Let Sino's Lamination Stacks Empower Your Project!

To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.

To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.

From the structural design and material selection of DC motor cores, to the precision stamping and assembly techniques used in production, as well as the critical post-processing and quality control measures, Sino has the experience and expertise to help you achieve perfection! Come and experience the difference our lamination stacks can make to your DC motor!

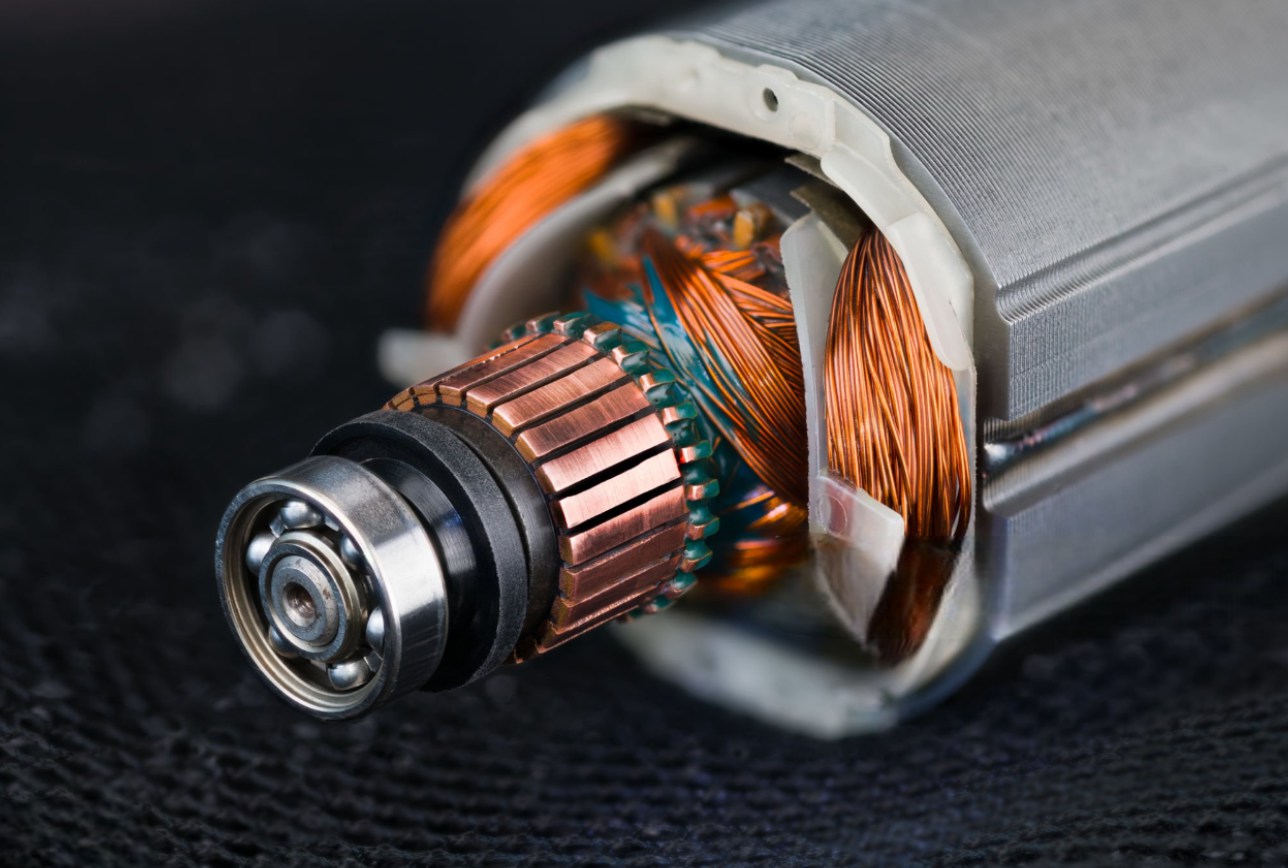

DC electric motors, from little consumer electronics to big industrial equipment and electric cars, rely basically on laminated cores for their magnetic circuits. These cores, making up slim sheets of electrical steel, are vital for guiding magnetic flux and minimizing energy losses, specifically eddy current losses, which are integral in alternating magnetic fields. Both the stationary component (stator) and the turning part (blades) of a DC electric motor use these laminated frameworks to ensure effective power conversion.

