Let Sino's Lamination Stacks Empower Your Project!

To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.

To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.

As Sino, a top global maker of precision motor laminations, with years of specialized experience in manufacturing high-precision lamination stacks, we’ve dedicated ourselves to mastering the intricacies of axial flux stator laminations. We understand that you’re not just buying steel; you’re investing in the core performance of your innovative designs. By knowing a lot about the different needs of various industries—from high-performance cars to modern aerospace, factory automation, and green energy—we offer custom solutions that go beyond the old limits of efficiency, power density, and reliability. We partner with you to turn complex magnetic challenges into tangible, high-performing realities.

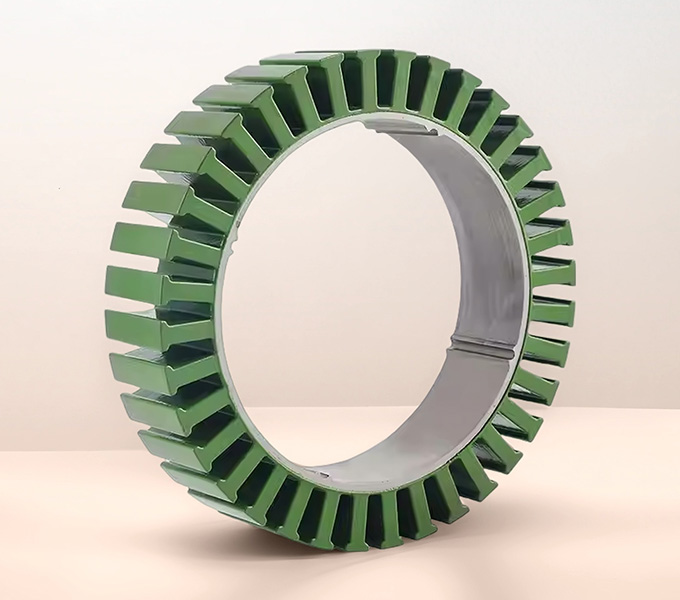

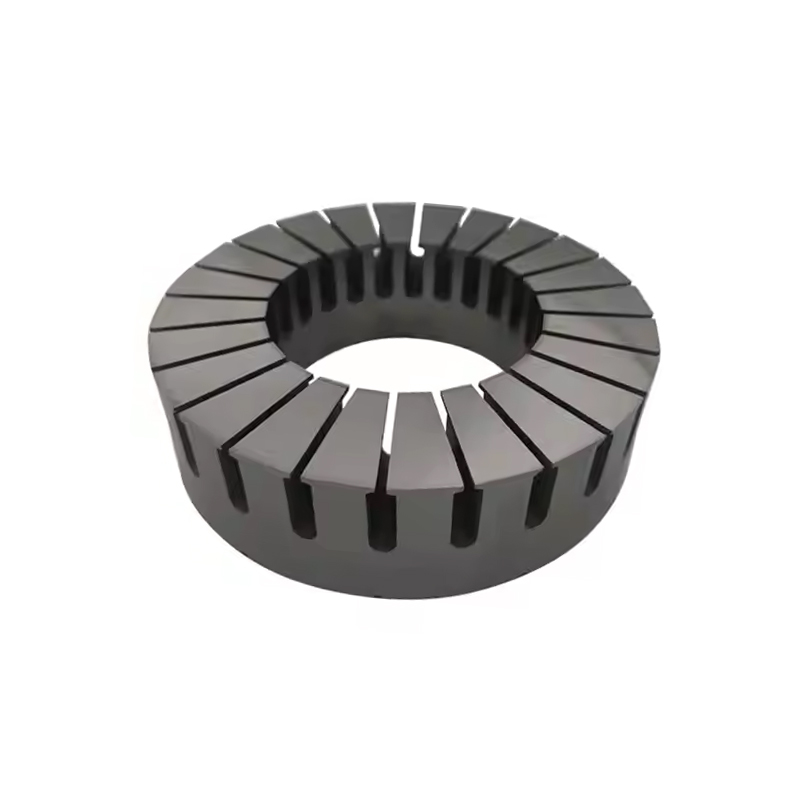

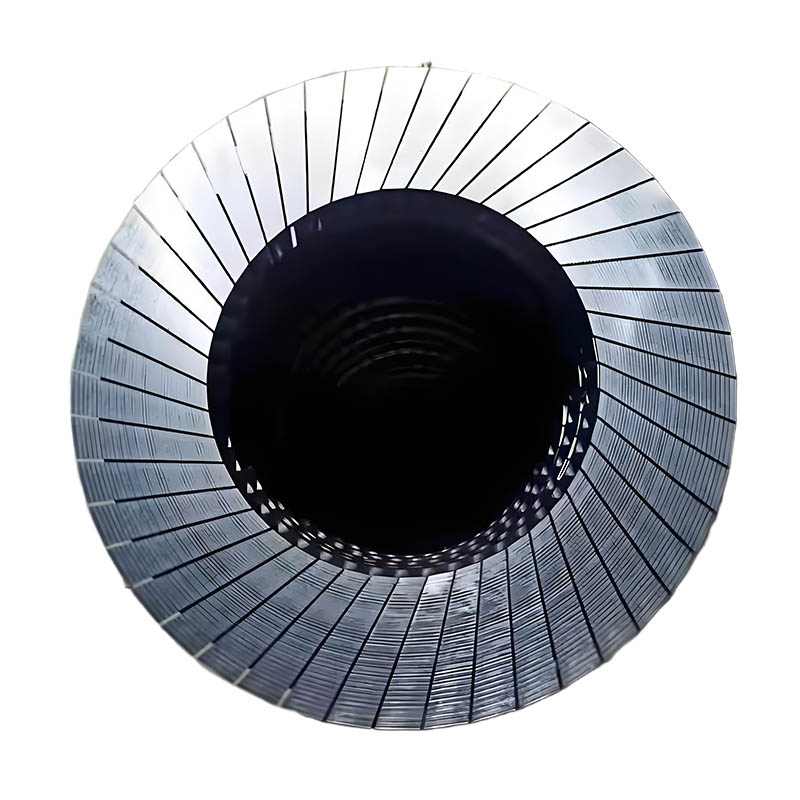

