Let Sino's Lamination Stacks Empower Your Project!

To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.

Three-phase induction motors do a lot of the hard work in our world today. You can find these strong induction motors in many places. They are in very big factory machines. They are also in the pumps that give you water. This article is a simple guide that will help you understand them. We will explain how a 3 phase induction motor is built and how it works, using easy steps. By the time you finish reading, you will know how this great electric motor works. You will also know why it is used so much.

A 3 phase induction motor is a kind of AC motor. In this motor, power is given to the rotor part using electromagnetic induction. This is the same main idea that a transformer uses. That is why people sometimes call these induction motors “rotating transformers.” The important thing to know is that there is no wire that connects directly to the part that moves, which is the rotor.

This type of motor is famous because it is built in a simple and strong way. It does not have parts called brushes, which some other motors have. Because of this, it does not need much care or many repairs. These induction motors also start by themselves. This is a big plus when you compare it to a single-phase induction motor. Because they are so simple and you can count on them, 3-phase induction motors are the most common type of ac motor you will find in factories. The main job of this phase induction motor is to change three-phase electricity into motion.

Every phase induction motor has two main parts. If you understand these parts, you can start to understand how the whole motor works. The induction motor consists of two important pieces:

There is a very small space between the stator and rotor. This space is the air gap. The air gap is made as small as possible to help the motor work better. How these two main parts work together is what makes all induction motors turn a shaft and get work done.

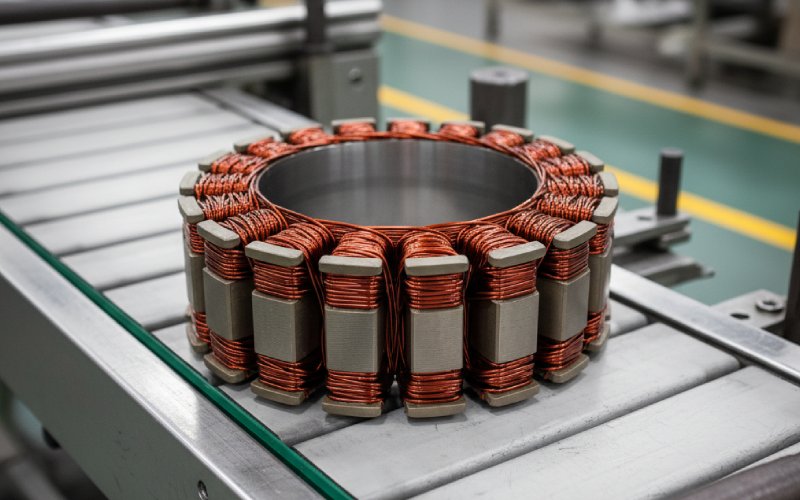

The stator of three phase induction motors is built with a lot of care. It is shaped like a hollow tube and is made of thin sheets of high-quality steel. These thin steel sheets are pressed together in a stack. Using thin sheets helps to lower the amount of energy that gets wasted. Inside the stator, there are cuts called slots. The stator winding is put into these slots. The winding is made from copper wire that has a special coating to keep the electricity from leaking.

This winding is not just one big loop of wire. It is really three different sets of windings. Each winding is for one phase of the three-phase ac supply. The windings are put into the slots in a very specific pattern. They are set 120 degrees away from each other. When you hook up a 3-phase ac power source to this three-phase winding, it makes a special kind of magnetic field. This field is the key to how all induction motors work. The stator is wound for a definite number of poles. The number of poles helps to set the motor’s speed. The motor consists of this very important part.

The kind of rotor you see most often is the squirrel cage rotor. It gets its name because of its shape. It looks a bit like a running wheel for a small animal. This rotor is made from a core of stacked, thin steel sheets. It has slots on its outside surface. This rotor does not have a wire winding. Instead, it uses thick bars of copper or aluminum. These bars are put into the rotor slots.

All of the bars are joined together at each end. They are connected by thick metal rings called end rings. This makes a full electrical path. The copper bar and end rings look like a cage, which is how it got the name squirrel cage. This design is very tough and not complicated. It has no brushes or slip ring parts that can break or wear down. The squirrel cage induction motor has a very robust construction. This makes it a machine you can count on, and it is not expensive to make. This is the reason that more than 9 out of 10 induction motors use this kind of rotor. The rotor of a three-phase induction motor is almost always this squirrel cage type.