We’ve honed the art of producing DC motor lamination stacks with incredible precision.

Consistency is key. We ensure our laminations meet exacting thickness specifications, because even slight variations can impact performance.

The integrity of the insulating layer between laminations is paramount. Our coating processes are designed for durability and high dielectric strength, ensuring those eddy currents stay trapped.

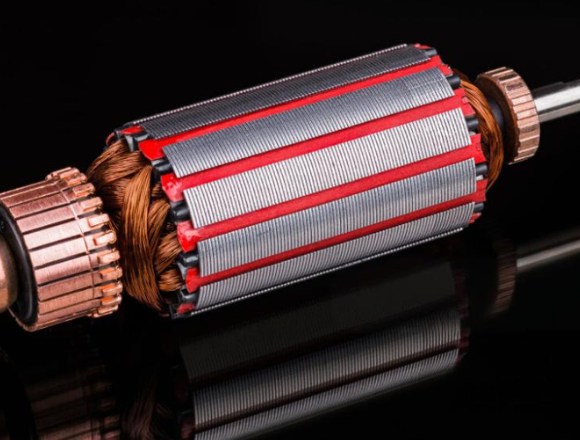

Whether your design calls for interlocking laminations or a bonded stack, our assembly techniques ensure a dense, mechanically stable dc motor core that minimizes air gaps and maximizes magnetic performance.

The material itself is a huge part of the equation. Manufacturers, including us at Sino, overwhelmingly choose silicon steel (often called electrical steel) for dc motor laminations and for very good reasons:

1

This means the steel can easily support and concentrate magnetic fields. You want the magnetic flux to flow readily through the core to do its work, not fight against the material. Silicon steel is excellent at this.

2

Iron’s magnetic domains flipping with rapidly changing fields dissipate energy as heat. Adding silicon reduces this “magnetic friction,” making steel more efficient for alternating magnetic fields.

3

While still a good conductor, silicon steel has a higher electrical resistivity compared to pure iron. This higher resistance, combined with the thinness of the laminations, further helps to suppress those eddy currents.

The efficiency of a DC electric motor lamination core is inherently linked to the residential or commercial properties of the electric steel where it is produced. At Sino, we thoroughly select products to optimize magnetic efficiency, mechanical honesty, and cost-effectiveness for varied DC electric motor applications.

For DC electric motor stator and rotor laminations, Non-Grain Oriented (NGO) electrical steels are overwhelmingly chosen over grain-oriented (GO) types. This choice stems from their isotropic magnetic buildings, which are crucial for the multi-directional change paths characteristic of DC machines. We mainly use well-established grades such as M19 (in 0.35 mm and 0.50 mm densities), M27, and M36, with silicon web content typically varying from 2.0% to 3.5%. These grades offer a balanced mix of magnetic and mechanical qualities suitable for high-volume manufacturing.

Feature | “Old School” Solid Iron Core | Sino’s Precision Laminated Core | Why It Matters for Your Motor |

Eddy Current Path | Large, unrestricted | Miniscule, highly restricted | Drastically cuts down on swirling, wasteful currents |

Eddy Current Magnitude | Rampant | Tightly Controlled & Minimized | Less magnetic “drag,” more power to the shaft |

Resultant Heat | Excessive, risk of damage | Minimal, well within design limits | Longer motor life, safer operation |

Energy Wasted | Significant | Negligible in well-designed motors | Better battery life, lower energy bills |

Motor Efficiency | Poor | Optimized for High Efficiency | More output power for your input power |

Core Loss Culprits | Dominated by Eddy Currents | Hysteresis & Minimized Eddy Currents | Balanced approach to loss reduction |

This table highlights the clear advantages. The specific improvements depend on the motor’s operating frequency, flux density, and the exact grade and thickness of Sino’s laminations chosen for the scenario.

The precision and performance of lamination marking are extremely important to producing high-grade DC motor cores. At Sino, we utilize advanced die design concepts and cutting edge machinery to guarantee exceptional dimensional accuracy, very little burr development, and high throughput.

