Let Sino's Lamination Stacks Empower Your Project!

To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.

Lots of folks obtain puzzled regarding cored and coreless DC motors. They choose one, and afterwards their item does not function fairly right. This post will get rid of points. We’ll check out the large difference between these 2 types of DC motors. You’ll discover what makes every one special. By the end, you’ll recognize exactly how to pick the most effective motor for your certain use. This will certainly assist you make a wise, educated choice and conserve you from frustrations later on!

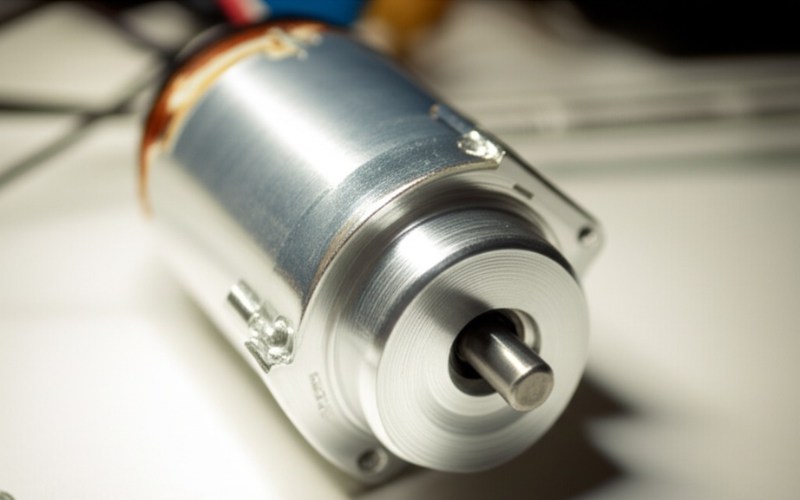

Let me inform you about the cored DC motor. It’s an extremely common type of electrical motor. You’ll find this motor in several gadgets we utilize daily. The “cored” part tells you something crucial concerning its framework. Inside this motor, there’s a rotor. The rotor is the component that rotates, often communicating with a stator that holds a permanent magnet. In a motor of this kind, this rotor has an iron core. Think about it like a little metal heart in the middle of the motor. This iron core is crucial. The wire winding, which carries the electric current, is wrapped around this main part. The visibility of this core aids to strengthen the magnetic field. This stronger area aids the motor to create more torque, or turning power. So, the core is a huge bargain for just how these DC motors work.

Currently, let’s speak about the coreless motor. As the name suggests, a coreless DC motor does not have that iron core in its rotor. Instead, the winding is made differently. It’s usually a self-supporting, hollow cylindrical tube, often appearing like a little basket. This winding then rotates around a central permanent magnet, or in some cases this magnet gets on the outside, creating the motor housing. This design makes a large difference in how the motor behaves. You might question if eliminating the main element is a great concept. Well, it provides some special benefits! Without the heavy inner component, the rotor is much lighter. This implies the coreless motor can start and stop very swiftly. It can change speed much faster than a DC motor with a core. This quick action is excellent for certain sorts of equipment and robotics where rapid movements are essential. The absence of an iron core is a large offer for this motor design.

The primary distinction between these electrical motors– having that main component or not– truly changes how they function. Think of it. The iron core in a DC motor with a core adds weight. This weight indicates the motor takes extra power and time to start spinning and to stop. It resembles attempting to spin a hefty bike wheel versus a really light one. The hefty one has more inertia. On the other hand, a motor without that main part, with its light, hollow rotor, has really reduced inertia. This is why it can respond so rapidly. This distinction in inertia affects the motor’s velocity and its capacity to make exact motions. Additionally, the iron core in a motor with an iron core can create some power loss and electrical noise. A coreless motor frequently runs smoother and with less electric interference. So, this interior structure is an essential style option that impacts virtually every facet of the motor’s operation.

A motor with a central element is often an excellent option when you need high torque at a reduced cost. That iron core truly assists boost the transforming power without making the motor as well pricey. These motors are workhorses. Many common uses require these electric motors. Think about power devices, automobile home windows, or perhaps some larger toys. If your item needs to be strong and you’re viewing your spending plan, a cored motor is frequently a very ideal option. They are additionally fairly durable and can take care of harder problems. When the project does not need super-fast begins and stops, however does need excellent, steady power, these DC motors shine.

