Let Sino's Lamination Stacks Empower Your Project!

To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.

To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.

As Sino, a top Chinese maker of transformer laminations, we know the important part that high-quality magnetic cores play in how well your power products work, how dependable they are, and how small they can be. Our promise is to supply transformer makers around the world with the newest UI-shaped core laminations, made with great care to meet the many different and tough needs of today’s electrical systems in many different fields.

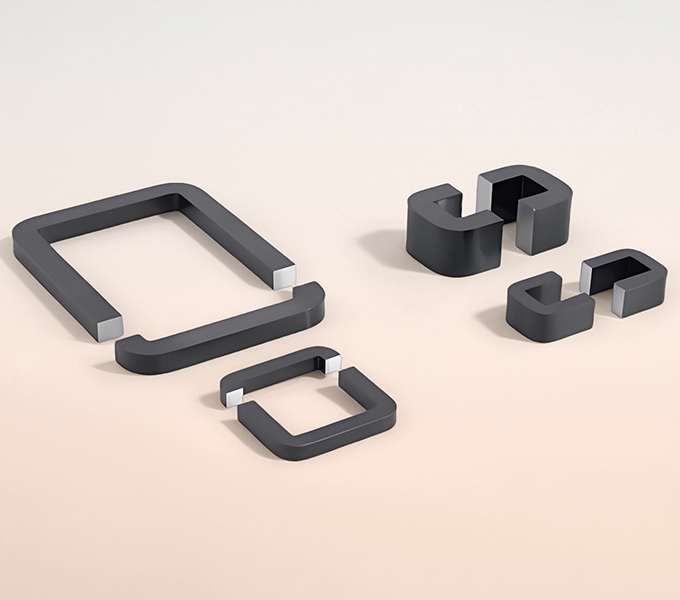

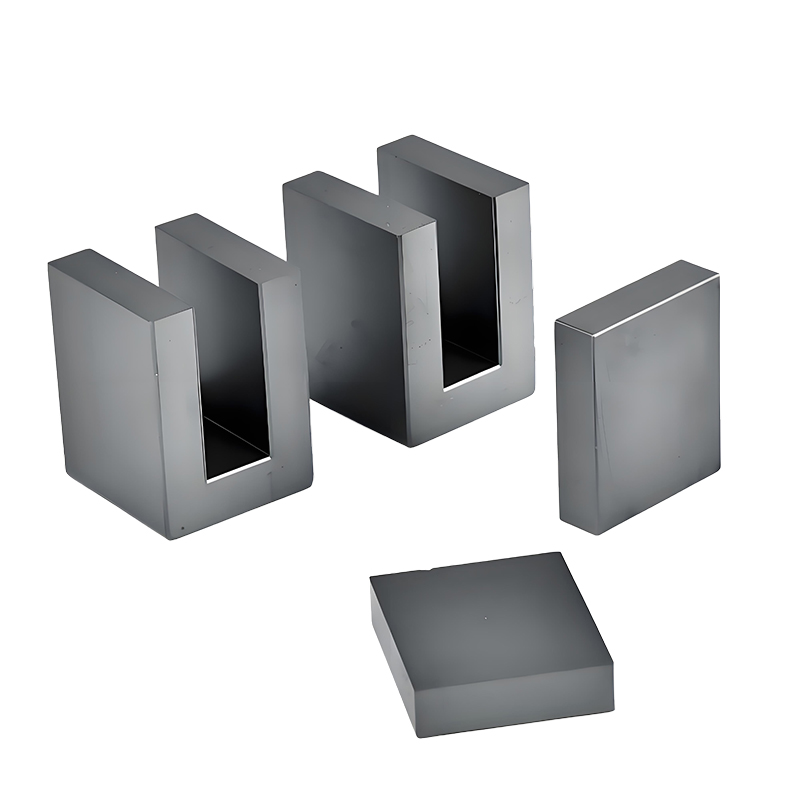

At Sino, we focus on making UI-shaped core laminations, which are a basic part of magnetic circuits. These cores are special because of their unique shape, making them a great choice instead of older core types for many different uses.

