Let Sino's Lamination Stacks Empower Your Project!

To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.

Have you ever wondered what’s inside a transformer? Transformers seemed like magic boxes. The transformer core is like the heart of a transformer, guiding the power. The core material used for this transformer core makes a big difference in how well the transformer works. In this post, I’ll share four main types of transformer core materials. Knowing this can help you understand how transformers work better and why choosing the right core material is so important for an efficient transformer.

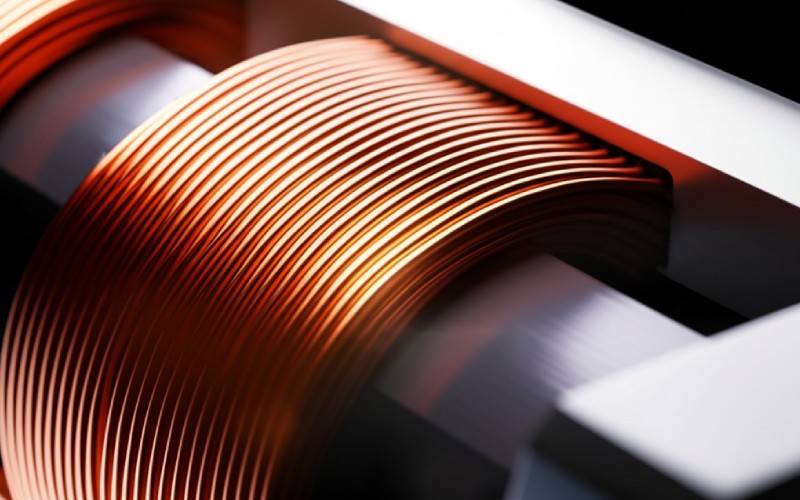

Simply put, the transformer core is the central part of a transformer that the windings (coils of wire) are wrapped around. Its main job is to provide a path for the magnetic flux. Think of it like a road for magnetic energy to travel easily from one winding to another. This magnetic flux is what allows the transformer to change voltage up or down.

The core material is super important. It decides how good the transformer core is at guiding that magnetic flux. A good core material means less energy loss and a more efficient transformer. If you choose the wrong core material for your transformer, you could end up with a lot of wasted power, or the transformer might not work as expected for its job. The magnetic properties of the core material directly impact the transformer’s performance.

Different core materials have different strengths. Some are great at handling high power, others are better for high speeds, and some are chosen to keep core loss very low. Understanding the type of transformer core and the material used is key to understanding the whole transformer. This is why looking at the transformer core design is a big step in making any transformer.

In this core design, the windings surround the transformer core. Imagine a square or rectangular donut – that’s kind of like the core type transformer shape. The primary and secondary windings are usually placed on two separate legs or limbs of this core structure. This core type is quite common.

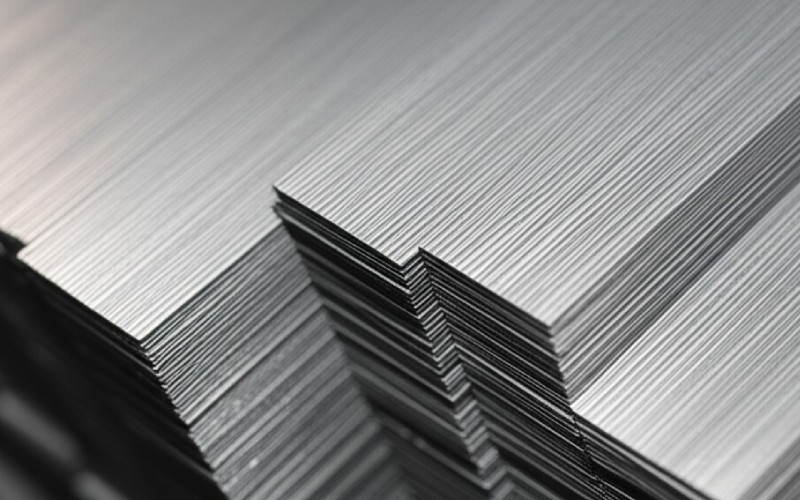

The core type transformer construction is often simpler, which can make it easier to make and fix. The transformer core itself is made of thin sheets, called transformer laminations, stacked together. This core type design allows for good cooling because the windings are more exposed to the air or cooling oil if it’s a big power transformer.