It’s easy to find out about the advantages of a motor without a main component– like its fast rate and high efficiency– and believe it’s constantly the champion. However no, this kind is not the ideal suitable for every single use-case. While they offer wonderful performance in some areas, there are times when another motor might be much better. For example, they can occasionally be extra fragile than a cored motor as a result of their structure. The cost can also be an element. Usually, these specialized DC motors are more costly to make. So, if your item is really cost-sensitive and doesn’t absolutely need the unique features of such a layout, a cored motor could be the extra functional choice. It’s all about matching the motor’s strengths to your specific need. The most effective choice really depends on what you require the motor to do.

Let’s dive a bit deeper into that steel core in a cored DC motor. This central part plays a big function. First, it focuses the magnetic field from the winding. This indicates you get more torque for the dimension of the motor. That’s a big plus for numerous applications. This main component makes the motor strong. However, this steel core isn’t all excellent information. It has actually something called “iron losses,” even if the part isn’t constantly pure iron. These losses happen since the electromagnetic field in this iron core is continuously altering as the motor rotates. This can produce warmth and minimize the motor’s overall effectiveness. Likewise, the permanent magnet in the motor can sometimes attract this component, causing a “cogging” sensation, specifically at reduced rate. This can make smooth, accurate control a little bit harder with some cored motor designs. This is an essential distinction when you take into consideration coreless vs cored methods.

So, what’s the huge deal with a coreless DC motor? The largest one is the low inertia due to the fact that there’s no heavy steel core in the rotor. This means the motor can accelerate extremely fast and stop just as rapidly. Think of a drone attempting to stay stable or a little robotic arm needing exact, fast relocations. A motor of this kind is commonly the star in these applications. One more amazing feature of lots of styles without a core is their high effectiveness. Without any iron losses (because there’s no iron core!), even more of the electrical power supplied becomes beneficial motion. The unique winding framework likewise contributes to this. This is terrific for battery-powered gadgets where you want every bit of power to matter. They additionally often tend to run really efficiently and silently. The preferred allure of this technology is expanding.

When you’re creating a product, particularly a battery-powered one, how much energy the motor uses is a large inquiry. So, let’s compare these DC motors: cored vs coreless, on this factor. Typically, a coreless motor has a tendency to be more reliable. The primary reason is the lack of that central steel core. This implies no “iron losses,” which provide wasted energy in motors with a core. A motor with a core, that cored DC motor type, can still be designed for good efficiency, but the style without a core has an all-natural edge. The lighter rotor in a coreless motor additionally implies much less power is needed to start and stop it. Numerous applications, like medical gadgets or mobile devices, where the high performance of a coreless motor makes a real difference to battery life. Nevertheless, for some high-torque, low-speed use instances, a properly designed motor with an iron core can still provide suitable efficiency for the energy made use of.

Cash always speaks, right? The cost of the motor is typically a big consideration for any kind of job. As a general rule, cored DC motors are usually more economical to buy than coreless DC motors. The manufacturing procedure for a motor with a core is usually easier and makes use of a lot more typical materials. This makes them a prominent option for high-volume, cost-sensitive applications. When it involves lifespan, both sorts of DC motors can be really trustworthy if they are top quality and utilized appropriately. Coreless DC motors, due to the fact that they often have no brush wear issues (if they are brushless coreless) or less mechanical stress because of lower vibration, can often provide a longer operational life. Nonetheless, a tough cored DC motor can additionally last a long time, especially in much less demanding tasks. The trick is to select a top quality motor from a great supplier, despite which kind you select. The total procedure and the details used will heavily influence this.

So, we have actually covered a whole lot about DC motors with and without cores. Now for the huge inquiry: exactly how do you choose the appropriate one? The primary step is to really understand your specific requirement. What does your tool or item need to do? Are you developing a small, fast drone or a strong, low-cost toy? The solution will aid you figure out the very best path. Think about these key points: Do you need high torque for heavy loads? A motor with a core could be your best option. Do you need very rapid acceleration and accuracy, like in robotics or a medical gadget? A coreless motor is likely a much better selection. Additionally consider your spending plan and if high performance is essential for battery life. Provide out your demands, contrast them to what each kind of motor can provide from different sources, and after that make your informed choice. Do not be afraid to check out datasheets and also check a few various DC motors if you can. This cautious factor to consider will certainly assist you choose the most appropriate electric motor.