Let Sino's Lamination Stacks Empower Your Project!

To speed up your project, you can label Lamination Stacks with details such as tolerance, material, surface finish, whether or not oxidized insulation is required, quantity, and more.

An electric motor is commonly the heart of lots of devices. When an electric motor has issues, it can stop whatever. This article will certainly share 6 key signs of electric motor failure. Understanding these indicators can save you time and money. You’ll discover how to identify problems early. This can aid you avoid big malfunctions and pricey downtime. It deserves reading because comprehending these typical reasons electrical motors break down can aid you repair and keep things running smoothly. We’ll take a look at typical causes and exactly how to detect a cause of motor issues.

When an electric motor feels much hotter than typical, that’s a big warning sign. This is called an overheating problem. Getting too hot can seriously damage the components of the motor, particularly the insulation around the windings. If the insulation breaks down, it can bring about short circuits and full motor failure. High temperatures are a clear adversary of any kind of electric motor.

There are lots of reasons an electric motor could overheat. Maybe functioning also hard, which is called an overload. Or, the area it remains in could be too warm. Occasionally, the motor’s cooling system is obstructed or broken. Poor voltage quality can also create the motor to overheat. If you see your electric motor is also warm to touch, you are required to discover the source. You ought to enable the motor to cool down and after that troubleshoot the problem. This initial cause, if unaddressed, can trigger overheating and major damage to the motor.

It is necessary to see to it that the motor has excellent airflow. Tidy the motor on a regular basis so dust and debris don’t trap heat. An electric motor will create warmth during the procedure, yet too much heat signifies motor troubles. This problem happens when the motor is stressed, commonly by excessive load. If an electric motor remains to overheat, its life expectancy will be much shorter. This is among one of the most usual reasons for motor problems.

Listen to your electric motor. If you listen to new or strange noises like grinding, squealing, or knocking, take note! Too much vibration is an additional tell-tale indicator. If your electric motor starts shaking more than typical, something is incorrect. This vibration can be a sign of imbalance or an imbalance in the rotor.

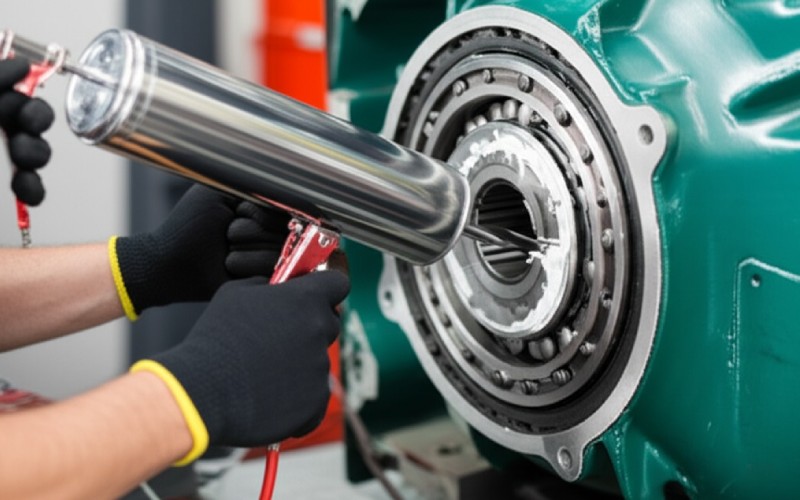

A bearing is an essential component that helps the electric motor shaft spin smoothly. If the bearing does not obtain enough lubrication, or if it’s old, it can begin to wear. This is called bearing wear. Bad bearings and other relocating parts create even more friction and heat, which vibration can harm various other motor components. Mechanical troubles like these frequently start little but can become big problems.

So, what can you do? Routinely evaluate your electric motor for any type of too much vibration or odd audios. Check for proper lubrication of the bearing. If there’s imbalance, it needs to be taken care of. Dealing with these problems early can prevent a serious motor failing and conserve you from expensive motor repair work. Capturing bearing wear early is vital.

A burning scent coming from your electric motor is an extremely poor indication. The winding is like the veins of the electric motor; it’s where the electrical energy moves to make the motor job. If the insulation fails, you can obtain brief circuits inside the motor.

This sort of damage to the motor commonly occurs due to an overheating problem or an overload. When the motor windings are too warm, the insulation breaks down. This is a serious fault. Damaged insulation can quickly lead to motor failure. You could discover the electric motor battling to run or quiting entirely. This is one of the usual causes that can trigger electrical motors to stop working permanently.

If you smell burning, turn off the electric motor right now if it’s risk-free. You need to check the insulation resistance. If the winding or insulation is harmed, the electric motor will likely need a major motor repair or even substitute. Do not overlook this smell; it’s a clear signal of prospective motor catastrophe. The current flow may be too high, creating it to get too hot.

Has your electric motor started tripping the circuit breaker a lot? Or perhaps you’ve noticed it’s pulling way too much power, which we call excessive current draw. This is a large warning. It usually suggests the electric motor is working also hard, which is an overload. An overloaded motor will attempt to attract even more current flow than it’s made for. This can trigger the motor to overheat and bring about significant motor problems.

When a motor might trip a breaker, it’s shielding itself and the circuit from damages. But it additionally tells you there’s a hidden concern. It could be an excessive load on the electric motor, or perhaps there are electrical faults in the winding or electrical connections. In some cases, a poor voltage supply can also trigger these motor issues.

You require to explore why the electric motor is experiencing an overload or attracting excessive current. Check the current draw against the motor’s specifications. Look for any kind of mechanical problems that might be making the electric motor work tougher. Fixing the root cause of the overload can stop a full electric motor failure and save you from duplicated downtime.

