Let Sino's Lamination Stacks Empower Your Project!

To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.

“B-H curve,” “magnetization curve,” and “hysteresis loss”, these terms seemed complicated, but understanding these ideas is extremely essential if you deal with any type of motor, especially a DC motor. This short article is for you if you have actually ever before questioned what these curves mean and why they matter. We’ll check out the renowned B-H curve, see exactly how it shows the magnetic properties of a material, and learn why hysteresis loss can be a real energy-waster in your motor.

Think about it as a map that demonstrates how a magnetic material behaves when you attempt to make it a magnet. The “H” on this curve represents magnetizing force (or magnetic field strength). This is the effort you place in, like from a coil of wire with electric current flowing through it, to produce an electromagnetic field. The “B” on the B-H curve represents magnetic flux density. This tells you exactly how strong the electromagnetic field ends up being inside the magnetic material itself. This magnetization curve is essential to recognizing magnetics. So, the B-H curve plots this connection. As you raise the magnetizing force (H), the magnetic flux density (B) in the material is magnetized and likewise boosts. This first contour is frequently called the initial magnetization curve. The steepness of this contour tells us regarding the material’s permeability — how easily it allows magnetic flux to be established. A good B-H curve assists us select the right ferromagnetic material for points like an electromagnet or parts of a motor. The B-H curve is basic to recognizing magnetization. This B-H curve is not just a simple line for lots of products. The method the magnetization happens and afterwards undoes itself is special, and that’s where the concept of a loop comes in. We check out this B-H curve a whole lot when developing electrical motors and transformer cores. The B-H curve reveals the magnetic properties of the product like silicon steel. It’s an important curve for engineers.

This is where the “hysteresis” part of hysteresis loss comes in. Hysteresis suggests “to lag behind.” The magnetization of the material does not perfectly adhere to the magnetizing pressure when it changes. The B-H curve reveals this lag. When you boost the magnetizing force in the positive direction, the magnetic flux density goes up along one curve. But when you reduce the magnetizing force back to zero, the magnetic flux density does not return to zero along the same curve. The material is magnetized and keeps a few of its magnetization. This “memory” is a crucial feature revealed by the B-H curve. This lagging effect is mainly to recognize the B-H curve and the residential properties of a material. This delay occurs due to tiny little locations inside the ferromagnetic product called magnetic domains. Think of them as small magnets. When you apply an external electromagnetic field, these magnetic domains line up. Yet when you eliminate the electromagnetic field, they don’t all turn back completely. This resistance to transform develops the unique form of the B-H curve or B-H curve.

Since we know the magnetic material delays, what is hysteresis loss? Well, every time the magnetization of a ferromagnetic material goes through this delayed cycle– being magnetized one method, then the various other, like in an AC circuit or a rotating motor — some energy is lost. This shed energy shows up as warm in the magnetic product. This is hysteresis loss. This loss depends on the magnetic material itself. Picture you are pressing and drawing something that has a lot of friction. You ‘d consume energy, and that power would certainly develop into warmth. It’s comparable with magnetization and demagnetization cycles in a magnetic material. The B-H curve creates a loop, and the area inside this magnetic hysteresis loop tells us the quantity of loss per cycle. A larger loop on the B-H curve means even more hysteresis loss. This hysteresis loss is very important to take into consideration in devices like a transformer and DC machines. This hysteresis loss is a sort of power that is dissipated as heat within the product. It is among the factors motors and transformers obtain cozy. Minimizing hysteresis loss is a large goal for engineers to make devices more efficient. The hysteresis loss can be a large bargain if not handled, particularly when dealing with silicon steel in a motor.

The B-H curve that shows this delayed result is called a magnetic hysteresis loop (or B-H hysteresis loop). Let’s map it. We start with a ferromagnetic material that isn’t magnetized. As we use a magnetizing force (H) in a positive direction, the magnetic flux density (B) boosts. This is the initial magnetization curve. At some point, the material is magnetized to its full degree; it gets to saturation point. Now, if we decrease the magnetizing force (H) back to zero, the magnetic flux density (B) doesn’t most likely to zero! The curve reveals that the ferromagnetic product still has some magnetization. This is called residual magnetism or remanence. To get the magnetic flux density back to zero, we have to apply a magnetizing force in the reverse direction. The quantity of this reverse force needed is called the coercive force. The magnetic hysteresis loop reveals this whole magnetisation process. If we keep using the magnetizing force in the negative direction, the material will certainly reach saturation once more, yet with opposite magnetic poles. After that, bringing H back to zero and right into the positive direction once more will complete the magnetic hysteresis loop. This curve, the magnetic hysteresis loop, is a fingerprint of the magnetic product, like silicon steel. The area of the magnetic hysteresis loop is key. The curve of the ferromagnetic core complies with types of this loop.

