Let Sino's Lamination Stacks Empower Your Project!

To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.

AC servo motor and DC servo motor, they sound similar, but they have some big differences. If you’re trying to choose the best motor for your equipment or robot, or just interested in how these motors achieve that smooth motion, you’re in the right place! This article will help you understand the difference between AC servo motors and DC servo motors in simple terms.

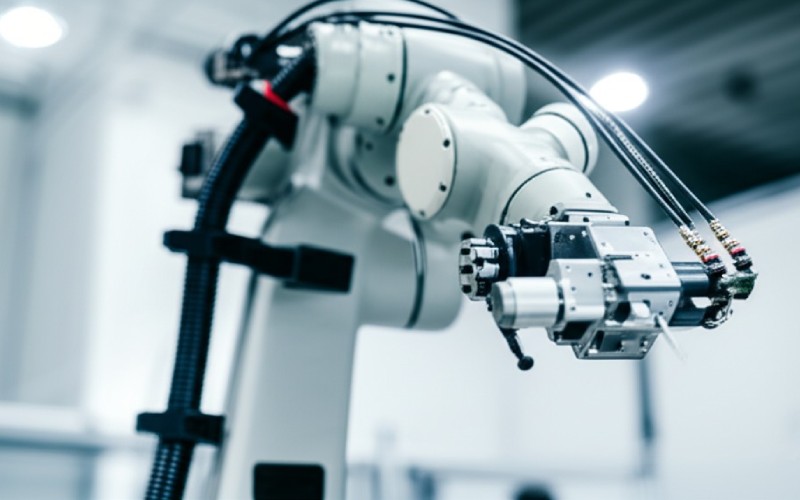

A servo motor is a special type of motor that is used when you need really precise control of position, speed, or torque. Think about a robot arm needing to move to an exact spot. That’s where a servo motor (whether AC or DC) frequently shines.

The magic of a servo motor is its closed-loop system. This means it gets feedback concerning its position or speed. An encoder or a tachometer usually provides this feedback to the controller. This feedback helps the servo system to make quick adjustments to ensure the motor is doing exactly what it’s told. So, a servo motor consists of the motor itself, a feedback device, and a controller or servo drive. This configuration helps achieve high control precision for motion control tasks. It’s all about that precise control of angular or linear position.

Now, let’s zoom in on the DC servo motor. As the name says, this type of motor runs on direct current (DC power). Many DC servo motor types use a permanent magnet in their stator (the fixed part) and an armature (the rotating part) with windings.

The “DC” in the DC servo motor tells us it uses direct current. A common type is the brushed DC servo motor. This DC motor uses a brush and commutator system to get power to the rotor (the spinning component). The DC servo motor is fantastic for tasks requiring excellent speed control and torque. A small DC motor can be a DC servo motor if it’s part of a servo system designed for precise control. The simplicity of a DC motor can be a big plus sometimes.

Okay, let’s switch gears to the AC servo motor. This one works with alternating current (AC power). Unlike a simple AC motor like an induction motor, an AC servo motor is built for that same precise control we discussed, but often with more muscle.

Most AC servo motor designs are brushless. This is a big difference from many DC servo motor types. An AC motor like a synchronous AC motor can be used as an AC servo motor. The stator in an AC servo motor has windings, and the rotor usually has a permanent magnet. The controller creates a rotating magnetic field in the stator to make the rotor turn. This design helps give the AC servo motor its good torque and efficiency.

In a brushed DC motor, which many DC servo motor units are, the brushes are how electrical current reaches the spinning armature. These little bits of carbon, the brush set, rub against a part called the commutator. This commutator and brushes system is crucial.

The presence of brushes means there’s wear and tear. Over time, brushes will certainly wear down. This means maintenance. You have to check and replace the brushes in a DC servo motor. If you don’t, the DC motor could stop working well, or at all. This mechanical commutation done by the brushes and commutator is a key feature of a brushed DC servo motor. Many a DC servo motor relies on this simple, yet wearing, brush system.

