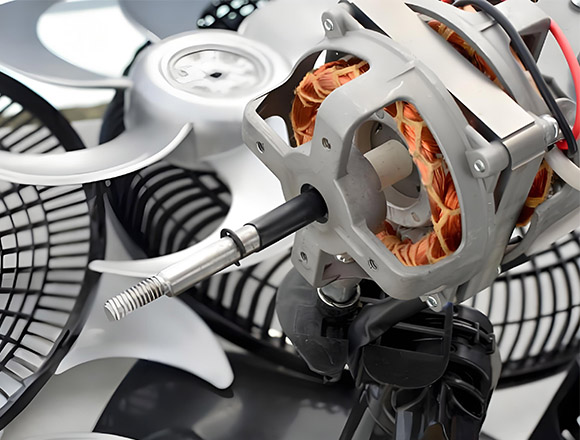

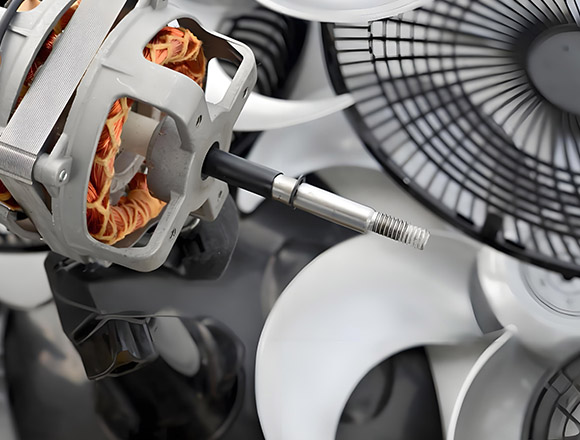

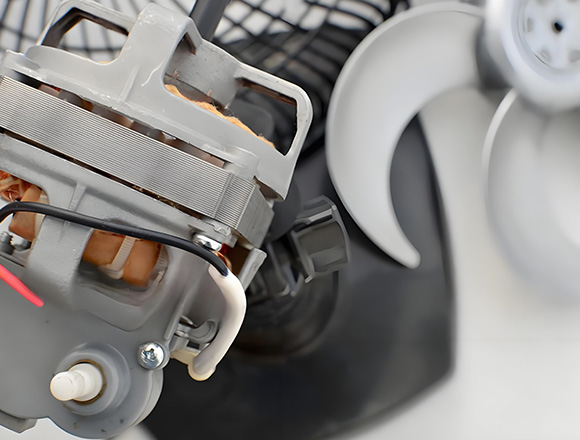

The quiet efficiency and lasting coolness of a table fan are fundamentally determined by its high-quality stator lamination stack. Sino specializes in the precision manufacturing of table fan stator laminations, dedicated to enhancing motor performance and helping you create superior fan products. Choosing Sino’s table fan stator laminations means selecting core technology for more energy-efficient, quieter, and reliable fans.

