Let Sino's Lamination Stacks Empower Your Project!

To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.

Designing motors for electric semi-trucks is more than just swapping a diesel engine for an electric one; it’s a completely new way of thinking about the core of these powerful trucks. In this article, I’ll guide you through the important design choices, the problems we face, and the new solutions that are leading to a greener future in shipping. We will look at everything from torque needs to low-cost manufacturing, giving you a complete look at what it takes to power the next generation of commercial vehicles.

When we talk about power in a standard diesel truck, we often focus on horsepower and the engine’s ability to pull heavy loads over long distances. With an electric vehicle, however, the topic changes. It’s not just about raw power; it’s about smart power delivery. An electric motor gives immediate power from a complete stop, which is a big advantage for a fully loaded semi-truck that needs to get moving. This instant acceleration changes how it feels to drive and makes it more efficient in stop-and-go traffic. The design of modern electric powertrains allows for steady and even power across a wide range of speeds. This means the vehicle can reach and stay at highway speeds even on steep hills, something that can be hard for a normal diesel truck.

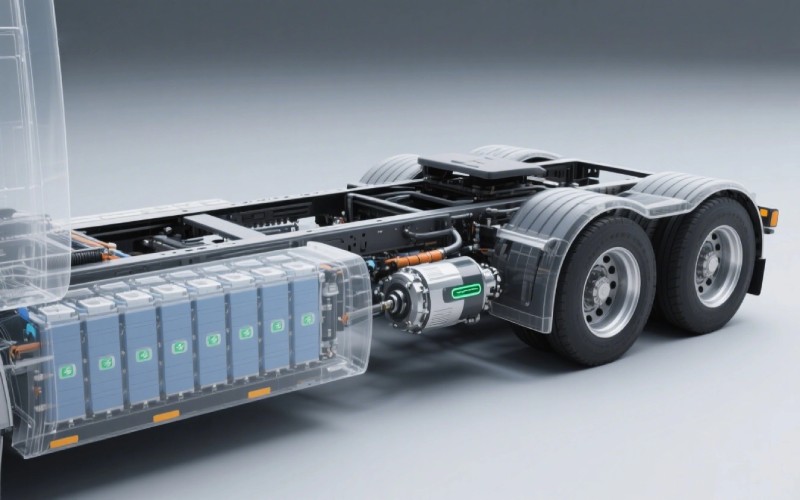

The new way of thinking about power also includes the way the whole vehicle is built. Without a large diesel engine, there is more open space and a better balance of the vehicle’s weight. This can lead to better handling and stability. Also, the power source, the battery pack, can be built into the chassis. This lowers the vehicle’s center of gravity and makes it less likely to roll over. The talk about power in heavy-duty vehicles is no longer just about the motor’s output in kW; it’s about how the entire electric powertrain works together to give a smarter, quicker, and more efficient performance. This complete-system view is what truly makes the modern electric truck different from older ones.

In my experience, there is no one-size-fits-all setup for the powertrain of every electric truck. The best setup depends a lot on what the truck will be used for. The main setups we see today are the central direct drive and the increasingly common electric drive axles, or e-axles. The central drive setup is often seen as a cheaper way to make existing truck platforms electric. In this setup, the diesel engine is replaced with a large electric motor that connects to a transmission and driveshaft, much like a normal vehicle. While this method can make the switch to electric simpler, it may not take full advantage of the space and energy savings of an electric powertrain.

The e-axle, on the other hand, is a more all-in-one solution. Here, the electric motor, power electronics, and sometimes even a gearbox are all located directly on the axle. This setup gets rid of the need for a long driveshaft, which cuts down on weight, makes the drive system shorter, and improves how well the whole system works. The space saved can be used for more battery capacity, which could increase the driving range. We’re also seeing more dual-motor setups, which offer better power delivery and improved performance for heavy loads. The choice between these setups means balancing development cost, how hard it is to build, and the desired level of performance and efficiency for that specific vehicle.

This is a question I get a lot, and the answer is a definite yes. In fact, an electric motor can often do better than a diesel engine when it comes to delivering torque. The key difference is how they create torque. A diesel engine has to get to a certain speed (RPM) to produce its highest torque. An electric motor, however, delivers its maximum torque right away, from a complete stop. This instant high torque is a huge benefit for heavy-duty use. Picture a fully loaded semi-truck on a steep hill; the great ability to start and control by applying maximum turning force to the wheels from a standstill is amazing.

