Let Sino's Lamination Stacks Empower Your Project!

To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.

If you have an electric motor , this is for you. If you repair electric motors, this is for you as well. Core loss testing assists to see to it that your motor functions well. Reviewing this will help you discover. You will certainly find out why motor core loss testing is a big deal for your motor repair work jobs. It is also vital for the motor core . It assists your motor last long. It helps it run better.

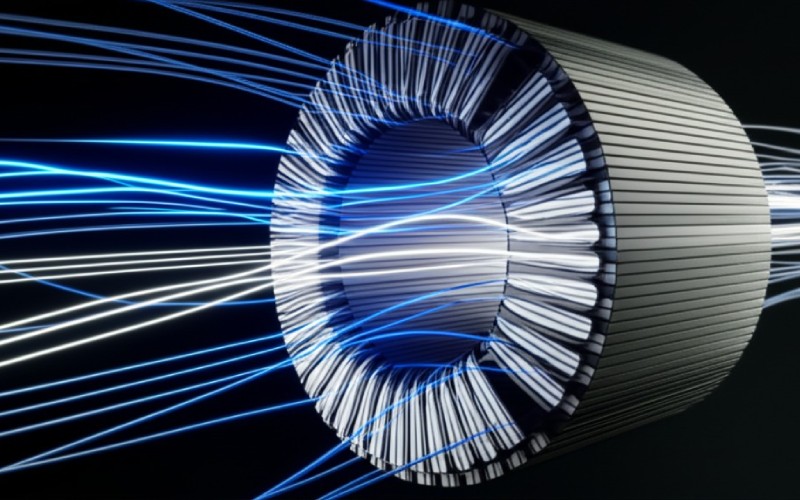

So, what is core loss testing? It resembles a medical examination. It inspects an inside component of your electric motor . This part is the stator core . The stator core is constructed from lots of slim steel plates . These are called lamination sheets. Makers laminate these sheets with treatment. The sheets need to insulate from each other. This means they need to not pass current conveniently between them. This helps the motor work right. When your motor runs, a strong pull, like a magnet, is made in this stator core . This is a magnetic pull. Core loss testing helps us see if this magnetic part is great. The test sends out a current with an unique cord. This wire is wrapped around the stator core . The rotor is removed from the motor first. We see just how much power the stator core utilizes. If it utilizes too much, there are issues. These troubles are core losses . Good core loss testing finds these problems. It finds them before they make a large problem for the motor. This testing is a diagnostic procedure that is extremely crucial.

You might ask, “Why are core losses a large problem for my electrical motor ?” Well, core losses are wasted power. The motor core is part of the stator core . When this component has damages, it makes more massaging, like friction . It likewise makes even more warmth. This heat is bad for your motor . It implies your motor functions more difficult than it requires to. This waste of power indicates you pay more for electrical energy. The additional warmth can additionally get too hot the cords in the motor . These are the motor windings. Warmth harms the covering on these cords, called insulation . This can bring about insulation breakdown. This can make the motor not last as long. It can shorten its life. So, high core losses suggest the motor is not working well. This is inefficient . It can make your motor quit working too soon. This also means considerable power losses . That is why looking for them with core loss testing is wise. It helps the motor to have good dependability .

Before we even think about rewinding a motor , we do this test. Why? The stator core resembles the base of a home. If the base misbehaves, a new residence on it will not be excellent. The stator core is the foundation of your motor ! If we place new cords in a motor with a bad stator core , the motor will not last. If core loss testing reveals high losses, we know the stator core needs help. Possibly the lamination sheets are stuck. This can take place if the motor had a burnout . An exhaustion is when a motor gets too warm and stops. The burnout process can harm the insulation between the slim metal plates. If they are not shielded, current can flow where it ought to not. Finding this very early with core testing stops much of the problem. It means the motor repair service will be great. The motor will certainly run well. This loss testing is a diagnostic device. It tells us just how healthy the motor stator core is. We can see if there are hot spots. Hot spots are small locations that get too hot. These can trigger the motor to fall short early after the motor repair service . For me, core loss testing is generally a need when rewinding a motor . It seems to me that rewind is a great concept.