Our assembly line predominantly utilizes progressive dies , which are the market criterion for high-speed DC electric motor lamination production. These innovative dies enable multiple operations– such as blanking, piercing, scratching, and interlocking– to be performed in a solitary press stroke. Modern designs include modular die sections for quick upkeep and reconfiguration, allowing our systems to attain rates surpassing 1,200 strokes per min (SPM) while constantly keeping tight dimensional resistances of ± 0.01 mm.

To combat the rough nature of electric steels, particularly high-silicon grades (0.35– 0.65 mm thick), we employ tungsten carbide strikes and dies. Sourced from leading vendors like Sumitomo Electric and Kennametal, carbide tooling offers superior wear resistance and side retention, extending die life by 3– 5 times contrasted to conventional device steels (e.g., D2, M2). When paired with maximized clearances, this tooling is important in decreasing burr elevation to much less than 10 µm, an essential consideration protecting against inter-lamination shorting.

Maintaining accurate die placement at high speeds is critical. We integrate high-precision ball or roller guide articles to lessen side punch-die imbalance, which is a key reason for burrs and premature wear. Some of our advanced systems include in-die sensing units for real-time surveillance of die positioning and punch penetration, making sure regular top quality throughout the production run.

To further boost tool life and reduce rubbing, we use innovative PVD and CVD layers such as TiAlN , CrN , and DLC (Diamond-Like Carbon) to our punches and dies. Current research studies verify that multilayer coverings can double device life and lower burr development by up to 30% contrasted to uncoated carbide, bring about better parts and minimized upkeep.

Our modern passes are developed to incorporate in-die interlocking attributes (e.g., V-notches, tabs). This enables the mechanical setting up of lamination heaps directly within the marking procedure, removing the requirement for outside welding or captivating in many applications. This not just simplifies setting up yet also enhances motor performance by minimizing eddy existing losses related to heat-affected areas from welding. We attain pile elevations with an advancing error of less than 0.02 mm through these specific in-die procedures.

From aerospace actuators to HVAC systems, from office equipment to hobbyist projects, wherever a DC motor needs to perform reliably and efficiently, high-quality dc motor laminations like those from Sino are playing a vital role.

Imagine you’re a contractor, and your cordless drill is your lifeline. You need it to last through a demanding workday. If that drill’s DC motor had a poorly made core, or worse, a solid one, eddy currents would rapidly drain the battery and cause the tool to overheat, potentially even failing mid-job.

Sino’s Impact: Our precision dc motor laminations ensure the motor in that drill operates with peak efficiency. This translates to longer battery life per charge, cooler operation even under load, and a more reliable tool that won’t let you down. We help keep professionals productive.

Your car is packed with small DC motors – for power windows, seat adjustments, windshield wipers, HVAC blowers, and even in some hybrid/EV auxiliary systems. Each one needs to be efficient and reliable. A sluggish window motor or a noisy seat adjuster is an annoyance; a failed critical component is a bigger problem.

Sino’s Impact: By providing high-quality dc motor core components, Sino contributes to the smooth, quiet, and dependable operation of these automotive features. Lower energy draw from our efficient laminations also puts less strain on the vehicle’s electrical system.

Think about a modern factory floor: robotic arms assembling products, conveyor belts whisking components along, automated guided vehicles (AGVs) navigating warehouses. These systems rely on countless DC motors working in perfect synchrony, often 24/7. Inefficiency here means massively inflated energy bills and increased risk of downtime due to motor overheating or premature failure.

Sino’s Impact: For industrial automation, reliability and energy efficiency are non-negotiable. Sino’s robust dc motor laminations form the core of motors designed for longevity and continuous, efficient operation. We help industries cut operational costs and maintain productivity.

