Let Sino's Lamination Stacks Empower Your Project!

To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.

One of the biggest questions we have is about the transmission. Do these futuristic cars even have one? The short answer is yes, they do. But it’s not the kind of transmission you might be used to from a gasoline-powered vehicle. In this article, we’ll explore why they are different and what the future holds for this technology. This is a must-read if you’re curious about how electric cars work and what makes them so unique.

In a car with a traditional internal combustion engine, the transmission is a crucial component. Think of it as the car’s gearbox. Its main job is to transfer power from the engine to the wheels. A combustion engine only generates efficient power within a certain range of revolutions per minute (RPM). This means the engine has a “sweet spot” where it operates best. To keep the engine in this sweet spot, whether you’re starting from a stop or cruising on the highway, you need to change gears. A manual transmission requires the driver to shift gears using a clutch pedal and a gear stick. An automatic transmission does this work for you, automatically selecting the right gear for the vehicle’s speed and the engine’s RPM.

Think of it like riding a bicycle with multiple gears. You use a low gear to start pedaling, which makes it easier to get going. As you pick up speed, you shift to higher gears to go faster without having to pedal furiously. A car’s transmission works on a similar principle, using different gear ratios to manage the engine’s power output. The transmission allows a conventional vehicle to accelerate smoothly, maintain a cruising speed, and even go in reverse. Without a transmission, a car with an internal combustion engine would be incredibly inefficient and practically undrivable.

Yes, electric cars do have transmissions, but they are much simpler than the ones found in gasoline-powered vehicles. The main difference is that most electric cars use a single-speed transmission. You might also hear it called a single-speed gear reducer, a fixed gear, or a direct drive. This is a stark contrast to the multi-speed transmissions, like a 6-speed manual or an 8-speed automatic, that are common in cars with internal combustion engines. The reason for this simplicity lies in the nature of the electric motor.

An electric motor is a very different beast from a combustion engine. An electric motor delivers power to the wheels almost instantly, providing a consistent amount of torque across a very wide RPM range. There’s no need to “rev up” the engine to get the best performance. This instant torque is what gives electric cars their famously quick and smooth acceleration. Because the electric motor is so efficient at a wide range of speeds, a complex multi-speed transmission is simply not necessary. The single-speed transmission in an EV is designed to regulate the power from the electric motor to the wheels, moving the vehicle forward or in reverse.

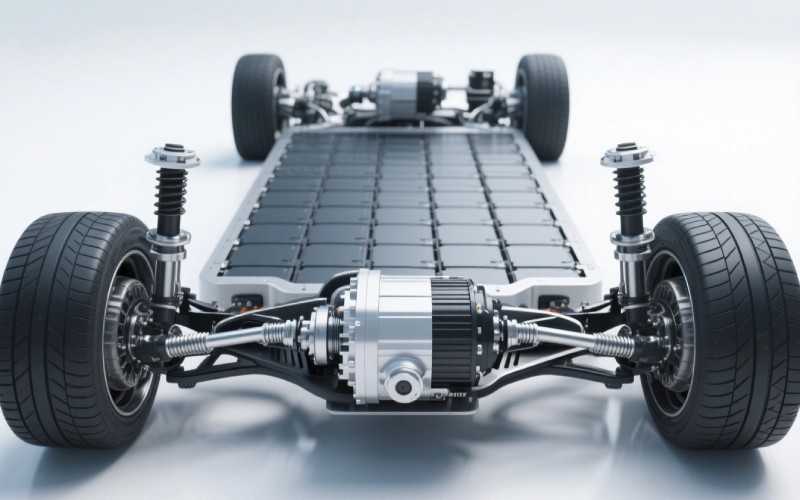

An electric vehicle transmission, or more accurately, its gearbox, is a much more compact and simpler device. It has far fewer moving parts than a traditional transmission. This simplicity is a huge advantage. It means less weight, which can help improve the vehicle’s range. It also means there are fewer things that can break, potentially leading to lower maintenance costs.

The design of an EV’s single-speed transmission is all about efficiently managing the high rotational speed of the electric motor. An electric motor can spin at incredibly high RPMs, often exceeding 10,000 or even 20,000 revolutions per minute. This is much faster than the typical 6,000 RPM redline of many internal combustion engines. The gearbox in an EV uses a single gear to reduce this high RPM to a more suitable speed for the wheels. This process also multiplies the torque from the motor, giving the car the power it needs to accelerate.

The way a single-speed transmission works in an electric car is elegantly simple. When you press the accelerator, electricity flows from the battery to the electric motor. This causes the motor to spin. The motor is connected to the single-speed gearbox, which then turns the wheels. The beauty of this system is its directness. There are no gear shifts to interrupt the flow of power, which is why the acceleration in an EV feels so seamless.