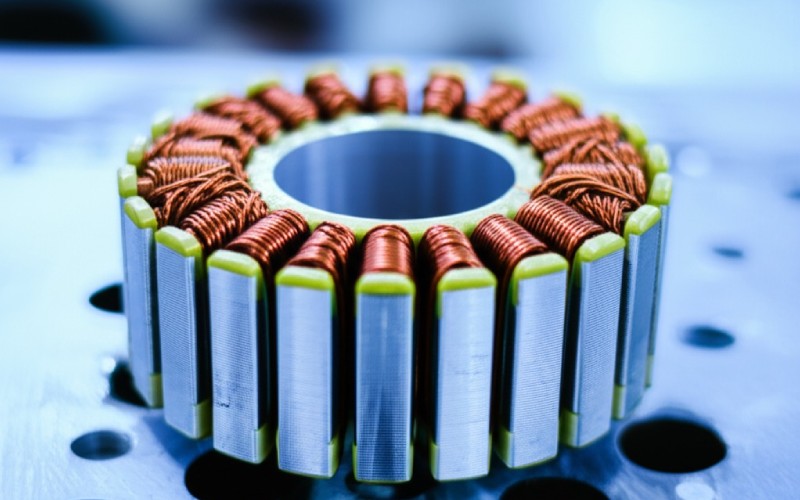

In a DC motor, components of the ferromagnetic material (like the core constructed from silicon steel) are constantly having their magnetization changed as the motor rotates. Each time the magnetization cycles, it traces that magnetic hysteresis loop on the B-H curve. And as we found out, the area of that loop stands for power shed as heat– the hysteresis loss. This hysteresis loss indicates your motor requires more power to do the same amount of work. This unwanted warmth from hysteresis loss can be a problem. It can make the motor less effective. Excessive warmth can also harm the motor’s insulation or bearings over time. So, for a good motor design, especially in DC machines, we wish to pick a magnetic material that has a small hysteresis loss. This implies we want a ferromagnetic material with a narrow hysteresis loop on its B-H curve. The amount of loss from hysteresis loss builds up. If you have a motor running for a long period of time, also a little percentage of hysteresis loss per cycle can mean a lot of thrown away power and extra warmth. That’s why researching hysteresis and the B-H curve is so important for motor efficiency. We desire the hysteresis loop to be as tiny as possible.

No, not all magnetic materials coincide! This was a large “aha!” minute for me. They have different magnetic properties, which indicates their B-H curve forms are different. We commonly speak about 2 primary types: hard and soft magnetic materials. Hard magnetic materials, like those used for permanent magnets, have a wide magnetic hysteresis loop. They are hard to magnetize but, once they are, they remain a solid magnet. They have high retentivity and high coercive force. Soft magnetic materials, on the other hand, are what we generally want for motor cores and transformer cores. These products have narrow hysteresis loops resulting in very small amounts of hysteresis loss. Instances include silicon steel and some magnetic composites. Soft magnetic materials are easily magnetised and demagnetised. This implies their B-H curve will show a narrow hysteresis loop. This is terrific because it indicates less energy is shed as heat during each magnetization cycle. The option of magnetic material, like silicon steel, directly affects the hysteresis loss. For applications with transforming electromagnetic fields, like in an AC circuit or a rotating motor, we choose soft magnetic materials or soft ferromagnetic products. They have low residual magnetism and a low coercive force. This assists maintain the hysteresis loss down and performance up. Making use of soft magnetic products is essential for decreasing hysteresis loss.

Bear in mind when we lowered the magnetizing force (H) back to zero after reaching saturation, yet the magnetic material stayed magnetized? That staying magnetization is called residual magnetism or remanence. Retentivity is the capacity of a magnetic product to keep this residual magnetism after the exterior electromagnetic field is eliminated. On the B-H curve or magnetic hysteresis loop, retentivity is the point where the curve goes across the B-axis (where H is zero) after saturation. A high retentivity suggests the ferromagnetic material remains highly magnetised after the external magnetic field is gone. This is excellent for permanent magnets, but not so good for parts of a motor or transformer core that need to transform their magnetization rapidly and conveniently. High retentivity in a core material would cause a bigger magnetic hysteresis loop and a lot more hysteresis loss. So, for applications like electric motors or solenoids and transformers, where the magnetic product is constantly being magnetized and demagnetized, we typically want a material with low retentivity. This assists make the magnetic hysteresis loop smaller, lowering hysteresis loss. The residential properties of a product like retentivity are shown on its B-H curve. Silicon steel is commonly selected because it can have good permeability, but relatively low retentivity for a soft magnetic material.

