Let Sino's Lamination Stacks Empower Your Project!

To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.

To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.

As Sino, a top Chinese maker of very accurate motor core laminations, we know the important part our components play in the performance, efficiency, and long life of your BLDC motors. We promise to offer the newest lamination solutions that meet the many different and tough needs of motor makers in the car, airplane, factory, and electronics industries all over the world.

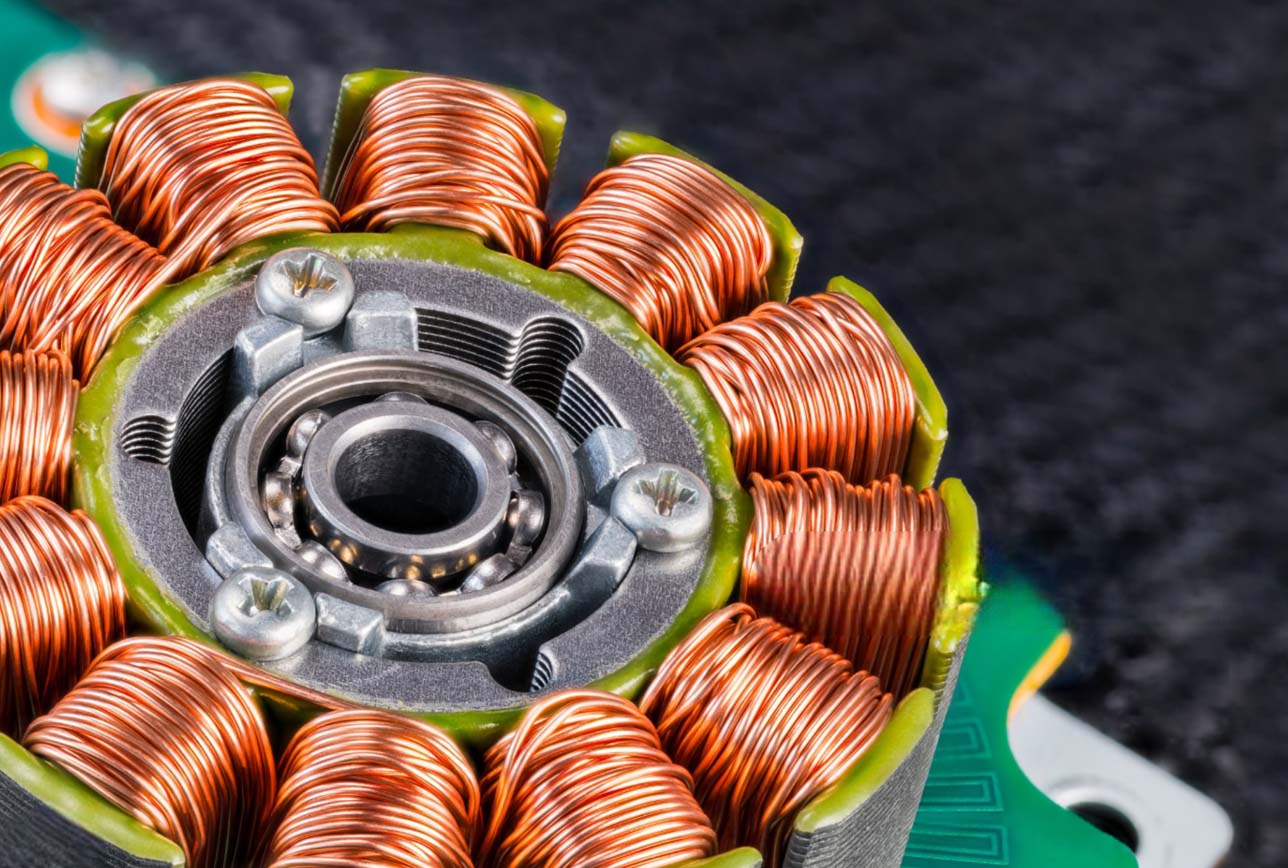

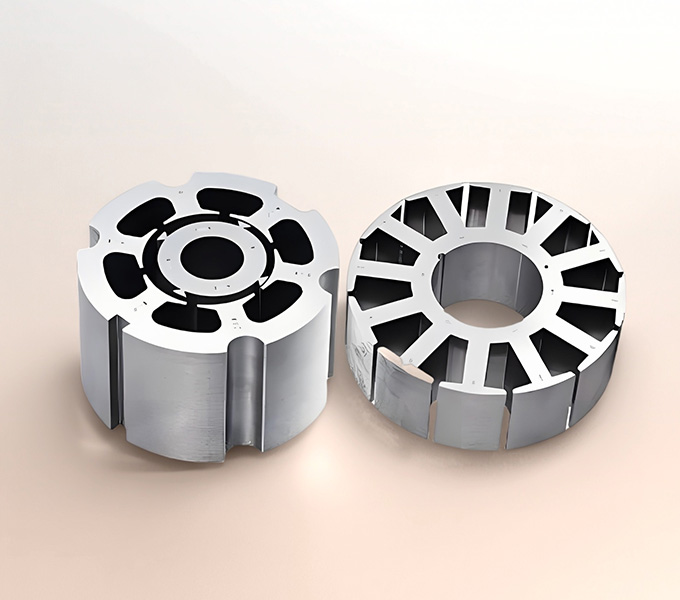

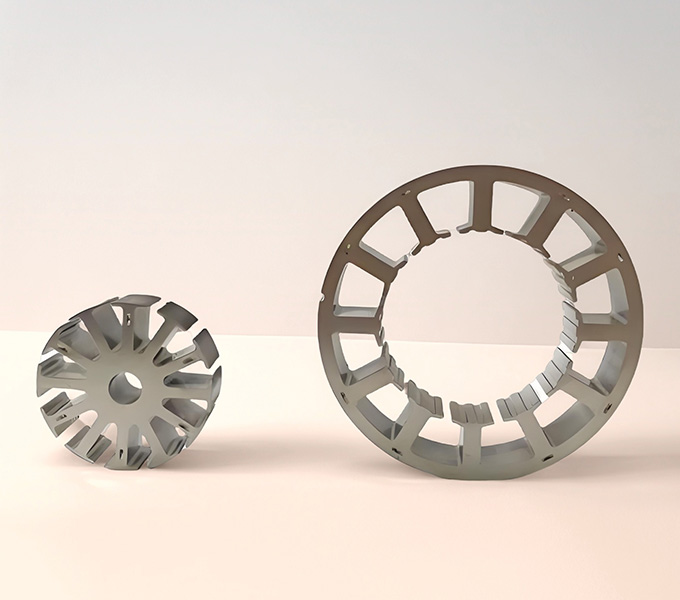

Brushless DC (BLDC) motors are a key part of today’s electric and automatic systems. They have better efficiency, more power for their size, and better control than old-style brushed motors. The core lamination, which makes up the stator and rotor, is probably the most important part. It directly affects the motor’s magnetic power, how it handles heat, its noise and shaking, and how long it lasts. At Sino, we are experts in designing and making these complex parts. We know that one single solution doesn’t work for the special jobs they are used for today.