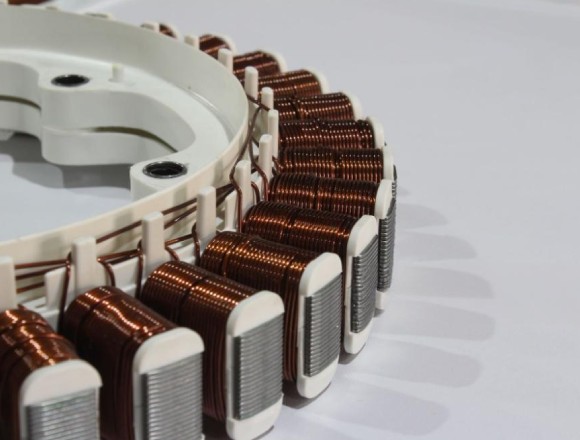

Axial flux electric machines are a major change in motor design, offering amazing smallness and power. At their center, axial flux stator laminations are carefully made magnetic metal parts that guide and focus the magnetic field in a line with the machine’s spinning axis. Unlike regular radial flux machines where the field flows out from the center, the axial setup allows for a flat, disc-like shape, making them perfect for uses where space is tight.

The main job of axial flux stator laminations is to create the magnetic path for the stator windings, reducing energy losses from eddy currents and hysteresis, while also giving strength and support to the coils. Their special shape allows for a shorter magnetic path and a bigger airgap area compared to radial flux designs. This naturally results in more torque for their size and better efficiency. This key benefit is why they are being used more and more quickly in many fast-growing areas.