Yes, it sure can! Dependability suggests your motor keeps functioning. It does not break down. No one desires a motor that quits usually. It helps most when done throughout a motor repair service . Or when you rewind a motor . It makes the motor have far better dependability . When we discover core losses early, we quit the motor from getting too warm. Heat is a large adversary of any kind of electric motor . Warmth harms the insulation . It can make the motor fall short fast. By using core loss testing, we make certain the stator core is good. This indicates less warmth. It means much less hard work, or stress and anxiety , for the motor parts. So, the motor lasts longer. A motor with a great core runs well. It uses power well. This means fewer unexpected shutdowns. That is what dependability is for your motor . The core testing helps us to understand just how good the performance of the stator core is. If the core losses under different running problems are reduced, the motor will certainly live longer. This is excellent durability . This kind of testing is a diagnostic treatment . It directly helps the effectiveness and integrity of the motor .

Missing core loss testing before a rewind ? I assume that is throwing down the gauntlet. People wish to conserve time or cash. Yet it frequently costs more later. If you rewind a motor with a negative stator core , you will likely have troubles. The motor may get too hot quickly. Its motor efficiency will be bad. This means it will certainly utilize a lot more electrical power . It will use more power to do the same job. The brand-new motor winding you just paid for can fall short much sooner. This is because the bad core makes added heat. It likewise causes magnetic issues. This leads to power waste in rewound electric motors . You may also have a burnout again. And it can happen quicker than you believe. So, that skipped examination can result in an additional expensive motor fixing . Or you could require a new electric motor . The stator core makes the electromagnetic field . If this core has negative areas, like stuck lamination sheets, the magnetic flux (the flow of magnetic power) will be incorrect. This injures the power output . It additionally influences the operating temperature of the motor. We want to rewound electric motors to keep their efficiency and performance .

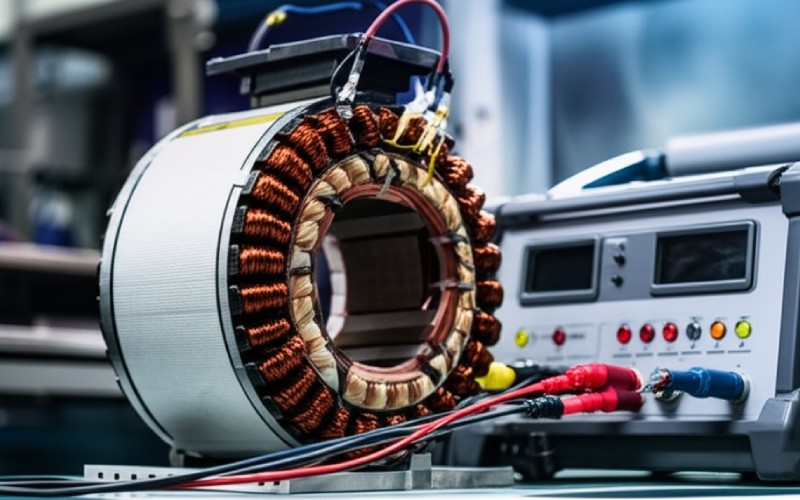

Some individuals assume core loss testing is really difficult. Yet it is not so negative. Devices like the AR-100 make it simpler. The main idea is simple. We take the rotor out of the motor . The rotor is the component that spins. After that, we wrap a test cable around the motor stator . The stator is the component that stays still. This cable makes a magnetic field in the core. It is like when the motor is running. We placed a specific voltage to this test wire. Then we inspect the resulting current. We additionally examine the power loss within the motor’s core . This informs us just how much power the core is wasting. The devices often reveal this as watts per pound . This assists us contrast the core to good ones. You do require the right devices. You need to follow policies, like from IEEE 432 . However it is a regular part of a good motor job. We obtain test reports . They reveal the general test results plainly. The objective is to make an electromagnetic field . It should be like the one the motor has when it runs. We take a look at the current circulation . We check out the power losses in the stator . The back iron of the stator core is also essential. Its cross-section should allow enough. The examination helps see if the insulation in between lamination sheets still quits eddy current losses. These are undesirable currents.

So, just how can you know if your electric motor has high core losses ? Exactly how can you recognize even prior to a test? One huge indicator is if the motor runs hotter than it should. If the motor really feels too warm, that is a red flag. If its operating temperature is constantly high, that is also a sign. An additional sign is reduced motor effectiveness . Your power bills may increase. Yet the motor’s job has actually not altered. High core losses can be the reason. You may additionally see the motor can not offer its full power result . In some cases, you can also listen to a new humming sound from the motor . This can take place if the magnetic components of the core are wrong. Utilizing thermal imaging video cameras can reveal locations on the stator core . These reveal prospective concerns . They could be from circulating currents or poor insulation . These indications indicate raised power losses and inefficiency . While loss testing should be conducted to make sure, these signs tell you to take a look at the motor much more. If a motor has these signs, act. This is extremely true after burnout. Or after a rewind where core testing was missed.