At Sino, our Steel Laminations are engineered to maximize these advantages:

By effectively confining eddy currents, Sino’s precisely manufactured laminations ensure that more of your electrical input is converted into useful torque, not unwanted heat. We achieve this through careful selection of high-grade silicon steel, which inherently has higher electrical resistivity, and by ensuring the integrity and uniformity of the insulating coating between each sheet.

Our Steel Laminations are not just thin; they are crafted to optimize the magnetic circuit. We work with materials that offer excellent permeability, allowing for strong magnetic fields, while our manufacturing processes ensure minimal air gaps and consistent stacking factors. This holistic approach to the BLDC motor core ensures that efficiency isn’t just a byproduct, but a design goal.

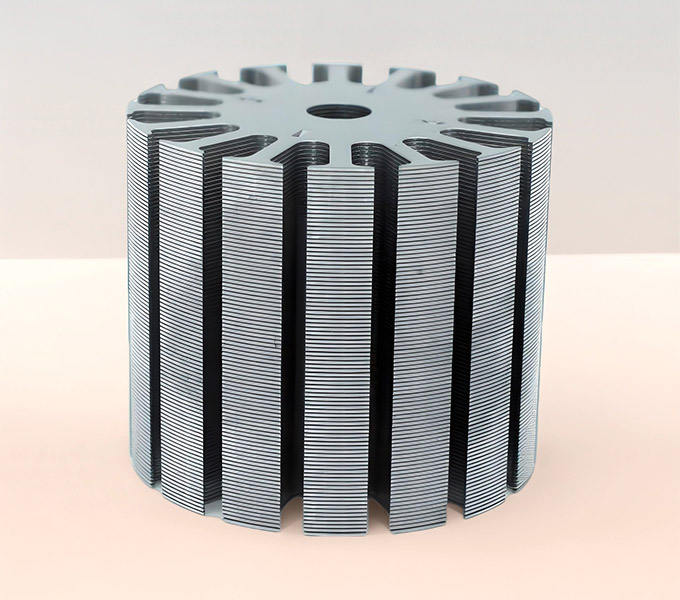

For applications like high-speed CNC spindles, medical drills, or advanced servo motors, Sino offers laminations down to 0.20mm or even 0.1mm. These ultra-thin options are critical for maintaining efficiency and preventing overheating in demanding high-frequency scenarios.

At Sino, we understand that the choice of material, the precision of the stamping process, the quality of the insulation, and the consistency of the stacking all play vital roles.

1

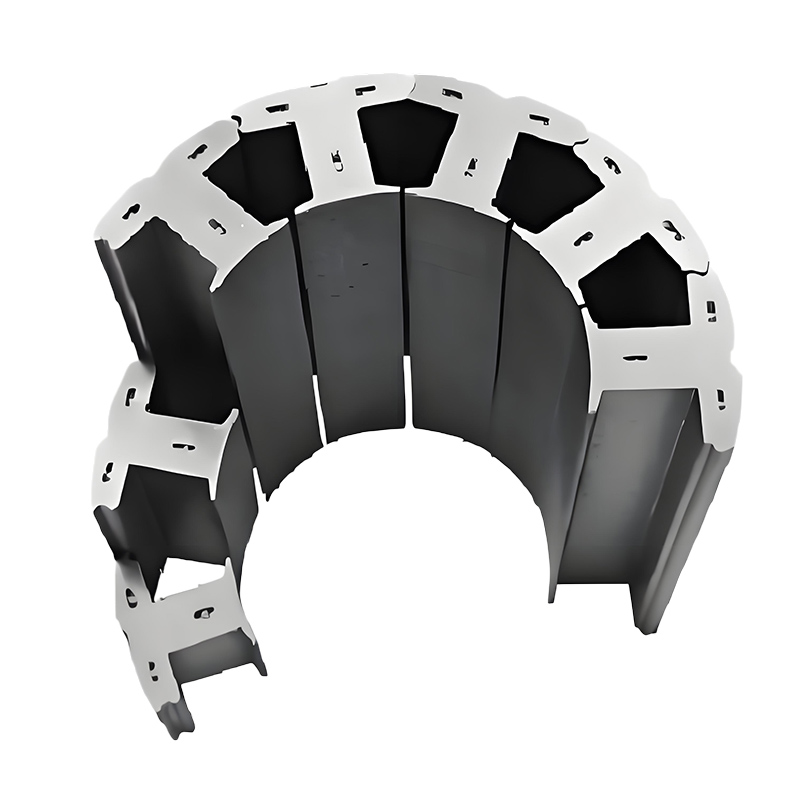

As we’ve seen, thinner is generally better for combating eddy currents. Sino offers a comprehensive range of Steel Lamination thicknesses, typically from 0.20mm up to 0.65mm, to suit diverse operational frequencies and cost targets. However, going too thin can increase manufacturing complexity and cost, and can slightly reduce the “stacking factor” (the proportion of actual iron in the core volume). Our engineers help clients navigate this trade-off to find the optimal solution.

2

We primarily utilize high-grade silicon steel (often called electrical steel). The addition of silicon (typically 1-4%) significantly increases the steel’s electrical resistivity – a key factor in reducing eddy currents – and also helps to minimize hysteresis losses (another type of core loss related to the magnetic domains reorienting). Different grades of silicon steel offer varying magnetic properties, loss characteristics, and mechanical strengths. Sino sources and processes these materials to exacting standards.

