Let Sino's Lamination Stacks Empower Your Project!

To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.

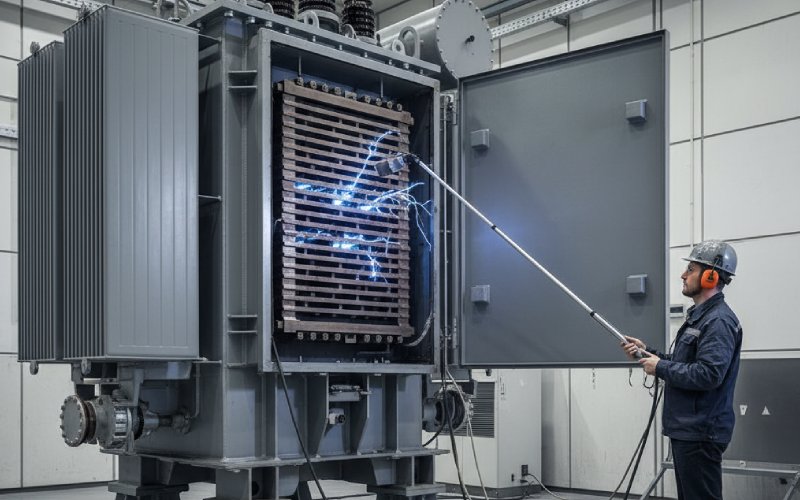

Magnetostriction in grain-oriented electrical steel is one of the main drivers of transformer core vibration and acoustic noise. That isn’t new; it’s been shown across lab studies, full-core tests, and recent reviews on transformer vibration.

A few working points, just to align language:

None of that makes noise by itself. The lamination stack does. The gaps, the clamping, the coating, the way your CRGO is cut and assembled. That’s where magnetostriction turns into a vibrating mechanical system.

From a buying perspective, “magnetostriction” can feel like one more obscure line on a steel datasheet. Yet it ties directly into cost items you actually see:

Suppliers of GO steels now explicitly position “low magnetostriction” and “noise reduction” as value points, not just academic properties.

So the question for purchasing isn’t “What is magnetostriction?” It’s: “How much magnetostriction can I afford, given my noise target and cost structure?”

That’s where a simple mental map of CRGO options helps.

Not all CRGO is equal. And not all “low noise” claims mean the same thing in a stack. Based on published low-noise patents, CRGO datasheets, and measured core tests, you can think in ranges like this:

Note: Numbers below are indicative, not guaranteed values. Always refer to the specific mill’s datasheet and test method.

| CRGO / lamination option | Typical magnetostriction level* | Indicative impact on core noise (same design) | Relative material cost | Where it usually makes sense | ||

|---|---|---|---|---|---|---|

| Standard CRGO (conventional grades) | “A few ×10⁻⁶” at ~1.7–1.9 T | Baseline; may struggle with tight low-noise specs | 1× (reference) | Rural substations, industrial sites with relaxed noise requirements | ||

| Low-magnetostriction CRGO | Target | λ | roughly in the low ×10⁻⁶ range; some products specify ≤ ~1.5×10⁻⁶ at defined B | Often ~2–4 dB(A) lower vs. standard, when stacking and clamping are controlled | ~1.1–1.2× | Urban distribution, hospitals, commercial buildings |

| Ultra-low-noise CRGO / domain-refined + tension coatings | Similar or lower | λ | but with waveform shaped to cut higher harmonics | Additional reduction, especially in higher-frequency components that human ears pick up | ~1.2–1.4× | Premium low-noise specs, high-profile urban projects |

*Rough engineering-level descriptions; different mills specify at different test points (B, f, λ definition).

Material choice alone won’t guarantee your target dB(A). But it sets the floor. If you start with a noisy steel, the best stack in the world can only do so much.

Magnetostrictive strain is microscopic. Noise in the test bay is not. The bridge between them is mechanical:

Summary: CRGO grade sets the potential. The lamination stack decides how much of that potential you actually get.

For engineers, it helps to sort all the options into a few controllable “knobs”:

You already juggle core loss and material cost when setting design induction. Magnetostriction adds another axis:

Noise-critical designs sometimes deliberately use:

Taken together, that combination can meet both loss and noise limits without heroic tank damping.

Power quality at the primary doesn’t stay perfect. DC bias and harmonic distortion in B:

From a design and grid-integration standpoint, this means:

When you evaluate CRGO offers, magnetostriction-related details to note:

These are not marketing trivia. They tell you how the steel will behave once cut, stacked, clamped.

