Let Sino's Lamination Stacks Empower Your Project!

To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.

I’ve been working with electric vehicle tech for years, and I’ve seen many new ideas that promise to make them better. But I’ve learned that the biggest improvements often come from parts people don’t think about. We often talk about big batteries and smart software, but the real secret to a better electric motor and a strong regenerative braking system is in the motor’s core: the motor laminations. These thin steel sheets are the hidden helpers that greatly improve how your EV gets energy back. This article will show you how these parts work, why they’re so important for getting back energy, and how they help you drive farther and be more eco-friendly.

From what I’ve seen, many drivers, even EV owners, don’t really understand how cool regenerative braking is. To put it simply, it’s a smart system that gets back the car’s moving energy when you slow down. In a regular gas car, when you hit the brake pedal, the friction brakes create heat to slow the car, and all that energy is just wasted into the air. It’s a huge waste. A regenerative braking system, however, does something smart. It makes the electric motor run in reverse, turning it into a generator.

This process changes the moving energy from the car back into electricity, which then goes back to the battery. Think about it: the same force that was pushing the car forward is now used to charge its power source. Getting this energy back works best when you’re starting and stopping a lot, like driving in a city. The result is a car that uses less energy, can drive farther, and makes better use of energy that would just be lost. It’s a big part of making modern EVs eco-friendly.

People often ask me why electric motors aren’t just one solid piece of metal. It sounds easier, right? But with magnets and electricity, “easy” usually isn’t “good.” If the motor’s core was a solid piece of metal, the fast-changing magnetic fields inside would create a lot of unwanted electrical currents. These are known as eddy currents.

A solid core would let these currents flow around in big circles, which creates a ton of heat and wastes a lot of energy. This heat doesn’t just make the motor work poorly; it could make the motor overheat. This could damage it and make it wear out much faster. Also, this problem would badly hurt the motor’s ability to work as a generator during regenerative braking. Most of the kinetic energy you capture would turn straight into heat instead of electricity for the battery. Using a solid core would make the whole braking system work much worse.

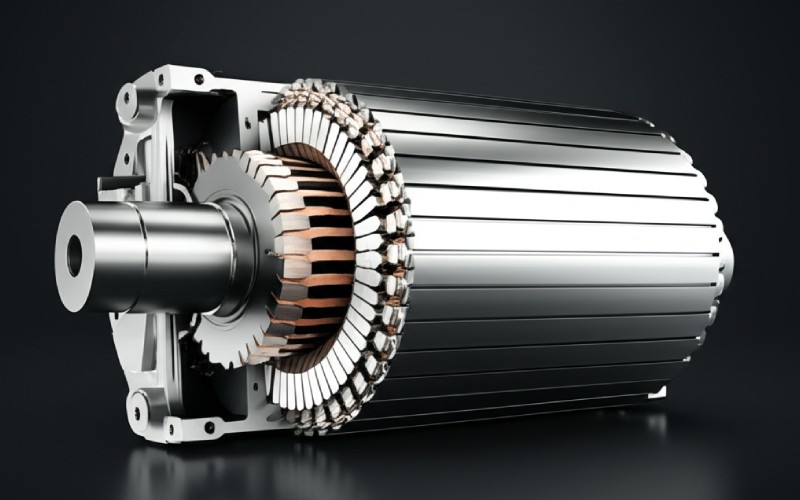

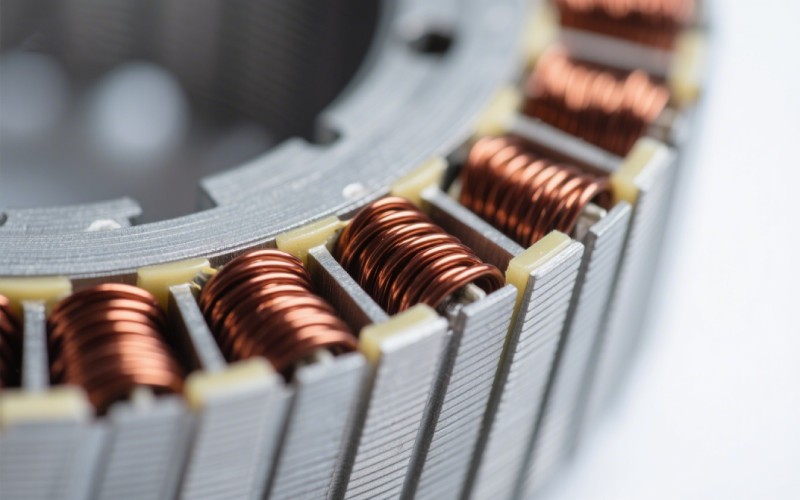

This is where the smart idea of motor laminations comes in. Instead of being one solid piece, the core of an electric motor—both the part that stays still (stator) and the part that spins (rotor)—is made of a pile of very thin metal sheets. These are often called steel laminations. Each thin sheet is separated from the next one, usually with a thin coat of varnish or an oxide layer.

By cutting the core into these separate layers, the paths for eddy currents are broken into much smaller pieces. The currents can no longer flow in big circles that waste energy. This simple but smart design greatly cuts down on lost energy. This makes the motor work better when you speed up, and it also hugely improves how it performs during regenerative braking. A motor that works better can turn more of the car’s kinetic energy into electricity. This sends more power back to the battery and makes the whole regenerative braking system do its job better.

