Let Sino's Lamination Stacks Empower Your Project!

To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.

If your electric motor isn’t working right, it can be a huge migraine. However, don’t fret! I’m here to share some basic tools and methods for electric motor testing. Understanding the fundamental motor screening steps can assist you discover motor problems early. This can save you money and time prior to a major motor failure occurring. This post will certainly show you how to utilize some common motor testing equipment. You’ll find out very easy checking techniques for your motor. This will assist you maintain your motor running well. We’ll cover screening tools and techniques that are understandable. Reading this will aid you with your following motor test and keep your electric motor in top form.

Allow me to inform you, taking care of your motor is a large deal. Regular electric motor testing is like giving your motor a health exam. It helps you find tiny problems before they become huge, costly fixings. By also doing standard motor screening regularly, you can extend the life of your electric motor. Think of it this way: an electric motor is often the heart of a machine. If the motor fails, the whole machine stops. This can stop your work or production. Regular testing of the general health of your motor aids prevents this. These testing procedures can spot trouble with insulation, bearings, or windings. Catching these early ways your electric motor remains reliable. It’s a wise method to manage your equipment and stay clear of unexpected equipment damage.

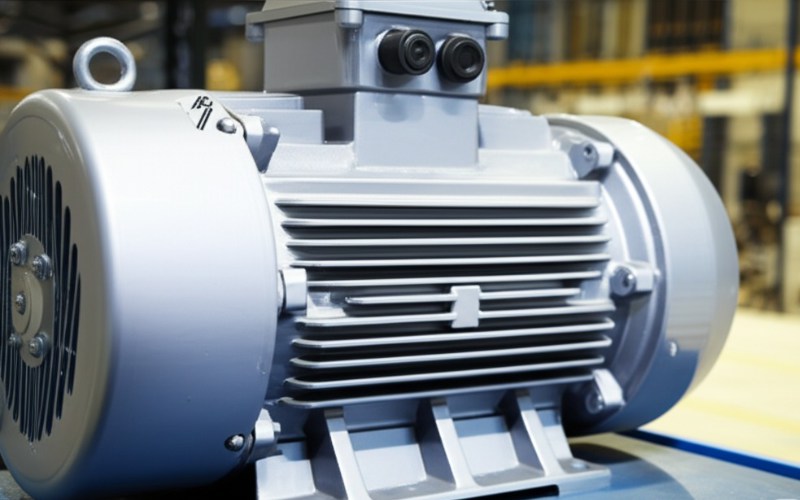

One of the most common ones you’ll likely see are AC (alternating current) motors and DC (direct current) electric motors. AC electric motors, like induction motors, are very common in fans, pumps, and factory equipment. DC motors are commonly found in things that need variable speed, like some power tools or car parts. Each motor type can have its own little traits. Knowing the motor type you are working with is important. This is because some motor testing methods might be somewhat different for each. For example, checking the brushes on a DC motor is a step you wouldn’t do on a brushless AC motor. The nameplate or manual of the motor is your best friend here. It typically informs you of the motor type and its crucial information, which aids in any motor test.

A digital multimeter is one of the common motor testing tools. It resembles a Swiss Army knife for electrical checks! You can utilize a digital multimeter to check for voltage at the motor terminals. This tells us if the motor is obtaining the right amount of power. If the voltage reading at the motor is low or too high, the motor won’t run best and could get damaged. You can also utilize multimeters to check for continuity. This means seeing if there’s a complete electric path. You also can use it to check the resistance of the motor windings. A good digital multimeter can also measure current, though a dedicated ammeter is sometimes better for higher currents. For any kind of electric motor testing, having a trusted digital multimeter is a must. It’s a basic but powerful diagnostic tool.

An ammeter is a tool that gauges electric current, which we determine in amps. When an electric motor is running, it draws a particular amount of current. If a motor is drawing excessively, it’s a sign something is incorrect. Maybe overloaded, or there might be a problem with the motor winding. You just clamp it around one of the motor conductors, and it gives you a reading without having to disconnect anything. Checking the current is a crucial component of a motor test, especially when the motor is running. You should contrast the amp reading you obtain with what’s listed on the motor’s nameplate or manual. If it’s much higher, your motor is working too hard. This can lead to overheating and ultimately motor burnout, and predicting potential motor failure becomes much easier if you monitor this. It’s one of the essential testing methods to troubleshoot motor problems.

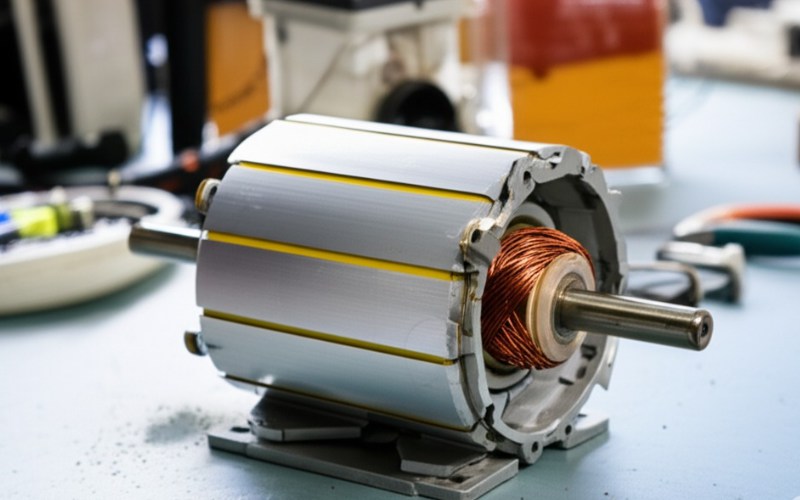

Now, let’s discuss insulation. The insulation in an electric motor is super essential. It maintains the power flowing where it should, inside the copper windings. If the motor insulation breaks down, you can get shorts, and the motor will certainly fail. This is where a megohmmeter, often called a Megger (which is actually a brand name, like Kleenex for tissues), comes in. A megohmmeter is a special sort of ohmmeter that makes use of a high voltage (but low current) to measure insulation resistance. Excellent insulation will have very high resistance, meaning it doesn’t let much current leak through. A megohmmeter helps me to see if the motor insulation is excellent or if it’s beginning to break down due to age, heat, moisture, or even contamination. This is a vital part of electric motor testing.

Sure, the megger test is an extremely common and helpful motor test. When performing a megger test, examining the quality of the motor’s insulation. Firstly, ensure the motor is switched off and separated from power. Safety first, always! Then, connect the megohmmeter leads. One lead goes to the motor frame (ground), and the other leads to one of the motor conductors or terminals. The megohmmeter then applies a DC voltage and gauges the leakage current through the insulation. It gives a reading in megohms (millions of ohms). A high reading means the insulation resistance is great. A low reading indicates poor or failing insulation. This could suggest the insulation is dirty, damp, or harmed. This diagnostic test aids in spotting motor burnout and predicting potential motor problems prior to them causing a major motor failure. It’s an essential component of insulation resistance testing for any kind of electric motor.

A surge test is a more advanced motor testing approach, but it’s excellent for discovering tricky problems in a motor winding. This test includes sending out a very brief, high voltage pulse (a surge) through the motor winding. The testing device then takes a look at just how the voltage pulse reflects. If the winding is excellent, the reflections from various parts of the winding (or various stages in a three-phase motor) will certainly look the same. But if there’s a problem, like shorted turns in the motor windings or weak insulation between turns, the reflections will certainly be different. A surge test can aid find these very early signs of weak insulation within the winding itself. It helps identify issues in a specific set of windings to isolate their performance. This is great for anticipating potential motor failure.

Power quality is a large deal for any type of electric motor. Think about it like food for your motor. If the food is bad, the motor will not be healthy. Poor power quality can include things like voltage sags or swells, harmonics (distortions in the power waveform), or an unbalanced voltage in a three-phase motor. Lots of motor problems caused by poor power quality. When the power quality is poor, your electric motor can run hotter, be less reliable, make even more noise, and wear faster. Sometimes, a sudden rise in voltage can harm the motor insulation. You can make use of a power quality analyzer to examine the power supplied to the motor. This device can show you the current and voltage waveforms and tell me if there are any issues. Good power quality suggests a better, longer-lasting motor. A power quality analyzer is one of the advanced diagnostic tools to aid spot and diagnose motor problems.

Yes, there are several various other testing methods besides the ones we have actually focused on. For example, vibration analysis can inform you a whole lot concerning the electrical and mechanical health of a motor, like problems with bearings (both front and rear bearings) or alignment. Thermography, using an infrared camera, can identify hot spots on the motor, which may indicate an overload or a failing component prior to it becoming a severe motor problem. These testing methods have advanced with time. There’s additionally something called a hipot test (high potential test). The hipot test can disclose weaknesses in the motor’s insulation by applying a higher voltage than common for a short time to check for current leakage. Some modern motor testing equipment are computer-guided instruments that can do several tests and give in-depth reports. Some devices also incorporate the testing capabilities of many single-function tools right into one device. These tools can help provide a full image of your motor’s condition. Recognizing these various motor testing methods gives you even more means to keep your electric motor healthy.

Even basic motor testing can make a substantial distinction for your motor. You do not always need fancy, expensive motor testing equipment to begin. A good digital multimeter is an excellent base for checking voltage and continuity in your electric motor. Learning to make use of a megohmmeter can save your motor from insulation failure. Always be safe when doing any type of electric motor testing. Ensure the motor is off and locked out. Check out the motor’s nameplate or manual — it has vital details. Routine checks of your motor for things like current draw (amp reading), insulation resistance, and proper voltage reading at the motor terminals can stop numerous motor problems. These basic motor testing methods are your first line of protection to troubleshoot motor problems and ensure your electric motor has a long, productive life. If an electric motor fails, these checks can commonly indicate why. These testing capabilities are accessible to many.