Let Sino's Lamination Stacks Empower Your Project!

To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.

A DC motor that isn’t taken care of is a motor just waiting to cause large troubles. We’re speaking about abrupt motor failure, which suggests your job stops. This costs a great deal of cash in downtime and for a new motor or repair work. This article is everything about just how you can quit these issues before they start. These tips will help maintain your DC electric motors running fresh. You’ll discover simple steps for preventative maintenance. These essential maintenance jobs will prolong the life of your motor. They will certainly save you from lots of frustrations and assist you plan your maintenance schedule. Trust me, spending a little time on appropriate maintenance currently conserves a great deal of time and money later on. This is vital for all your tools.

A DC motor is a sort of motor that makes use of direct current (DC) power. You see these electric motors in several locations, from tiny devices to huge industrial equipment. They are great because you can control their speed conveniently. However, like any kind of tireless equipment, a DC motor has parts that can wear. Key elements like brushes and bearings require it to operate well.

So, why trouble with maintenance? Well, think about it like this: if you do not change the oil in your automobile, the engine will damage. It coincides with a DC motor. Regular maintenance aids the motor to run well for a long time. It quits small troubles from becoming large, pricey ones. Good preventive maintenance can truly extend your motor’s life-span and protect against unforeseen quits. This means your motor works when you need it.

Normal evaluation resembles a health check for your DC motor. It’s a core component of any kind of great preventative maintenance strategy. By looking and paying attention, you can find small signs of trouble before they lead to a major motor failure. “An ounce of avoidance deserves a pound of remedy,” is so true for a motor. A routine evaluation does not take long, but it can conserve you from a significant failure.

When you check your motor, you search for any wear and tear. You check for loosened parts or strange smells. Is the motor making any type of brand-new sounds? Catching these points early implies you can repair them quickly. This quits them from triggering a large motor issue later. A basic check can be the distinction between a tiny fix and an overall motor replacement. Make evaluation a regular part of your maintenance schedule.

The brushes and commutator are super vital parts of a DC motor. The brushes carry power to the spinning part of the motor, which is called the armature. The commutator aids this power to the ideal areas in the motor winding. These parts strive and can be used down. If you do not give them attention, your motor will certainly have problems. Not enough interest below causes inadequate motor performance.

You usually need to check the brushes. Are they worn down and also short? This is called brush wear. If they are, they need to be replaced. Also, examine the brush spring tension to make certain they press on the commutator just right. The commutator surface area itself needs to be tidy and smooth. If it’s unclean or resembles it may grind, it needs to be cleaned or repaired. Uneven wear of the commutator or too much carbon dust means difficulty for your motor. Good maintenance right here keeps your DC motor happy.

Allow’s speak about the motor bearing. Every DC motor has bearings. They help the motor shaft spin efficiently. Without good lubrication, these bearings will certainly wear quickly. This can create the motor to get too hot, make a lot of sound, or even seize up completely. That means a large motor failure.

Proper lubrication is key. But how much lubrication is needed? Insufficient lubrication misbehaves, but excessive lubrication can also trigger troubles for the motor. It can get involved in places it should not. Constantly adhere to the motor manufacturer’s guide for what sort of lubrication to use and exactly how usually. Inadequate lubrication is a typical reason for bearing failure. Dealing with the bearing with the appropriate lubrication will certainly make your motor last much longer.

A clean motor is a delighted motor. Dirt and debris are enemies of your DC motor. If way too much dirt builds up on the motor housing or within, it imitates a blanket. This blanket traps warmth. When a motor can not cool itself, it will get too hot. Overheating is really bad for the motor. It can harm the motor winding and insulation.

So, how do you keep your DC motor clean? You can use a vacuum to suck up loosened dirt. Sometimes, dry compressed air can blow dust out of hard-to-reach spots and the vent openings. Ensure the motor’s vent areas are not obstructed. These enable air to stream and aid the motor to stay awesome. A normal clean aid keeps the best operating temperature and protects against a damaging build-up of dirt.

Watching exactly how your motor is functioning is a clever action. This is called track motor performance. You can jot down points like just how much power the motor makes use of or its temperature level. Maintain a log of these readings gradually. This creates a service history for the motor. This sort of predictive maintenance is very cost-efficient.

