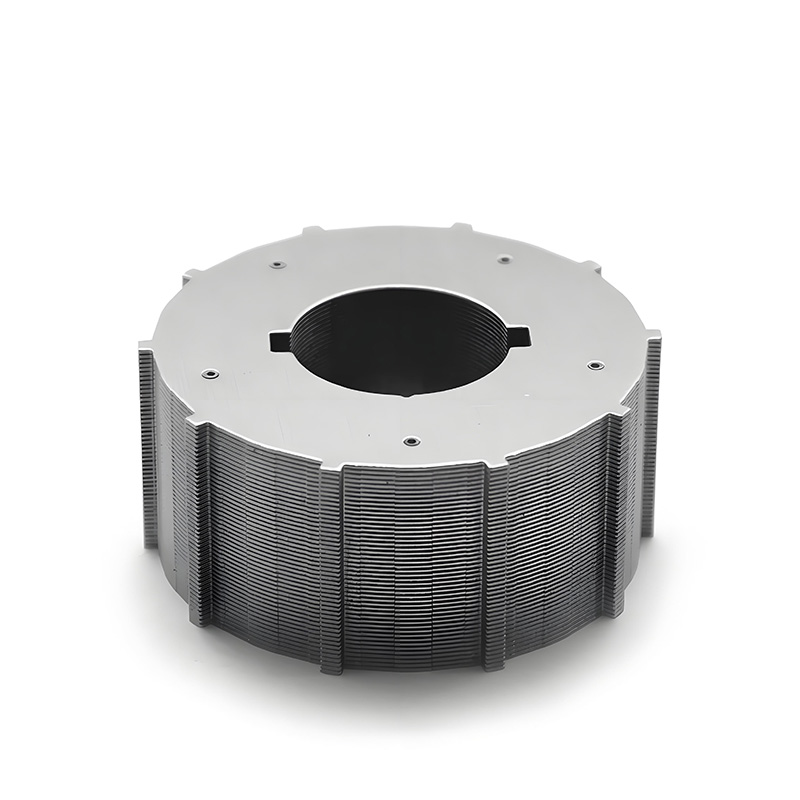

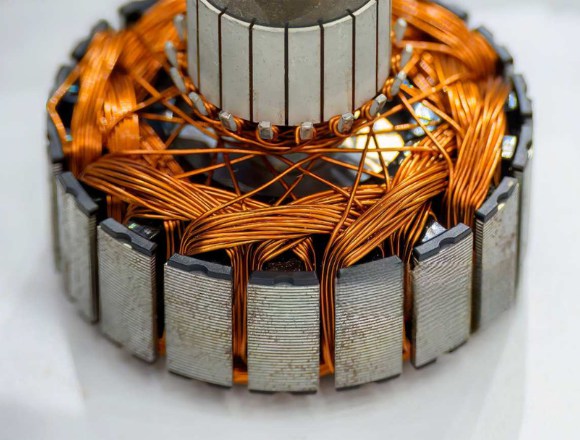

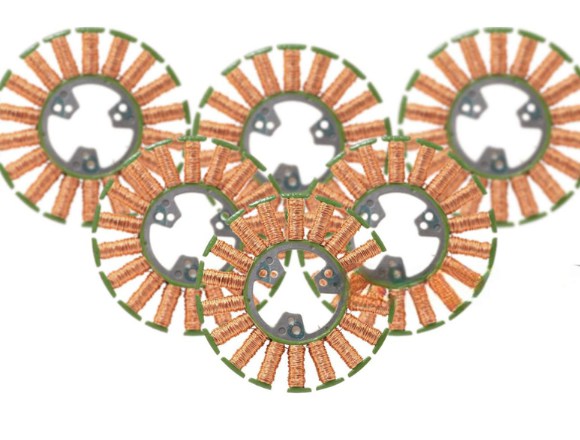

Let Sino's Lamination Stacks Empower Your Project!

