Let Sino's Lamination Stacks Empower Your Project!

To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.

When you work on motor design, the materials you select are incredibly, incredibly vital. Think of it like cooking a cake. If you use poor quality ingredients, you obtain a poor cake. Exact same with an electric motor design! Good materials make your motor function well, last a long, very long time, and not waste power. This article is worth reading if you want to construct a terrific motor. I’ll help you understand the very best materials for the job. We’ll check out magnet choices, wires for the winding, and other essential components of your e-motor. Obtaining the materials right from the beginning will save you migraines later. It’s the primary step to making a really high-performance motor.

The right materials ensure your motor does its task. They affect exactly how strong the motor is. They additionally transform how much energy the motor uses. A great motor requires good bones, and those bones are the materials. Think about it. An electric motor transforms electrical energy right into mechanical energy. The materials made use of inside the motor control how well this conversion occurs. Poor materials can indicate a motor that gets too hot. Or a motor that breaks down. Or a motor that simply does not have adequate power. So, for any electric motor design, picking clever materials is the first step to success. This is true for every motor you make. Choosing wisely aids the motor efficiency a great deal. It also influences the price and how easy the motor is to make. So, spending time on material selection for your motor is a smart step. It makes your motor reliable.

The magnetic components of a motor are incredibly essential. They produce the magnetic field that makes the motor rotate. For this, you require excellent magnetic materials. These materials are required to guide magnetic flux well. There are 2 major kinds: soft magnetic materials and hard magnetic materials (like a permanent magnet). Soft magnetic materials are used partly like the stator and rotor core. They help to concentrate and guide the magnetic flux. Good soft magnetic materials have high permeability. This suggests they allow magnetic flux travel through conveniently. They must also have reduced losses at the motor’s operating frequency. These assists make the motor a lot more efficient. The flux density they can handle is likewise crucial for an effective motor. Hard magnetic materials are what we make use of for a permanent magnet. These are the bits that make their very own magnetic field regularly. We’ll speak a lot more concerning them next. Picking the appropriate magnet material for your motor aids to obtain the best magnetic performance. A strong magnet frequently means a stronger motor.

An irreversible magnet produces a steady magnetic flux without requiring any electrical present for excitation. This is a big plus! It implies your motor can be smaller, lighter, and frequently a lot more efficient. These magnets are essential to a contemporary motor. When you make use of a strong irreversible magnet, like those made from rare earth materials such as neodymium or samarium cobalt, you can get a truly high torque density. This suggests even more power from a smaller motor. Neodymium magnets provide the highest energy product however could not be best for high temperature work unless you get special grades. Samarium cobalt magnets manage greater temperature better. Utilizing a great magnet is important for any type of high-performance motor. The option of magnet impacts the whole motor style. You need to consider the magnetic field toughness you need. Also, think of how warm the motor will obtain. Different magnet kinds act in a different way. A powerful magnet helps enhance the performance and effectiveness of the motor. The magnetic flux from the magnet is what drives the motor.

Currently, let’s talk about Soft Magnetic Composites, or SMC. SMC materials are made from iron powder particles. Each fragment has a shielding layer around it. This structure is quite cool for sure kinds of motor applications. One large plus of SMC is that it permits 3D magnetic flux paths. This is various from typical lamination steels, which mainly guide flux in 2D. This 3D property can aid you develop a motor with a more complex geometry. It can likewise bring about a smaller sized and sometimes a lot more reliable motor. SMC materials additionally have reduced eddy currents losses, particularly at greater frequencies. This is wonderful for a higher frequency operation motor. Nonetheless, SMC materials also have some downsides. Their permeability is generally lower than lamination steels. This means they may not be the very best for every single motor. They can likewise be more complex to work with during assembly. But also for a specific motor design that needs reduced losses at high regularity or a special form, SMC is a great choice to take into consideration. It can enhance your motor.