To give you an idea of the numbers, some modern electric semi-trucks have very high torque numbers that match or even beat their diesel versions. For example, dual-motor setups can deliver peak torque in the tens of thousands of pound-feet. This high torque output lets electric trucks speed up quickly even when they are carrying a full cargo load. The challenge for engineers isn’t just getting high torque, but controlling it well to make sure tires and other parts last a long time. The design of the controller and the whole powertrain management system is key to controlling this huge amount of power smoothly and well.

Regenerative braking is one of the biggest benefits of an electric powertrain, especially for a heavy vehicle. In a normal truck, when the driver hits the brake, the moving energy of the vehicle is turned into heat by the brakes and is basically lost. Regenerative braking, however, lets the electric motor work in reverse, like a generator. This process slows the vehicle down and at the same time turns the moving energy back into electrical energy, which is then saved in the battery. This recovery of energy can greatly increase how far an electric truck can go. Some studies suggest it could add about 20% more range for a 40-ton vehicle doing regional deliveries.

Improving regenerative braking in heavy-duty vehicles requires a smart combination of the electric motor, the controller, and the regular friction brake system. The system needs to smoothly combine the two braking types to give the driver steady and reliable braking. Advanced electronic braking systems check things like vehicle speed and steering angle to smartly spread the braking force between the regenerative and mechanical systems. The goal is to get back the most energy without risking safety or how the vehicle drives. Also, the driver can often adjust how strong the regenerative brake is, which lets them adjust how the braking feels for the specific driving situation and what they like. Using regenerative braking well not only saves energy but also reduces wear on the normal brake parts, which means lower repair costs over the life of the vehicle.

It’s very important to have good thermal management in the design of an electric motor for a heavy-duty vehicle. These motors are put under a lot of pressure, working for long hours with heavy loads, which creates a lot of heat. If this heat isn’t removed well, it can lead to many problems, including lower efficiency, parts aging too quickly, and even the motor failing. A strong cooling system is needed to make sure the electric powertrain is durable and reliable. The main problem is designing a cooling system that works well and is small, without adding too much weight or difficulty to the vehicle.

There are two main ways to cool electric motors: air cooling and liquid cooling. Air cooling is simpler and cheaper, but it might not be enough for the high-power needs of a heavy truck. Liquid cooling, which moves a coolant through paths in the motor case, is usually better at removing heat. Many modern electric truck motors use advanced liquid cooling systems, sometimes even spraying oil right onto the hottest parts to keep them at the best temperature. The thermal management system often goes beyond just the motor, connecting with the cooling systems for the battery and power electronics to create a complete cooling solution for the whole vehicle. This connected approach allows for smart heat management, where waste heat from one part can be used to warm up another, making the whole system work better.

The need for a transmission in a modern electric truck is a topic people are still discussing and improving. Unlike a diesel engine, which has a small range where it works best, an electric motor works well at many different speeds. This has led some companies to choose a single-speed gearbox, which can make the powertrain simpler and with fewer mechanical parts. A single-speed design can work well for many uses, especially for driving in cities with lots of stops and starts.

However, for heavy-duty trucks that work in many different conditions, from slow-speed turning to high-speed highway driving, a multi-speed transmission can offer big benefits. A 2-speed or even a multi-speed gearbox can help keep the electric motor running in its most efficient range. This can lower overall energy use and increase the driving range. It can also make performance better, giving more torque for starting on steep hills and better efficiency at cruising speeds. The decision to add a multi-speed transmission comes down to carefully planning to get the best performance from the whole powertrain for the specific job, balancing the good parts of better efficiency and performance with the extra difficulty and cost of a more complex gearbox.

The axle, a basic part of any vehicle, is changing in a big way with new electric powertrains. In a normal truck, the axle is a simple part that just sends power from the driveshaft to the wheels. In an electric truck, however, the axle is becoming a smart and active part of the drive system. The biggest change here is the e-axle, which, as I said, puts the electric motor, power electronics, and gearing all together in the axle unit. This all-in-one setup has many good points, including less weight, better efficiency, and a smaller design that opens up useful space on the vehicle chassis.

The e-axle can also be set up in many ways. For instance, several e-axles can be used together to give all-wheel drive and better grip. This is especially helpful for heavy-duty trucks that work in tough conditions. Also, the electronic control of the e-axle allows for advanced features like torque vectoring, where the power sent to each wheel can be controlled separately to improve stability and handling. We are also seeing new drive systems where each side of the axle has its own power unit, allowing for even more exact control and the ability to recover 100% of the energy during regenerative braking. This new way of thinking about the axle makes the next generation of high-performance, efficient, and eco-friendly heavy-duty vehicles possible.