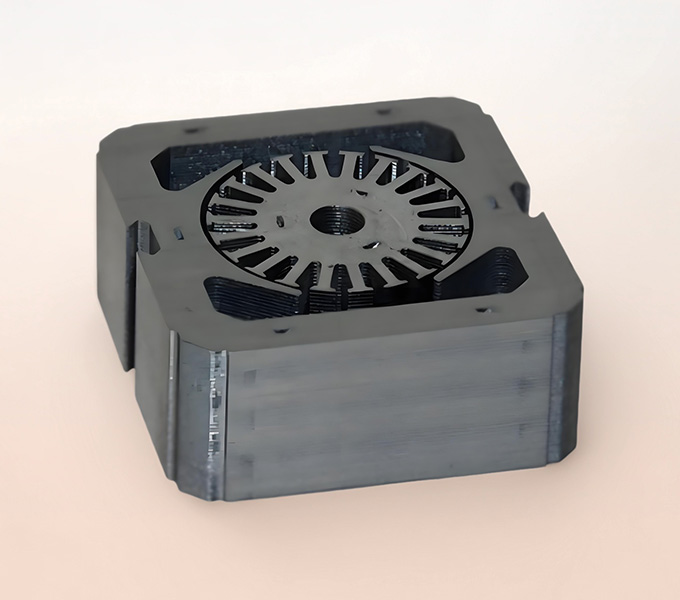

To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.

To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.