When you have this log, you can look for a trend. Is the motor utilizing even more power than prior to? Is it running hotter? These adjustments can be a very early caution, an abnormality that something is beginning to go wrong. By finding a fad, you can prepare maintenance before the motor falls short. This preparation and scheduling helps you take care of the motor when it’s best for you, not when it instantly breaks.

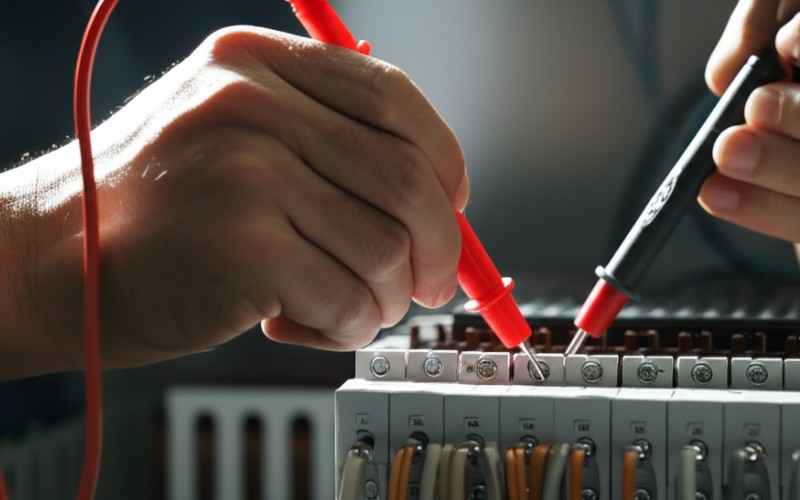

Your DC motor runs on power, so electrical checks are a large part of dc motor maintenance. You want to make sure all the electrical connections are tight and not loosened. Loose connections can fume and create the motor to burn or stop working. Likewise, look for any kind of indications of deterioration on these connections.

An additional crucial check is the insulation resistance of the motor winding. The winding is the cables inside the motor. The insulation quits the electrical power from going where it shouldn’t. If the insulation is bad, the motor can short circuit. This can destroy the motor windings. You require special devices for this check, but it’s extremely vital for the health of your electric motors. It helps avoid severe electrical failure in the circuit.

A healthy DC motor must run pretty smoothly and silently. If your motor begins to shake a lot or make odd noises, that’s a sign something is incorrect. Don’t disregard these indicators! Too much vibration can be caused by an imbalance in the motor, like if a fan blade is bent or the shaft is not directly. It can also mean a bearing is failing.

Listen for any type of unusual noises. A click, a hum, or a grind can all point to different troubles. For example, a used bearing could make a roaring noise. Look for where the noise or vibration is originating from. The frequency of the vibration can likewise inform an expert what might be wrong. Attending these mechanical concerns promptly can avoid more damage to the motor.

Yes, absolutely! The environment where your DC motor has to run plays a large role in its maintenance requirements. Is the motor in an extremely warm area? Is it dusty or humid? These things can impact the length of time your motor lasts and how much care it requires. For example, a motor in an extremely dusty industrial environment will need to be cleaned more frequently.

Heats can make a motor overheat much faster. Moisture can trigger rust and corrosion on motor parts and electrical components. If your motor remains in a difficult atmosphere, you may require maintenance more often. Think of methods to shield the motor if you can, like a cover or far better airflow to keep the operating temperature level down. The right environment aids the motor to do its work without extra anxiety.

Preventative maintenance is everything about stopping issues. However occasionally, a motor still has a concern or a failure. That’s when corrective maintenance can be found in. This indicates you are fixing something that has actually gone wrong with the motor. It might be a small repair service or a bigger one. The objective is to get the motor back to working right.

When a motor shows indications of trouble, you need to repair to locate the root causes. Maybe a part needs to be changed, or a modification is needed. Corrective maintenance is essential because it stops a tiny problem from resulting in a full motor malfunction. Even with the best treatment, parts can break. Being ready to repair your devices quickly is part of great total motor treatment.