For a lamination supplier or transformer OEM, key choices include:

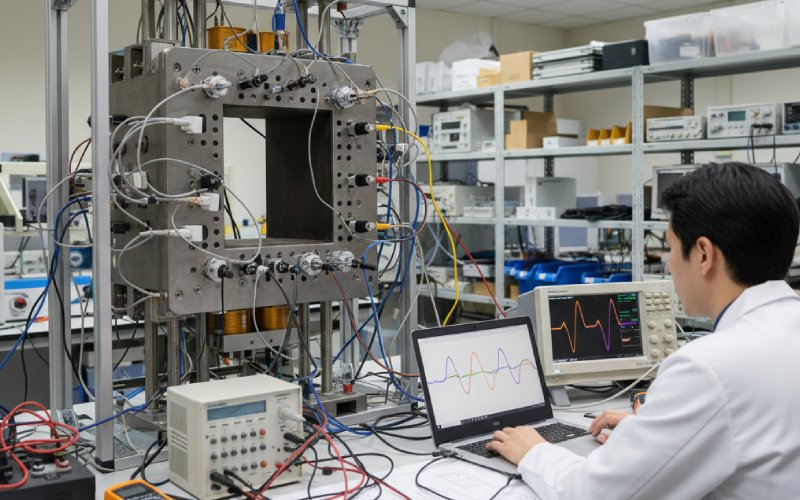

Each combination shifts how magnetostriction is transmitted to the tank and to the surrounding air. A comprehensive 2024 review shows that models which include lamination-level magnetostriction and stacking details match measured vibration and noise much better than simplified ones.

Let’s move to the practical buying side.

When you receive offers for CRGO lamination stacks or cores, a “noise-aware” reading looks at more than just core loss and price.

Questions to ask suppliers:

If the offer simply says “equivalent to Grade X” with no λ, you’re flying blind on a property that directly affects dB(A).

It helps to describe, explicitly, the lamination stack expectations:

Technical papers on bonded laminations show that the bonding method can change measured vibration by a large margin. If you don’t mention it, suppliers will optimize for cost and throughput, not necessarily for noise.

Noise disputes often come from mismatched expectations:

Since magnetostriction is very sensitive to B and waveform, you want:

You can’t change physics later with paperwork.

For purchasing and engineering teams working together, here’s a compact checklist:

If most boxes are blank or answered vaguely, you know the risk is being transferred to you.

No. You also have:

Electromagnetic forces in windings

Cooling equipment (fans, pumps)

Tank and structural resonances

That said, for many power and distribution transformers, magnetostriction in CRGO laminations is a major contributor to core noise, especially at 2f and its harmonics.

It depends on:

Starting steel

Flux density

Stack design

Tank structure

Published work and manufacturer data show combinations of low-magnetostriction steel and optimized stack design achieving several dB(A) of noise reduction compared to conventional grades in similar designs.

Think of it as: material choice sets the range, but you still need good stacking and mechanical design to capture the benefit.

Often, but not automatically.

Domain refinement (laser scribing or chemical/etching methods) is widely used to lower core loss and can also reduce magnetostriction or modify its harmonic content.

However:

If later processing introduces high residual stress

Or if coatings are damaged

Or if the stack is poorly assembled

The theoretical noise advantage can shrink or disappear. You still need a lamination process designed for low noise, not just a “good” steel.

Sometimes.

If noise is strongly core-related (and not mainly windings or cooling), re-laminating with:

Better CRGO grade

Improved stacking pattern

Tighter lamination quality control

can help. Field guides note that re-lamination is one possible remedy when core noise is excessive, though it’s labor-intensive and not always economical.

Better approach:

A simple starting clause set might look like:

Required CRGO grade(s), with magnetostriction limits or targets at a stated B and f.

Required stacking pattern (e.g. defined step-lap) and lamination tolerances.

Requirement for tension or stress-relief coating compatible with the core manufacturing process.

Statement that the lamination stack must support compliance with the specified transformer noise limit at the defined test conditions.

This doesn’t replace detailed design work, but it signals that noise and magnetostriction are not “nice to have” topics. They are part of the evaluation.

For a lamination stack supplier or transformer OEM, CRGO lamination magnetostriction is not just a materials property; it’s a contract outcome.

If you choose the right steel, specify the lamination stack properly, and align tests with reality, transformer noise becomes predictable and manageable instead of a late-stage surprise.