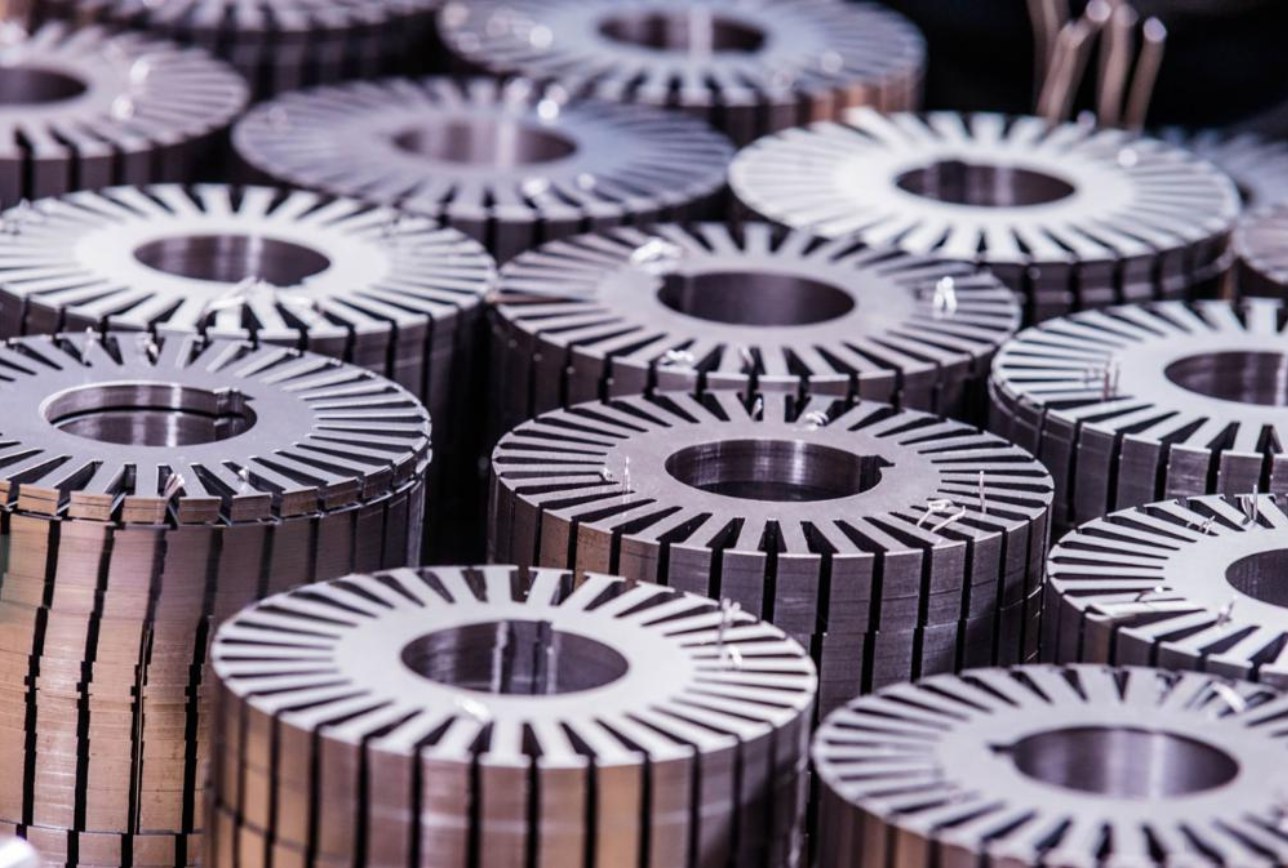

At Sino, we’re not just a motor core maker. We are an expert partner, helping our clients—suppliers and traders—get the best cold-rolled motor laminations. We know a lot about how motors are used, are skilled with modern electrical steel types, use the latest manufacturing methods, and pay close attention to performance and cost. This makes us a special choice in the world market.

What’s the big deal about “cold rolled,” and why are these thin slivers of specialized steel so critical? Cooling the rough metal sheets, then meticulously working and pressing them until their structure is refined. Simply put, this is the essence of cold rolling. This process, applied to specialized electrical steel, transforms it, bestowing upon it properties that are a dream come true for motor designers. At Sino, we’ve mastered this art, turning high-grade cold rolled motor lamination coil into impeccably precise cold rolled motor lamination sheet components ready to form the heart of your next motor.

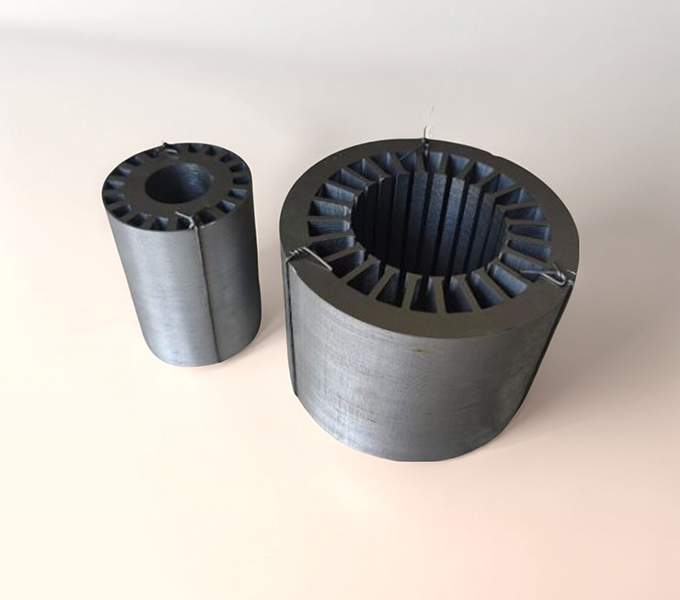

Cold rolling allows for incredibly tight control over the thickness of each lamination – we’re talking tolerances measured in mere hundredths of a millimeter. Furthermore, it yields a much smoother, more consistent surface finish compared to hot-rolled alternatives.

A higher stacking factor means more actual steel and less air (or varnish) in a given core volume. Uniform thickness ensures that when the laminations are stacked and compressed, they fit together snugly. This maximizes the amount of magnetically active material, directly contributing to better magnetic performance.

That smooth surface is crucial for the even application and integrity of the thin insulating coating (like C5 or C6 coatings) that each cold rolled motor lamination receives. If the surface is rough, the coating can be uneven or damaged during handling and stacking, creating short circuits between laminations and compromising all those efforts to reduce eddy currents.

