Let Sino's Lamination Stacks Empower Your Project!

To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.

You understand, those handy assistants for all types of jobs. We’re most likely to check out two kinds: brushless power tools and brushed power tools. It can be puzzling to understand the difference between a brushless vs brushed power tool. Yet don’t worry! This article is worth reading because understanding this difference can help you pick the best power tool for your needs. It can also save you money and make your work easier. Let’s learn about these tools together!

Consider a brushed motor as the older style of motor in many power tool designs. Inside this motor, there are small components called brushes. These brushes are normally made of carbon. Their job is to conduct electrical power to the rotating part of the motor.

These carbon brushes make physical contact with another part of the motor called the commutator. This contact allows electrical current to flow and make the motor run. Yet, because the brushes are constantly rubbing, they can wear out over time. This is a key characteristic of a brushed motor. It’s a simple design, and it works, but these parts can wear down. This means you would need to replace the brushes in your power tool from time to time.

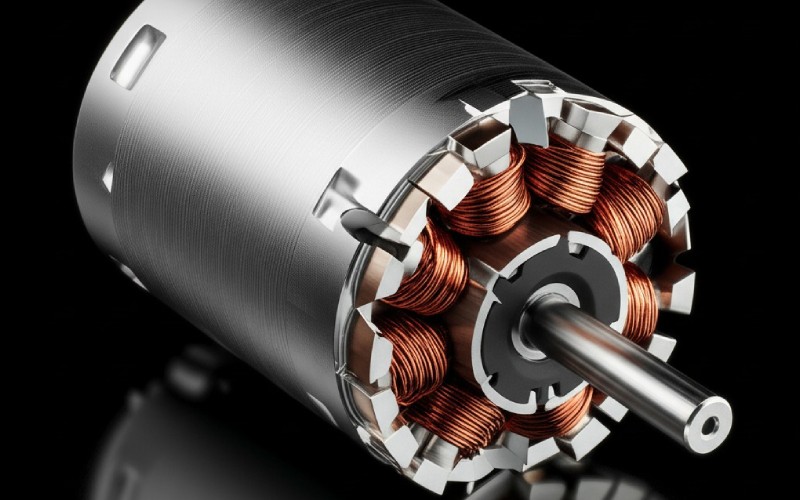

Now, let’s discuss the newer kid on the block: the brushless motor. A brushless motor is a more modern type of motor for your power tool. The big difference is right in the name—it has no brushes! Instead of brushes and a commutator, a brushless motor uses an electronic controller and magnets.

This electronic controller is like a tiny computer inside the tool. It tells the motor precisely how to rotate and how much power is needed. Because there are no brushes making physical contact, there’s less friction. This means much less wear and tear on the motor parts. The design of a brushless motor is more complex, but it typically results in a more efficient power tool. This type of motor can make your tool run smoother and for a longer time.

So, you’re most likely asking, “What’s the real difference between a brushless and a brushed power tool?” The biggest thing to understand is how the motor receives and manages its power. A brushed motor uses brushes to conduct electricity to its rotating part. A brushless motor uses an electronic controller to manage how power is delivered to the motor, without physical brushes. This one change causes many other differences in how the power tool works.

Think about it like this: a brushed motor has parts that rub together. This rubbing creates friction and heat. It also means the brushes will wear out. A brushless motor doesn’t have these rubbing parts. This means less friction, less heat, and less wear. This is the key difference that impacts the tool’s performance, lifespan, and even how long a battery lasts in cordless models.

Well, a brushless tool usually gives you more power in a smaller package. This means the tool can be lighter and more compact. If you’re working in tight spaces or holding a drill over your head for a while, a lighter tool is a big help.

Another reason is efficiency. A brushless motor adapts to the job. If you’re driving a small screw into soft wood, it uses less power. If you’re drilling a large hole with a large bit into hard material, the electronic controller delivers more power to the motor. This smart use of power means a brushless power tool can often run longer on a single battery charge compared to brushed tools. This is a great advantage for large DIY projects.