The winding in your electric motor is like its muscles. It’s generally a coil of magnet wire, and when an electric present flows through it, it produces an electromagnetic field. This engages with other magnetic components to make the motor transform. So, the magnet wire you choose is really crucial for your motor. Copper has actually great electrical conductivity. This suggests it lets electrical energy flow conveniently with less resistance. Less resistance suggests less energy wasted as heat. This assists the efficiency of the motor. For a typical motor, copper windings are a common selection. Occasionally, aluminum wire is taken into consideration. It’s lighter than copper. However its conductivity is reduced. So, you would certainly require a thicker aluminum magnet wire to lug the exact same present as a copper one. This can make the motor bigger. The magnet wire additionally needs excellent insulation, normally an enamel coating, to prevent shorts between the turns of the winding. This insulation needs to deal with the voltage and heat inside the motor. The option of magnet wire affects the general motor performance.

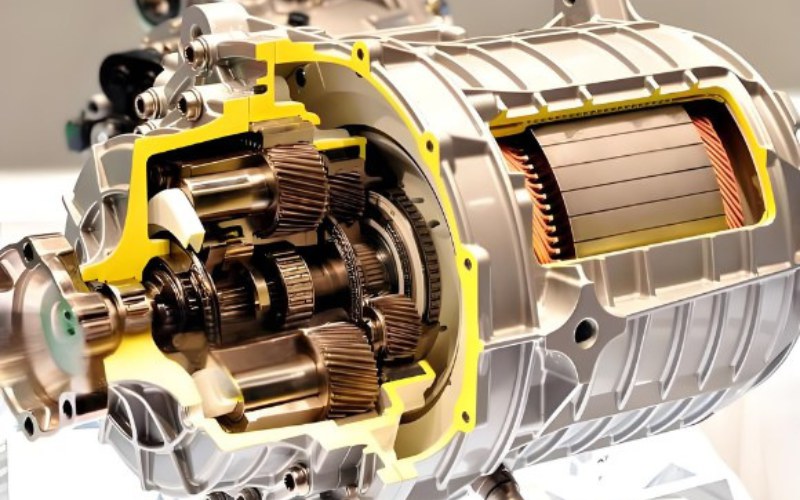

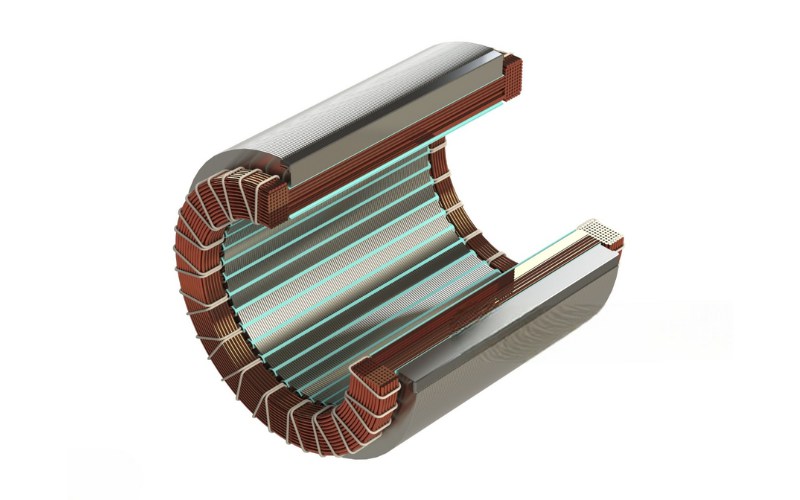

These components are generally made from stacks of thin steel sheets called laminations. (The material itself is lamination steel or electrical steel). You might question why we use slim sheets for the stator lamination as opposed to a strong block of steel for the motor. The factor for using laminations is to reduce power losses called eddy currents. When an electromagnetic field changes promptly in a conductive product (like steel in a motor), it develops these swirling currents. Eddy currents waste power as warmth and make the motor less efficient. By using thin lamination sheets, each electrically insulated from the next, we break up the courses for these currents. This significantly minimizes the losses in the motor. An excellent stator core is made from top quality lamination steel. The kind of steel made use of for the lamination additionally issues. We search for steel with excellent magnetic properties, like high permeability and reduced losses at the operating frequency of the motor. Thinner lamination sheets are much better for greater frequency motors, but they can cost more to manufacture and assemble. So, there’s a tradeoff in motor style. The stator and rotor laminations are essential for an effective motor. The flux path in these laminations overviews the magnetic energy in the motor.