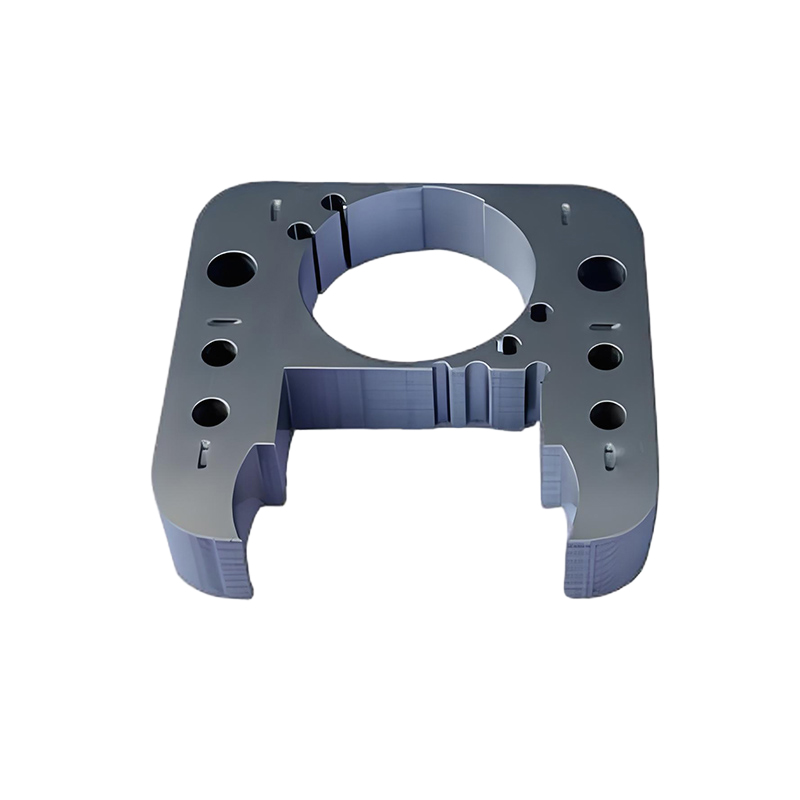

A precisely stacked core is more mechanically stable and balanced. This is especially vital in high-speed motors, where even slight imbalances can lead to excessive vibration, noise, premature bearing wear, and, in extreme cases, catastrophic failure.