3

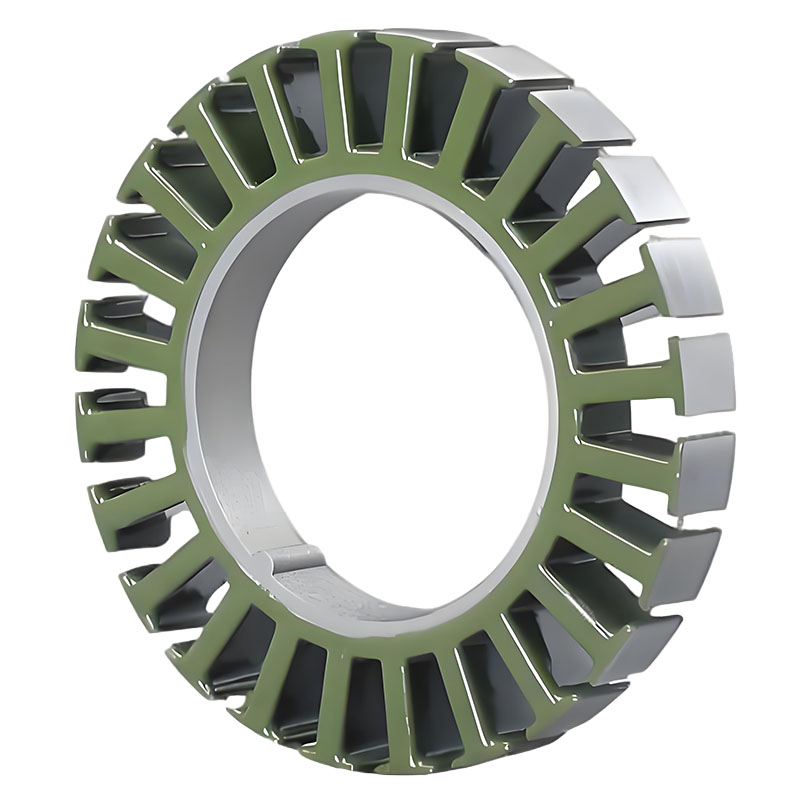

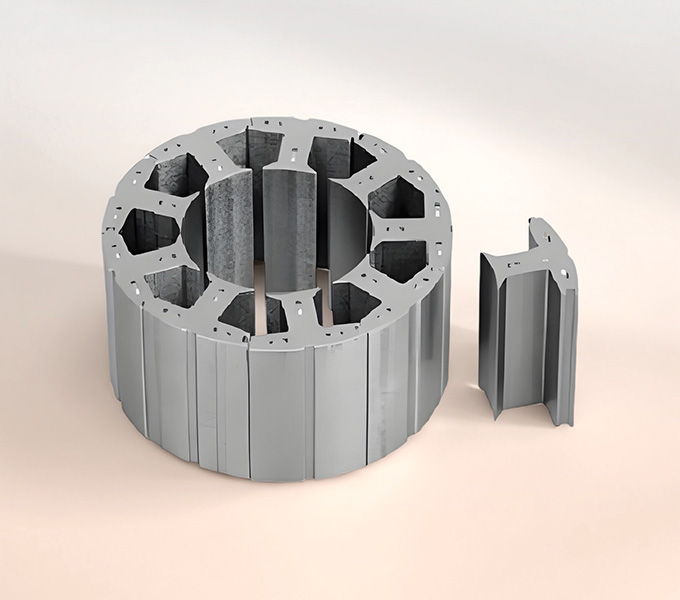

Sino employs advanced stamping techniques to ensure clean edges and precise geometries, minimizing burrs that could breach insulation or create unwanted air gaps. Our insulation coatings are uniformly applied and cured to withstand the temperatures and mechanical stresses of motor assembly and operation. Whether it’s interlocking designs for mechanical integrity or precision welding for robust bldc stator lamination stacks, our focus is on creating a core that performs as a perfectly integrated unit.

This table gives a conceptual idea of how lamination choices, like those Sino offers, can influence performance:

Lamination Thickness (mm) | Sino’s Grade / Typical Application Focus | Relative Eddy Current Loss Factor (Conceptual) | Key Benefit Sino Delivers |

0.65 | Sino Standard Grade / General Purpose Motors | Moderate (e.g., ~2.5x baseline) | Cost-effective solution for less demanding scenarios |

0.50 | Sino Performance Grade / Efficient Industrial Motors | Baseline (1x) | Excellent balance of performance and cost for many BLDCs |

0.35 | Sino High-Efficiency Grade / EVs, Premium Appliances | Lower (e.g., ~0.5x baseline) | Superior efficiency, reduced heat for demanding applications |

0.20 | Sino Ultra-High Frequency Grade / Servo, Aerospace | Very Low (e.g., ~0.15x baseline) | Minimizes losses at high PWM or rotational frequencies |

Specialized <0.20mm | Sino Custom Solutions / Cutting-Edge R&D | Extremely Low | Pushing boundaries for niche, ultra-high-performance use |

Disclaimer: Loss factors are illustrative and vary based on specific material grade, flux density, and operating frequency. Source: Adapted from general motor design principles and Sino’s internal characterization data.

Choosing the right material for the lamination is the basis for good performance in a BLDC motor core. Sino offers a wide variety of materials. Each one is picked and treated to get the right magnetic and physical features, made to fit what our customers need.

The most common choice for BLDC motor laminations is still high-silicon electrical steels, which usually have 2–3.2% Si. This is because they have a good mix of low energy loss in the core and let magnetic fields pass through easily. We work with different types, including:

Sino is leading the way in using advanced soft magnetic materials in BLDC motor cores, because we see they can be extremely efficient, especially at high speeds.