Many people see brushless motor technology in cordless power tools, like a cordless drill or saw. And it’s true, brushless motors are popular in cordless models because they help extend battery life. The efficiency of a brushless motor means the battery doesn’t have to work as hard, so it lasts longer.

However, brushless motor technology isn’t just for cordless tools. You can also find corded power tool options that have a brushless motor. These tools still offer benefits like a longer lifespan for the motor and more consistent power tool performance. So, whether you like a cordless tool for freedom of movement or a corded tool for uninterrupted power, you can find a brushless option. You don’t always need to go cordless to get a brushless power tool.

First, they are normally more efficient. The motor adjusts its power output to the job. This smart control means the tool uses only the power it needs, which is great for battery life in cordless models. A brushless tool can often run much longer on the same battery compared to brushed counterparts.

Second, brushless motors often have a longer lifespan. Because there are no carbon brushes to wear out, the motor itself generally experiences less wear and tear. This can mean a longer tool life for your investment. Third, you often get more power and torque from a more compact tool. This means the tool can be lighter and easier to handle without sacrificing performance. And finally, they produce less heat because there’s less friction, which can also help extend the lifespan of the tool.

Absolutely! Despite all the talk about brushless tools, brushed motor power tools still have their place. For years, they were the only option, and they got a lot of work done for me and many others. The main advantage of a brushed motor tool is often the price. They are typically cheaper to buy. If you just need a power tool for occasional, light tasks, a brushed power tool may be perfectly fine.

If you’re just starting with DIY projects or have a tight budget, a brushed motor drill or saw can be a good way to build your tool collection. They are known, dependable tools. The main disadvantage is that the carbon brushes will eventually wear out and need to be replaced. But for some users, this lower initial price makes the brushed motor tool the right choice. You just need to check the brushes from time to time.

When you look at the price tag, a brushless power tool usually costs more than a brushed motor tool. So, how can it save you money? First, because brushless motors have a longer lifespan, your tool is likely to last longer. This means you might not have to replace your power tool as often. This can save you money on buying a new tool.

Second, there’s less maintenance. With a brushed motor, you would have to buy and replace carbon brushes. While brushes themselves aren’t typically very expensive, the time and effort to repair or replace them can add up. A brushless motor doesn’t require this sort of brush replacement, offering low maintenance. Additionally, if you use cordless tools, the better efficiency means longer battery life. This could mean you need fewer batteries or your batteries last longer before they need to be replaced, saving more money.

This really depends on how you plan to use your power tool. If you’re a professional or a serious DIYer who uses your tools frequently and for heavy-duty tasks, then a brushless tool is probably a good investment. For example, if you’re doing a lot of cutting with a saw or drilling many holes with a drill, the power, efficiency, and longer lifespan of a brushless motor will certainly be a big advantage. The tool will likely perform better and last longer under constant use.

On the other hand, if you just need a power tool for small jobs around your home once in a while, a brushed motor tool might be all you need. If your tool use is light, the wear on the brushes will be slow. The lower initial cost might be more important to you. You have to balance the cost with how much you’ll use the tool and what you need it to do. Think about the types of DIY projects you do. A brushed power tool is a good tool for many jobs.

Think about the advantages we’ve talked about: longer tool life, better efficiency (which means longer battery life for cordless tools), more power in a compact tool, and less maintenance because there are no brushes to wear out or replace. These benefits can make your work easier and more enjoyable.

While the upfront cost is higher, the overall cost of ownership over the life of the tool can be lower. You might save money on repairs, replacement brushes, and even replacement batteries. Plus, a tool that performs better and lasts longer is typically worth the extra investment. If you plan to use your power tool regularly or for demanding tasks, the brushless power option will likely pay off. It’s a tool that can run and run. You should check your local store to compare prices and feel the difference in a brushless tool.