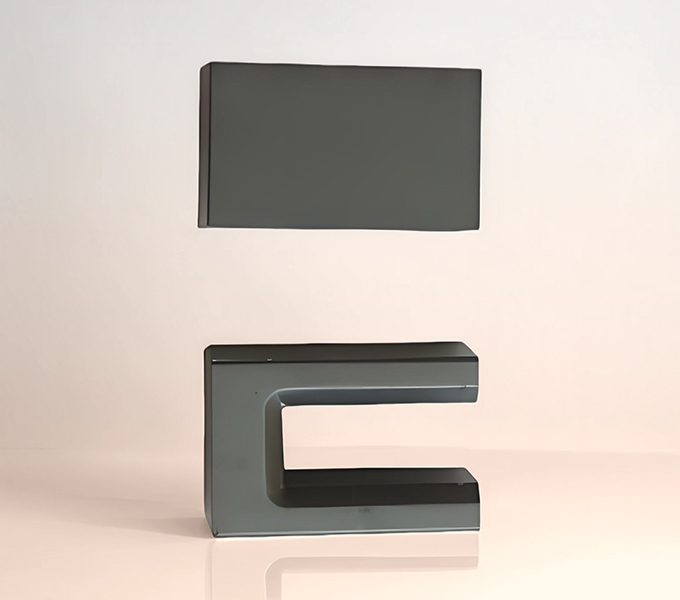

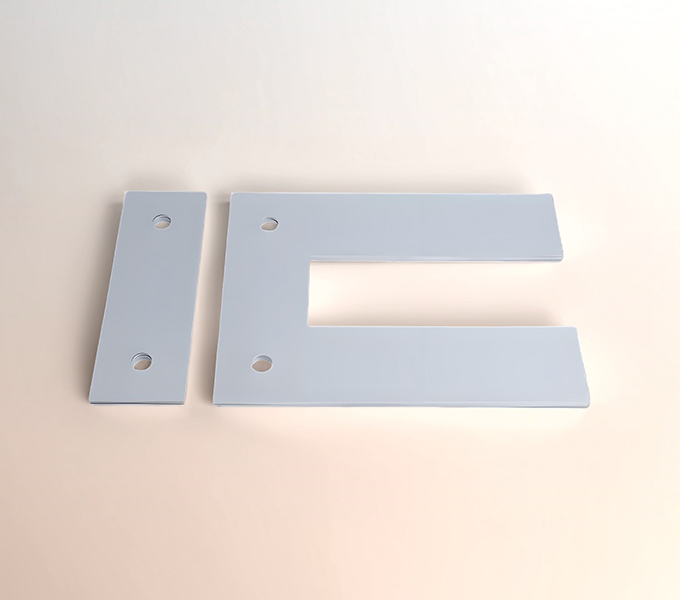

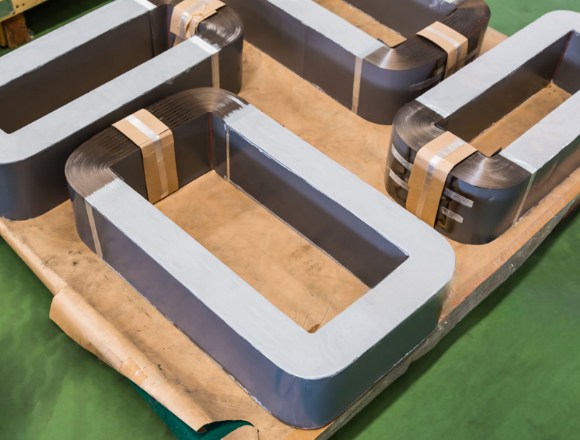

A UI core is cleverly made from two separate layered parts: the ‘U’ section and the ‘I’ section. The ‘U’ section, a U-shaped stack of layers, makes a non-stop path for magnetism with two arms that run side-by-side. The ‘I’ section, a straight bar of layers, is used to complete the magnetic loop by connecting the open ends of the ‘U’.

