Let Sino's Lamination Stacks Empower Your Project!

To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.

To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.

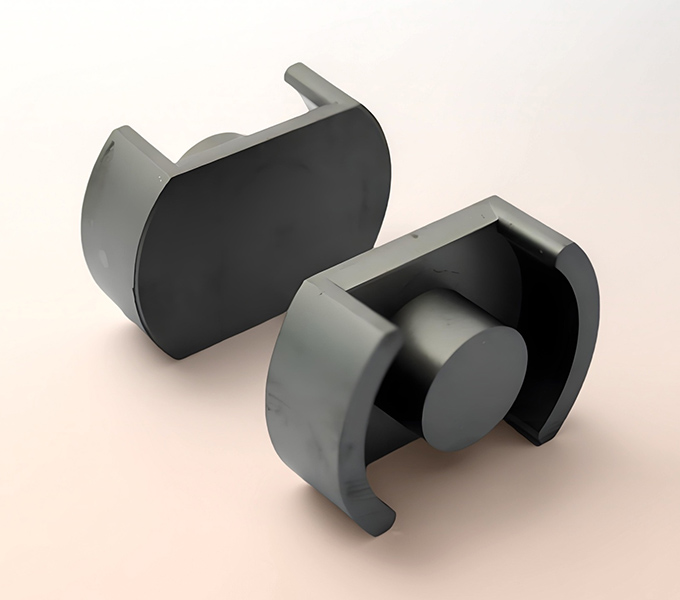

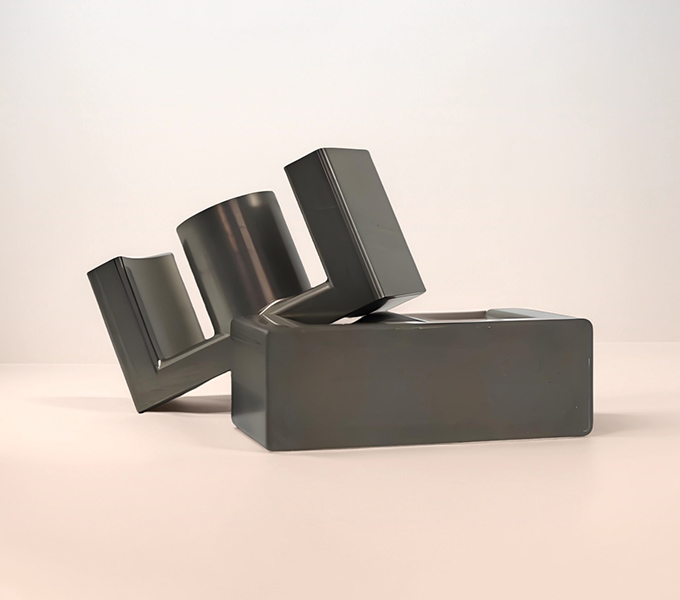

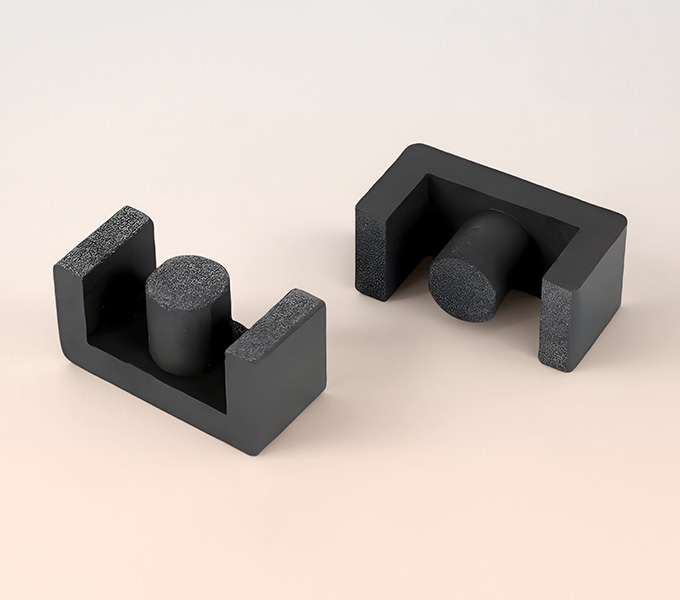

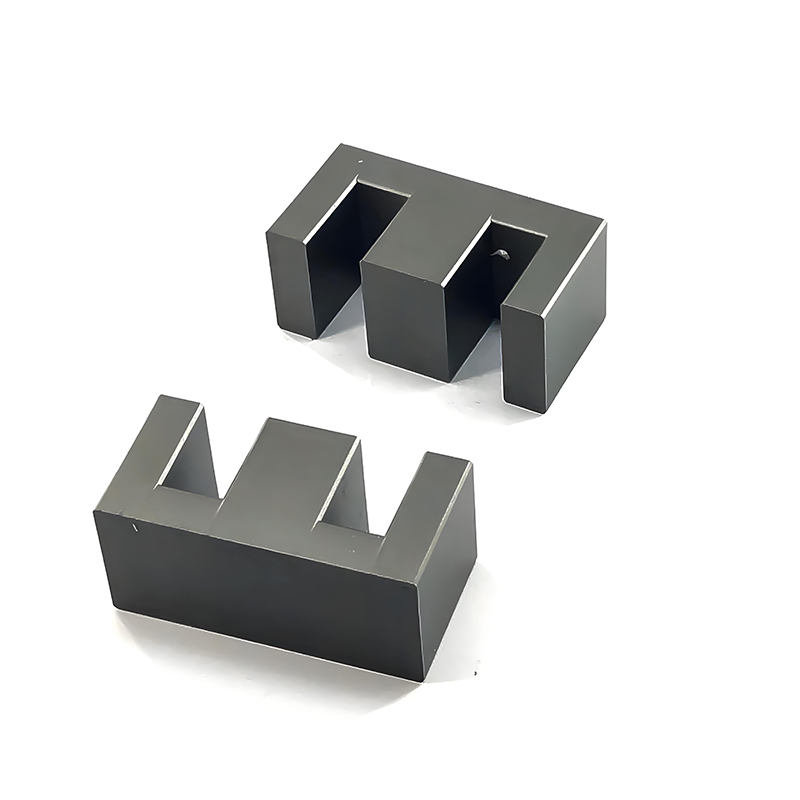

As Sino, a top Chinese maker of high-quality transformer laminations, we are proud to show you everything we can do to provide excellent EI core laminations to transformer makers around the world. We focus on making things very accurately, using the best materials, and doing strict quality checks. This makes sure our products are the dependable core of your magnetic parts, helping them work better and more efficiently in many different uses.

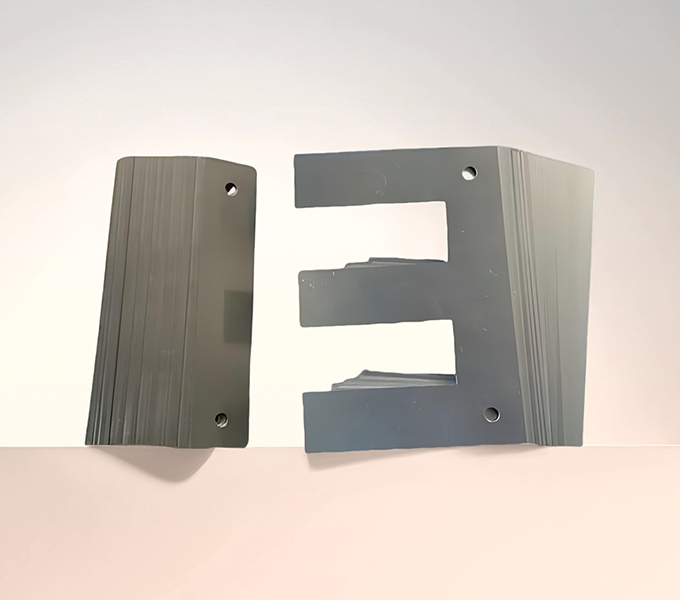

At Sino, we know that the core is the most important part of any top-quality magnetic component. EI core laminations, named for their special E and I shapes, are a key part of making magnetic circuits work well. Their main job is to reduce energy loss from eddy currents, a big problem that was found in the late 1800s as electrical machines got bigger. Solid iron cores, while good at letting magnetic fields pass through, wasted a lot of energy as heat because of these swirling currents, which greatly reduced how well they worked.

At Sino, we offer EI laminations in a variety of standard thicknesses – from 0.35mm (often designated as M36 or similar) to 0.5mm (like M47) and even thinner for specialized needs – allowing you to balance cost against efficiency requirements. We ensure that the insulating coating applied to our steel, or inherent in its mill processing, maintains its integrity even after stamping and stacking. This focus on insulation integrity is critical for an efficient ei transformer core.

Sino supplies laminations to manufacturers who build compact, efficient power supplies for phones or laptops by the millions. Our consistent quality means their automated assembly lines run smoothly, and the end products are reliable.

