Let Sino's Lamination Stacks Empower Your Project!

To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.

A single-phase motor is a very common tool. You can find it in many homes and small shops. The most important part of this motor is its winding. But what is a motor winding? It is a group of wires coiled up inside the motor. These wires turn electricity into movement. This guide will teach you all about these very needed windings. Reading this article will help you learn how your motor works. You will also learn how to find problems and keep your tools working well.

A motor winding is a coil of copper wire that is put inside a motor. You can think of it like the motor’s muscle. When electrical power goes through this winding, it makes a special kind of force. This force is what causes the motor to spin and do its job. The winding needs to be in good condition for the motor to run correctly. If the wire has a break or is hurt, the motor will not run.

The wire in the winding has a thin cover. This cover is called insulation. The insulation is very, very important. It makes sure the electricity flows on the correct path along the wire. If the insulation gets damaged, electricity can find a shortcut. This shortcut is called a “short”. A short will make the motor fail. The motor needs a healthy motor winding and good insulation to work.

A single-phase motor has a special kind of winding setup. It runs on single-phase power, which is the kind of power in a house. Because of this, it needs a special trick to start spinning. This is why you often find two windings inside most single phase motors. Knowing what each winding does is the first step to figuring out any motor problem. The power of the motor comes from a good motor winding.

Most single phase motors have two main windings. One is called the “start winding“. The other is called the “running winding”. They work as a team to make the motor go. A single-phase motor cannot begin to spin by itself with only one winding. It needs an extra push to start moving in the correct direction. The start winding does this job.

The start winding is made of a thinner wire. It has more turns in its coil. It is made to work for just a few seconds when the motor starts up. It makes another magnetic field. This field gives the motor a push to help it start spinning. When the motor is almost at its full speed, a switch turns off the start winding. The motor keeps spinning with just the running winding.

The running winding is made from a thicker wire. It has fewer turns in its coil. This winding is made to stay on the whole time the motor is working. It gives the motor the power to keep spinning. If the start winding does not shut off, it will get too hot and fail. If the running winding is broken, the motor will not have enough power and might just hum instead of turning. Having two windings is a smart design for single phase motors.

A motor winding works using a simple idea about electricity and magnets. When electric current moves through a wire, it makes a magnetic field around that wire. In a motor, the winding is a very long wire that is wrapped into a coil many times. This makes the magnetic field very strong. The winding is put in the part of the motor that does not move, called the stator.

When you give power to the motor, the electricity flows into the winding. This creates a strong magnetic field inside the motor. This field then pushes and pulls on the part of the motor that spins, which is called the rotor. The start winding helps by making a lopsided magnetic field at the beginning. This uneven field is what forces the rotor to begin to turn.

After the motor is running, the magnetic field from the running winding is what keeps the rotor moving. The field changes its direction very fast, matching the changes in the AC power. This pushing and pulling action keeps happening. It gives the motor smooth and steady power. The entire way the motor works is because the winding is correctly making this magnetic field.

A motor winding can fail for a few different reasons. The reason they fail most often is because they get too hot. If a motor gets very hot, the thin insulation on the winding wires can melt. It can also get old and crack or break easily. This can cause a short, where wires touch each other or the metal motor body. A motor can get too hot if it is working too hard, if there is not enough air to cool it, or if its start winding stays on for too long.

Another common reason for a winding to fail is just old age and wear and tear. After many years of working, the insulation can slowly break down. The shaking of the motor can also make the wires in the winding rub together. This rubbing can wear off the insulation. This will cause the motor winding to fail over time.

Wetness and dirt can also hurt a motor winding. Water can cause a short circuit. Dirt can hold in heat, which makes the motor run hotter than it should. This extra heat will damage the insulation. When a motor fails, it is often because its winding was hurt in one of these ways. A bad winding means the motor will need to be repaired or replaced.