1

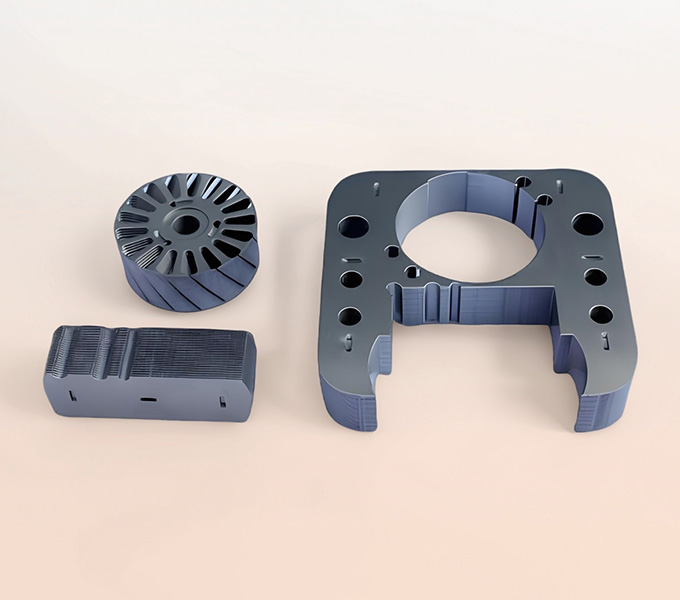

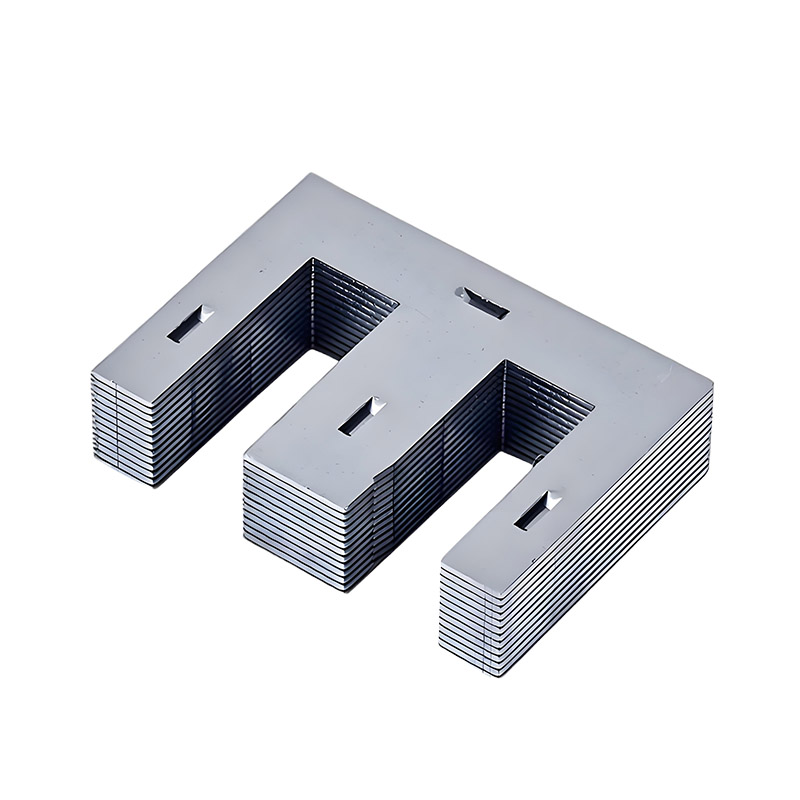

The method of joining the laminations – whether it’s through interlocking (creating small, stamped features that lock adjacent laminations together), cleating, welding along the outer diameter, or bonding with adhesives – has a significant impact on the core’s mechanical integrity, dimensional stability, and even its magnetic properties.

2

Our automated stacking lines and skilled technicians ensure that each core is built to tight tolerances, maximizing that all-important stacking factor and minimizing any potential for noise, vibration, or performance degradation due to a sub-optimal assembly.

3

When you receive a lamination stack from Sino, you’re getting a component that’s ready to become the reliable heart of your motor. This commitment to quality assembly ensures maximized stacking factor and minimizes potential issues like noise, vibration, or performance degradation, delivering a component optimized for performance and reliability.

Choosing and handling the right electrical steel is key to how well a motor works. Sino is skilled with a wide range of cold-rolled electrical steels, focusing on their natural magnetic, mechanical, and heat-related qualities.

We know the subtle differences between fully processed and semi-processed NGO electrical steels and help our partners choose the best material for what they need:

Fully Processed NGO Steels

Semi-Processed Steels

Thermal Conductivity

Both steel types have similar thermal conductivities (typically 20–25 W/m·K). Fully processed grades might be slightly lower because they have more alloys and a finer grain structure. This is usually less important than magnetic losses.