You’ll hear “brushless” a lot with an AC servo motor, and yes, it’s a pretty big deal. Going brushless means no physical brushes to wear out. This is one of the major advantages. An AC servo motor generally uses electronic commutation instead of a mechanical commutator and brushes. This means the controller handles switching the current in the motor coils.

This brushless design in an AC servo motor leads to much less maintenance. It also means the AC motor can often run at higher speeds and more efficiently. The heat from friction is also less of a problem. So, many modern AC servo motor designs are brushless for these reasons. This brushless nature contributes to the reliability of AC servos, especially in demanding automation tasks. AC servo motor and (brushed) DC servo systems vary considerably here.

When choosing a motor, performance is key. The key distinctions between AC and DC servo motor types here are important. AC servo motors tend to offer higher torque at higher speeds. They also typically have better acceleration because their rotor can have low inertia. This makes an AC servo motor great for tasks requiring rapid starts and stops.

A DC servo motor, specifically a brushed DC one, can provide excellent torque at low speeds. However, the brush system can limit its top speed and acceleration. Speed control can be excellent with both, but the method it’s done is different. The differences between AC and DC also appear in how they handle overload—an AC servo motor often handles it better. Considering these differences between AC servo motors and their DC counterparts helps in choosing the right actuator.

Now, you might hear about a BLDC motor, or brushless DC motor. This sounds like it mixes things up! A BLDC motor is indeed a brushless DC servo motor in many cases. It operates on DC power (often from a DC voltage source that’s regulated by the controller) but uses electronic commutation, like an AC servo motor. So, a BLDC motor has no brushes to wear out.

A brushless DC servo, like a BLDC, often uses a permanent magnet on its rotor. The controller for a BLDC motor is more complex than for a simple brushed DC motor because it needs to handle the electronic commutation. These brushless DC motors offer excellent torque and efficiency, making the BLDC a popular choice for many motion control applications, including robotics.

For large industrial automation machines, an AC servo motor is often the go-to. Because they are generally brushless, they require much less maintenance, which is great for systems that run constantly. The ability of an AC servo motor to deliver high torque across a wider speed range is a big plus.

If my application needs highly dynamic performance—quick acceleration and fast reversals—the low-inertia rotor of an AC servo motor is a real champion. AC servo motors are used in demanding tasks like CNC machinery and complex robotics. A combination of AC servo and DC systems might exist in larger setups, but for the prime mover, AC servos often handle the heavy lifting. AC power input is also readily available in industrial settings. AC servo motors typically have a more complex controller, but the performance usually warrants it.

But don’t count out the DC servo motor! There are times when it’s just the right fit. If you have a project that runs on batteries, a DC servo motor is a natural choice because it uses DC power. For smaller machines or applications where you need very smooth motion control at low speeds, a DC servo motor, especially a brushed DC servo, can be excellent. One of its primary benefits is its simplicity, especially for the brushed DC motor.

The controller for a brushed DC servo motor can be simpler and less expensive than for an AC servo motor or a BLDC motor. This makes a DC servo motor an excellent option for simpler or budget-sensitive projects requiring precise control. DC servo motors may not have the top-end speed of an AC servo motor, but for many tasks, their ability to provide great torque and position control is excellent. DC servo motors require attention to the brushes if it’s a brushed DC type, but they are workhorses.

Yes, the controller and overall servo system can be quite different. This is a crucial area when we look at the difference between AC servo and DC types. An AC servo motor, being brushless, requires a more complex controller (often called a servo drive) to handle the electronic commutation and create the rotating magnetic field. This controller precisely manages the current to the stator windings.

A brushed DC servo motor has a simpler control circuit because the commutation is done mechanically by the brushes and commutator. However, both types use a closed-loop system, meaning they rely on feedback from an encoder or similar device to achieve precise control of position, speed, or torque. The controller is the brain, ensuring the motor (whether DC servo or AC servo) hits its target. Whether it’s control of angular or linear position, the controller plays a significant role. Both AC and DC servo motor systems aim for that high position control precision.