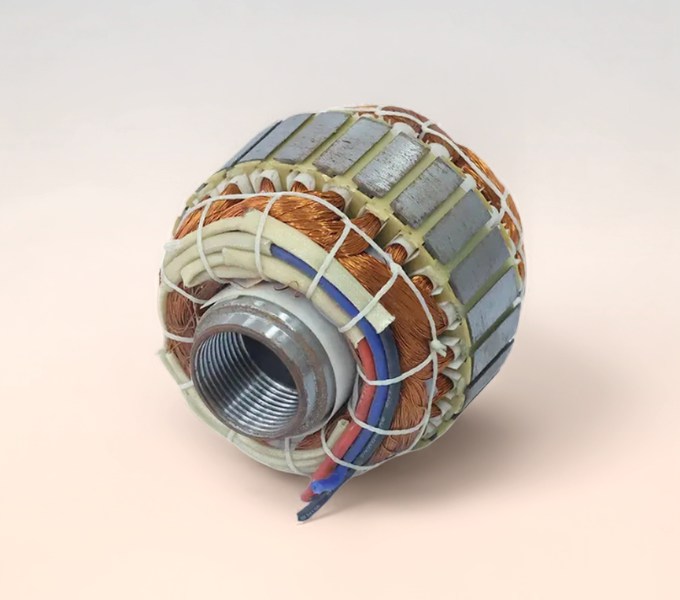

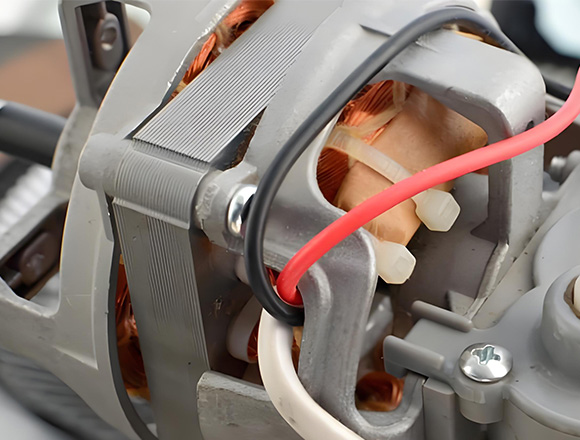

The table fan stator core is constructed from a stack of very thin sheets of specialized electrical steel. Crucially, each of these individual sheets, or laminations, is coated with an insulating layer – often a varnish or an oxide coating. This can help:

At Sino, we’re not just stamping out metal; we’re engineering pathways for efficiency. We understand that the precision of the lamination thickness and the integrity of its insulating coating are paramount. For a table fan stator, achieving the right balance between performance and cost is key, and our manufacturing processes are honed to deliver just that.

At Sino, we predominantly utilize high-grade silicon steel, also known as electrical steel, for our table fan stator laminations. This material is specifically engineered for magnetic applications due to several key properties:

Adding silicon to steel significantly increases its electrical resistance. A higher resistance naturally discourages the flow of those pesky eddy currents.

Silicon steel is formulated to have “soft” magnetic properties, meaning these domains flip more easily, thus minimizing this hysteresis loss. For a continuously running appliance like a table fan, minimizing both eddy current and hysteresis losses is crucial for overall efficiency.

High permeability means the steel can become strongly magnetized with less current in the windings, leading to a more potent and efficient motor. It helps the table fan stator do its main job effectively.

Different grades of silicon steel offer varying levels of these properties, often trading off with cost. For example, a higher silicon content typically improves performance but can make the steel more brittle and harder to stamp. Part of Sino’s value is helping our clients select the optimal grade of electrical steel for their specific table fan stator requirements, balancing performance targets with budget realities.

Let’s look at an illustrative example of how lamination thickness, a direct result of material processing, impacts performance:

Lamination Characteristic | Typical Cheaper Steel (0.65mm) | Sino Standard Grade (0.50mm) | Sino Premium Grade (0.35mm, higher Si) |

Relative Eddy Current Loss | 42 | 25 | 12 |

Relative Hysteresis Loss | 30 | 22 | 15 |

Total Relative Core Loss | 72 | 47 | 27 |

Manufacturing Complexity Factor | 1.0 | 1.2 | 1.5 |

Relative Material Cost Factor | 0.9 | 1.0 | 1.3 |

As you can see, moving to thinner laminations (like Sino’s 0.50mm standard or 0.35mm premium options) dramatically reduces total core losses. While thinner laminations or higher silicon content steel might involve slightly higher initial material or manufacturing costs, the long-term benefits in energy savings, improved product lifespan, and enhanced performance often provide a compelling return on investment for fan manufacturers. At Sino, we work with these trade-offs every day to deliver the best value.

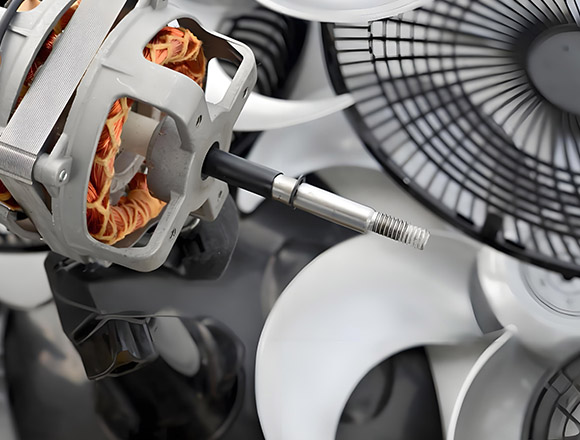

Having the right electrical steel is just the starting point. How those table fan stator laminations are designed, stamped, and assembled is equally critical to unleashing their full potential. This is where Sino’s decades of manufacturing experience really make a difference. We’re not just metal stampers; we’re lamination specialists.