While exact figures depend on the specific grade of steel and processing, here’s a conceptual idea of the improvements cold rolling brings, which Sino consistently delivers:

Property | “Basic” Steel Core (Conceptual) | Sino’s Cold Rolled Motor Lamination (e.g., NGO M270-35A equivalent) | Unit | Significance for Your Motor |

Core Loss @ 1.5T, 50Hz | > 6.0 W/kg | Typically < 2.70 W/kg (often better with Sino’s process control) | W/kg | Dramatically reduced energy waste, higher efficiency |

Lamination Thickness | Can be variable, thicker | Precisely controlled, often 0.35mm, 0.50mm, or even thinner | mm | Significantly lower eddy current losses |

Inter-laminar Resistance | Lower / Inconsistent | High & Consistent (due to quality coating on each sheet) | Ohm-cm² | Blocks eddy currents between laminations effectively |

Table 1: Property Comparison

| Property | “Basic” Steel Core (Conceptual) | Sino’s Cold Rolled Motor Lamination (e.g., NGO M270-35A equivalent) |

|---|---|---|

| Core Loss @ 1.5T, 50Hz | > 6.0 W/kg | Typically < 2.70 W/kg (often better with Sino’s process control) |

| Lamination Thickness | Can be variable, thicker | Precisely controlled, often 0.35mm, 0.50mm, or even thinner |

| Inter-laminar Resistance | Lower / Inconsistent | High & Consistent (due to quality coating on each sheet) |

Table 2: Units and Significance

| Property | Unit | Significance for Your Motor |

|---|---|---|

| Core Loss @ 1.5T, 50Hz | W/kg | Dramatically reduced energy waste, higher efficiency |

| Lamination Thickness | mm | Significantly lower eddy current losses |

| Inter-laminar Resistance | Ohm-cm² | Blocks eddy currents between laminations effectively |

Source for general properties: Manufacturer datasheets from leading electrical steel producers like ThyssenKrupp Electrical Steel (now part of Tata Steel), AK Steel (Cleveland-Cliffs), Posco, etc., and standards like ASTM A677/A677M.

Consider the burgeoning electric vehicle (EV) market. Every watt-hour of battery energy is precious. If an EV motor has high core losses, that’s energy being drained as heat instead of propelling the car further. By using high-quality, thin-gauge cold rolled motor lamination from Sino, EV manufacturers can design motors that are significantly more efficient. This translates directly to:

Magnetic permeability is a super important property for your motor’s oomph. It’s a measure of how easily a material can be magnetized, or how well it “conducts” magnetic flux. You need high permeability in your motor core.

The carefully controlled deformation and annealing processes involved in producing cold rolled motor lamination sheet significantly enhance this permeability. The refined grain structure and, in some specialized grades, preferred crystallographic orientation, make it much easier for the magnetic field to establish itself and flow through the core. At Sino, we don’t just take any cold rolled motor lamination coil; we select materials and process them in ways that optimize this crucial characteristic.

The work hardening that occurs during the cold rolling process naturally increases the steel’s yield strength and hardness. This is a good thing, as it makes the individual cold rolled motor lamination sheet more resistant to deformation. However, there’s a balance to be struck. If it’s too hard, it becomes difficult to punch or stamp cleanly, leading to increased tool wear and potentially poor-quality laminations with excessive burrs.

