Let Sino's Lamination Stacks Empower Your Project!

To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.

When you make transformer windings, what is the best material to use? Picking between copper windings and aluminum windings is a very big deal. It changes the transformer’s size, how well it works, and how much it costs. If you pick the wrong one, you can have problems later. These problems could be high bills or things that need fixing.

In this article, I am going to show you what is really going on. We will look at the real difference between copper and aluminum. I will share what I know about the good and bad sides of each one. We will look at how your choice changes how your transformer works and what you pay for it. When we are done, you will know which material is the right one for what you need to do.

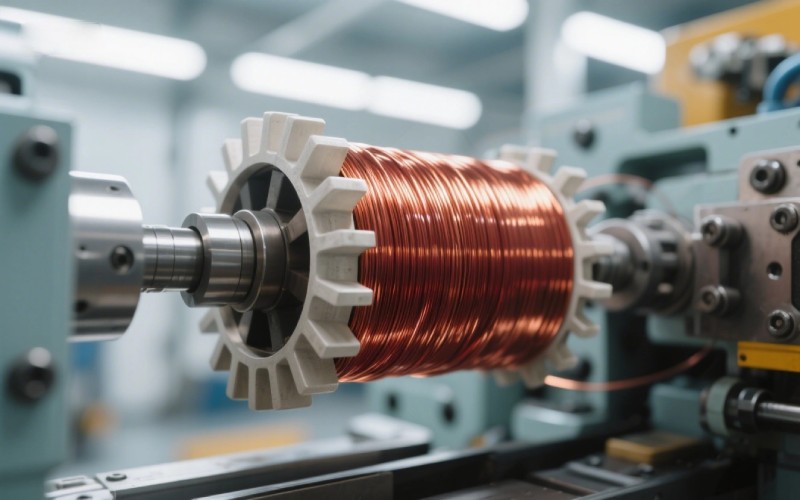

I have been around a lot of electrical things, and I know the transformer is like the heart of a power system. And the windings? They are like the tubes that carry the blood. These coils are usually made of copper or aluminum. They move electrical power from one place to another. Choosing the right material for these transformer windings is a very big choice.

The first winding, called the primary, takes power from a source. The second winding sends that power out. The material you use to wind these coils changes how well the transformer works. It also changes its size, how heavy it is, and, of course, the final cost. It is like picking an engine for a car. Two different engines can make the car go, but they change how fast it is, how much gas it uses, and how much it costs. The same is true when you pick if aluminum or copper is right for your transformer.

For a very long time, copper was the top choice for transformer windings. In fact, the very first transformers were all made with copper windings. There are some very good reasons for this. The most important reason is that copper is great at letting electricity pass through it. It has very high electrical conductivity. This means that electrical power can move through it very easily.

Because it is such a good conductor, a copper transformer can be smaller than an aluminum one that does the same job. When you do not have much room, this is a very big help. Copper is also very strong and can be pulled into a thin copper wire without breaking. This quality makes it easier for a factory to wind the coil. It also makes a stronger coil that can handle being shaken better than an aluminum coil.

Copper has been used for a long time, but aluminum is now very popular. There are two good reasons for this: price and weight. In my work, the first price is often a very big deal for any job. Aluminum costs a lot less than copper. The pricing for copper can change a lot, which makes it hard to guess the cost of a job. Aluminum pricing usually stays more steady.

The other big plus for aluminum is how much it weighs. If you take the same amount of aluminum and copper, the aluminum is much lighter. This can be a big help in large transformers, where you use a lot of material. A lighter transformer is often easier and cheaper to move and set up. This makes aluminum-wound transformers a great pick for jobs where cost and weight are the most important things.

One of the first things you will see is that a copper transformer and an aluminum transformer are different sizes. Copper has a higher electrical conductivity, so you do not need as much of it to carry the same amount of electrical power. This means copper wire sizes can be smaller than aluminum wire sizes for the same job. The result is a smaller coil, which means you can have a smaller transformer.