1

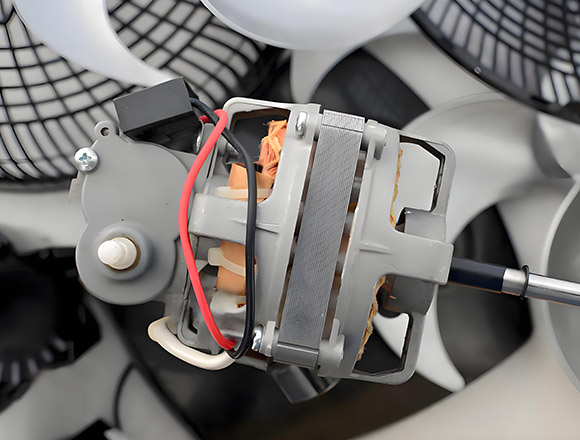

Burrs create unintended electrical short circuits between laminations, effectively negating some of the benefits of laminating in the first place and increasing those dreaded eddy currents. We invest heavily in high-quality, regularly maintained stamping dies and precision manufacturing processes. Our target at Sino is to keep burr heights well below industry norms, often aiming for figures like 0.02mm or less, depending on the lamination thickness. This ensures the integrity of the inter-laminar insulation.

2

A higher stacking factor means more magnetic material packed into the same space, leading to a more powerful and efficient motor. Our process control ensures consistent lamination flatness and precise coating thickness. We also offer various stacking techniques, including interlocking designs, precision riveting, or laser welding (depending on the specific table fan stator design and volume), to achieve optimal compression and a high stacking factor, often exceeding 95-97%.

3

The insulating coating on each lamination must be thin yet robust, uniform in thickness, and able to withstand the temperatures and stresses of motor assembly and operation. We partner with reputable coating suppliers and implement stringent quality checks on incoming coated steel. Our handling and stamping processes are designed to minimize any damage to this crucial layer. We can provide laminations with various types of coatings (e.g., C5 organic, C6 inorganic) suited to different operating temperatures and environmental conditions that a table fan stator might encounter.

4

Sino thrives on working with clients to produce custom table fan stator laminations tailored to their exact specifications – from unique slot designs for winding optimization to specific outer and inner diameters. We understand that a one-size-fits-all approach rarely delivers peak performance.

Choosing Sino for your table fan stator laminations isn’t just about buying a component; it’s about gaining a partner dedicated to enhancing your product’s performance and reliability.

From raw material inspection to final stack dimension checks, quality is embedded in every step of our process at Sino. We employ statistical process control (SPC) and rigorous testing to ensure every batch of table fan stator laminations meets your exacting standards.

Our team of experienced engineers is ready to work with you. Whether you have a complete design or just a concept for your table fan stator, we can provide insights on material selection, lamination geometry optimization for better magnetic flux paths, and manufacturability to help you achieve your performance and cost targets.

We understand the demands of modern manufacturing. Sino is committed to reliable lead times and flexible production schedules to keep your assembly lines running smoothly.

While we never compromise on quality, our deep understanding of materials, tooling, and efficient manufacturing processes allows us to offer competitive pricing. We help you achieve better table fan stator performance without breaking the bank.

The demand for more energy-efficient appliances isn’t going away; if anything, it’s intensifying. Regulatory bodies worldwide are continually tightening efficiency standards (think Energy Star ratings or EU Ecodesign requirements). Consumers, too, are increasingly savvy about long-term running costs and environmental impact.

This means the design of every component, especially the motor and its table fan stator, will come under even greater scrutiny. At Sino, we’re already preparing for this future by:

We believe that the journey towards perfectly efficient, whisper-quiet table fans is ongoing, and Sino is committed to being at the forefront of lamination technology to help make that happen.

If you’re a manufacturer looking to elevate your table fan’s performance, reduce energy consumption, or simply build a more reliable product, the journey starts with superior table fan stator laminations. And that’s where Sino comes in. Let’s talk about how our expertise can help you build better fans. Reach out to us today, and let’s engineer a cooler tomorrow, together.

Note: To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.

To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.