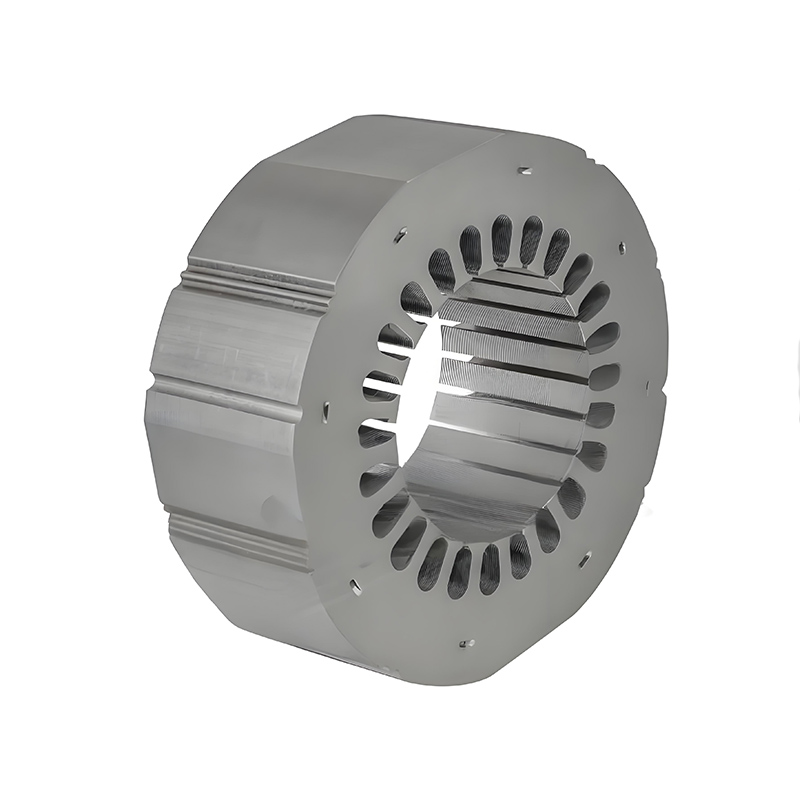

Sino’s manufacturing skill is based on the latest methods that turn raw steel coils into very precise motor laminations. Our complete process ensures the best material qualities and lamination standards.

It starts with careful processing of the steel coil, followed by advanced heating techniques that are very important for getting the magnetic qualities we want.

Annealing Technologies

Microstructural Control

Our heating processes are carefully controlled to improve the material’s internal structure. Continuous annealing at 850–900°C for 2–3 minutes creates a mix of grain sizes (average 30–50 μm), balancing eddy current loss and permeability. We also stop hard particles (Fe3C, MnS) from forming at grain boundaries. This leads to better stress relief and lower magnetostriction, which directly cuts down on noise in high-speed motors.

Sino’s stamping work is designed for the highest accuracy, especially for thin-gauge (<0.2mm) electrical steel, which has its own difficulties.

Reducing Stamping Problems

Process Control and Tooling Improvements

Applying high-quality insulation coatings is very important for cutting down on eddy currents between layers and ensuring the motor can handle heat. We use coatings that fit specific needs, from standard C-5/C-6 to advanced high-temperature inorganic silicate or polyimide-based coatings that can handle up to 250°C.

Our manufacturing processes consider the important heat-control needs of motor laminations:

Sino is committed to eco-friendly manufacturing. We know that getting raw materials and making steel cause most of the GHG emissions (70–80% of the total). Our processes work to lessen our environmental impact:

The applications for Sino's high-quality cold rolled motor lamination products are as diverse as the modern world itself:

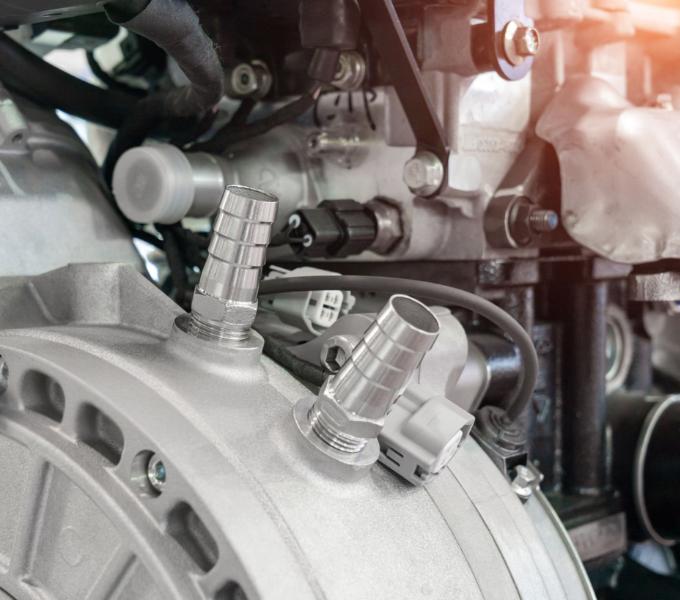

From main traction motors in EVs and hybrids to countless auxiliary motors for power steering, HVAC blowers, window lifts, and seat adjusters.