Insulation resembles the safety equipment for your electric motor. It might not seem as amazing as the magnet or the winding, however it’s extremely crucial. Without excellent insulation, your motor can short out, stop working, or perhaps end up being unsafe. We need to insulate various components of the motor. The main task of insulating materials in a motor is to maintain electrical power where it should be. The magnet wire in the winding has its very own enamel finish. After that, we need insulation in between the winding and the stator core. This is typically finished with slot liners. We additionally need insulation in between different phases of the motor windings. This assists prevent partial discharge. Partial discharge can degrade the insulation with time, especially at higher voltage degrees. The insulation system in a motor should take care of the operating temperature, the voltage stresses, and any type of vibrations or chemicals it might face. A product with good thermal conductivity can likewise aid conduct heat far from the motor windings, which is a reward. If the insulation fails, the motor falls short. So, never skimp on excellent insulation for your motor. Proper insulation is essential to a resilient motor.

Heat is a major enemy of any electric motor, specifically a high-performance motor. When a motor runs, it creates warmth. This comes from resistance in the copper windings, losses in the stator laminations (like eddy currents), and magnetic losses. If this heat generated isn’t removed (or dissipated), the motor can obtain too warm. This can harm the insulation, weaken the magnet (particularly a neodymium magnet), and minimize the life of the motor. So, good thermal management is key in motor style. The materials you choose can help. For instance, utilizing materials with good thermal conductivity for components like the motor housing can help dissipate warmth. Some motor designs might require an air-cooled system with fins. More powerful (or higher power density) motors might need a liquid-cooled system. The goal is to supply a great path for warmth to escape from the hot components of the motor, like the winding and stator. Things like varnish used on the winding can likewise play a role. It assists holding the wires with each other however additionally needs to conduct heat. Better thermal performance implies the motor can run harder for longer. We aim for low thermal resistance from the heat source to the outside of the motor. This helps maintain the motor cool.

Picking better materials straight results in better motor performance and higher efficiency of the motor. It is just one of the most effective methods to boost the performance of any type of electric motor style. Each and every single motor benefits from cautious product selection. For example, utilizing a higher strength permanent magnet can boost the motor’s torque and torque density. This suggests you can obtain even more power from the very same dimension motor, or make the motor smaller for the very same power. Utilizing higher conductivity copper wire for the winding decreases power loss as heat. This makes the motor extra efficient. Better lamination steel for the stator and rotor reduces core losses, once more boosting performance, particularly at higher frequencies. These enhancements accumulate. A motor made with superior materials will certainly run cooler. It will last longer. And it will certainly utilize less electrical energy to do the very same quantity of work. This is not just great for the motor itself, however additionally for conserving power overall. Higher motor quality originates from these options.

When I’m working with a motor design, choosing materials always involves some give-and-take. This is what we call a tradeoff. There’s hardly ever one “perfect” material for each part of every motor. You need to stabilize different things. For instance, a very strong magnet material like neodymium provides fantastic performance at higher power levels. However it may be extra pricey or not handle heat as well as a samarium cobalt magnet. So you trade some magnetic performance for expense or temperature resistance. Or, utilizing thinner lamination steel decreases losses in the motor yet can make the stator more difficult and more costly to manufacture or assemble.

You also need to consider the overall objectives for the motor. Is expense the top priority? Or is it the maximum efficiency of the motor? Or possibly the smallest possible size for the motor (high torque density)? Or does the motor need to operate in an extremely hot environment? Answering these questions helps guide your material options. Every motor designer deals with these tradeoffs. The key is to understand them for your certain motor application and make smart decisions to achieve the preferred motor performance. It is essential for the motor to fulfill its goals.

A: Copper is one of the most common. It has fantastic electrical conductivity. This means much less energy is shed as warm in the motor winding. Occasionally aluminum is used if less weight is critical for the motor, but copper is generally much better for motor performance.

A: Neodymium magnets are very strong for their dimension. This means they can produce a powerful magnetic field in the motor. This helps make the motor smaller, lighter, and give high efficiency with great torque. They offer the highest energy product for a magnet.

A: Lamination sheets (or laminations) are slim layers of steel. They are utilized to create the stator and rotor cores in a motor. Making use of thin, shielded sheets helps to decrease energy losses called eddy currents. This makes the motor a lot more effective.