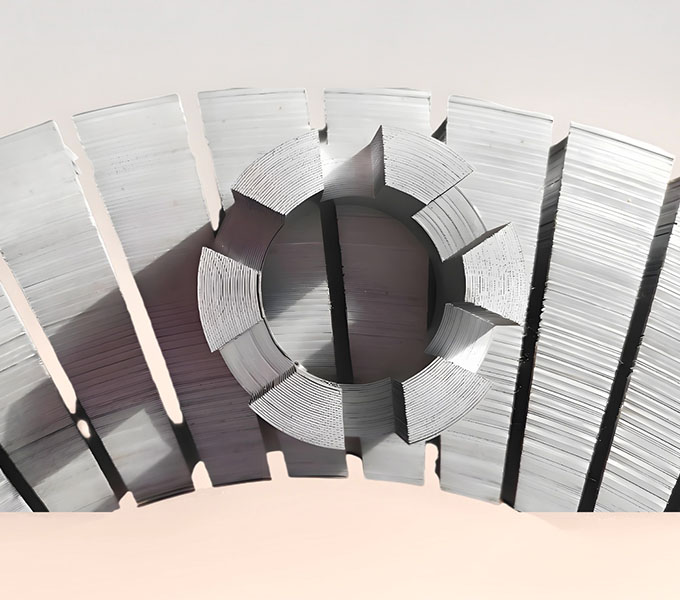

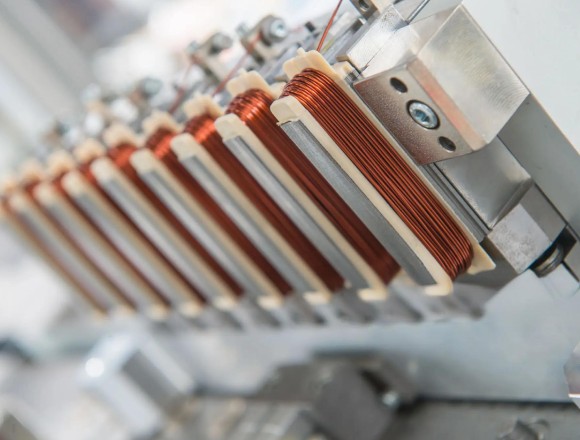

At Sino, we employ advanced tension control and proprietary insulation techniques during winding to ensure that each layer remains electrically isolated. Furthermore, we understand the mechanical stresses involved in forming these wound cores into their final, often complex, slotted shapes. Our post-processing treatments, including precision annealing, are designed to relieve these stresses and restore the steel’s optimal magnetic properties, ensuring those lab-condition benefits translate to your real-world motor.

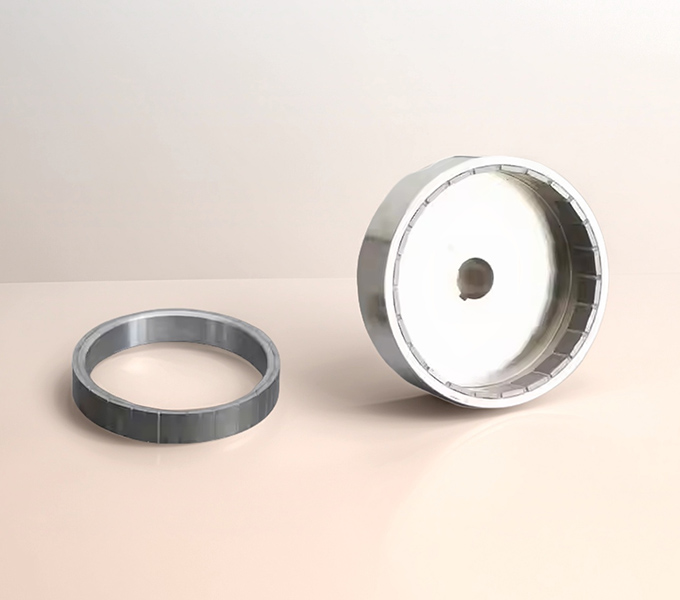

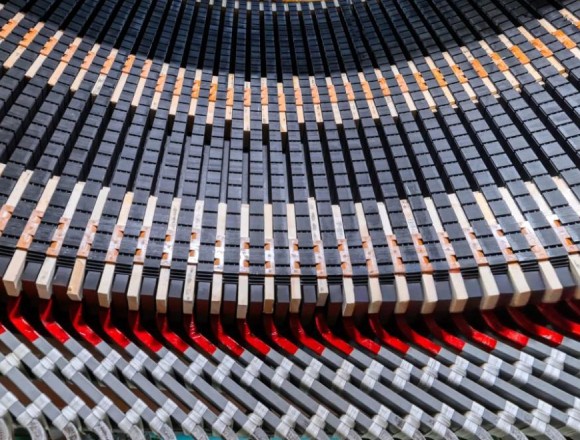

Another compelling strategy for crafting an axial flux stator is to build it from multiple, individually laminated segments. The challenge with segmented cores lies in precision and assembly. If segments don’t fit together perfectly, you can introduce unwanted air gaps, increasing reluctance and potentially creating localized magnetic saturation or noise. At Sino, our state-of-the-art stamping and laser-cutting facilities produce segments with exceptionally tight tolerances. We also collaborate closely with our clients on inter-segment locking features and assembly protocols to ensure excellent magnetic continuity across the entire axial flux motor stator. Our rigorous quality control, including advanced optical inspection, guarantees that each segment meets your exact specifications, paving the way for a seamless and high-performing final assembly.

At Sino, we maintain a comprehensive inventory of high-quality electrical steels from globally recognized mills, including popular grades like M270-35A, M19-29G, and specialized thin-gauge options for high-frequency applications. Our engineers work hand-in-hand with your design team to understand your specific operating conditions – speed range, flux densities, thermal constraints, and cost targets. We can help you navigate the trade-offs. For instance, while a super-thin lamination might look great on paper for eddy current reduction, we can help assess if the added cost and potential reduction in stacking factor provide a genuine net benefit for your specific axial flux motor stator design.