While the upfront cost of an electric truck can be higher than a similar diesel truck, the total cost over time is often much better. This is a very important point I always make when talking about electric commercial vehicles. Several things help make an electric motor and the whole electric powertrain a good value. The biggest of these is the lower cost of electricity compared to diesel fuel for each mile driven. This can lead to big savings on fuel over the life of the vehicle.

Also, an electric powertrain has a lot fewer moving parts than a diesel engine and its related systems. This means much lower repair costs. There are no oil changes, no complex exhaust systems, and less wear on parts like the brake system, thanks to regenerative braking. As battery and electric motor technology gets better and more are made, the starting cost of electric trucks is expected to go down, making them an even better financial choice. Government rewards and tax breaks for buying electric vehicles and charging stations can also help pay for the starting cost. When you look at all of these points, it’s clear that for many commercial uses, an electric vehicle powered by a cost-effective electric motor can be a good money decision in the long run.

For any commercial vehicle, durability and reliability are must-haves. When a truck isn’t working, it’s not making money, so these heavy trucks are built to last for millions of miles of hard work. When designing systems for heavy-duty electric vehicles, making sure they are strong is very important. This starts with the electric motor itself. Motors for heavy-duty use must be designed for a long working life, able to handle high torque needs and the constant shaking of real-world driving. Using high-quality materials and hard testing is needed to ensure the motor’s long life.

Besides the motor, every part in the electric powertrain, from the battery pack to the controller and the e-axle, must be built to be strong. This includes designing parts that can handle extreme temperatures, wetness, and dust. The battery management system has a key job in protecting the battery pack, the most expensive part of the EV, by stopping overcharging, over-draining, and overheating. How the different systems work together is also key to reliability. A well-designed management system makes sure that all parts work together smoothly, which can help stop parts from breaking down too early. As the technology gets better, we are seeing a greater focus on designing systems for heavy-duty electric vehicles with the same strength and durability that the industry expects from their diesel trucks.

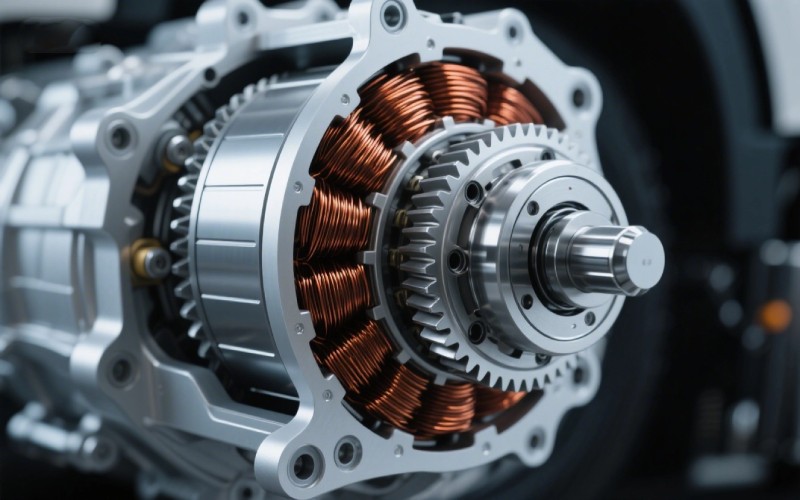

If the electric motor is the heart of the electric truck, then the controller is the brain. This advanced electronic unit controls how energy moves through the entire powertrain. It takes signals from the driver, like how far the accelerator pedal is pushed, and changes them into exact instructions for the electric motor. The controller decides how much torque the motor should make, how it should be delivered, and when to use regenerative braking. It is the key to getting the best balance between performance, efficiency, and how easy it is to drive.

The controller does much more than just manage the motor. It also talks to the battery management system to check the battery’s charge level and health. It has a key role in thermal management, making sure that both the motor and the battery stay in their best temperature ranges. Also, in vehicles with more than one motor or an e-axle, the controller is in charge of sending torque between the wheels to improve grip and stability. The software that runs on the controller is always being improved to increase efficiency and add new features. In short, the controller is what lets the powertrain do everything it can, making it a very important part in the design of any modern electric vehicle.