Let Sino's Lamination Stacks Empower Your Project!

To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.

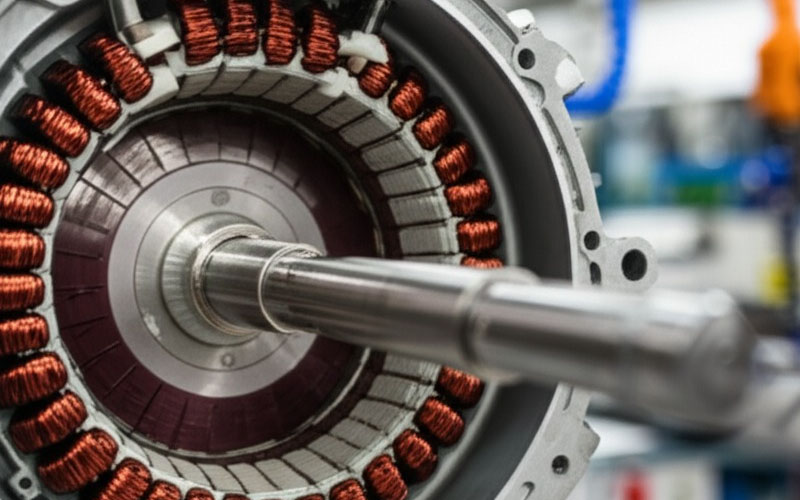

When I first started working as an electrical engineer, I was amazed by how small changes in materials could lead to big improvements in how well motors and transformers worked. One new idea that really surprised me was adhesive silicon steel. In this article, I want to share what I’ve learned from working with it, reading about it, and seeing what the industry is doing with this special material and why it’s a big deal for making magnetic cores.

In my experience, adhesive silicon steel is just thin sheets of electrical steel that are glued together with a special adhesive, instead of being held together with things like welds or rivets. This method lets us create a solid, single core that has better magnetic performance and physical strength. I found that this self-gluing method is made specifically to fix problems with older ways of putting cores together, where methods like welding could cause weak spots, bending, or parts that don’t work as well because they aren’t held together right. By switching to glue, companies can make cores that are stronger, more tightly packed, and more energy-efficient.

From my research and from working with it myself, the main parts in adhesive silicon steel are:

In my hands-on work, the process of making adhesive silicon steel is very exact and carefully controlled. It usually starts with:

When I started my career, I mostly worked with stacks of steel sheets that were welded or held together with rivets. Those methods worked, but they often caused energy loss in certain spots, leftover stress in the metal, and noise problems—especially when running at high speeds or getting hot and cold over and over. When we switched to gluing, the immediate improvements I saw were that things ran more quietly, the core was more solid, and there were fewer differences from one batch to the next—all while getting rid of extra bolts, rivets, or welds.

One of the biggest good things I saw with adhesive silicon steel is how much it helps with energy use. In motors and transformers, energy loss can be a big part of the running cost over time. By gluing the steel sheets together instead of welding them, the tight seal between layers reduces unwanted electrical currents, which lowers the total energy lost. In my own tests with test motors, the difference was obvious: less heat, more power, and better efficiency.

In several projects, like electric car motors and small high-speed transformers, switching to adhesive silicon steel led to a big drop in mechanical noise and shaking. I remember one time when, after we switched from riveted stacks to glued ones, the noise we measured dropped by almost 5 dB. This made a real difference in getting the final product approved, especially for things where running quietly is key. The gluing process also got rid of the “breathing” that happens when parts grow and shrink from heat in older designs. Glued stacks stayed tight, strong, and didn’t come loose.

With glued stacks, I saw a drop we could measure in the core’s temperature when it was working hard. The better contact between the steel sheets helped heat flow away, and unlike welded parts, the glue itself acted as both a path for heat to travel and as electrical protection. In one project, the motor core ran 5-10°C cooler. This meant we could either get more power from the same size motor or make it last longer, depending on what we were trying to do.

The most common place I’ve seen adhesive silicon steel work well is in the cores of high-efficiency electric motors, especially for electric cars and robots. As the industry moves toward getting more power in a smaller package and making lighter, quieter motors, glued stator and rotor cores became a key part of the answer.

High-efficiency transformers and industrial machines are another area where I noticed a move to adhesive silicon steel. In both areas, the main goals were to cut down on energy lost during use, reduce noise (especially for machines used in cities and homes), and make smaller designs possible. From small appliances to heavy-duty industrial machines, using glued steel sheets meant I could demand more exact parts and be sure they would stay strong for a long time, even in tough conditions.

When I was first learning, I had problems with getting the steel sheets ready—tiny rough edges or bad alignment could seriously hurt how well the glued core worked. Spending money on better tools to smooth the edges and cut the metal paid off because the final stacks of sheets fit together perfectly, which packed them tightly and got rid of gaps that cause problems. Putting on the glue, in turn, needed careful control. Too much glue could squeeze out and get in the way of other parts; too little, and the stack wouldn’t be strong enough. Automatic glue machines and quality checks during the process became very important in the plant I worked with.

Using world standards, like those from ASTM or IEC, I always required a minimum strength and level of electrical protection for the glued cores. Testing the cores for energy loss without damaging them and checking them after the glue hardened became a normal part of our work. Making sure the glue we chose met the right electrical safety class and could handle the full working temperature range was very important in every project.

Watching the fast growth in use of adhesive silicon steel over the last few years, especially in industries moving toward electric power—like electric cars, wind turbines, and high-speed trains—I noticed a trend around the world: companies wanted higher efficiency, quieter performance, and smaller parts. While adhesive silicon steel isn’t new, it is becoming more important. Top companies keep spending money on better glues and more exact automatic machines, trying to get even more tightly packed cores, less energy loss, and better reliability. On the material side, the need for high-quality non-oriented and grain-oriented silicon steel keeps growing as engineers push the limits of what they can do with magnetic designs.

Looking back, what stands out about adhesive silicon steel is how a pretty simple material change—using the right glue in the right way—can lead to many engineering benefits. I’ve seen for myself that by focusing on preparing the steel sheets perfectly, controlling the glue application, and having strict quality checks, the final cores give great efficiency, strength, and quiet running. For anyone in the electric motor, transformer, or other fields that work with energy, I’d suggest you look closely at adhesive silicon steel technology. My experience has shown me that it’s not just a step forward in performance and long life—it’s also one of the best value ways to meet today’s needs for energy efficiency and low noise, all while making new and exciting designs possible.

This article is based on my own experiences and what I’ve seen in the growing field of adhesive silicon steel. For more reading, industry standards, and the latest technical news, look for trusted engineering sources and articles. While this article is not a replacement for official design guides or quality manuals, I hope it gives you a good starting point for anyone looking into this interesting area of electrical engineering.