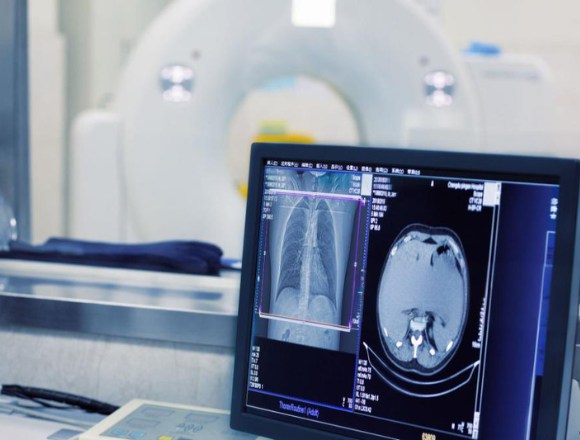

In the medical field, there’s no room for error. DC motors are found in a variety of critical devices, from infusion pumps delivering precise doses of medication to surgical tools and diagnostic equipment. These motors must be exceptionally reliable, generate minimal heat (to avoid discomfort or affecting sensitive samples), and be highly efficient, especially if battery-operated.

Sino’s Impact: We understand the stringent requirements of the medical device industry. Our dc motor laminations are manufactured to the tightest tolerances, ensuring the motors they go into perform flawlessly and safely.

The insulating layer is critical. Sino employs advanced coating technologies and rigorous quality checks to ensure a robust, uniform, and high-dielectric strength insulation on every lamination, effectively corralling those eddy currents.

Off-the-shelf isn’t always the answer. Many applications demand custom dc motor lamination profiles, specific stack heights, or unique interlocking features. Sino has the engineering capability and manufacturing flexibility to produce custom lamination stacks tailored to your exact specifications. Bring us your challenges!

From raw material inspection to final stack dimensional checks and electrical testing, quality assurance is embedded in every step of our process. We ensure that every dc motor core component leaving our facility meets or exceeds your expectations.

Once private laminations are precisely stamped, their assembly into total stator and blades cores is an essential action that significantly influences the final motor’s efficiency and mechanical integrity. Sino employs a varied variety of innovative setting up methods, each picked based on the particular application needs, wanted efficiency qualities, and production quantity.

Interlocking/Keying (Self-Locking Tabs)

Interlocking, likewise called keying or self-locking tabs, is an extensively adopted technique in our facilities, especially for tiny to tool DC electric motors. This technique entails marking tabs or keys directly into the lamination sheets, which are after that curved or pushed to mechanically lock the stack with each other.

Welding (Laser, TIG, MIG, Resistance Spot)

Welding is utilized to fuse lamination stacks, usually at the perimeter or at certain factors. Laser welding (e.g., using equipment from Trumpf, IPG Photonics) is significantly preferred for its precision and minimal heat-affected areas, making it suitable for high-performance applications. Resistance place welding is also common, particularly in auto DC electric motor production.

Riveting

Riveting includes inserting metal pins or tubes via pre-punched openings in the lamination pile, which are after that warped to hold the pile together. This technique is frequently used for larger DC makers and traction electric motors.

Adhesive Bonding (Epoxy, Phenolic, Polyimide)

Sticky bonding includes using a slim layer of high-temperature-resistant adhesive in between laminations, adhered to by curing under stress. This method is acquiring traction in high-efficiency and noise-sensitive applications, such as e-mobility and aerospace.

Shrink-Fitting

Shrink-fitting is a specialized method where the external ring or housing is warmed, the lamination stack is inserted, and then permitted to cool down and agreement, securing the stack. This is used in highly specialized high-speed rotors (e.g., turbo-machinery, some aerospace DC electric motors).

Cleating (Edge Clamping)

Cleating uses metal strips or cables kinky around the perimeter of the stack to hold laminations with each other. This is an easier, lower-cost approach.

Choosing Sino for your dc motor laminations and dc motor core requirements means choosing a partner dedicated to:

Slash those energy losses and get more work done with less power.

Cooler running motors last longer and require less maintenance.

Precision manufacturing you can count on, stack after stack.

Leverage our knowledge to optimize your motor designs.

We see ourselves as more than just a supplier. We aim to be your partner in motor optimization. Our technical team is ready to collaborate with your designers, offering insights and solutions to help you achieve the best possible performance from your DC motors.

Don’t let suboptimal core components hold your DC motors back. Let Sino provide the high-performance heart they deserve.

Note: To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.

To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.