The way they are put together usually involves stacking the ‘U’ and ‘I’ layers, one after the other or in matched sets, to create a full magnetic loop. Coils are then wrapped around one or both arms of the ‘U’ section. This design naturally has a short and straight path for magnetism, which greatly reduces magnetic resistance (reluctance) compared to more complex E-I or C-core designs.

In any manufacturing endeavor, the bottom line talks loudly. You’re constantly looking for ways to deliver top-notch products without sending your budget into orbit. This is precisely where Sino’s ui lamination cores step into the spotlight. We’ve honed our manufacturing processes to a fine art. At Sino, we’ve invested in precision stamping technology and optimized our material utilization, meaning less waste and more efficient production. It translates directly into a more competitive price point for a critical component.

The beauty of the UI design is its elegant simplicity when it comes to putting things together. Unlike, say, toroidal cores which often require specialized, sometimes finicky, winding machinery to thread copper wire through a closed loop, the UI geometry is far more accommodating.

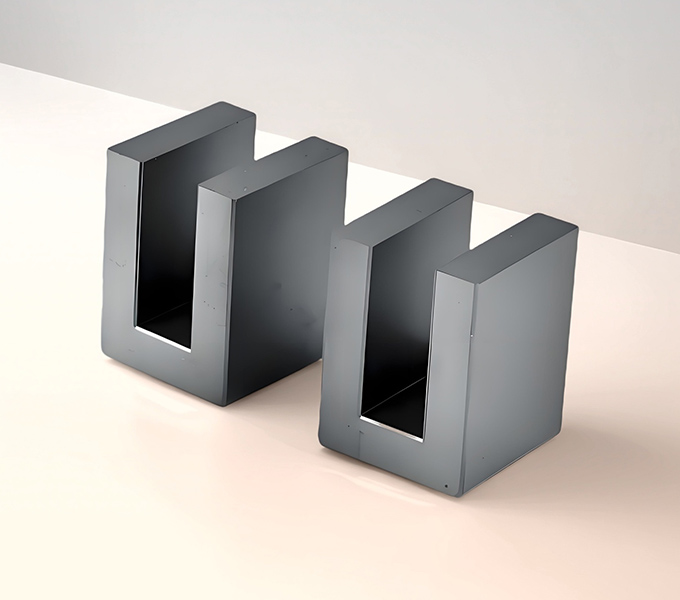

At Sino, we craft our ‘U’ and ‘I’ pieces with tight tolerances. This precision means that when your team is ready to assemble, it’s a breeze. Typically, your coils are pre-wound onto a bobbin – a relatively straightforward and quick operation. Then, our ‘U’ and ‘I’ laminations are simply brought together around this bobbin. It’s almost like a satisfying click as two puzzle pieces fit perfectly. These are then secured, often by clamping, welding, or even by being potted within an enclosure.

Sino’s UI laminations deliver a fantastic balance of magnetic performance, especially for those ubiquitous line frequency scenarios (your 50Hz or 60Hz power systems). While you might find niche materials that eke out a tiny bit more performance in very specific, often high-frequency, switch-mode power supply (SMPS) designs, our ui lamination cores provide truly respectable magnetic properties that are more than ample for a vast range of tasks, and they do it without the premium price tag of some exotic alternatives.

At Sino, we craft our laminations from high-quality silicon steel, often referred to as electrical steel. This isn’t just any steel; it’s engineered specifically for electrical scenarios to offer:

1

This is all about how easily the material allows magnetic flux lines to form within it. Good permeability means efficient magnetic coupling between windings in a transformer, or effective energy storage in an inductor.

2

Our ui lamination can manage a substantial amount of magnetic flux before its performance starts to taper off, which is crucial for preventing distortion or inefficiency under load.

3

Each ‘U’ and ‘I’ section we produce at Sino is composed of multiple thin sheets of electrical steel, each electrically insulated from the next by a thin coating. This layered construction breaks up the paths for eddy currents. Our meticulous lamination process significantly curtails these losses, leading to a more efficient component.