A damaged stator core can make your electric motor weak. The stator core is where the magnetic field magic happens. This area makes the motor transform. It makes it function. If the core is harmed, it screws up this magnetic field. For example, the thin metal plates (the lamination sheets) may be stuck. When the electromagnetic field is weak or otherwise also, the motor can not make its full power result . It is like attempting to run with a hurt leg. The motor has to draw more current. It does this to try to offset the poor magnetic problems. This additional current results in a lot more heat. It likewise squanders electric power . So, a poor core indicates less power. It additionally makes the motor work harder and hotter. This causes energy consumption problems. Damages can happen during a burnout process . Or if the motor is struck hard. The thickness of the steel plates and the strength of the magnetic field should collaborate. Any damage here can make troubles worse. It can escalate them. This results in extra inefficiency . It places a lot more tension on the motor . The performance of the stator core is connected to the motor’s performance and power. The amount of eddy current losses is usually symmetrical to how thick the steel plates are. It is additionally connected to just how quick the magnetic area adjusts.

This is really vital for me. Motor core loss testing is linked right to much better motor effectiveness . When we speak about core losses , we indicate lost power. This power becomes warmth. It does not develop into good work. An electric motor with high core losses is like a leaky pail. You maintain placing power (electrical energy) in. However a great deal of it is shed. By doing motor core loss testing, you locate these “leakages.” This is really true when you rewind a motor . If the examination reveals the stator core is good, the motor will certainly run well. It will certainly run near its best performance and efficiency . This indicates it makes usees much less electrical power to do its job. This saves money on power expenses. A healthy and balanced motor core makes certain that the electric energy going into the motor develops into great power. The test helps us to measure watts per pound of loss. If watts per pound are too high, the motor will not be efficient utilizing power. Keeping these losses reduced is key. It is vital for good motor effectiveness . It is vital for optimal performance . It also assists with the thermal (warmth) control of the motor . Less power is squandered as heat. This is a large reason loss testing needs to be performed .

Yes, there are great ways to do motor core loss testing. These are called the finest methods . We do not “just presume”! Great shops adhere to policies like IEEE 432 . These guidelines help in making sure tests are done right. They assist in making sure the general examination results are true. One usual device is the AR-100. It is made for this type of core testing . A crucial practice is to examine the stator core . The rotor was eliminated initially. We power up the core. We make a magnetic flux (magnetic power circulation) in it. It must resemble when it runs typical. Then we inspect the power loss within the motor’s core . It is key to check the ordinary core temperature level . We likewise try to find hot spots . The location is a tiny area that is also hot. If a place gets greater than 10 ° C (Celsius) hotter than the remainder, that is an issue. This can be created within 10 minutes . Or it can happen within 20 minutes of beginning the test. These hot spots can go beyond safe warm levels fast. The stator windings are eliminated for this test. A temporary examination winding is utilized. EASA is a group that helps motor shops. They give EASA-provided information. This information informs what excellent loss degrees are (like watts per pound ). The objective is to see how much current circulation is needed. This exists to make the appropriate magnetic field . We also measure hysteresis losses and eddy current losses. These are sorts of power waste. Following these ideal practices assists the motor . It assists it to have great integrity . It assists it to have great longevity . The examination reports must show all this. It is essential to use a good conductor (wire) for the test. We also enjoy the alternating current (AC) waveform (the form of the electrical wave). We wish to know core losses under various operating problems . Not chilli one quick look.

A: Yes, the majority of the time! The devices and means may change a bit. This is true for extremely small or huge electric motors. However the main idea coincides. We inspect the stator core for core losses . This helps a lot of AC (Alternating Current) motor types. It is a vital test of long-term motor reliability .

A: For me, core loss testing is a must. It must be done for any kind of huge motor repair service . It is really crucial for a rewind . It is not a typical check like adding grease. Yet if a motor begins to get too hot , this examination can help. If it loses motor effectiveness , this test can find the problem.

A: Occasionally, yes. If hot spots are found, we might deal with the poor lamination components. This could suggest taking sheets out and putting them back. Or making use of new sheets. But if the stator core damage is too bad, the motor could not deserve fixing. That is why this core testing is so handy.