An aluminum transformer needs its wires to be thicker to work as well as copper. This makes the coil bigger. A bigger coil needs a bigger core and a bigger box to hold it all. Even though aluminum is lighter, the need for a larger transformer can sometimes cancel out the weight savings. When you have very little space, a smaller copper transformer is usually the perfect choice.

I have worked with many copper and aluminum transformers. Each one is good at some things and not as good at others. It is important to know these good and bad points before you choose. For copper, the good points are very clear.

Good Points of Copper Windings:

But copper has bad points, too. The high cost of copper is a big one. Its price can change a lot, which makes it hard to plan a budget. Also, while rust on copper is not as big a problem as it is with aluminum, if it starts, it can spread all the way through the metal.

| Part | Copper |

|---|---|

| Conductivity | High |

| Size | Smaller |

| Cost | Higher, Changes a lot |

| Strength | High |

Now, let’s look at aluminum. I have seen many more people using aluminum-wound transformers, especially in the last few years. The number one reason for this is the cost.

Good Points of Aluminum Windings:

The biggest problem with aluminum is its lower conductivity. This means you need bigger wire sizes, and that makes the transformer bigger. Also, electrical connections with aluminum need more attention. Aluminum gets bigger when it is hot. This can make connections get loose over time if they are not put in the right way. The chance of a loose connection was a big worry in the past. It sometimes led to problems like a fire.

| Part | Aluminum |

|---|---|

| Conductivity | Lower |

| Size | Larger |

| Cost | Lower, Steady |

| Strength | Lower |

When you get right down to it, can an aluminum transformer work as well as a copper one? Many times, the answer is yes. A well-made aluminum transformer can work just as well and last just as long as a copper transformer. The important part is how it is made. The factory just uses a thicker aluminum wire to make up for it not being as good a conductor.

But, there are times when copper is a much better choice. In places with certain kinds of electrical problems called harmonics, the bigger wires of an aluminum winding can cause more energy to be lost. Copper also works better when the electrical load is too high because it is better at handling heat. So, both materials can do the job. But copper is often better for jobs that are harder. How well the transformer works is very important to think about.

One thing people always talk about in the aluminum vs. copper question is rust, or oxidation. Both metals react with the air, but they do it in different ways. When aluminum touches the air, it quickly makes a hard layer of aluminum oxide on the outside. This oxide layer does not let electricity pass through it. This can make it hard to get a good, strong electrical connection.

To fix this, you have to use special methods and parts. These make sure the connection is sealed from the air and can break through the oxide layer. Copper, on the other hand, makes a soft oxide that does let electricity pass through. This makes it much easier to get a solid electrical connection with copper. The rust problem is one of the main reasons that aluminum connections need to be put in more carefully and might need more checking over time.

A transformer is not something that just sits still. It can shake, and it gets bigger when hot and smaller when cold. Sometimes, it can face a lot of force from a short circuit. Copper is a stronger material. It is less likely to slowly change shape over time when under stress. This makes a copper winding tougher. It is less likely to break because of these physical problems.

Aluminum is a softer material. It also gets bigger than copper when it gets hot. This growing and shrinking can put stress on the electrical connections and the coil. Today, new ways of making aluminum-wound transformers have made them much more reliable. But copper is still stronger and lasts longer, especially when conditions are tough. This can mean a copper transformer will have a longer life.

After looking at all of this, the choice of whether aluminum or copper is right for you really comes down to what you need and what is most important to you. There is not one single material that is “best” for every job. I have seen both kinds of transformers work well for many years when they are picked and set up in the right way.

You should think about a copper transformer for your job if:

On the other hand, an aluminum transformer could be the perfect choice if:

To sum it up, the question of copper versus aluminum transformer windings is not about which material is better all the time. It is about which one is better for a specific job. The final choice is a mix of cost, size, weight, and how well it needs to work.