One of the core type transformer features is how the magnetic flux has one main path through the core column. The primary and secondary coils share this magnetic core. This direct path for the magnetic flux is a key part of how this type of transformer works. Many distribution transformers use this core type because it’s effective and reliable for stepping down voltage.

The way a transformer core is built, its core construction, really changes how the transformer acts. It’s not just about the core material; it’s also about the shape and how it’s put together. For example, most transformer cores are not solid blocks of metal. Instead, they are made of many thin sheets of core material, like silicon steel. These are called transformer laminations or core lamination.

Why use thin sheets? This helps reduce something called eddy currents. These are tiny, unwanted currents that can flow within the core if it’s a solid piece. Eddy currents cause energy loss by heating up the transformer core. By using a laminated core, we break up the paths for these currents, making the transformer more efficient. The transformer core laminations are a clever bit of core design.

The actual core design also includes how the windings are placed around the core. In a core type transformer, the windings surrounding the core are key. In a shell type transformer, the core surrounds the windings. This difference in core configuration affects things like cooling, how strong the transformer is, and even the amount of core material needed. The design of the core is all about optimizing transformer performance.

When transformers were first invented, a solid iron core was a common choice. Iron is a good magnetic material, meaning it can carry magnetic flux well. So, an iron core seemed like a good idea. I’ve seen some very old transformers that used this approach. The basic idea was to get as much iron as possible to make a strong magnetic field.

However, there’s a big problem with a solid iron core, especially when dealing with the changing current found in most transformer applications. This changing current creates a changing magnetic field, which in turn can create those pesky eddy currents inside a solid iron core. These currents just swirl around, creating heat and wasting a lot of energy. This means a high core loss.

So, while a solid iron core might be simple, it’s not very efficient for most modern transformers. The energy loss is just too high. That’s why you don’t see them much anymore, especially in a power transformer or distribution transformers where efficiency is key. We learned better ways to make an iron core, like using silicon steel and laminations.

Silicon steel is definitely the workhorse core material for many types of transformer. It’s an alloy of iron with a small amount of silicon added, usually around 3%. This addition of silicon does a couple of great things for the transformer core.

First, silicon steel increases the electrical resistance of the iron. This helps to reduce core losses, especially those caused by eddy currents. Second, it has good permeability, which means it allows magnetic flux to flow easily. This makes for a more efficient transformer. Most silicon steel used in transformer cores comes in thin sheets, forming transformer laminations. Stacking these transformer core laminations further cuts down on energy loss.

You’ll find silicon steel in many transformer types, from small ones in your electronics to large power transformers and distribution transformers. It offers a good balance between cost and performance. The core loss is manageable, and it’s a reliable core material. It’s a common choice for both core type and shell type transformer designs because it’s so versatile. We often see it used in distribution transformers.

Amorphous steel, sometimes called metallic glass. This was a game changer! Unlike regular silicon steel, which has a crystal structure, amorphous steel has a random, non-crystalline structure. This unique structure is what makes it special for transformer cores.

The biggest advantage of amorphous steel as a core material is its very low core loss. Because it doesn’t have the grain boundaries found in crystalline steel cores, it’s much harder for those energy-wasting eddy currents to form. This means less heat and much less energy loss, especially when the transformer isn’t heavily loaded. This is great for enhancing transformer performance. This material has high permeability too.

While amorphous steel cores are used to make a very efficient transformer core, they can be a bit more expensive and sometimes harder to work with than silicon steel. However, for transformer applications where energy savings are critical over the life of the transformer, like in some distribution transformers, the extra cost can be worth it. The focus here is on achieving low core losses.

Nanocrystalline cores are a newer type of magnetic core material and they are quite exciting. Nanocrystalline materials are made by taking an amorphous metal ribbon (similar to amorphous steel) and then heat-treating it very carefully. This process creates tiny, nano-sized crystal grains within the amorphous structure. It’s like getting the best of both worlds!