To put this into perspective, consider this illustrative comparison of how material and construction choices might influence key parameters (actual values will vary based on precise design and operating conditions):

Feature | Sino Tape-Wound (e.g., M270-35A, 0.35mm) | Sino Segmented (e.g., M235-35A, 0.35mm) | Alternative: SMC (Not by Sino) |

Targeted Core Loss (Typical) | Lower (e.g., 2.8 W/kg @ 1T, 50Hz) | Low-Moderate (e.g., 3.2 W/kg @ 1T, 50Hz) | Higher Hysteresis Component |

Eddy Current Suppression | Very Good | Good | Excellent (Isotropic) |

Permeability | High | High (Segment-wise) | Moderate |

Manufacturing Precision | Sino High Standard | Sino High Standard | Different Process (Molding) |

Design Flexibility | Good for Toroidal base | Excellent for Complex Shapes | Very High (Net Shape) |

Mechanical Integrity | Excellent | Very Good (Assembly Dependant) | Moderate |

Sino Specialization | Core Expertise | Core Expertise | Not a Sino Product |

While Soft Magnetic Composites (SMCs) offer isotropic magnetic properties and are sometimes considered for axial flux machines due to their 3D flux capabilities, they generally come with trade-offs like lower permeability and higher hysteresis losses compared to the high-grade laminated steels Sino specializes in. For applications demanding the utmost efficiency and flux-carrying capability from traditional laminations, Sino is your go-to partner.

Manufacturing world-class axial flux stator laminations goes beyond just choosing the right steel and cutting method. It’s about an end-to-end commitment to quality and continuous improvement.

1

Whether your design calls for intricate tooth shapes or ultra-precise segment outlines, Sino’s cutting-edge stamping presses and high-speed laser cutting systems deliver unparalleled accuracy and repeatability, minimizing burrs that can compromise insulation.

2

The quality of the insulation coating on each lamination (often an organic or inorganic coating like C5 or C6) and its integrity after stamping and stacking are crucial. We meticulously control our coating application and handling processes to ensure maximum electrical resistance between layers.

3

Sino’s precisely controlled annealing furnaces restore the material’s grain structure, optimizing permeability and minimizing coercivity, which translates directly to lower hysteresis losses in your axial flux motor stator.

4

From raw material inspection to final dimensional checks and magnetic property testing (where applicable), our multi-stage QC process ensures every lamination stack leaving our facility meets or exceeds your specifications. We leverage tools like coordinate measuring machines (CMMs), vision systems, and Epstein frame testing to validate our output.

Good heat management is a key factor in how much power an axial flux motor can produce continuously, its efficiency, and how long it lasts. The small size and high power of axial flux designs naturally comes with big heat challenges. At Sino, we know that the stator lamination design plays a key part in getting rid of heat, and we include advanced heat-related ideas in every part of our making process, from picking materials to optimizing shapes and connecting with cooling systems.

One of the most important improvements in axial flux heat management is adding tiny channels directly inside the stator laminations.

Besides built-in channels, the overall shape of the laminations can be improved to help with both natural and forced air cooling. Research from places like TU Delft and ETH Zurich shows that making the surface area of stator laminations bigger with ribbed or finned designs can greatly improve heat transfer.

New materials are key to better heat performance. The use of Fe-Si alloys that are better at transferring heat (up to 35 W/m·K, like Hitachi’s HiB steel) and the smart use of copper or aluminum pieces inside the lamination stack are becoming more popular.

The toughest axial flux jobs often use advanced active cooling systems.

Being reliable over a long time is very important. Studies (Fraunhofer Institute, 2023) show that repeated heating and cooling (ΔT > 60°C, 10,000+ times) can cause tiny cracks in the lamination insulation and separation at TIM connections. This leads to higher core losses (5–10%) and a shorter insulation life (by up to 20%).

So, what does all this mean for you when you choose Sino for your axial flux stator lamination needs?

Our precision manufacturing, material expertise, and optimized designs directly translate to lower eddy current and hysteresis losses. This means more of your input power goes into producing useful torque, not unwanted heat.

By enabling more efficient magnetic circuits and better thermal performance, our laminations help you squeeze more power out of smaller, lighter motors – a key objective for most axial flux scenarios.

Whether you need tape-wound or segmented cores, specific material grades, or intricate geometries, we collaborate to create the optimal

Quality materials and manufacturing mean a stator core that performs consistently and endures the rigors of its operational environment.

Our expertise can help you avoid common pitfalls in lamination design and manufacturing, getting your innovative axial flux motors to market faster.

The journey to a game-changing axial flux motor is complex, but the path to superior stator laminations is clear. At Sino, we’re more than just a supplier; we’re your dedicated partner in innovation. We bring our deep knowledge of materials, manufacturing processes, and the unique demands of axial flux stator design to your project.

Are you ready to unlock the full potential of your axial flux motor designs? Are you tired of compromising on performance due to limitations in your stator core? Let’s talk. Bring us your challenges, your specifications, your ambitious ideas. Together, we can engineer and manufacture axial flux stator laminations that will not only meet your requirements but also set new benchmarks for performance in your industry.

With Sino’s precision-engineered laminations at the core of your axial flux motor stator, you’re not just keeping pace; you’re leading the charge. Contact us today to discuss your project and discover how Sino can help you build the heart of your next innovation.

Note: To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.

To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.