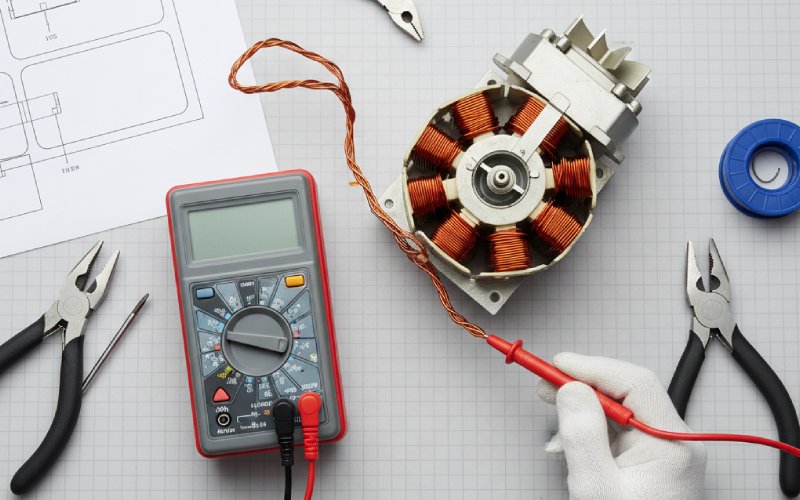

To check the windings on a single phase motor, you do not need special or expensive tools. The most needed tool is a multimeter. A multimeter is a device that can measure electricity in different ways. To test a motor winding, you will use it to measure resistance. You will also use it to check for continuity.

Here is a short list of tools that will help:

Before you begin any test, be sure that the motor is not connected to any power source. Your safety is the most important thing. This small group of tools will let you do the most common checks to see if a motor winding is good or bad.

Testing for continuity is a way to check if a wire is broken. A winding is made of one long wire. If there is a break in that wire, electricity cannot get through. This means the motor will not work. This kind of break is called an open circuit. You can easily test for continuity with a multimeter.

Follow these steps to test windings on a single phase motor:

This easy continuity check is the first thing to do if you think there is a problem with your motor. No continuity means the winding is broken and needs to be fixed.

After you check for continuity, you should look at the resistance number in ohms. Every motor winding has a certain resistance value that is normal for it. A reading that shows high resistance, but is not a full open circuit, can also mean there is a problem.

High resistance can be a sign that some wires in the winding are hurt or burned. When a wire gets very hot, its resistance can go up. This can happen if the motor has been getting too hot. A winding with high resistance will not let the right amount of electricity pass through. This will make the motor run weak, get very hot, or not be able to start. The motor will have a hard time doing its job.

You might need to look up the correct resistance numbers for your exact motor. You can sometimes find this information on the motor’s label or in its instruction book. If you check both the start and running windings, their numbers will be different. The start winding will usually have a higher resistance number than the running winding. This is because it is made with a thinner wire. A reading that is much higher than it should be points to a bad winding.

A short is a very common way for a winding to fail. A short happens when the insulation on the wires gets damaged. This lets the electricity take a “shortcut”. There are two kinds of shorts you should check for: a short to ground, and a short between two windings.

A short to ground means a winding wire is touching the metal body of the motor. This is very unsafe. It can make the outside of the motor have electricity on it. To check for this kind of short:

A short can also happen between the start winding and the running winding. To check for this, be sure the windings are not connected to each other. Put one multimeter lead on a wire from the start winding. Put the other lead on a wire from the running winding. Once again, the reading should be endless. If you see any continuity or resistance number, the windings may be shorted to each other. This kind of short will stop the motor from working the right way.

When you discover that a motor winding is bad, the next thing to ask is if it can be fixed. The answer is based on the kind of motor and the kind of damage. For a small, common single-phase motor, it is usually cheaper and easier to buy a new motor than to try to fix the winding.

A professional can fix it by doing a motor rewinding. This is a job that takes a lot of skill. A worker will take out the old, bad winding from the motor with great care. Then, they will put in a brand new coil of wire. This is a hard job that needs special tools to be done right. A motor winding repair is normally only done for bigger, more costly motors. It makes sense when a new motor costs a lot of money.

If a lead wire is broken right where it connects, you might be able to fix it yourself. But if the problem is deep inside the winding, it is not easy to repair. For most single phase motors in a home or small shop, if the winding is open or has a bad short, the best and safest thing to do is to buy a new motor. The old motor with the bad winding should be taken to a recycling place. The winding is like the motor’s heart. When it fails, the motor has reached the end of its life.

Using a multimeter, or meter, might seem difficult. But for checking a motor, you only need to know what a few basic readings mean. This table is a simple guide to what the readings say about your single phase motor windings.

| Multimeter Reading (on Ohms setting) | What It Means for the Winding | Is This Good or Bad? |

|---|---|---|

| “OL” or “1” (Endless Resistance) | The winding is open. The wire is broken somewhere inside. | Bad. No continuity. |

| A Low, Steady Number (like 2-20 Ohms) | The winding has good continuity. Electricity can flow through. | Good. This is what you want to see. |

| A Reading Near Zero (0) Ohms | Wires in the winding are touching. This is a short. | Bad. This is a short circuit. |

| Zero Ohms to Motor Body | The winding is touching the motor’s metal case. It’s a short to ground. | Very Bad. This is not safe. |

Always try to compare your readings to the normal values for your motor. But this guide gives you a good start to know what your multimeter is telling you about your motor’s health.