The single gear in the transmission has a fixed gear ratio that is carefully chosen by the manufacturer. This ratio provides a good balance between quick acceleration from a standstill and efficient performance at higher speeds. Think of it as being stuck in a single, very versatile gear on a bicycle. It’s a gear that’s good for starting, accelerating, and cruising. The electric motor’s wide RPM range makes this possible. It can provide the necessary power and torque without needing to switch between multiple gears.

More gears always meant better performance? But with electric cars, that’s not the case. The main reason most EVs do not have multi-speed transmissions is because they don’t need them to operate efficiently. An electric motor produces a consistent amount of torque at any given RPM within its operating range. This is fundamentally different from a combustion engine, which needs to be kept within a narrow RPM range to produce efficient power.

Adding multiple gears to an EV would introduce unnecessary complexity and weight. This would not only increase the production cost of the vehicle but could also reduce its overall efficiency and range. A multi-speed transmission would also mean more moving parts, which could lead to more potential points of failure and higher maintenance costs. The single-speed design of most EV transmissions is a perfect example of elegant engineering – it’s simple, efficient, and effective.

While most electric cars have a single-speed transmission, there are a few exceptions. Some high-performance electric vehicles, like the Porsche Taycan and the Audi e-tron GT, use a two-speed transmission. This is fascinating because it shows that engineers are always looking for ways to push the boundaries of performance. In these cars, the first gear is used for very strong acceleration from a stop. The second, higher gear is used for greater efficiency and a higher top speed when cruising on the highway.

The decision to use a multi-speed transmission in these high-performance models is all about optimizing the power output of the electric motor for specific driving situations. It allows the car to have both incredible pickup and efficient long-distance cruising ability. While this technology is currently found in a small number of luxury electric vehicles, it will be interesting to see if other manufacturers adopt similar designs in the future as they continue to improve the performance and range of their electric car offerings.

This was another question that had me scratching my head. Without a traditional transmission with a reverse gear, how does an electric car back up? The answer is surprisingly simple and another testament to the elegance of electric motor technology. To go in reverse, the electric motor simply spins in the opposite direction. There’s no need for a separate, complex reverse gear like in a car with a combustion engine.

The driver selects “Reverse” using a button or a lever, and the vehicle’s electronic controller reverses the flow of electricity to the motor. This causes the motor to rotate in the opposite direction, which in turn makes the wheels turn backward. This is a much more direct and efficient way to achieve reverse motion compared to the mechanical complexity of a conventional transmission. It’s another example of how electric vehicles are designed for simplicity and efficiency.

Many electric cars today offer all-wheel drive (AWD) for improved traction and performance. I was curious how this worked without the traditional driveshafts and transfer cases found in gasoline-powered AWD vehicles. It turns out that many all-wheel drive EVs use a very clever design. Instead of one motor, they have two electric motors – one for the front wheels and one for the rear wheels.

This dual-motor setup allows for very precise control over the power sent to each axle. Some vehicles even have different gear ratios for the front and rear motors to optimize for different driving conditions. For example, one motor might be geared for quick acceleration, while the other is geared for more efficient highway cruising. The vehicle’s computer can instantly adjust the power output to each motor to provide the best possible traction and performance in any situation. This design not only provides the benefits of all-wheel drive but also enhances the overall efficiency of the vehicle.

The world of electric vehicle technology is constantly evolving, and transmissions are no exception. While the single-speed transmission is currently the standard for most EVs, some manufacturers are experimenting with new designs to further improve efficiency and performance. We’re already seeing two-speed transmissions in some high-performance models, and it’s possible that we could see even more advanced multi-speed gearboxes in the future.

Other innovations include continuously variable transmissions (CVTs) which can provide an infinite number of gear ratios for maximum efficiency. Some companies are even looking at in-wheel motors, which would eliminate the need for a traditional transmission altogether by placing a small electric motor inside each wheel. The future of electric vehicles is likely to bring a variety of transmission technologies, each tailored to the specific needs of different types of vehicles, from small city cars to high-performance sports cars. The goal will always be to maximize efficiency, performance, and range.

The shift from the complex, multi-speed transmissions of internal combustion engines to the simple, single-speed transmissions of electric cars is more than just a change in technology. It’s changing the entire driving experience. The smooth, quiet, and instant acceleration of an EV is a direct result of its simple and efficient powertrain. There are no gear shifts to interrupt the delivery of power to the wheels, creating a more seamless and enjoyable ride.

This new technology is also making cars easier and potentially cheaper to maintain. With fewer moving parts in the transmission, there’s less that can go wrong. As battery technology continues to improve and charging infrastructure becomes more widespread, the simplicity and efficiency of the electric car’s transmission will play a key role in making electric vehicles an even more attractive option for drivers. The future of the automobile is electric, and the humble transmission is playing a big part in that revolution.