The result is a core material with incredibly high permeability. This means it can channel magnetic flux extremely well with very little effort. Nanocrystalline cores also have very low core losses, even lower than amorphous steel in some cases, especially at higher frequencies. This makes them great for specialized transformer applications, like in high-frequency power transformers or a current transformer.

Nanocrystalline cores are helping us build even more efficient transformer designs. While they might be more costly than silicon steel, their superior magnetic properties can lead to smaller, lighter transformers with better performance. These types of transformer core materials will play a big role in optimizing transformer technology as we move forward, especially where space and energy loss are big concerns.

If the choice between a shell type transformer and a core type transformer affects the core material? The short answer is: not really, but the core design itself is different. Both shell type and core type designs can use common core materials like silicon steel. The main difference is in the core construction and how the windings and transformer core are arranged.

In a core type transformer, as we discussed, the windings surround the core. The transformer core usually has two limbs, and the primary and secondary windings are placed on these limbs. The magnetic flux has a single path. This core type transformer construction is often seen.

In a shell type transformer, the transformer core surrounds the windings. It’s like the windings are a sandwich, and the core material is the bread on both sides and around the edges. The shell type design often has a central limb where both primary and secondary windings are placed, and the magnetic flux has two paths to return around the outside of the core. A shell type can sometimes offer better support against electromagnetic forces and might have a more compact core structure. For example, a three limb core or even a four limb core can be part of a shell type or a larger core type transformer design. The material used will still be chosen for its magnetic properties and ability to reduce core losses.

Magnetic flux is the key to how a transformer works. It’s the magnetic field flowing within the core, linking the primary and secondary windings. When an alternating current flows in the primary winding, it creates this changing magnetic flux. This flux then cuts across the secondary winding, making a current flow in it. So, good control of magnetic flux is essential for an efficient transformer.

Core loss, on the other hand, is something we want to minimize. It’s the energy loss that happens in the transformer core itself. This loss turns into heat. There are two main types of core loss: hysteresis loss (due to the magnetic domains in the core material resisting changes in magnetization) and eddy current loss (those unwanted currents we talked about). A good core material and core design, like using transformer laminations of silicon steel, helps to keep core loss low.

Minimizing core loss is crucial for transformer efficiency. If a transformer has high core loss, it wastes energy, costs more to run, and can overheat. This is especially important for power transformers and distribution transformers that are on all the time. So, a lot of effort in transformer core design goes into choosing materials and construction methods that keep magnetic flux flowing well and core loss down.

Choosing the right core material is a big decision when designing or selecting a transformer. It really depends on the specific transformer applications. I’ve seen how different needs lead to different choices in material and design. For example, if you need a step-down transformer for general power distribution, silicon steel is often a good, cost-effective choice. It’s commonly used in distribution transformers.

For applications where minimizing energy loss is the absolute top priority, even if it costs a bit more upfront, amorphous steel or nanocrystalline cores are excellent. These are great for making a very efficient transformer. Think about high-efficiency distribution transformers or specialized power supplies. The low core losses of these materials can save a lot of energy over the transformer’s lifetime.

Then there are high-frequency transformer applications, like in switch-mode power supplies. Here, ferrite cores are commonly used, or even nanocrystalline cores because they perform well at high frequencies with low losses. The permeability and loss characteristics of the core material at the operating frequency are critical. So, understanding the demands of the application helps in choosing the right transformer core and ensuring the overall efficiency of the transformer. The right core makes all the difference to transformer performance.

A1: The main job of a transformer core is to provide an easy path for the magnetic flux to flow between the primary and secondary windings of the transformer. This allows the transformer to transfer energy and change voltage efficiently.

A2: Transformer cores, especially those made of silicon steel, are laminated (made of thin sheets) to reduce eddy currents. Eddy currents are unwanted currents that cause energy loss and heating in the core. Transformer core laminations break up the path for these currents.

A3: Core loss is the energy loss that occurs in the transformer core when it is magnetized by the alternating current in the windings. It’s made up of hysteresis loss and eddy current loss and results in heat. Minimizing core loss improves transformer efficiency.

A4: Silicon steel is a very common core material used in transformer cores. Adding silicon to iron improves its magnetic properties and increases electrical resistivity, which helps to reduce core losses. It’s used in many types of transformer, including power transformer and distribution transformers.