Let Sino's Lamination Stacks Empower Your Project!

To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.

Understanding the transformer core is key to understanding how a transformer works and why some are better than others. This guide to transformer cores will show you everything you need to know about transformer parts. We will look at what they do, what they are made of, and why their core design is so important. If you want to choose an efficient transformer and save on energy costs, this article is for you.

The main purpose of a transformer is to change the level of voltage and current in an electrical circuit. Think of it like a ramp for electricity. A transformer can either “step-up” the voltage to a higher level or “step-down” the voltage to a lower level. This is done without changing the total amount of power. When the voltage goes up, the current goes down. When the voltage goes down, the current goes up.

This is a very important job. Power plants create electricity at a very high voltage to send it over long distances with less energy loss. When this electricity reaches your town, a transformer steps the voltage down to a safer level for homes and businesses. Different devices need different power requirements. A transformer helps match the power from the wall outlet to what your device needs.

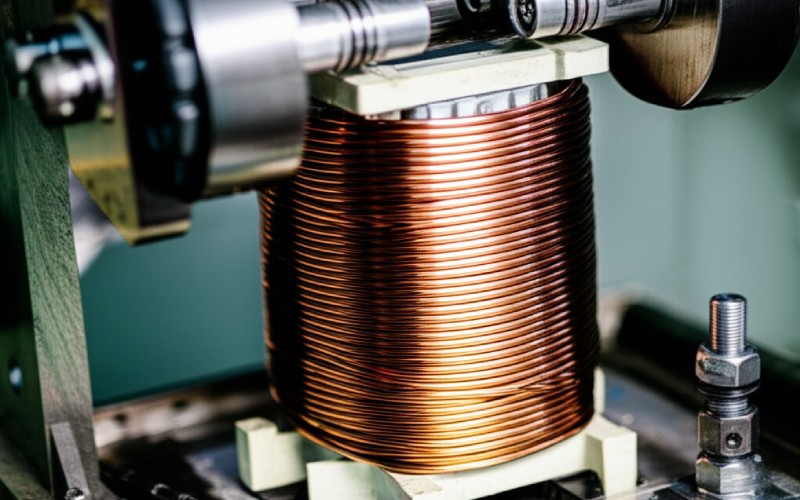

The transformer does this using a process called electromagnetic induction. It has two sets of wires, called primary and secondary windings. The first coil (primary) receives the electrical energy. This creates a magnetic field. The transformer then uses this field to transfer energy to the second coil (secondary), which sends out the power at a new voltage. All types of transformers work on this basic rule.

Now, let’s talk about the star of the show: the transformer core. If the windings are the arms of the transformer, the core is like the body that connects them. The transformer core is the central part of a transformer. Its main job is to provide a path for the magnetic flux to flow. When the primary winding creates a magnetic field, the core guides this field over to the secondary winding.

Without a good transformer core, the magnetic flux would spread out in the air. Much of the energy would be lost. The core acts like a highway for the magnetic field, making sure it travels from the primary coil to the secondary windings with very little getting lost along the way. This is what makes a transformer so good at transferring power. The magnetic core is key to an efficient transformer.

The transformer core is usually made from a material that is very permeable to magnetic flux. This means the magnetic field can flow freely through it. A common choice is an iron core. The better the transformer core guides the magnetic flux, the more efficient the energy transfer will be. This is why the design of the core is so important. An efficient transformer core ensures the device works well. The transformer relies on this part.

The core design is everything for a transformer. A good transformer core design makes sure the transformer works well and does not waste a lot of energy. A poor core design can lead to high energy loss, heating, and a shorter life for the transformer. The goal is always to create a path for the magnetic flux that is as easy to travel as possible.

The core design affects many things. It decides how much magnetic flux the core can handle, which is called flux density. It also helps to reduce energy waste. The shape and size of the transformer core must match the amount of power the transformer needs to handle. For high-power applications, you need a bigger, more robust core design. For smaller electronics, a different transformer core design is used.

Thinking about core design is how we make an efficient transformer. We want to minimize power losses. For example, a good core design will have very few air gaps. These gaps can resist the flow of magnetic flux and cause energy loss. The way the transformer core is built, from its material to its shape, all add up to how well the transformer performs its job. This design ensures that the transformer will work properly.

The material used for the transformer core is very important for its performance. The goal is to use materials that have high permeability. This means they let the magnetic flux pass through them easily. The most common materials are silicon steel and amorphous metals.

Silicon steel is a special type of steel with a small amount of silicon added. This addition increases the steel’s ability to resist current flow within the core itself, which helps to reduce energy loss. Often, this is a special type of silicon steel called CRGO, which stands for Cold Rolled Grain Oriented steel. CRGO steel has very good magnetic properties in the direction the steel is rolled, making it perfect for a transformer core. The transformer benefits greatly from these materials.

Another amazing material is amorphous metal, sometimes called metallic glass. Amorphous cores are made from metals that are cooled so quickly they do not form a crystal structure. This messy structure makes it very easy for the magnetic field to change direction, which dramatically cuts down on energy loss. An amorphous core is great for making a transformer with higher efficiency, especially in distribution transformers that are always on. Other materials like ferrite are also used, often in high-frequency current transformers. These materials make a huge difference.

If you ever look closely at a transformer core, you might notice it is not a solid block of metal. Instead, it is made of many thin sheets stacked together. This is called lamination. The core construction uses these laminated sheets for a very important reason: to stop something called eddy currents.