Yes, there is another kind of rotor. People call it a wound rotor or a slip ring motor. This type of rotor is not like the squirrel cage version. A wound rotor has a full 3 phase winding, much like the winding in the stator. It does not use solid bars. The winding is made of coated copper wire and is placed into the slots on the rotor. This is why we call it a phase wound rotor.

The ends of this rotor winding are not connected to each other like in a squirrel cage. Instead, they are wired to three special metal rings that are on the shaft. These are called slip rings. Small carbon blocks, called brushes, press against these slip rings. This lets you connect outside parts, like resistors in the rotor circuit. By adding resistance, you get more control over how the motor works. For example, it gives the motor a much stronger starting torque than a squirrel cage motor. A slip ring induction motor is used for jobs that need a lot of power to get started. This wound motor is more difficult to build and costs more money.

| Feature | Squirrel Cage Rotor | Wound Rotor (Slip Ring) |

|---|---|---|

| How It’s Built | Very simple, with bars and end rings | More complex, with a 3-phase winding |

| Starting Power | Good | Very strong, and you can change it |

| Cost | Low | High |

| Upkeep | Very little, has no brushes | Needs more care because of brushes and slip rings |

| Control | Speed control is hard to do | Good control of speed and starting current |

| Used For | Fans, pumps, most things in factories | Cranes, lifts, elevators, heavy jobs |

The working principle for all induction motors comes from a science rule called Electromagnetic Induction. This rule says that if you move a wire (a conductor) through a magnetic field, a voltage (emf) will be made, or induced, in the wire. The same thing happens if the magnetic field is moving and the wire is still. What matters is that one is moving compared to the other. This is called relative motion.

In a 3 phase induction motor, the stator winding makes a magnetic field that spins around. This spinning field moves past the metal bars of the rotor. The rotor bars are all connected, making a full circle for electricity. The induced emf makes a current flow through them. This current flows in the rotor bars. Now you have a conductor with current in it (the rotor) sitting inside a magnetic field (from the stator). This makes a turning force, or torque, on the rotor. This torque is the force that makes the rotor spin. The power gets from the stator to the rotor just by using electromagnetic induction from the stator.

A rotating magnetic field is the secret that makes three-phase induction motors work so well. When you connect a good three-phase power source to the stator winding, something cool happens. Each of the three windings makes its own magnetic field. This field gets stronger and weaker as the AC power changes. But because the windings are spaced 120 degrees from each other, their magnetic fields add up to create one big magnetic field.

This new, combined magnetic field does not stay in one place. It spins around the stator at a steady speed. We call this speed the synchronous speed. The synchronous speed is set by two things: how fast the AC power source cycles (its frequency) and the number of poles the stator was made with. It is this rotating magnetic field that moves past the rotor’s conductors and starts everything. If it did not have this field, the phase induction motor would not be able to start on its own. The magnetic field of the stator has to spin.

The rotor of an induction motor will always spin a little bit slower than the stator’s rotating magnetic field. The difference in speed between the synchronous speed of the field and the real speed of the rotor is what we call slip. We usually talk about slip as a percentage. If the rotor could spin at the exact same speed as the magnetic field (at synchronous speed), then the field would not be moving past the rotor.

If there is no motion between them, the magnetic field would not cut through the rotor conductors. This means no emf would be made, and no current would flow in the rotor. If there is no current, there is no torque. Without torque, the rotor would slow down. So, in order for the motor runs, the rotor must spin slower than the magnetic field. This is the only way to make torque. This is also why an induction motor is sometimes called an asynchronous motor (meaning not in sync). The amount of slip gets bigger when you put more work on the motor. A normal induction motor may have a slip of 3% to 5% when it’s working at its hardest.

Most 3-phase induction motors have a box with six connection points. These points are the ends of the three windings inside the stator. There are two main ways to connect them: Star (also called Wye) and Delta. The way you choose to connect them changes how the motor will run.

Even though 3-phase induction motors are great machines, they are not perfect. They have a few weak points you should know about. Here are the main disadvantages of 3 phase induction.

Even with these problems, the good things about induction motors, like the fact that they are very reliable and do not cost a lot, make them the top choice for many, many jobs.