The power that feeds your electric motor, the voltage, needs it to be correct/stable. If the voltage supply is too high, also reduced, or unequal, it can trigger large troubles. A voltage imbalance, particularly in three-phase motors, is a stealthy trouble. This means that not all phases of power are equal.

When voltage is too low, the electric motor will attempt to draw even more current to do its job. This added current can create overheating and damage the motor windings. High voltage can additionally emphasize the insulation and shorten the life expectancy of the electric motor. A voltage imbalance is especially poor since it makes the electric motor run inefficiently and fume. This can occur if the motor isn’t protected.

So, what should you do? It’s an excellent concept to examine the power supply consistently. Guarantee that the motor is getting the proper voltage as provided on its nameplate. If you presume voltage problems, you may need to utilize voltage regulators or stabilizers. Seeing that the electric motor is wired properly is also really crucial to avoid imbalance. A stable voltage is vital for healthy motor procedure.

Sometimes, an electric motor will just stop working. Or, you may notice a huge decrease in its motor performance — it runs slower, or it doesn’t have the power it used to. This could be as a result of a number of usual causes, from an inner fault to an issue with the power mosting likely to the electric motor.

An unexpected quit can be brought on by short circuits in the motor windings, a significant bearing failure, and even an issue in the control circuit. Poor motor performance can build up in time. It might be because of damage to parts of the motor, recurring overload problems, or perhaps issues with a variable frequency drive if you use a motor with one. These drives can occasionally cause their very own set of motor problems otherwise.

If your electric motor quits or isn’t functioning well, you need to repair it very carefully. Evaluate the wiring and connections. Look for any type of evident mechanical damage. In some cases the root cause of motor stoppage is easy, yet usually it indicates a much more severe electric motor failure. Resolving these indicators promptly can often save the electric motor, but other times, a motor repair or substitute is the only means. This is why you are required to routinely evaluate and maintain your equipment.

In my experience, there are numerous really usual causes of electric motor failure. Overheating is probably top. When an electric motor gets too warm, its insulation breaks down. This is often as a result of overload — making the motor function harder than it’s developed for. Poor lubrication causing bearing wear is an additional large one. Bearings need excellent lubrication to run efficiently.

Contamination is likewise a constant offender. Dust, dirt, and moisture can get inside the motor and create all types of motor issues. They can block the cooling system, causing it to get too hot, or trigger brief circuits. Voltage issues, like an imbalance or levels that are expensive or low, are additionally high on the listing of common reasons. These electrical faults put a lot of tension on the electric motor components. Lastly, misalignment of the motor with the devices it drives can cause vibration and premature bearing failure.

Recognizing these typical causes helps in preventive maintenance. If you understand what typically goes wrong, you can take steps to prevent it. For any common electric motor, these are the areas to enjoy.

The bearing permits the motor shaft to rotate freely with little friction. Yet when a bearing begins to break, it creates a lot more rubbing. This extra rubbing creates warmth, which can trigger the motor to overheat. An overheated condition, as we know, is very negative for the motor windings and insulation.

Bearing wear additionally triggers extreme vibration. This resonance does not just make noise; it trembles the whole electric motor. This can loosen up electrical connections, harm the rotor or winding, and even create imbalance with various other equipment. If a bearing seizes up entirely, it can cause an overload that trips breakers or wears out the motor. This is a classic bearing failure circumstance that leads directly to motor failure.

Appropriate lubrication is the best protection versus bearing wear. Making use of the right type and amount of lubrication at the correct times is critical. Also, paying attention to odd sounds and feeling for vibration can help you catch bearing troubles early. Repairing a bearing is more affordable than replacing a whole electric motor.

Absolutely, yes! High temperatures are among the largest adversaries of an electric motor. Every electric motor is developed to run within a certain temperature level variety. When it is too hot and goes beyond that variety– what we call overheating — poor things start to take place quickly. One of the most vulnerable parts is the insulation around the motor windings.

This insulation product safeguards the cords in the winding from touching each other and creating short circuits. When insulation gets too warm, it becomes fragile and splits, or it can also melt. Once the insulation is damaged, the electric motor goes to high danger of electric motor failure. Also if it does not fall short as soon as possible, high temperatures will greatly shorten the life-span of the electric motor. Each time it gets too hot, the insulation degrades a little bit more.

So, it’s crucial to make sure the motor has good cooling. Keep the cooling system clear of dirt. Don’t overload the electric motor, as this is a main source of motor overheating. If an electric motor runs too warm, it’s a sign you are required to examine the overheating and repair it to prevent significant damages to the motor.

Good motor maintenance is your friend in preventing unforeseen motor failure. First, consistently examine your electric motor. Seek signs of overheating, listen for strange noises, and feel for excessive vibration. These are early cautions of motor problems.

Keep your electric motor tidy. Dust and debris can create it to overheat by blocking the cooling system. Make sure lubrication for the bearing is done appropriately and on schedule. Utilize the appropriate kind of lubrication. Examine electrical connections to make sure they are tight and not corroded. Loosened connections can trigger voltage drops or overheat. Also, on a regular basis inspect and maintain the alignment in between the electric motor and the driven devices to prevent misalignment problems.

Examining the insulation resistance regularly can aid you capture harmed insulation prior to it bringing about a major fault. And constantly make sure that the motor is not constantly in an overload problem. Making use of a motor that is appropriately sized for the work is essential. These regular maintenance steps can substantially extend the lifespan of your electric motor and decrease downtime.