Here is what happens. When the magnetic field in the transformer core is always changing, it can create small, circular flows of current inside the core material itself. These are eddy currents. These tiny currents are a big problem because they do no useful work. They just create heat, which is a form of energy loss. This heating can damage the transformer and wastes electricity. A solid iron core would have large eddy currents.

By using lamination, we break up the path for these eddy currents. Each thin sheet, or lamination, has an insulating layer on it. This layer stops the current from flowing between the sheets. This means any eddy current can only flow in one very thin sheet, which makes it very small and weak. This simple trick of lamination is one of the best ways to reduce eddy current losses and make a more efficient transformer. This is a key part of transformer core construction.

When we talk about the main types of transformer cores, we are usually talking about the two most common shapes or configuration styles. These are the “core type” and the “shell type”. The choice between them depends on the power needs and what the transformer will be used for. Each core type has its own strengths.

The first core type is called, simply, the “core type”. In this design, the windings are wrapped around the core limbs. Imagine a square donut, and the wires are wrapped around two of its sides. This design is simple to build and provides good coupling between the primary and secondary windings. The transformer core is the center of the structure.

The second major core type is the “shell type”. In a shell type transformer, the core surrounds the windings. It is like the winding is the soft center and the transformer core is the hard shell protecting it. This design provides a better path for the magnetic flux because it has a large central limb. A shell-type design also offers better mechanical protection for the coil and winding. This is one of the most common types of transformer cores. This transformer is very reliable.

Let’s dig a little deeper into these two designs. In a “core type” transformer, the winding surrounds the transformer core. The core itself is usually a simple rectangle shape with two limbs. The primary and secondary windings are placed one over the other on both limbs of the core. This core construction is easier to take apart for repairs. However, the path for the magnetic flux is longer, which can sometimes lead to more energy loss.

In a “shell type” transformer, the opposite happens. The transformer core is built around the windings. The core has three limbs, and the coil is wound around the center limb. The two outer limbs provide a low-resistance path for the magnetic flux. This shell-type design helps to reduce energy loss because the magnetic flux has two paths to return, which lowers its resistance. The transformer is often more compact with this design.

So, when would you choose one over the other? Core-type transformers are often used in high-voltage power applications, like large power transformers. The shell type transformer is very common in smaller electronics and distribution transformers where a compact size and higher efficiency are important. The choice of core type really depends on the specific job the transformer needs to do. Both are designed to make the transformer work well.

The way the transformer core is put together is called its assembly configurations. This is especially important for three-phase power, which is used in most industrial settings. For these types of power requirements, the core needs to handle three separate magnetic field flows at once. The most common designs are the three limb core and the five limb core.

A three limb core is the standard for most three-phase distribution transformers. It has three vertical legs, or limbs, and a top and bottom yoke to connect them. Each limb holds the primary and secondary windings for one phase of the power. This core design is simple and cost-effective. The magnetic flux from each phase shares the same path, which works well most of the time.

For very large power transformers, a five limb core is often used. This design adds two outer limbs to the standard three. These extra limbs are not wound with a coil. Their job is to provide an easier return path for the magnetic flux, which helps to reduce energy loss and no-load losses. A four limb core configuration also exists but is less common. These different configurations are chosen to ensure efficient operation for a specific transformer. The transformer needs the right core construction for its job.

The relationship between the coil and the transformer core is at the heart of how a transformer works. The coil, also known as the winding, is made from a conductor, usually copper or aluminum. There are at least two windings in a transformer: the primary winding and the secondary winding.

The process starts when an alternating current flows through the primary coil. This current creates a changing magnetic field around the winding. This is where the transformer core comes in. The core, being made of a material with high magnetic permeability, captures this magnetic field. It then guides the magnetic flux efficiently along its path. The core is like a channel for this magnetic energy. The windings surrounding the core are where the action starts.

The magnetic flux, now flowing through the common core, passes through the secondary winding. This changing magnetic field moving across the secondary coil induces a voltage in it. This creates a new current that can power a device. The ratio of turns in the primary coil to the secondary coil determines the output voltage. This is how a transformer performs its step-up and step-down function. The transformer core ensures that almost all the magnetic flux from the primary coil reaches the secondary, which increases the efficiency of the energy storage and transfer. The core can also be built around the coils.

When you hear people talk about a good transformer, they are often talking about transformer efficiency. This is a measure of how much power is lost as it moves through the transformer. No transformer is perfect; there will always be some energy loss. But a well-designed transformer with an efficient transformer core can get very close to perfect. To know about transformer cores is to know about efficiency.

There are two main types of energy loss in a transformer. The first is “load loss” or copper loss, which happens in the winding due to the resistance of the wire. The second, and often bigger, is “no-load loss” or iron loss. This happens in the transformer core itself. This energy loss is caused by eddy currents and something called hysteresis. Hysteresis loss is the energy used to change the direction of the magnetic field in the core material. This is where amorphous materials shine, as they have very low hysteresis losses.

An efficient transformer core is designed to reduce these no-load losses. Using high-quality materials like amorphous metal or CRGO silicon steel and using lamination to stop eddy current losses are key. Reducing energy loss is not just about performance; it is also about money. A transformer with higher efficiency wastes less energy, which means lower operating costs over its lifetime. For anyone choosing a transformer, this is a critical point to consider. The efficiency of the transformer is directly tied to its core design. This is what you need to know about transformer efficiency.