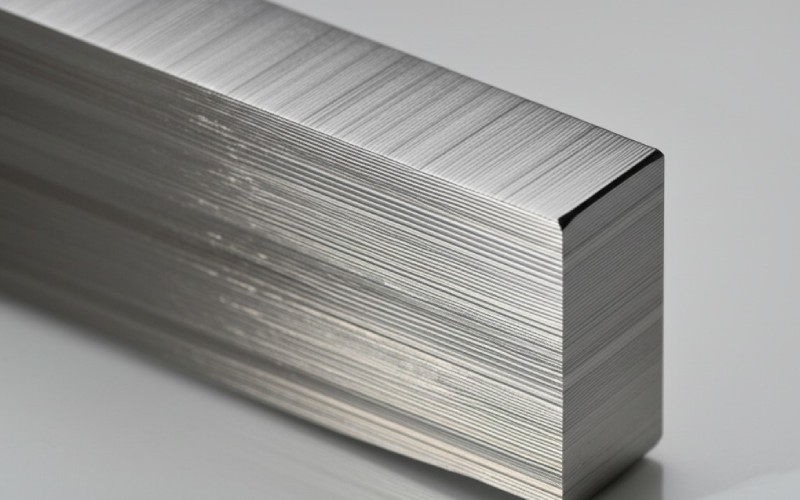

This is a huge inquiry for any person creating or dealing with a motor! Considering that hysteresis loss comes from the area of the magnetic hysteresis loop on the B-H curve, the primary means to lower it is to choose a magnetic product with a narrow hysteresis loop. As we talked about, soft magnetic materials are the means to go. Silicon steel is a very typical option. Why silicon steel? Adding silicon to iron (making silicon steel) changes its magnetic buildings. It raises the material’s electric resistivity, which helps in reducing one more sort of loss called eddy current loss (a tale for an additional day!), but it also helps to create a narrow hysteresis loop, thus decreasing hysteresis loss. The coercive force can be made smaller, and for soft magnetic materials, low residual magnetism is also desired. Various other means consist of running the magnetic material at lower optimal magnetic flux density degrees, ideally. The hysteresis loop depends upon how much up the B-H curve you press the magnetization. Also, cautious manufacturing of the ferromagnetic core is magnetised parts can aid. Occasionally, unique heat treatments or using thin laminations of silicon steel can optimize the magnetic homes and reduce total losses, consisting of hysteresis loss. It’s vital that the B-H hysteresis loop is as small as possible. The loop depends upon the nature of the magnetic material like iron or steel.

For small values of magnetizing force (H), the magnetic flux density (B) may rise somewhat slowly. Then, for a variety of H values, the contour obtains much steeper– this is where the permeability of the ferromagnetic material is high, and the magnetic flux density (B) also increases swiftly. This part of the curve is really reliable for magnetization. This non-linear behavior of the B-H curve is because of those magnetic domain names we mentioned. Initially, just the easily moved domain name wall surfaces change. As the magnetizing force rises, even more domain names straighten, causing a rapid rise in magnetization. The B-H curve shows this intricate interior procedure within the ferromagnetic material. If it were perfectly direct, life may be less complex, however the distinct buildings of ferromagnetic products like silicon steel give us strong magnets and effective cores, even if their B-H curve is not straight. At some point, as the magnetizing force obtains very high, the majority of the magnetic domain names are lined up, and it ends up being harder and more difficult to enhance the magnetic flux density further. The magnetization curve then flattens out. This bending and flattening of the B-H curve is characteristic of ferromagnetic materials and is really different from just how air or non-magnetic products reply to a magnetic field, which is linear. The magnetization curve is a crucial curve.

Saturation is a crucial idea when you’re looking at a B-H curve or magnetization curve. Envision you’re attempting to pack an increasing number of items right into a traveling bag. In the beginning, it’s easy, but eventually, the bag becomes complete, and you can’t fit far more in, despite how tough you press. Saturation in a ferromagnetic product like silicon steel is similar. As you enhance the magnetizing force (H), the magnetic flux density (B) inside the material is allured and increases. Nevertheless, there’s a limitation. At a certain factor, nearly all the magnetic domains inside the ferromagnetic product have actually lined up with the electromagnetic field. Once this occurs, also if you increase the magnetizing force a great deal a lot more, the magnetic flux density hardly boosts. The material is said to be magnetically saturated. This is the saturation point on the B-H curve, where the curve flattens out. The flux density gets to its optimum useful value, called the saturation induction. Recognizing saturation is important. If you design a motor or transformer and the core material gets to saturation too quickly, it won’t carry out as anticipated. The permeability goes down substantially at saturation. This means the B-H curve tells us the operating limits for a magnetic material. When a ferromagnetic product gets to saturation, its capacity to even more boost the electromagnetic field is considerably lessened. You want to run below this saturation level for most applications where a high permeability is desired.