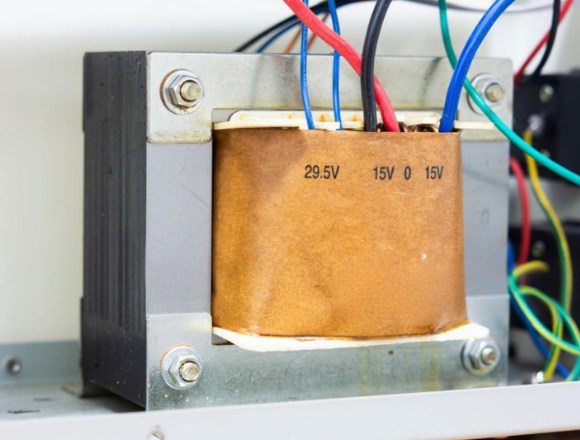

Control panels for machinery, automation systems, and industrial power supplies often rely on robust transformers and inductors built with EI core laminations. These environments can be demanding, with temperature fluctuations and electrical noise. Sino’s durable laminations, built from appropriately graded steel, ensure that these critical components keep running day in and day out.

Many excellent audio amplifiers, pre-amplifiers, and power conditioners utilize transformers with EI laminations for their power supplies or as output transformers. The consistent stacking and low-loss characteristics of Sino’s laminations help minimize hum and distortion, contributing to a better listening experience.

From traditional fluorescent ballast transformers to certain types of LED driver transformers, EI laminations have played a role. Sino has worked with lighting manufacturers to provide custom ei core lamination stacks that meet specific size and efficiency targets.

Even in the burgeoning field of renewable energy, components like grid-tie inverters or charge controllers sometimes utilize transformers or inductors based on EI core lamination designs for certain auxiliary power or filtering functions, especially where cost and reliability are key drivers. Sino is actively exploring these scenarios with innovators in the green tech space.

The heart of any EI core lamination is the electrical steel. The silicon content (typically a few percent) increases the electrical resistivity of the steel, which helps to reduce eddy current losses.

At Sino, we don’t just stamp steel; we partner with you to select the optimal grade and thickness for your specific scenario. Our technical team can discuss your operating frequency, flux density, efficiency targets, and cost constraints to recommend the most suitable material for your ei transformer core or inductor. We source our steel from reputable mills, ensuring consistent quality and adherence to international standards, which is a cornerstone of our product quality.

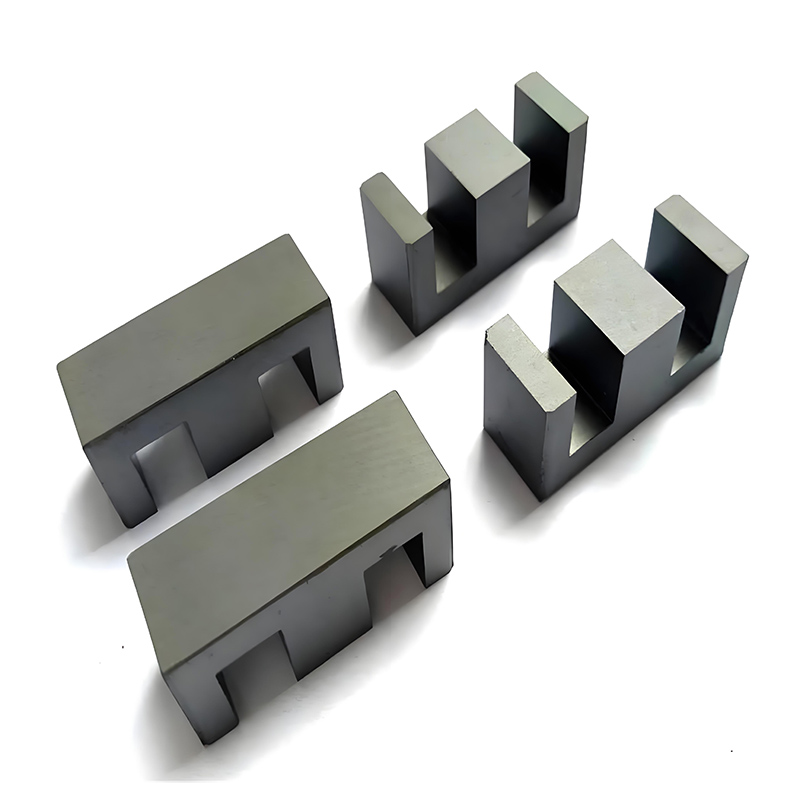

At Sino, we offer a wide variety of electrical steels. Each one is chosen and prepared to get the best magnetic performance for what you need.