Generators in wind turbines, where maximizing energy conversion is paramount.

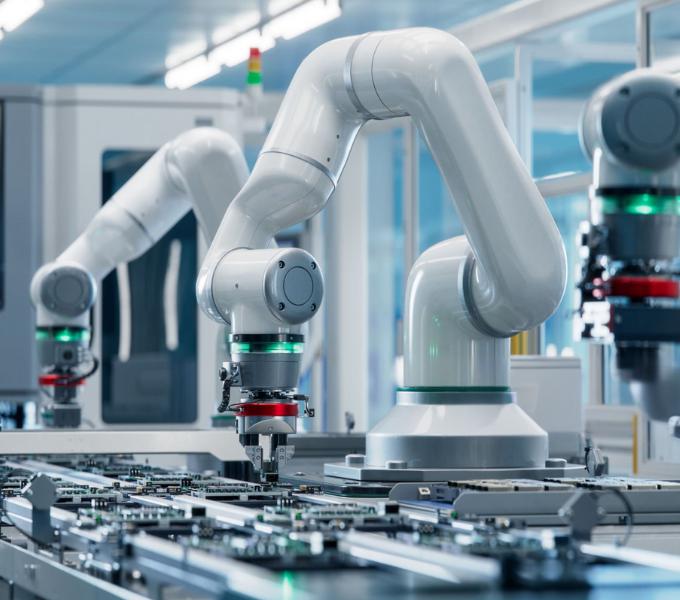

Servo motors, stepper motors, and general-purpose induction motors driving conveyor belts, robotic arms, machine tools, and pumps.

Specialized motors requiring high power density and extreme reliability in demanding environments.

Motors for washing machines, dryers, refrigerators, air conditioners, vacuum cleaners, and kitchen gadgets, where efficiency and quiet operation are key.

Motors for surgical tools, diagnostic equipment, and patient mobility aids, where precision and dependability are life-critical.

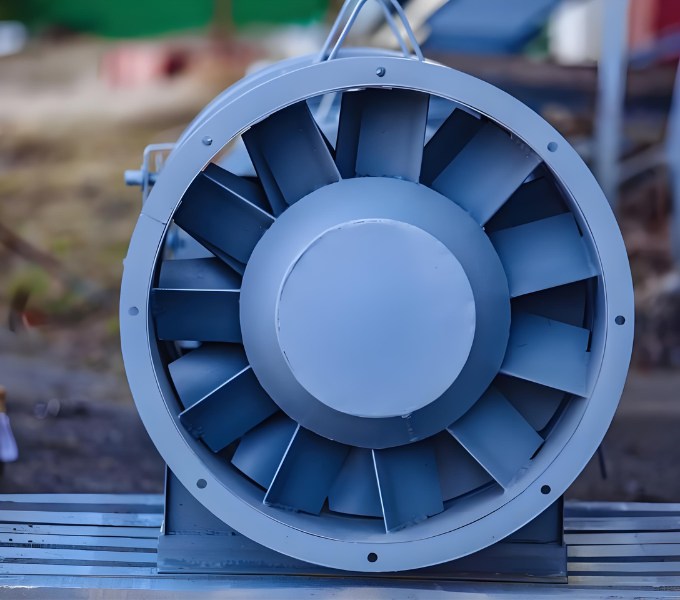

Fan and blower motors that need to run efficiently and reliably for years.

At Sino, we’re not just keeping pace; we’re anticipating these changes. We continuously invest in our processes, explore advancements in electrical steel and insulation technologies, and work closely with our clients to understand their future needs. Whether it’s ultra-thin laminations from the latest cold rolled motor lamination coil for ultra-high-speed motors or specialized geometries for axial flux machines, Sino is committed to being at the forefront of lamination technology.

Don’t let subpar laminations be the weak link in your design. Experience the Sino difference. Let’s build the future of motion, together.

Note: To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.

To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.