To give you a clearer picture, here’s a quick rundown of how Sino’s UI laminations generally stack up:

Feature | Sino’s UI Lamination Advantage | Your Key Takeaway |

Manufacturing Cost | Lower due to Sino’s high-volume precision stamping & optimized tooling | Better margins for your end product. |

Assembly Simplicity | Superb; open structure allows easy bobbin insertion | Faster production, reduced labor. |

Winding Process | Straightforward; coils usually wound on separate bobbins | Less specialized machinery needed. |

Magnetic Performance | Excellent for line frequencies; reliable permeability & saturation | Dependable operation for most power applications. |

Structural Integrity | Robust once assembled; simple to mount securely | Durable and easy to integrate into your chassis. |

Size & Power Handling | Wide range of sizes from Sino for diverse power levels | Scalable solutions from small signal to power. |

Data based on typical characteristics of electrical steel grades (e.g., M6, M19, M22 as per ASTM/IEC standards) utilized in Sino’s manufacturing processes and established electrical engineering principles.

One size rarely fits all, especially in the diverse world of electronics. That’s why at Sino, we ensure our ui lamination offerings provide a remarkable degree of versatility. You’re not shoehorned into a limited selection. We produce ui lamination cores in an extensive array of standard sizes, catering to power requirements from milliwatts up to kilowatts. Whether you’re designing a tiny signal transformer for a delicate medical sensing device or a chunky choke for heavy-duty welding equipment, chances are Sino has a ui lamination that’s just the ticket.

Beyond just physical dimensions, we also offer these laminations in various grades of electrical steel. You might hear terms like M6, M15, M19, or M22 being thrown around. They’re industry-standard designations (often based on ASTM or IEC specifications) that relate to the steel’s magnetic properties, particularly its core loss characteristics at specific frequencies and flux densities. What this means for you, as a designer, is choice.

How well a UI core works is basically decided by the magnetic material used to make its layers. Sino offers UI core laminations in several advanced materials. We choose each material for its specific magnetic features and how it loses energy at different frequencies.

In the real world, components need to withstand the rigors of assembly, shipping, and long-term operation. You’ll find that Sino’s ui laminations, once assembled, form a remarkably robust and structurally sound unit. The inherent geometry of the ‘U’ and ‘I’ pieces, when brought together and secured (whether by traditional clamps, robust welds, or full encapsulation in potting compound), creates a solid, dependable block.

This structural integrity isn’t just about surviving a bumpy ride; it also makes them incredibly easy to integrate into your final product. Most ui lamination assemblies lend themselves to straightforward mounting techniques. They can often be bolted directly to a chassis, secured to a printed circuit board (PCB) using mounting brackets or clips, or even form part of the structural support themselves in some designs. This practical, no-fuss integration is something engineers genuinely appreciate. There’s no need for elaborate or delicate mounting arrangements.

So, with all these inherent benefits of ui lamination cores, why should you specifically choose Sino? Because we’re not just stamping steel; we’re crafting solutions.

At Sino, quality control isn't an afterthought; it's woven into every step of our manufacturing process, from raw material inspection to final dimensional checks. We adhere to stringent standards to ensure every ui lamination leaving our factory meets your expectations.

We’ve been in the lamination game for a long time. Our team possesses deep knowledge of materials, magnetic properties, and manufacturing techniques. We’re happy to discuss your specific scenario and help you select the optimal ui lamination core for your needs.

We see ourselves as partners in your success. Whether you need standard off-the-shelf sizes or have requirements for slight modifications, we’re here to listen and deliver.

We understand the importance of a dependable supply chain. Sino is committed to consistent production and timely delivery, helping you keep your production lines running smoothly.

When you choose Sino for your ui lamination needs, you’re not just buying a part; you’re investing in decades of manufacturing expertise, a commitment to quality, and a partner dedicated to helping you bring your best products to market.

Ready to see how Sino’s UI laminations can make a difference in your next project? Don’t hesitate to reach out to us. Let’s talk about your requirements, explore solutions, and get you the samples you need. We’re confident that once you experience the Sino difference, our ui lamination cores will become a go-to in your design toolkit.

Note: To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.

To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.