Silicon steel (Fe-Si alloys, usually with 3–4% Si) is still the most common material for EI laminations because it has a great mix of magnetic properties and is a good value for the money. When Silicon steel was first used in the early 1900s, it greatly lowered both eddy current and hysteresis losses compared to plain iron. This was a big help for modern electrical engineering.

Non-Grain-Oriented (NGO) Silicon Steel: NGO Silicon Steel has tiny crystals (grains) that point in random directions. This gives it magnetic properties that are the same in all directions. This means its magnetic performance isn’t really affected by the direction of the magnetic field compared to the direction the steel was rolled.

Grain-Oriented (GO) Silicon Steel: GO Silicon Steel is known for its highly organized crystal structure (called Goss texture, {110}<001>). This gives it very different magnetic properties in different directions. This means it has much better magnetic performance along the direction it was rolled (RD).

Sino is also looking into and offering advanced materials for applications that need extremely low energy loss:

Here’s a quick rundown of common material types Sino works with, and their typical deployment:

Lamination Material Type | Key Characteristics | Typical Scenarios |

Highest permeability in the rolling direction, very low core loss. More expensive. | High-efficiency power transformers, distribution transformers, premium audio transformers. | |

Uniform magnetic properties in all directions. Good balance of cost and performance. | General purpose transformers, motors, generators, chokes, ballasts, appliance transformers. | |

Thinner Gauge Non-Oriented Steel (e.g., 0.2mm, 0.35mm) | Lower eddy current losses at higher frequencies than standard 0.5mm. | Higher frequency transformers (up to a few kHz), some SMPS applications, specialized motors. |

Extremely high permeability at low field strengths, excellent for shielding. | Very sensitive audio transformers, magnetic shielding, precision current sensors (less common for standard EI laminations but possible for custom projects). |

Choosing Sino for your EI core lamination needs means more than just getting a box of steel parts. We see ourselves as your partners in creating effective magnetic solutions.

While we stock many standard EI lamination sizes (from tiny EI-28s up to large industrial sizes), we excel at custom projects. Need a specific stack height? A unique interleaving pattern? Non-standard mounting holes? Talk to us. Our engineering team loves a challenge.

Got a technical question about material selection for your ei core lamination? Need a quote for a new project? Our sales and technical support teams are here to provide prompt, knowledgeable assistance.

Our ISO 9001 certified quality management system ensures that every batch of EI laminations leaving our factory meets stringent quality standards. From raw material inspection to final dimensional checks, we leave no stone unturned.

Thanks to our efficient manufacturing processes and strong supplier relationships, we offer competitive pricing without compromising on quality. We also understand the importance of on-time delivery to keep your production lines running.

Sino’s skill in making things comes from decades of experience, always putting money into the newest technology, and a strong dedication to quality. Our all-in-one production process makes sure that every EI core lamination has the right size and shape, good magnetic quality, and a smooth surface.

The process starts with cutting the electrical steel coils into the right widths. Our advanced cutting machines ensure the size is very accurate and we waste as little material as possible, getting the strips ready for the next step.

Our stamping machines are the key to creating the exact EI shapes:

Annealing is a key heating step that brings back the steel’s magnetic quality after it has been worked on. It also helps the tiny crystals inside the steel grow in the best way:

After annealing, the laminations are coated with a high-quality electrical insulation layer:

To stop unwanted currents between the layers (inter-laminar eddy currents) and make sure they last a long time, all our laminations are coated with high-quality insulation. We use:

Choosing the right material and coating is an important decision. Sino’s experts are here to help you weigh the costs and benefits to pick the best choice for your specific needs.

Our assembly process is mostly automated to make sure everything is consistent and high-quality:

Quality is a part of every step of our manufacturing process:

Sino’s advanced manufacturing skills and strict quality checks make sure that our EI core laminations are not just parts, but dependable foundations for your high-quality magnetic products.

In a world demanding ever-greater efficiency and reliability from electrical devices, the quality of every component matters. EI core laminations from Sino provide a robust, cost-effective, and high-performance foundation for your transformers, inductors, and motors.

We combine:

So, when your design calls for proven, dependable magnetic cores, look no further than Sino. Let us put our expertise in ei core lamination manufacturing to work for you. Reach out to our team today to discuss your project, request a sample, or get a quote. We’re ready to help you power your innovations!

Note: To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.

To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.