The accuracy and quality of BLDC motor core laminations depend directly on the making process we use and how strictly we check for quality. At Sino, we use the most modern methods, mainly high-speed stamping and laser cutting, along with advanced finishing steps and strict rules for making sure everything is good quality.

High-Speed Stamping

High-speed stamping is the way we like to make large amounts, because it’s super fast and saves a lot of money.

Laser Cutting

For making samples, test runs, or small numbers of special custom parts, laser cutting offers the best flexibility and accuracy.

Best For: Laser cutting can easily handle lamination thicknesses from 0.1 mm to 1.0 mm and can work with special materials (like cobalt-iron, amorphous alloys) and complex shapes (like segmented rotors, skewed slots) without changing any tools.

Sino also looks into and uses special methods for certain needs:

At Sino, we believe that manufacturing superior BLDC motor core lamination products goes beyond just stamping thin steel.

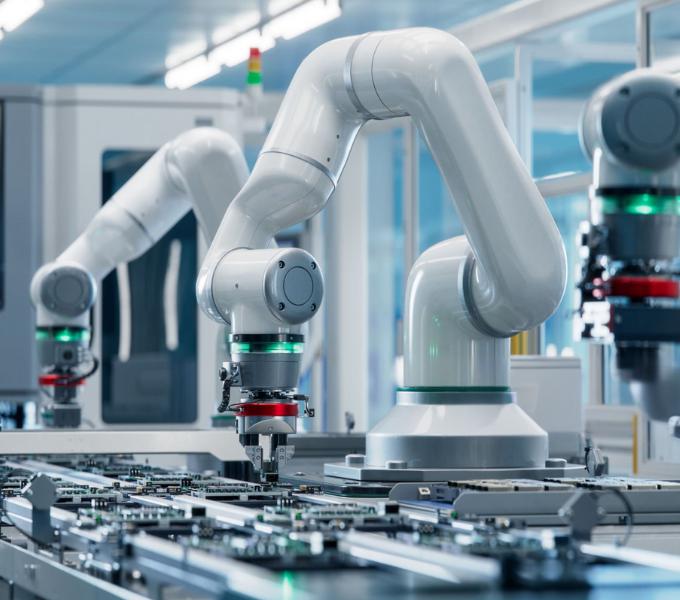

The impact of high-quality brushless motor laminations is felt across a vast spectrum of industries:

Here, every percentage point of efficiency translates to increased range and reduced battery size. Thermal management is also critical. Sino’s high-efficiency, low-loss steel laminations are key components in traction motors that deliver the power and endurance modern EVs demand.

For aerial applications, minimizing weight while maximizing power and flight time is the holy grail. Our lightweight, yet magnetically potent, thin laminations help drone manufacturers achieve impressive payload capacities and extended operational envelopes.

Precision, rapid acceleration, and long-term reliability are non-negotiable. Sino’s laminations contribute to the smooth, accurate, and enduring performance of servo motors and robotic actuators on today’s smartest factory floors.

Users demand more power, longer runtimes, and tools that don’t overheat. Our laminations help create compact, power-dense motors that can take a beating.

With energy efficiency being a major global focus, motors in fans, pumps, and compressors benefit immensely from low-loss laminations, contributing to significant energy savings over the system's life.

From surgical tools requiring ultra-smooth, low-vibration operation to diagnostic equipment needing silent, reliable motors, the precision and quality of Sino’s BLDC motor core lamination products are indispensable.

When you’re designing or manufacturing BLDC motors, the quality of the core laminations is not a place to compromise. Partnering with Sino for your Steel Lamination needs brings distinct advantages:

We live and breathe laminations. Our team understands the nuances of magnetic materials, stamping technology, and the specific demands of BLDC motor core and bldc stator lamination design.

From raw material inspection to final stack verification, quality is embedded in every Sino process.

We see ourselves as more than just suppliers; we are partners in your success. We work with you to understand your performance goals and provide laminations that help you achieve them.

You can count on Sino to deliver high-quality laminations, on time, every time, allowing you to streamline your own production.

The humble BLDC motor core lamination might not always grab the headlines, but it’s undeniably a foundational element of modern motion technology. By diligently controlling those invisible eddy currents, these precisely engineered steel sheets unlock efficiency, power, and reliability.

At Sino, we’re proud to craft the Steel Laminations that empower engineers and innovators to build the next generation of high-performance BLDC motors. If you’re ready to elevate your motor designs and ensure your products operate at their absolute best, let’s talk.

Discover how Sino’s dedication to lamination excellence can be your competitive advantage.

Note: To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.

To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.