Let’s look a little closer at these invisible bad guys. Eddy currents are circles of electricity created inside a metal object when it’s in a changing magnetic field. In an electric motor, the magnetic fields are always changing to create spin, so eddy currents are an unavoidable result. These currents make their own magnetic fields that push against the original field that made them. This means the motor is basically fighting itself.

This internal fight causes two big problems. First, it’s a direct waste of energy, which makes the overall motor efficiency lower. Instead of helping create the torque that moves your vehicle, this energy is wasted. Second, this wasted energy shows up as heat. Too much heat can break down the motor’s insulation, weaken its permanent magnets, and eventually cause parts to break. During regenerative braking, these losses mean less kinetic energy is successfully changed into electricity and stored in the battery. By cutting down on eddy currents, laminations help the motor run cooler and with high efficiency, making the regeneration process much more useful.

The change from a motor to a generator is the key to regenerative braking. When you take your foot off the gas or press the brake pedal in an EV, the controller changes how the electricity flows. The car’s forward motion keeps turning the rotor inside the motor. As the rotor spins through the magnetic field of the stator, it creates a voltage in the motor’s windings—this is how a generator works.

Laminations are key here because they make sure this process works as well as it can. By stopping energy-wasting eddy currents and other magnetic losses (like hysteresis), the steel laminations let the motor change the most possible kinetic energy from the vehicle into electrical energy. A motor with a poorly made core would lose much of this energy as heat before it ever got to the battery. Because of this, the high efficiency you get from laminations is what makes a strong regenerative braking system possible. It directly helps get back energy that makes the driving range longer.

Yes, for sure. The choice of material for motor laminations is a very important choice for engineers that directly affects performance. While most regular motors use silicon steel, the need for better performance in EVs has made companies look at more special metal mixes.

Here is a look at some common materials and what they do:

| Material | Key Good Points | Where It’s Used |

|---|---|---|

| Silicon Steel | Good with magnets, not too expensive, lasts a long time. | Most regular EV motors. |

| Cobalt-Iron Alloys | Handles strong magnetic fields, very strong, great for high-torque jobs. | High-performance EVs, big trucks, airplanes. |

| Nickel-Iron Alloys | Works well with weak magnetic fields, very low energy loss. | Special motor parts. |

| Amorphous Metals | Extremely low energy loss, works very well at high speeds. | High-efficiency transformers and new motor designs. |

The thickness of the lamination is also very important. Factory motors might use laminations that are 0.35mm to 0.5mm thick. But high-performance EV motors are now using much thinner ones—as thin as 0.2mm or even less. Thinner laminations are better at cutting down on eddy current losses, especially in high-speed motors. This lets engineers make the motor better, with more power in a smaller size, and enhance efficiency even more.

The link is clear and very important. By cutting down on energy loss from eddy currents and hysteresis, laminations improve the overall motor efficiency. A motor that works well needs less electricity from the battery to create a certain amount of torque. This means better acceleration and a longer EV range. This benefit works both ways.

During regenerative braking, the process is flipped. A motor that works very well, thanks to its great laminations, can change more of the vehicle’s kinetic energy into braking torque and then into stored electrical energy. Laminations made from materials that work well with magnets let the motor create a stronger magnetic field. This increases the torque it can produce without making it heavier. This leads to a better torque-to-weight ratio, which allows for smaller, more powerful motor designs that are needed for modern EVs. The right lamination design, in other words, helps make both driving and braking work better.

While laminations are the effective physical parts, the advanced control systems are the smart part of the operation. The vehicle’s brake controller is always watching things like wheel speed, how full the battery is, and how hard the driver is pushing the brake pedal. It then uses a smart program to decide the best mix between regenerative braking and the regular friction brakes.

The goal is to get back the most energy without making the car unsafe or unstable. For example, the controller will reduce regeneration if the battery is already full or if it senses a wheel is sliding, which could make you lose control. Modern systems use programs that guess what will happen to see driving conditions ahead of time and change the braking strategy as needed. This smart control makes sure that the highly efficient motor, with its advanced laminations, is used as much as possible. It smoothly mixes regenerative and friction braking to create a smooth, safe, and very efficient driving experience.

The focus on parts like motor laminations shows that the EV industry is growing up. As we push to make batteries better, we are also finding big improvements by improving and making every part of the powertrain perfect. For hybrid, plug-in, and fully electric vehicles, improving the electric motor and regenerative braking system is very important.

High-quality steel laminations directly lead to:

I believe the future of EV and hybrid vehicle development will focus even more on these basic parts. New ideas in materials like amorphous metals, along with better ways of making them, will keep making motors more efficient and energy recovery systems better.

Getting back the most energy is a whole-system problem that needs the physical parts and the software to work together perfectly. From what I’ve seen, the plan comes down to a few key things. First is the motor design itself; using a synchronous or AC induction motor built with thin, high-quality steel laminations is a basic and important step to create a high-efficiency generator. The choice of magnet type, like a permanent magnet, and how the windings are set up also play big roles.

Second, the braking strategy needs to be controlled smartly. The system needs to change the braking force on the fly between the electrical motor and the friction brakes to capture the most braking energy possible in all situations. This requires smart control programs that can consider the vehicle’s speed, battery health, and even how the driver behaves. Finally, the way a person drives can affect the result. Smooth driving and seeing stops ahead of time lets the regenerative braking system work more often and better than braking fast and hard, which uses the friction brakes more.

To finish, let’s go over the most important things I’ve learned about this topic over the years: